Weldability and Monitoring of Resistance Spot Welding of Q&P and TRIP Steels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Q&P and TRIP Steels

2.2. RSW Welding and Monitoring

2.3. Microstructural and Mechanical Characterization of Spot Welds

2.4. Statistical Analysis

3. Results

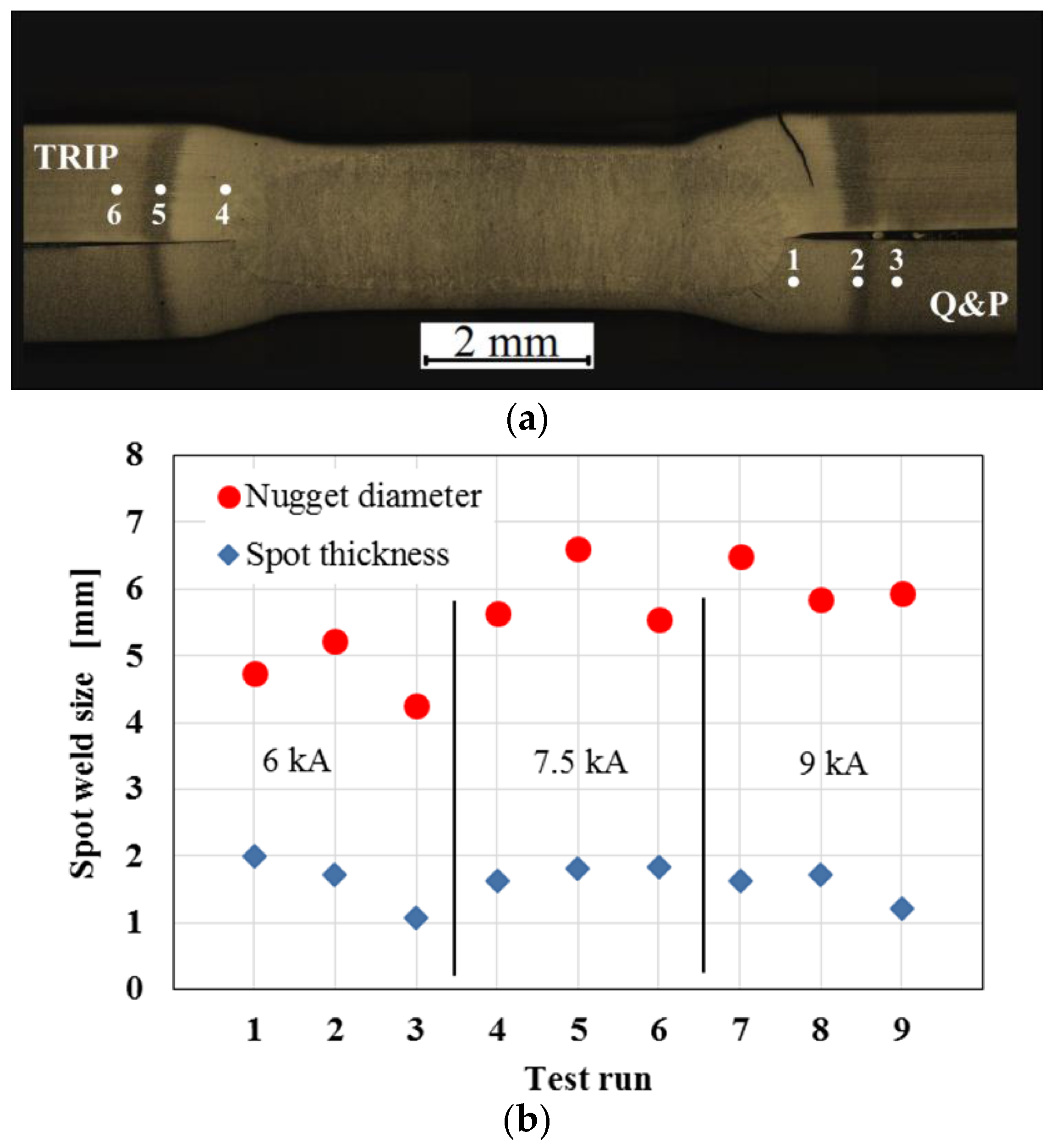

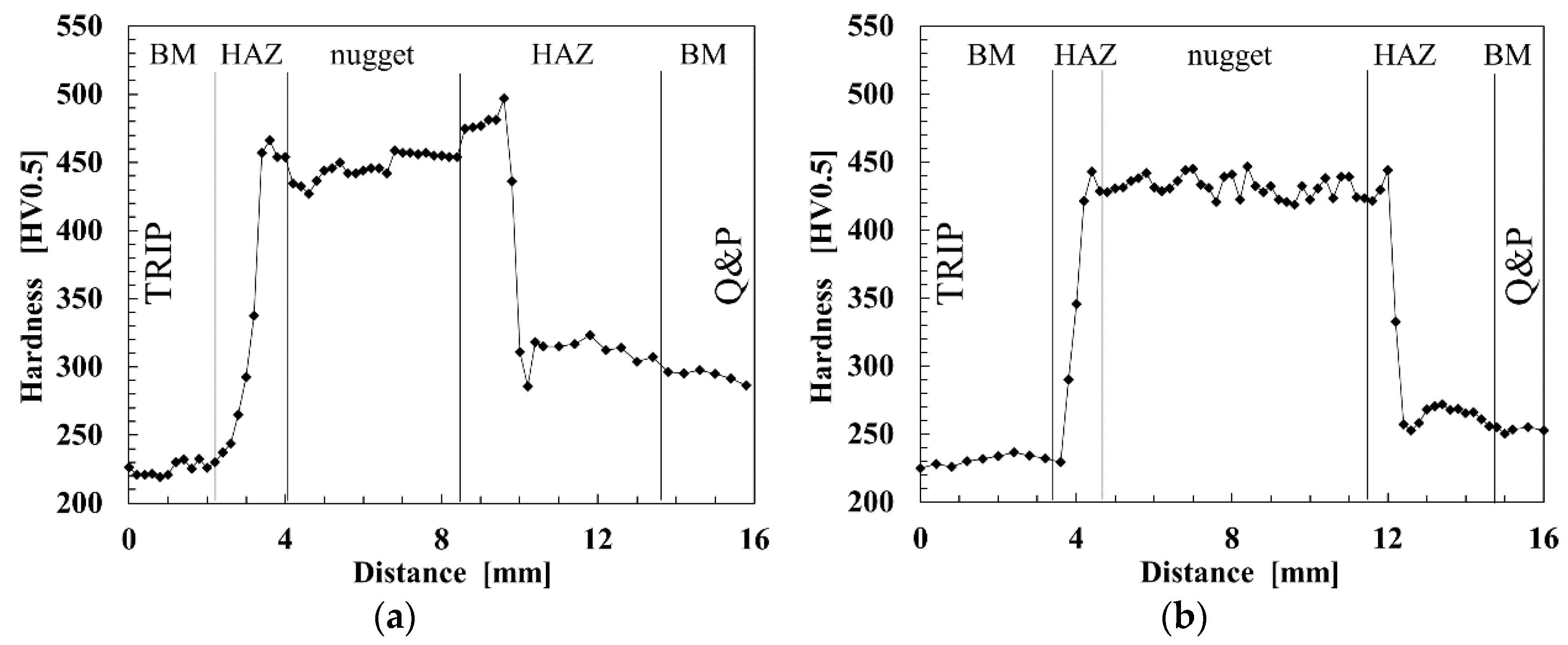

3.1. Spot Weld Microstructural and Hardness Characterization

3.2. Monitoring of the Welding Parameters

3.3. Shear and Cross Tension Tests

3.4. Spot Weld Fracture

4. Conclusions

- Based on the monitored signals, expulsion can appear as a single event or multiple events during the joining process, its severity being assessed by the extent of the dynamic resistance drop.

- The welding current is the most important parameter that affects the shear strength, followed by the clamping force and welding time. No statistical significant parameters have been found for the cross tension strength; however, the cross tension strength normalized by to spot size (α) points out the detrimental effect of a metal expulsion.

- If the expulsion occurs at the beginning of the joining process and for a short time, its harmful effect on shear strength is more limited for the longest welding time (sample No. 7, 450 ms).

- The shear-welded samples failed by interfacial and button pull fractures. Button pull fractures could occur by crack propagation along the nugget border or in the Q&P HAZ where previous martensite tempered.

- Cross-welded samples failed by interfacial and button pull, and button pull by partial dome fracture. Metal splashes promoted the crack propagation through the HAZ regions in partial dome fractures.

