The Effect of Rolling Temperature on the Microstructure and Mechanical Properties of Surface-Densified Powder Metallurgy Fe-Based Gears Prepared by the Surface Rolling Process

Abstract

:1. Introduction

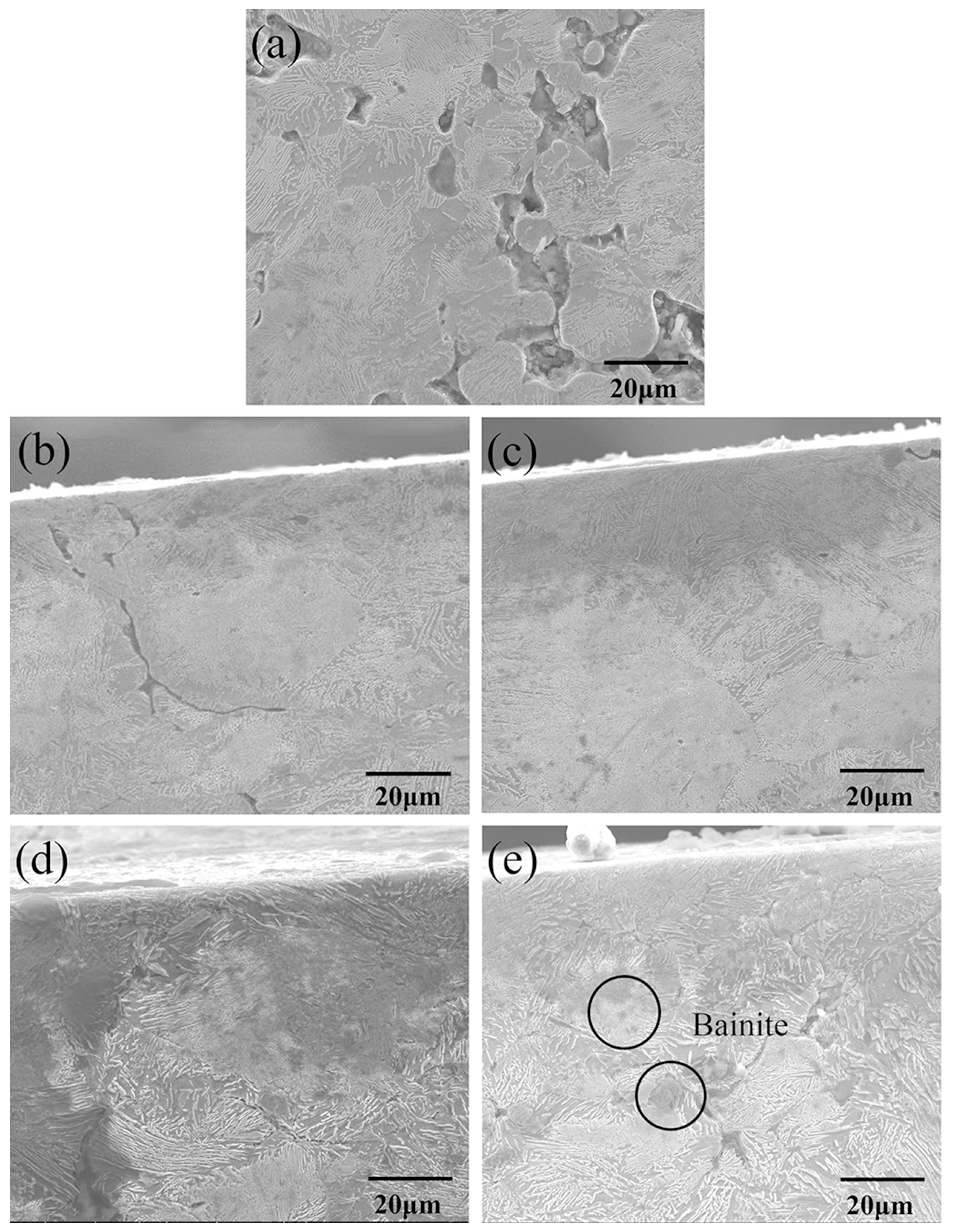

2. Materials and Methods

2.1. Preparation of Powder Metallurgy Parts

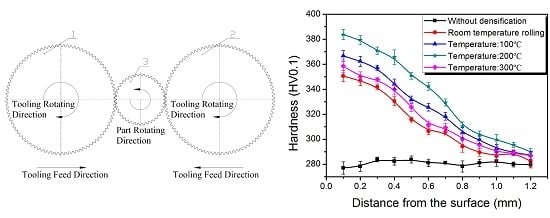

2.2. Warm Rolling Densification

2.3. Characterization

3. Results and Discussion

