1. Introduction

The growth of industry in developed countries comes with scientific and technological challenges in order to advance in sectors such as the aeronautical industry, biomedical components and the extraction of gas and petroleum. Industries of this kind have, as a common denominator, the use of advanced materials with excellent mechanical properties.

Typical examples of such materials are the nickel-based super alloys, such as Inconel 718 and Gamma TiAl alloys, which are common alternatives to steel alloys. These materials are widely used in high temperature applications due to their ability to retain their mechanical properties, showing good corrosion, oxidation and creep performance [

1]. Grade EA1N steel is another example; it is an alloy often used in the railway industry which has special properties to meet the demands of train axles.

These functional benefits entail a difficult challenge in terms of machinability. The high resistance of these materials, even at high temperatures, increases the mechanical load in the machining process and their low thermal conductivity produces heat accumulation in the cutting zone. These factors, among others, reduce tool life and consequently the productivity and cost-effectiveness of the machining process are decreased. These conclusions are summarized in the study made by Ezugwu et al. [

2], where titanium alloy machinability is analyzed and among other conclusions, it is mentioned that the correct use of coolants during machining operations greatly extends the life of the cutting tool.

Minimizing the temperature produced at the tool–work piece and tool–chip interfaces can help to avoid prominent failures as flank wear, crater wear, chipping or catastrophic failure [

2]. This is normally solved by using oil-based emulsion refrigeration, which is not entirely efficient for certain materials and causes serious ecological damage since the oils used in the emulsion are toxic. Moreover, conventional ways for supplying the coolant are inefficient for machining exotic alloys since the coolant is unable to reach the cutting zone due to the formation of a vapor blanket which prevents the penetration of the coolant to this high temperature region [

3]. Instead, this study proposes the use of a new cooling method, based on cryogenic fluids, that is capable of solving these problems during the milling process. Administering the coolant directly into the cutting zone is required to minimize the temperature and to ensure an efficient machining of difficult-to-cut alloys.

Many researchers have selected the option of using liquid nitrogen (LN) or CO

2 as a solution to the aforementioned machining problems. These fluids, which are able to reach very low temperatures, are directed to the cutting tool in order to reduce the temperature in the machining area. In most cases, the use of this technique allows for increasing the cutting speed and consequently the productivity, as shown by Wang et al. [

4]. Subsequently, there have been numerous studies in the field of turning, highlighting the work developed by Pusavec et al. [

5], Ahmed et al. [

6], Hong et al. [

7] and Bermingham et al. [

8].

However, only a few studies of cryogenic milling can be found in the literature, given the difficulty entailed by the rotation of the tool at high revolutions per minute. The main investigations in milling have been carried out in the last decade, such as the work of Klocke et al. [

9], where the positive effect of CO

2 and LN on the milling of Ti6Al4V is demonstrated. Aramcharoen and Chuan [

10] and Shokrani et al. [

11] found an increase in tool life of around 50% and an improvement of surface finish by up to 88% in the milling of Inconel 718 by using cryogenic cooling instead of conventional cooling. In this case, the cryogenic alternative does not improve the machining of these alloys. Cordes et al. [

12] also developed a milling tool adapated to the use of CO

2, being in this case a through the spindle configuration. Major effects of the cryogenic cooling can be seen in higher material removal rates (+72%) and in tool wear reduction (−63%) when machining stainless steel 1.4962.

Other approaches related to cryogenic milling involve the use of combined cooling methods. Supercritical CO

2 consists of diluting oil in carbon dioxide in order to combine the cryogenic cooling capacity and the lubrication power of the oil [

13]. Another possibility is to combine chilled air or cryogenic fluid with Minimum Quantity Lubrication (MQL), which can be profitable in the milling of thermo-resistant alloys [

14]. Pereira et al. [

15] developed an external CryoMQL technology that was tested in machining hardened steel and Inconel 718.

All the cryogenic systems used in the aforementioned studies, except the one developed by Cordes et al. [

12], have an external configuration. This configuration consists of a single jet of fluid fixed away from the cutting edge. This differs from the concept developed in the prototype presented in this work which is based on internal conduits that direct the cutting fluid through the tool holder up to each tool edge. On the other hand, three new studies have been recently published that use internal refrigeration systems, similar to the one used in this work. Pereira et al. [

16] tested an internal device that combines cryogenic and MQL lubrication when machining Inconel 718. The use of internal CryoMQL improves the machining process in comparison with other green technologies, like external CryoMQL or MQL. Besides, compared with wet machining, a lower efficiency is obtained. Tapoglou et al. [

17] show a comparative study between different coolants for machining Ti6Al4V, which concludes that cryogenic machining is not as effective as flood emulsion for machining this material. Tao Lu et al. [

18] present a through-spindle cryogenic cooling system and summarize a study about Ti6Al4V machining, comparing the cryogenic and traditional technologies in economic terms.