- Run No. 5 (7.5 kA, 3 kN, 450 ms) represents the best welding combination since it ensures spot welds with high shear and cross tension strengths and the absence of metal expulsion.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- De Moor, E.; Speer, J.G.; Matlock, D.K.; Kwak, J.H.; Lee, S.B. Effect of carbon and manganese on the quenching and partitioning response of CMnSi steels. ISIJ Int. 2011, 51, 137–144. [Google Scholar] [CrossRef]

- Sun, J.; Yu, H. Microstructure development and mechanical properties of quenching and partitioning (Q&P) steel and an incorporation of hot-dipping galvanization during Q&P process. Mater. Sci. Eng. A 2013, 586, 100–107. [Google Scholar] [CrossRef]

- Rossini, M.; Russo Spena, P.; Cortese, L.; Matteis, P.; Firrao, D. Investigation on dissimilar laser welding of advanced high strength steel sheets for the automotive industry. Mater. Sci. Eng. A 2015, 628, 288–296. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Ludovico, A.D. Laser-arc hybrid welding of wrought to selective laser molten stainless steel. Int. J. Adv. Manuf. Tech. 2013, 68, 209–216. [Google Scholar] [CrossRef]

- Peterson, W.; Borchelt, J. Maximizing cross tension impact properties of spot welds in 1.5 mm low carbon, dual-phase, and martensitic steels. In SAE Technical Paper 2000-01-2680; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Donders, S.; Brughmans, M.; Hermans, L.; Tzannetakis, N.O. The effect of spot weld failure on dynamic vehicle performance. Sound Vibrat. 2005, 39, 16–25. [Google Scholar]

- Wang, B.; Duan, Q.Q.; Yao, G.; Pang, J.C.; Li, X.W.; Wang, L.; Zhan, Z.F. Investigation on fatigue fracture behaviors of spot welded Q&P980 steel. Int. J. Fract. 2014, 66, 20–28. [Google Scholar] [CrossRef]

- Russo Spena, P.; Maddis, M.D.; Lombardi, F.; Rossini, M. Dissimilar resistance spot welding of Q&P and TWIP steel sheets. Mater. Manuf. Process. 2016, 31, 291–299. [Google Scholar] [CrossRef]

- Russo Spena, P.; Cortese, L.; Maddis, M.D.; Lombardi, F. Effects of process parameters on spot welding of trip and quenching and partitioning steels. Steel Res. Int. 2016, in press. [Google Scholar] [CrossRef]

- Zhang, H. Expulsion and its influence on weld quality. Weld. J. 1999, 78, 373-s–380-s. [Google Scholar]

- Zhang, H.; Senkara, J. Resistance Welding: Fundamentals and Applications, 2nd ed.; CRC Press: London, UK, 2011. [Google Scholar]

- AWS D8.9M, Test Methods for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials; American Welding Society (AWS): Miami, FL, USA, 2012.

- International Organization for Standardization. Resistance Welding-Weldability-Part 2: Alternative Procedures for the Assessment of Sheet Steels for Spot Welding; ISO Copyright Office: Geneva, Switzerland, 2004. [Google Scholar]

- CWT Specification, Power Electronic Measurement Ltd. Available online: www.pemuk.com (accessed on 7 November 2016).

- AWS D8.1M, Specification for Automotive Weld Quality—Resistance Spot Welding of Steel; American Welding Society (AWS): Miami, FL, USA, 2013.

- Dickinson, D.W.; Franklin, J.E.; Stanya, A. Characterization of spot welding behavior by dynamic electrical parameter monitoring. Weld. J. Weld. Res. Suppl. 1980, 59, 170–176. [Google Scholar]

- Garza, F.; Das, M. On real time monitoring and control of resistance spot welds using dynamic resistance signatures. In Proceedings of the 44th IEEE 2001 Midwest Symposium on Circuits and Systems MWSCAS, Dayton, OH, USA, 14–17 August 2001.

- Pouranvari, M.; Asgari, H.T.; Mosavizadch, S.M.; Marashi, P.H.; Goodarzi, M. Effect of weld nugget size on overload failure mode of resistance spot welds. Sci. Technol. Weld. Join. 2007, 12, 217–225. [Google Scholar] [CrossRef]

- Chao, Y.J. Failure modes of spot welds: Interfacial versus pullout. Sci. Technol. Weld. Join. 2003, 8, 133–137. [Google Scholar] [CrossRef]

- Biro, E.; Cretteur, L.; Dupuy, T. Higher than expected strengths from dissimilar Configuration advanced high strength steel spot welds. In Proceedings of the Sheet Metal Welding Conference XV, Livonia, MI, USA, 2–5 October 2012.