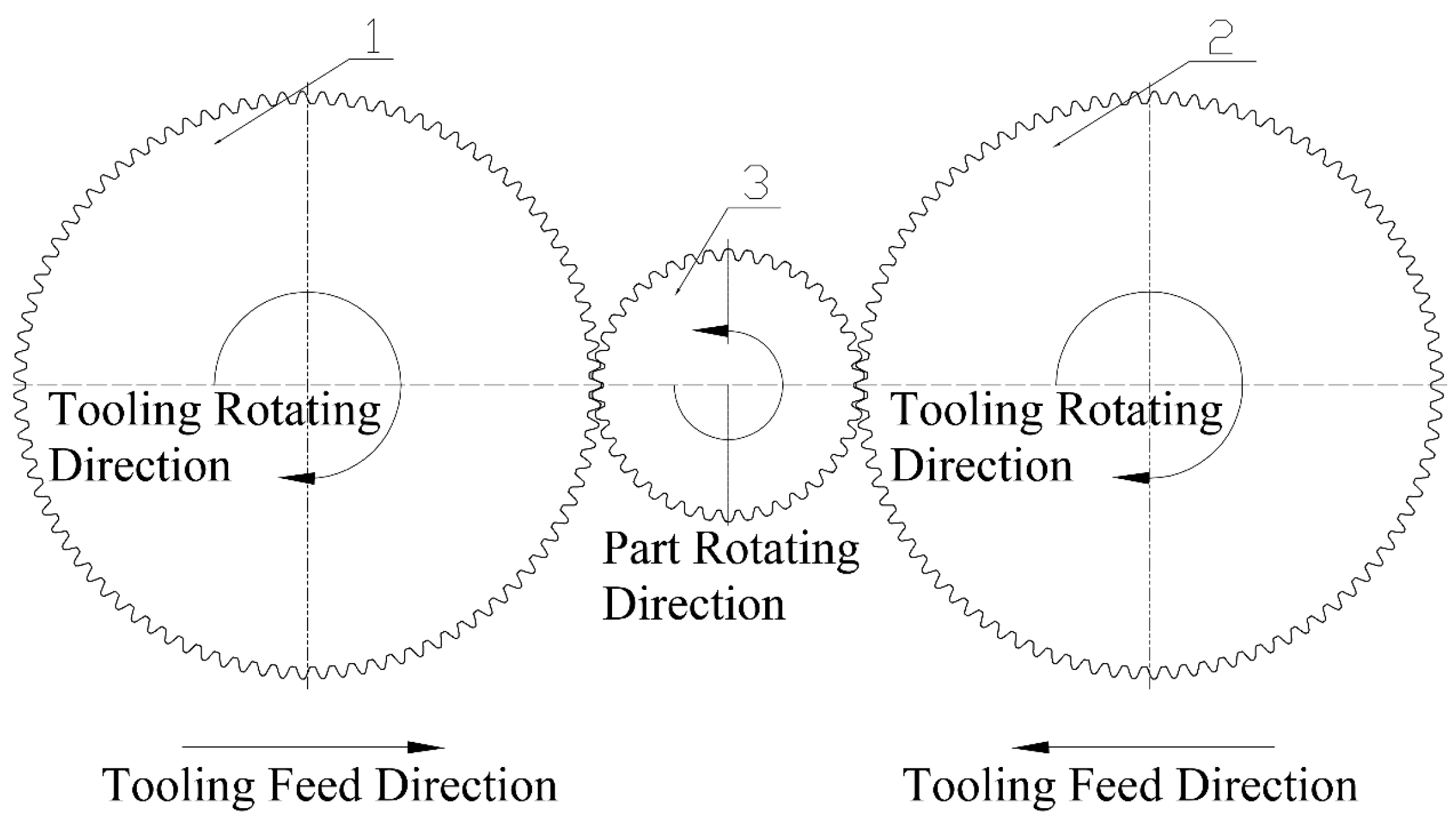

3.1. Surface Density Analysis

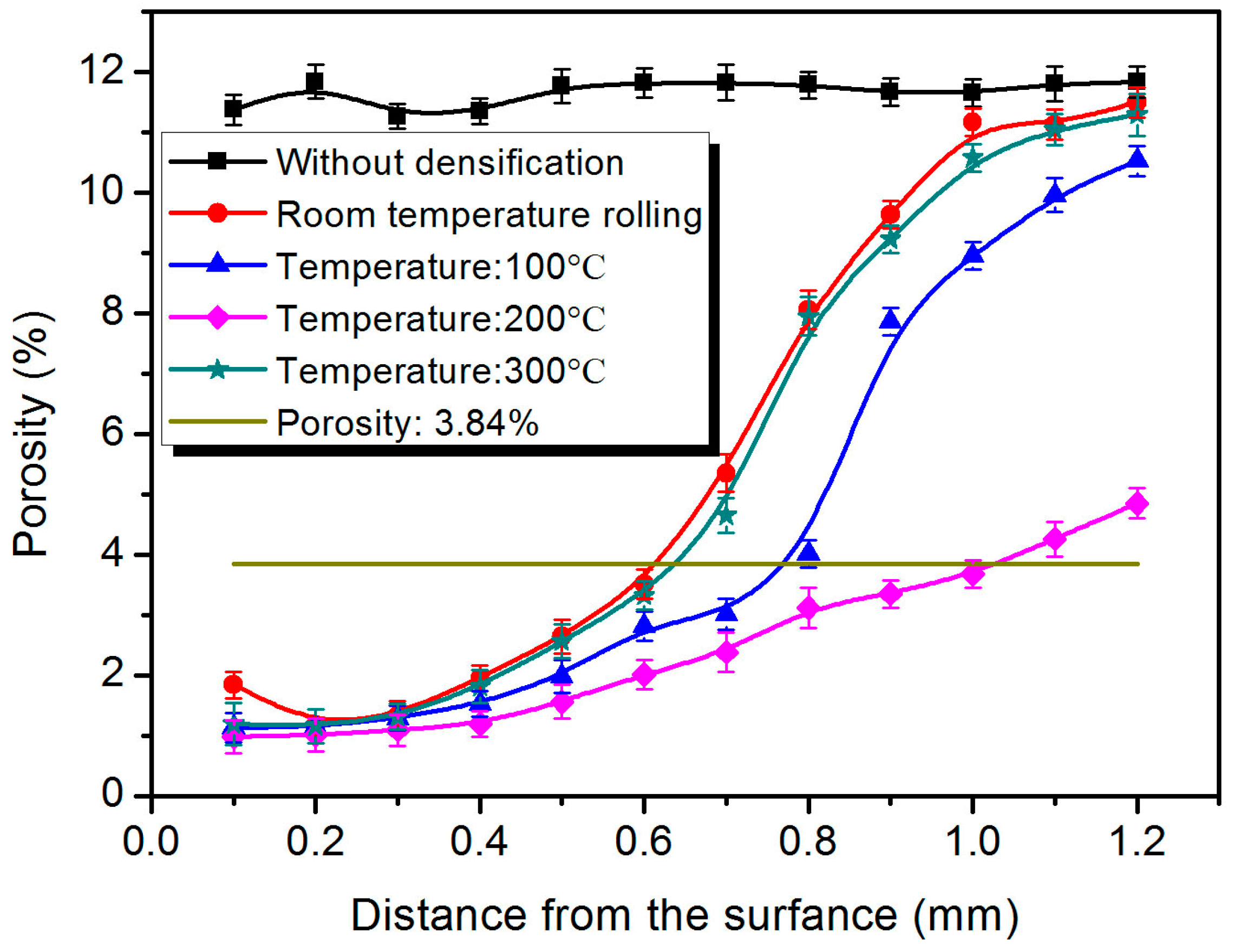

3.2. Microscopic Hardness Analysis

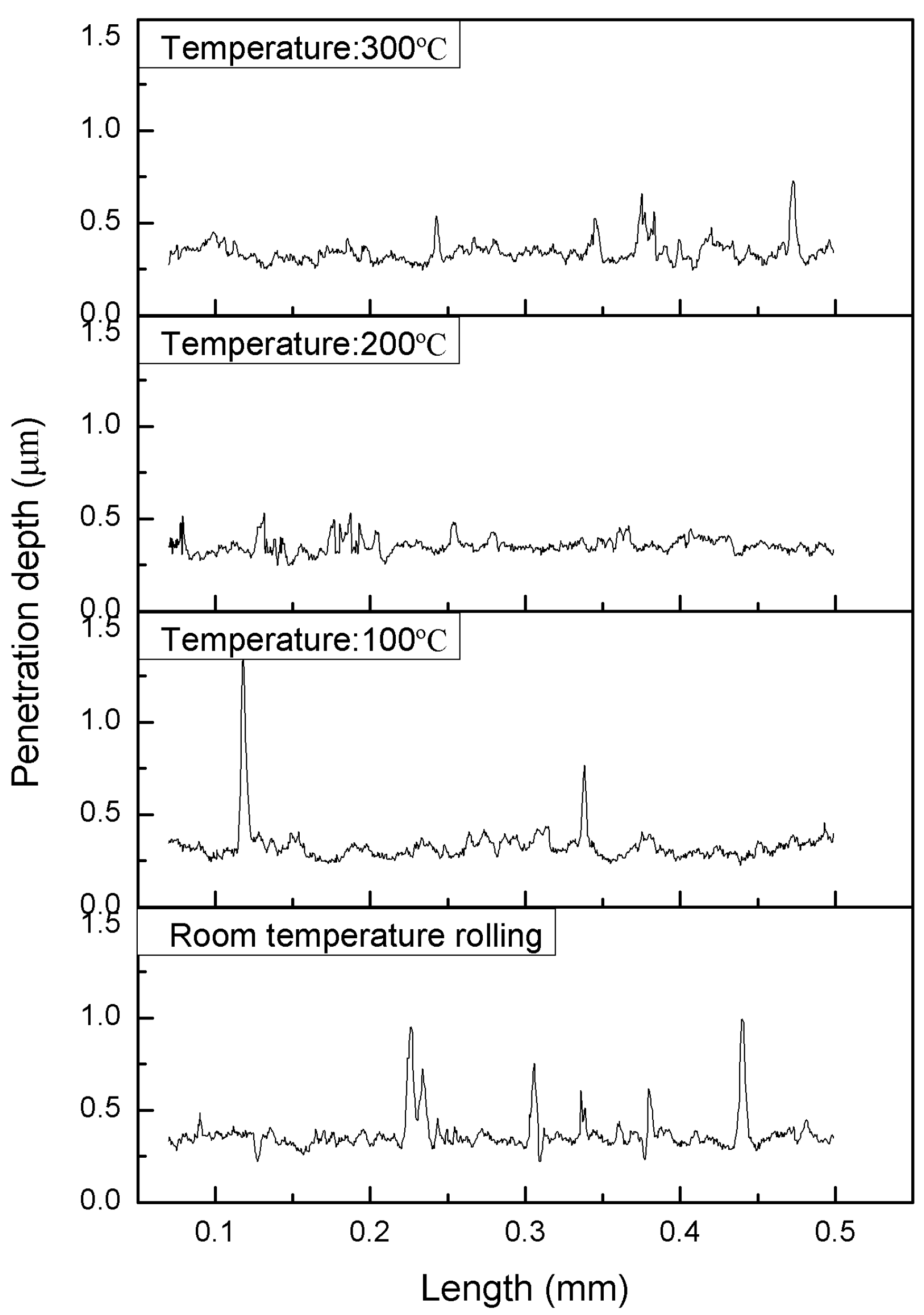

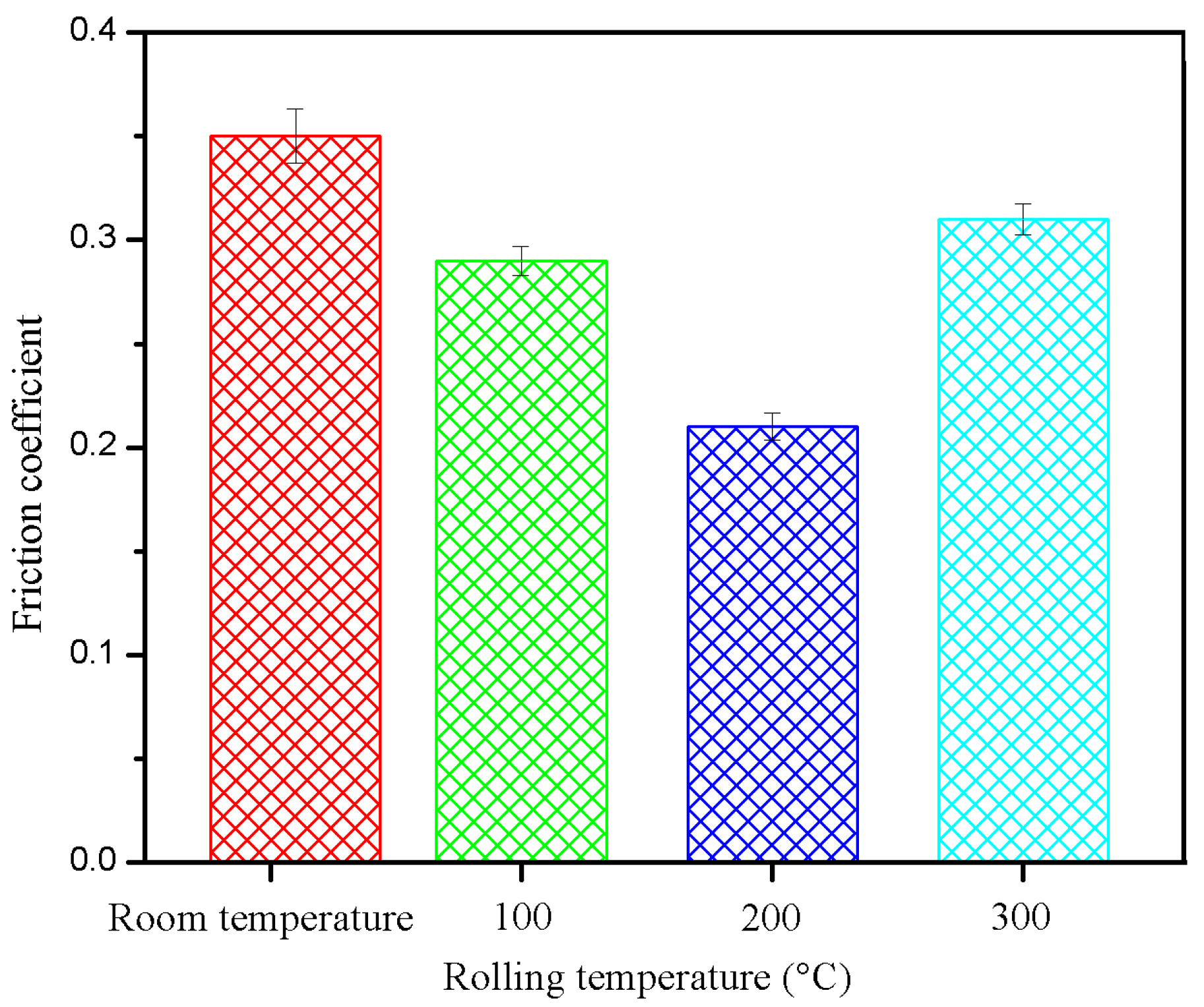

3.3. Wear Resistance Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Takemasu, T.; Koide, T.; Takeda, Y.; Kamimura, D.; Nakamoto, M. Properties of densification by surface rolling and load bearing capacity of 1.5Cr-0.2Mo high density