Influence of Submerged Entry Nozzles on Fluid Flow, Slag Entrainment, and Solidification in Slab Continuous Casting

Abstract

:1. Introduction

2. Experimental Work

3. Results and Discussion

3.1. Fluid Flow and Surface Velocity

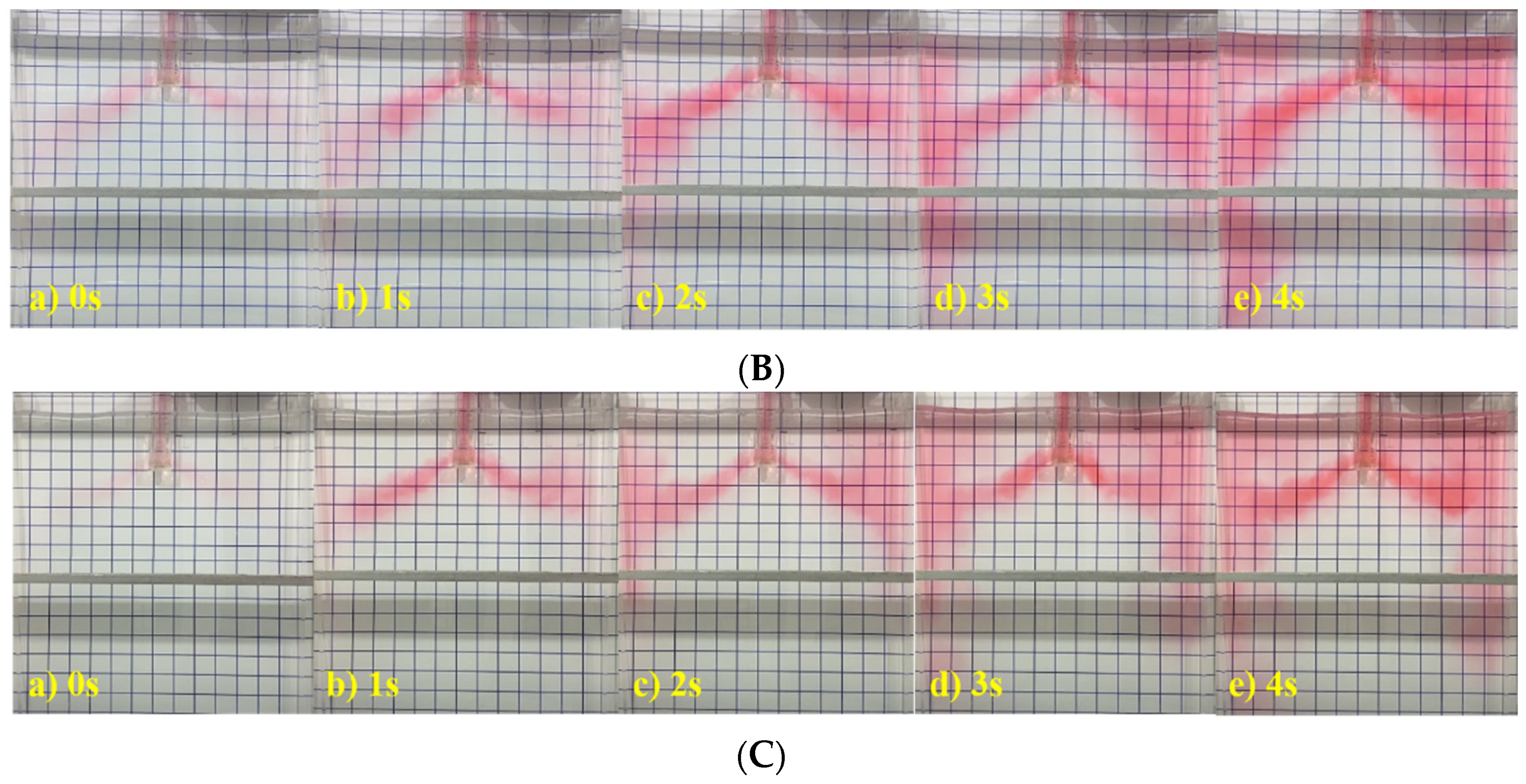

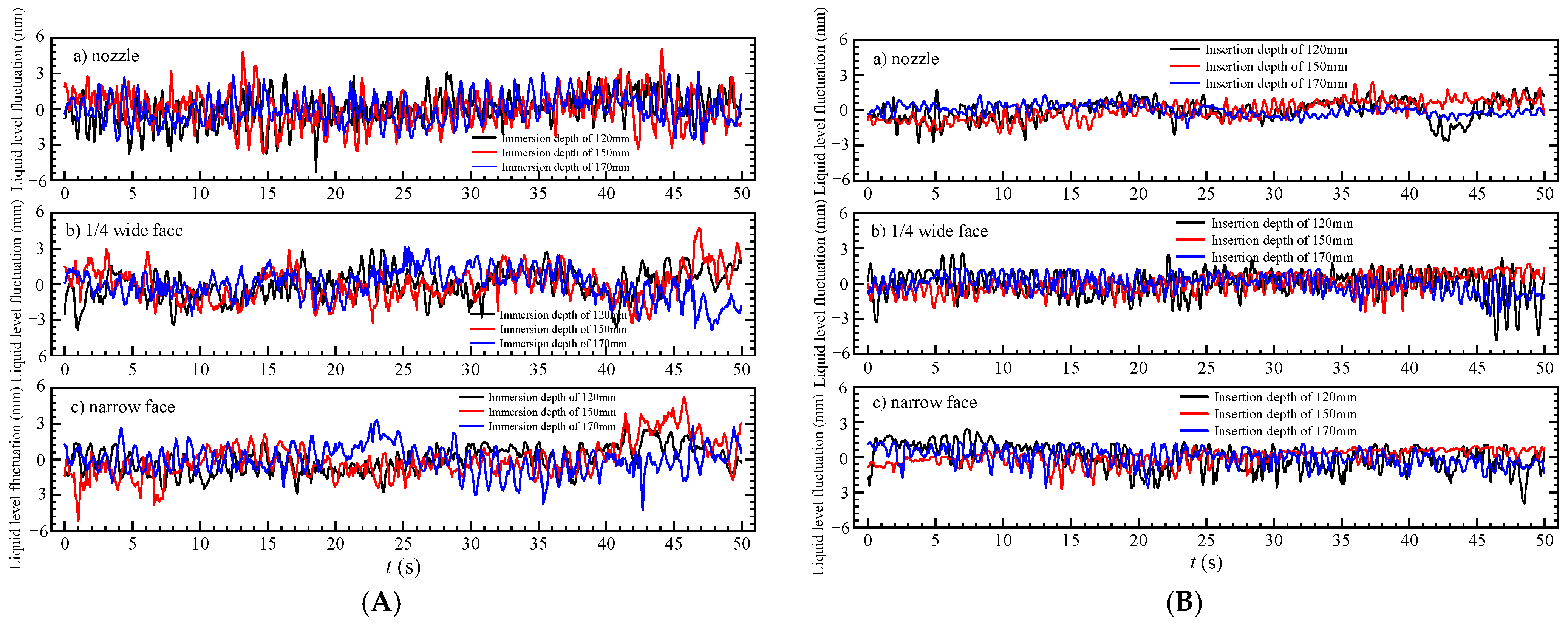

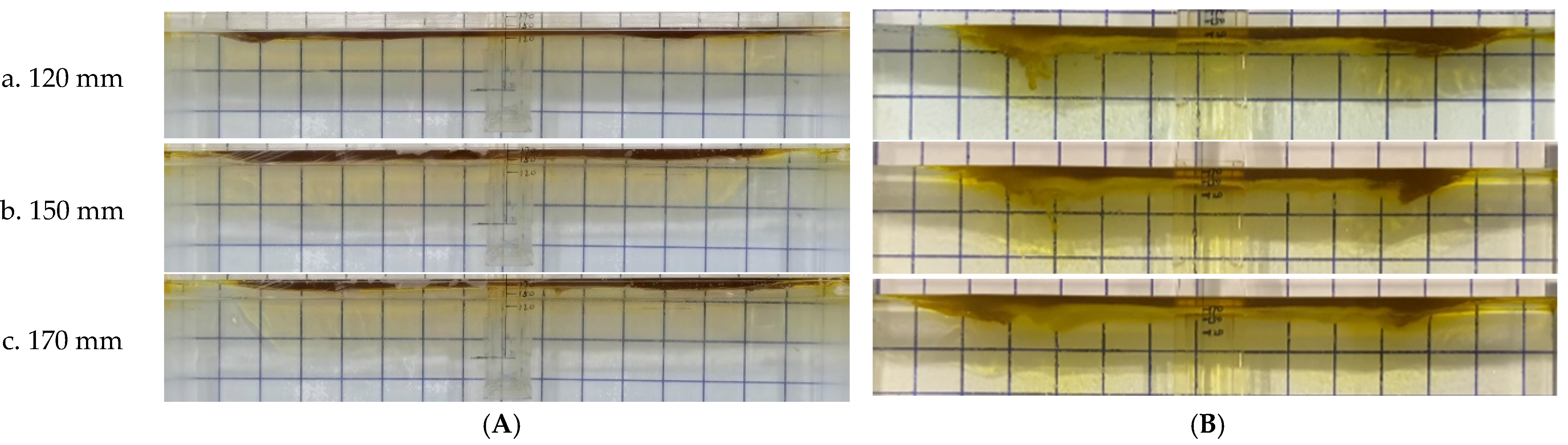

3.2. Level Fluctuation and Slag Entrainment

3.3. Velocity Distribution and Shell Thickness

4. Conclusions

- For type A SEN, the surface velocity was larger than that using type B SEN. The surface velocity for the immersion depth of 120 mm was higher than that of other immersion depths. With the increase in the SEN immersion depth, the velocity at the top surface was decreased.

- For type A SEN, the larger shear effect on the top surface made the slag phase at narrow face impacted to the vicinity of 1/4 wide face, while the