- Huin, T.; Dancette, S.; Fabrègue, D.; Dupuy, T. Investigation of the failure of advanced high strength steels heterogeneous spot welds. Metals 2016, 6, 111. [Google Scholar] [CrossRef]

| Steel | C (%) | Si (%) | Mn (%) | P + S (%) | Al (%) | Nb (%) |

|---|---|---|---|---|---|---|

| Q&P | 0.22 | 1.41 | 1.88 | <0.02 | 0.04 | <0.001 |

| TRIP | 0.20 | 0.31 | 2.23 | <0.02 | 1.05 | 0.022 |

| Steel | YS (MPa) | UTS (MPa) | ef (%) | Hardness (HV0.5) |

|---|---|---|---|---|

| Q&P | 655 | 1000 | 22 | 260 |

| TRIP | 525 | 890 | 27 | 225 |

| Run | Iweld (kA) | Fclamp (kN) | tweld (ms) |

|---|---|---|---|

| 1 | 6 | 2 | 200 |

| 2 | 6 | 3 | 325 |

| 3 | 6 | 4 | 450 |

| 4 | 7.5 | 2 | 325 |

| 5 | 7.5 | 3 | 450 |

| 6 | 7.5 | 4 | 200 |

| 7 | 9 | 2 | 450 |

| 8 | 9 | 3 | 200 |

| 9 | 9 | 4 | 325 |

| Run | Shear Tension | Cross Tension | α (kN/mm2) | ||||

|---|---|---|---|---|---|---|---|

| Strength (kN) | Energy (J) | Displ. (mm) | Strength (kN) | Energy (J) | Displ. (mm) | ||

| 1 | 15.8 ± 0.9 | 21.9 ± 3.1 | 2.7 ± 0.3 | 4.96 | 30.4 | 10.9 | 0.95 |

| 2 | 16.1 ± 0.5 | 23.5 ± 1.3 | 3.0 ± 0.3 | 4.68 | 39.4 | 12.3 | 0.81 |

| 3 | 14.6 ± 0.1 | 18.8 ± 2.0 | 2.5 ± 0.3 | 4.65 | 25.6 | 9.3 | 1.00 |

| 4. | 19.1 ± 1.0 | 30.8 ± 3.8 | 3.0 ± 0.2 | 4.83 | 50.7 | 14.5 | 0.78 |

| 5 | 19.9 ± 0.8 | 35.8 ± 2.9 | 3.5 ± 0.1 | 5.33 | 67.3 | 17.0 | 0.71 |

| 6 | 17.2 ± 0.7 | 25.3 ± 2.6 | 2.8 ± 0.1 | 4.49 | 44.8 | 14.2 | 0.74 |

| 7 | 21.4 ± 0.8 | 37.8 ± 5.8 | 3.4 ± 0.4 | 5.03 | 68.4 | 16.9 | 0.70 |

| 8 | 19.1 ± 0.6 | 33.1 ± 1.8 | 3.3 ± 0.1 | 5.05 | 49.8 | 14.0 | 0.78 |

| 9 | 17.2 ± 0.6 | 23.9 ± 2.7 | 2.7 ± 0.2 | 4.69 | 52.5 | 15.6 | 0.72 |

| Parameter | SS | DoF | MS | F-Ratio | p-Value | Contribution (%) |

|---|---|---|---|---|---|---|

| Current | 75.06 | 2 | 37.53 | 46.1 | <10−5 | 55.9 |

| Force | 31.12 | 2 | 15.56 | 19.1 | <10−5 | 22.4 |

| Time | 9.01 | 2 | 4.50 | 5.5 | 0.012 | 5.6 |

| Residual | 16.28 | 20 | 0.81 | 16.1 | ||

| Total | 131.46 | 26 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Russo Spena, P.; De Maddis, M.; D’Antonio, G.; Lombardi, F. Weldability and Monitoring of Resistance Spot Welding of Q&P and TRIP Steels. Metals 2016, 6, 270. https://doi.org/10.3390/met6110270

Russo Spena P, De Maddis M, D’Antonio G, Lombardi F. Weldability and Monitoring of Resistance Spot Welding of Q&P and TRIP Steels. Metals. 2016; 6(11):270. https://doi.org/10.3390/met6110270

Chicago/Turabian StyleRusso Spena, Pasquale, Manuela De Maddis, Gianluca D’Antonio, and Franco Lombardi. 2016. "Weldability and Monitoring of Resistance Spot Welding of Q&P and TRIP Steels" Metals 6, no. 11: 270. https://doi.org/10.3390/met6110270