sintered steel rollers and gears. J. Solid Mech. Mater. Eng. 2011, 5, 825–837. [Google Scholar] [CrossRef]

- Klocke, F.; Schröder, T.; Kauffmann, P. Fundamental study of surface densification of PM gears by rolling using FE analysis. Prod. Eng. 2007, 1, 113–120. [Google Scholar] [CrossRef]

- Peng, J.; Zhao, Y.; Chen, D.; Li, K.; Lu, W.; Yan, B. Effect of surface densification on the microstructure and mechanical properties of powder metallurgical gears by using a surface rolling process. Materials 2016, 9, 846. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Liu, Y.; Gu, C.; Li, Z. Study on the progress of solidification, deformation and densification during semi-solid powder rolling. Powder Technol. 2014, 261, 161–169. [Google Scholar] [CrossRef]

- Kang, D.H.; Hong, J.K.; Park, N.K.; Kim, T.W. Densification behavior of titanium in direct powder rolling process. Trans. Korean Soc. Mech. Eng. A 2012, 36, 1255–1260. [Google Scholar] [CrossRef]

- He, J.; Zhao, A.; Huang, Y.; Zhi, C.; Zhao, F. Acceleration of bainite transformation at low temperature by warm rolling process. Mater. Today Proc. 2015, 2, 289–294. [Google Scholar] [CrossRef]

- Storojeva, L.; Ponge, D.; Kaspar, R.; Raabe, D. Development of microstructure and texture of medium carbon steel during heavy warm deformation. Acta Mater. 2004, 52, 2209–2220. [Google Scholar] [CrossRef]