From an industrial point of view, two companies have driven the use of cryogenic coolant technology in milling and have launched machining centers that include this technology: MAG in the USA and Okuma in Japan. This fact, along with the increase in research studies, are evidence of the important role of cryogenic milling in the machining of the future.

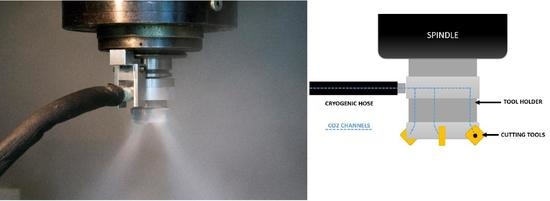

The aim of this paper is to present a new design for cryogenic milling that presents the particularity of driving the CO2 “through the tool holder”. This system allows each tool to have its own cryogenic fluid jet located just a few millimeters away from the cutting edge, optimizing the cooling process during machining. In this way, the coolant directly reaches the tool edge without excessively affecting the material to be cut. To check the possibilities of the system, a study about milling Inconel 718, a Gamma TiAl alloy, and grade EA1N steel has been carried out, comparing the traditional cooling with the cryogenic cooling approach. Particularly, carbon dioxide (CO2) was selected as cryogenic alternative, comparing it to flood emulsion as a traditional cooling/lubricating strategy. This paper describes the experimental tests made in these materials that have not been tested to date by an internal cryogenic machining device, to determine the efficiency of each tested cooling method in terms of cutting tool wear.

3. Results and Discussion

3.1. Tests Performed on Inconel 718

Face milling of the flat face of a 115 mm diameter cylinder was carried out twice in each test (cryogenic and emulsion). In both cases, severe flank wear was observed in the first cutting pass and considerable cracks in the second pass, so the end of life was reached. The material removed and machining time taken as a reference were therefore the same, as indicated in

Table 6. The test was repeated with identical results.

During machining, the tool wear mechanisms detected on the cutting tools were abrasion, adhesion and microchipping. In both cases, almost the same phenomena were observed. In the first cutting pass, flank wear was the predominant type of wear, although microchipping and adhesion were also detected. In the second cutting pass, chipping wear increased in almost all the cutting tools, reaching the end of life in all trials. The similarities between both cooling methods are remarkable, despite the great difference between them. Notch wear seems to be more frequent in the cryogenic machining and flank wear in the case of emulsion, although it is not always the case, as shown in

Figure 3. In the pictures, the four cutting tools used in each test can be observed after the second cutting pass, showing no significant difference between both processes. The same conclusion was drawn by Aramcharoen et al. [

10], who showed that the growth of tool wear under a cryogenic process is similar to that under conventional oil-based process.

Adhesion, which is a common problem in dry processes when machining Inconel 718 [

10], was remarkably reduced using both cooling systems, which proves the effectiveness of the used cooling methods. Nevertheless, the flank wear and notch wear could not be avoided. The cooling capacity of CO

2 (−78 °C) is not as great as that of liquid nitrogen (−196 °C) and may be insufficient for the demands of the process. In any case, the results of the traditional process with oil emulsion were reached with a sustainable technology, which is a remarkable step forward.

The similar results of both processes may be explained taking into account that the higher lubrication capacity that the oil provides is somehow compensated for by the greater cooling capacity offered by the CO2. The combination of both technologies or the use of a cryogenic coolant at a lower temperature might therefore improve the process. Further experiments have to be performed in order to check this.

It is complicated to compare the results with works made by other authors on cryogenic milling of Inconel 718, as the ones carried out by Musfirah et al. [

19] or Shokrani [

11] use external cryogenic systems and compare the results against dry machining. In such cooling systems, the coolant is applied from the outside through a single jet and the fluid does not directly reach the cutting edge of each tool, greatly affecting the machined material, which makes this refrigeration configuration hardly comparable to the one exposed in this study. However, it must be pointed out that Musfirah et al. found that the microchipping phenomenon that occurs in cryogenic milling was related to thermal shock in the process. The tool was chilled during exposure to the cryogenic spray and subsequently heated up during the removal of the chip. These changes might cause tool fatigue as well as proneness to cracks [

19].

3.2. Tests Performed on Gamma TiAl

For the second part of the study, the developed cryogenic system was evaluated for machining a titanium-based thermo-resistant alloy. In this case, the face milling process of a Gamma TiAl alloy (146 mm diameter cylinder) was tested. Again, two machining passes were completed in each trial, but in this case, tools under cryogenic machining showed less wear than the ones in which oil emulsion was used as coolant. The tools used with oil emulsion suffered critical breakage of the rake face during the first machining cut and consequently reached their end of life. Instead, most of the cutting inserts used with cryogenic cooling did not suffer such severe damage and some of them were still usable during the second cut.