slag phase at the top surface was relatively stable for type B SEN. When the immersion depth of 120 mm was adopted, the slag entrainment was higher than that of other immersion depths. Increasing the immersion depth of SEN decreased the slag entrainment.

- When type A SEN was used, the thickness of the solidified shell at the narrow face of the mold outlet was thin (12.3 mm) and there was a risk of breakout. For type B SEN, the liquid steel with high temperature would flow to the meniscus and it was beneficial to the melting of the mold flux. The thickness of the solidified shell at the narrow face of the mold outlet was increased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Calderón-Ramos, I.; Morales, R.D. The role of submerged entry nozzle port shape on fluid flow turbulence in a slab mold. Metall. Mater. Trans. B 2015, 46, 1314–1325. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, Y.Z.; Chen, D.F.; Long, M.J.; Duan, H.M. Optimization of submerged entry nozzle parameters for ultra-high casting speed continuous casting mold of billet. J. Iron Steel Res. Int. 2022, 29, 44–52. [Google Scholar] [CrossRef]

- Fang, Q.; Ni, H.W.; Zhang, H.; Wang, B.; Lv, Z.A. The effects of a submerged entry nozzle on flow and initial solidification in a continuous casting bloom mold with electromagnetic stirring. Metals 2017, 7, 146. [Google Scholar] [CrossRef]

- Kamal, M.; Sahai, Y. Modeling of melt flow and surface standing waves in a continuous casting mold. Steel Res. Int. 2005, 76, 44–52. [Google Scholar] [CrossRef]

- Gan, M.J.; Pan, W.J.; Wang, Q.Q.; Zhang, X.B.; He, S.P. Effect of exit shape of submerged entry nozzle on flow field and slag entrainment in continuous casting mold. Metall. Mater. Trans. B 2020, 51, 2862–2870. [Google Scholar] [CrossRef]