The main wear mechanisms observed were abrasion and material adhesion on the tool edge. This wear mechanism increased during the cutting and finally edge breakage occurred, even producing rake face chipping. These phenomena are linked to high temperatures, since mechanisms related to this aspect were observed in the tool face with adhesion of material particles and a detached coating layer. In addition, this phenomenon occurs faster in the traditional cutting process, where the cooling capacity is not as effective. Cryogenic machining with the developed system seems to eliminate heat from the cutting area more efficiently and slows down the wear process.

Comparing both processes from the point of view of tool life, the tools used with traditional coolant suffer critical breakage after the first cut while only one of the tools used with CO

2 was broken. After the second cut, however, the inserts already had severe damage and their end of life was reached in this trial. Therefore, the material removed in the cryogenic trial was approximately doubled compared with the traditional cutting process, as indicated in

Table 7. Despite this fact, the second machining pass was also completed for the traditional coolant in order to compare the tools from both trials, as shown in

Figure 4.

No studies were found in the literature analyzing the cryogenic machining of this particular alloy using an internal cryogenic system. However, the wear phenomenon described as abrasion and its subsequent crater are mentioned in other studies, like the review of M’Saoubi [

20]. In this report, the described wear is related to high temperature, so it seems natural that the use of a cryogenic internal system may help to reduce the wear. The use of a system that spears a jet directly to the cutting edge of the tool seems effective to optimize the process and prevents the excessive freezing of material that could alter it and reduce the machinability. Moreover, Klocke et al. [

21] analyze the influence of different cooling options (dry, flood, high pressure, MQL and cryogenic) for turning Gamma TiAl alloy. Although it is not the same cutting operation and nitrogen is used as coolant, cryogenic cooling is proved to be the most efficient lubrication strategy for this material. Liquid nitrogen decreases flank wear up to 61% in comparison with conventional lubrication, which resembles the results obtained in this study.

3.3. Tests Performed on Grade EA1N Steel

In the last round of tests, grade EA1N steel (140 mm diameter cylinder) was machined, a material with very different characteristics from the previous ones. The results show a greatly improved performance when CO

2 is used as coolant, as 11 passes of face milling were completed using this technology while only four were carried out when using oil emulsion. In this material, abrasion was the predominant wear mechanism, which takes place progressively until the insert suffers a critical breakage, causing the end of life in both tests. The results of machining time and material removed in each test are shown in

Table 8.

When analyzing the wear mechanism in detail, in both cases a similar tendency is observed, although the final break occurs much earlier in the case of the traditional coolant. The main wear mechanism, as mentioned above, is abrasion, although it happens very lightly. There is also a blackened region in the flank area as a consequence of the heat produced during the machining process in the tools used with oil emulsion due to the smaller cooling capacity of this coolant. There are no other wear mechanisms related to high temperatures such as adhesion or plastic deformation, which were frequent with the other materials. This aspect seems reasonable because this material is not a thermo-resistant alloy as the ones in the previous machining tests and the heat accumulated in the cutting area is much lower. In both tests, breakage takes place on three teeth, which denotes the end of life as shown in

Figure 5. Moreover, in both cases, the first edge break occurs in the second last shaping operation.

Although the process has less thermal effects than the previous materials, the use of CO2 as coolant seems to be effective, since it helps to delay the critical break of the cutting inserts, doubling its total life. The cooling effect introduced by the carbonic snow preserves the integrity of the cutting inserts for a longer time, so it seems to be a good option for improving the resistance of the cutting inserts when machining this kind of material.

As in the previously analyzed cases, comparison with other cryogenic machining studies is difficult, since there are no tests made with a material that resembles the one used in this work. In spite of this, a similarity with the work carried out by Cordes et al. [

12] can be considered, where a refrigeration system through the tool holder based in CO

2 is used and a non-thermo-resistant steel such as 14.962 stainless steel is tested. The results of this study show a 63% reduction in flank wear as compared to dry machining when using cryogenics. Although the study presented in this paper examines the comparison with oil emulsion, both studies show results that indicate clear improvements when using the cryogenic machining. The work of Cordes et al. also highlights the advantage of using an internal supply system that directs the CO

2 to the insert, which results in a clear reduction in the temperature in the cutting edge.

In general, it is observed that the use of CO

2 as a coolant brings improvements in terms of tool life compared to conventional refrigeration techniques. In agreement with the study of Cordes et al. [

12], it can be assumed that there is a reduction in temperatures both in the material and in the cutting tool when using an internal CO

2 cooling system. This phenomenon improves the life of the cutting inserts in two of the cases tested.

Cryogenic cooling clearly improves the machining of steel EA1N and Gamma TiAl alloy while it has no effect when machining Inconel 718, where almost the same performance of conventional machining is obtained. Inconel 718 is a material with lower thermal conductivity and higher yield/ultimate tensile strength compared to the other two tested materials. These properties counteract the cooling capacity of the CO2 used in the internal cooling system.