- Wang, P.; Tie, Z.P.; Xiao, H.; Zhu, J.L.; Tang, H.Y.; Zhang, J.Q. Optimizing of submerged entry nozzle for bloom continuous casting based on physical and numerical simulation. Steel Res. Int. 2022, 93, 2200402. [Google Scholar] [CrossRef]

- Gonzalez-Trejo, J.; Miranda-Tello, J.R.; Cervantes-de-la-Torre, F.; Carvajal-Mariscal, I.; Sanchez-Silva, F.; Gabbasov, R.; Real-Ramirez, C.A. Experimental analysis of a slab continuous-casting SEN with an inner flow divider. Metals 2022, 12, 1097. [Google Scholar] [CrossRef]

- Calderón-Ramos, I.; Morales, R.D.; Salazar-Campoy, M. Modeling flow turbulence in a continuous casting slab mold comparing the use of two bifurcated nozzles with square and circular ports. Steel Res. Int. 2015, 86, 1610–1621. [Google Scholar] [CrossRef]

- Wu, D.F.; Cheng, S.S. Effect of SEN design on surface fluctuation and solidifying shell in slab mold and its optimization. Acta Metall. Sin. 2008, 21, 341–350. [Google Scholar] [CrossRef]

- Morales, R.D.; Ramos, I.C.; Campoy, M.M.S. The role of nozzle-port geometry on flux entrainment in slab molds. In Proceedings of the 6th International Congress on the Science and Technology of Steelmaking(I), Beijing, China, 12–14 May 2015; pp. 485–488. [Google Scholar]

- Morales-Higa, K.; Guthrie, R.I.L.; Isac, M.; Morales, R.D.; Labrecque, C.; Lapointe, F. The effects of fluid flow on flux entrainment in a square billet mold. In Proceedings of the AISTech 2013—Iron and Steel Technology Conference, Pittsburgh, PA, USA, 6–9 May 2013; pp. 1461–1472. [Google Scholar]

- Pang, J.C.; Qian, G.Y.; Pang, S.; Ma, W.H.; Cheng, G.G. Design of a submerged entry nozzle for optimizing continuous casting of stainless steel slab. J. Iron Steel Res. Int. 2023, 30, 2229–2241. [Google Scholar] [CrossRef]

- Zeng, J.; Chen, W.Q.; Wang, G.S.; Cao, C.F.; Gao, Y.B. Development and application of an off-line soft reduction model during continuous casting of high-carbon rectangular billet. Metall. Res. Technol. 2015, 112, 403. [Google Scholar] [CrossRef]

- Wang, Y.F.; Zhang, L.F. Fluid flow-related transport phenomena in steel slab continuous casting strands under electromagnetic brake. Metall. Mater. Trans. B 2011, 42, 1319–1351. [Google Scholar] [CrossRef]

- Ramos, I.C.; Morales, R.D.; Garcia-Hernandez, S.; Ceballos-Huerta, A. Effects of immersion depth on flow turbulence of liquid steel in a slab mold using a nozzle with upward angle rectangular ports. ISIJ Int. 2014, 54, 1797–1806. [Google Scholar] [CrossRef]

- Szekely, J.; Yadoya, R. The physical and mathematical modeling of the flow field in the mold region in continuous casting systems: Part I. model studies with aqueous systems. Metall. Trans. 1972, 3, 2673–2680. [Google Scholar] [CrossRef]

- Bielnicki, M.; Jowsa, J. Physical modeling of mold slag entrainment in continuous steel casting mold with consideration the impact of mold powder layer. Steel Res. Int. 2018, 89, 1800110. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Sung, H.J.; Lee, S. Flow oscillations and meniscus fluctuations in a funnel-type water mold model. Metall. Mater. Trans. B 2010, 41, 121–130. [Google Scholar] [CrossRef]

- Li, B.; Tsukihashi, F. Vortexing flow patterns in a water model of slab continuous casting mold. ISIJ Int. 2005, 45, 30–36. [Google Scholar] [CrossRef]

- Ji, C.B.; Li, J.S.; Yang, S.F.; Sun, L.Y. Large eddy simulation of turbulent fluid flow in liquid metal of continuous casting. J. Iron Steel Res. Int. 2013, 20, 34–46. [Google Scholar] [CrossRef]

- Jin, X.; Chen, D.F.; Xie, X.; Shen, J.L.; Long, M.J. Investigation on water model for fluid flow in slab continuous casting mold with consideration of solidified process. Steel Res. Int. 2013, 84, 31–39. [Google Scholar] [CrossRef]

- Hagemann, R.; Schwarze, R.; Heller, H.P.; Scheller, P.R. Model investigations on the stability of the steel-slag interface in continuous-casting process. Metall. Mater. Trans. B 2013, 44, 80–90. [Google Scholar] [CrossRef]

- Cheng, C.G.; Lu, H.B.; Li, Y.; Qing, X.F.; Jin, Y. Mathematical modeling of flow and heat transfer behavior of liquid slag in continuous casting mold with argon blowing. ISIJ Int. 2019, 59, 1266–1275. [Google Scholar] [CrossRef]

- Zhang, L.F.; Wang, Y.F. Modeling the entrapment of nonmetallic inclusions in steel continuous-casting billets. JOM 2012, 64, 1063–1074. [Google Scholar] [CrossRef]

- Wang, Q.Q. Study on the Multiphase Flow, Heat Transfer and Solidification, Motion and Entrapment of Inclusions during Continuous Casting. Doctor’s Thesis, University of Science and Technology Beijing, Beijing, China, 2017. [Google Scholar]

- ANSYS FLUENT 14.0; ANSYS, Inc.: Canonsburg, PA, USA, 2011.

| Parameters | Prototype | Model |

|---|---|---|

| Cross section of mold (mm2) | 170 × 1550 | 170 × 1550 |

| Immersion depth (mm) | 120, 170 | 120, 170 |

| Casting speed (m/min) | 1.5, 1.7 | |

| Flow rate in water model (m3/h) | 26.4, 29.9 |

| Density (kg/m3) | Viscosity (Pa·s) | |

|---|---|---|

| Water | 998 | 0.001 |

| Silicon oil | 955 | 0.033 |

| Liquid steel | 7020 | 0.0067 |

| Slag | 2600 | 0.20 |

| Interfacial tension between liquid steel and slag (N/m) | 1.15 | |

| Parameter | Value |

|---|---|

| Density (kg/m3) | 7020 |

| Viscosity (Pa·s) | 0.0062 |

| Specific heat (J/kg/K) | 760 |

| Thermal conductivity (W/m/K) | 31 |

| Latent heat (J/kg) | 272,000 |

| Solidus temperature (K) | 1748 |

| Liquidus temperature (K) | 1791 |

| Heat flux at the narrow face of the mold (kW/m2) | −1500 |

| Heat flux at the wide face of the mold (kW/m2) | −1600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhen, X.; Peng, S.; Zhang, J. Influence of Submerged Entry Nozzles on Fluid Flow, Slag Entrainment, and Solidification in Slab Continuous Casting. Metals 2024, 14, 349. https://doi.org/10.3390/met14030349

Zhen X, Peng S, Zhang J. Influence of Submerged Entry Nozzles on Fluid Flow, Slag Entrainment, and Solidification in Slab Continuous Casting. Metals. 2024; 14(3):349. https://doi.org/10.3390/met14030349

Chicago/Turabian StyleZhen, Xingang, Shiheng Peng, and Jiongming Zhang. 2024. "Influence of Submerged Entry Nozzles on Fluid Flow, Slag Entrainment, and Solidification in Slab Continuous Casting" Metals 14, no. 3: 349. https://doi.org/10.3390/met14030349