- Datsko, J.; Hartwig, L.; Mcclory, B. On the tensile strength and hardness relation for metals. J. Mater. Eng. Perform. 2001, 10, 718–722. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, C.; Northwood, D.O. The warm deformation treatments for improving the resistance of high strength steel wires to low cycle fatigue and room temperature creep. Rare Met. Mater. Eng. 1999, 28, 569–573. [Google Scholar]

- Gunter, R.; Lorenz, S.S. PM Gear for a Passenger Car Gear Box. In Proceedings of the International Conference on Gears, Munich, Germany, 14–16 September 2005. [Google Scholar]

- Lorenz, S.S.; Gunter, R.; Delarbre, P. Quantification of Selective Surface Densification in PM Components. In Proceedings of the International Conference on Powder Metallurgy and Particulate Materials, Montreal, QC, Canada, 19–23 June 2005. [Google Scholar]

- Takemasu, T.; Koide, T.; Shinbutsu, T.; Sasaki, H.; Takeda, Y.; Nishida, S. Effect of surface rolling on load bearing capacity of pre-alloyed sintered steel gears with different densities. Procedia Eng. 2014, 81, 334–339. [Google Scholar] [CrossRef]

- Sasaki, H.; Shinbutsu, T.; Amano, S.; Takemasu, T.; Sugimoto, S.; Koide, T.; Nishida, S. Three-dimensional complex tooth profile generated by surface rolling of sintered steel helical gears using special CNC form rolling machine. Procedia Eng. 2014, 81, 316–321. [Google Scholar] [CrossRef]

- Jones, P.K.; Buckley-Golder, K.; Lawcock, R. Densification strategies for high endurance P/M components. Int. J. Powder Metall. 1997, 33, 37–44. [Google Scholar]

- Koide, T.; Ishizuka, I.; Takemasu, T.; Miyachika, K.; Fukai, Y. GSD-02 Load Bearing Capacity of Surface-Rolled High Density Sintered Metal Gears (Gear Strength and Durability, Including Gear Materials and Heat Treatment Techniques). In Proceedings of the JSME International Conference on Motion and Power Transmissions, Kyoto, Japan, 1–3 March 2017; The Japan Society of Mechanical Engineers: Kyoto, Japan, 2017; pp. 313–316. [Google Scholar]

- Jandeska, W.; Hoffmann, G.; Slattery, R. Rolling contact fatigue of surface densified FLN2-4405. Int. J. Powder Metall. 2005, 41, 49–56. [Google Scholar]

- Liu, X.; Xiao, Z.; Guan, H.; Zhang, W.; Li, F. Friction and wear behaviours of surface densified powder metallurgy Fe–2Cu–0.6C material. Powder Metall. 2016, 59, 329–334. [Google Scholar] [CrossRef]

- Bhargava, S.; Dube, R.K. Changes in the longitudinal flow and apparent plastic Poisson’s ratio of a porous metal strip during hot densification rolling. Metall. Trans. A 1988, 19, 1205–1211. [Google Scholar] [CrossRef]

- Ehinger, D.; Krüger, L.; Martin, U.; Weigelt, C. Temperature effects on the deformation behavior of high-density trip steel and particle-reinforced TRIP steel/zirconia honeycombs under quasi-static compressive loading. Adv. Eng. Mater. 2013, 15, 646–657. [Google Scholar] [CrossRef]

- Richards, M.D.; Burnett, M.E.; Speer, J.G.; Matlock, D.K. Effects of deformation behavior and processing temperature on the fatigue performance of deep-rolled medium carbon bar steels. Metall. Mater. Trans. A 2013, 44, 270–285. [Google Scholar] [CrossRef]

- Zhe-Long, H.E.; Lei, L.P.; Pan, Z. Effect of warm surface rolling on fatigue property of H13 steel. J. Plast. Eng. 2017, 24, 74–78. [Google Scholar]

- Lee, C.S.; Duggan, B.J.; Smallman, R.E. A Theory of deformation banding in cold rolling. Acta Metall. Mater. 1993, 41, 2265–2270. [Google Scholar] [CrossRef]

- Sigl, L.S.; Rau, G.; Dennert, C. Selective surface densification for high performance P/M components. Powder Metall. Technol. 2012, 30, 144–150. [Google Scholar]

| Element | C | Cu | Astaloy 85Mo |

|---|---|---|---|

| Content (%) | 0.80 | 1.50 | Balence |

| Temperature (°C) | RT | 100 | 200 | 300 |

|---|---|---|---|---|

| Depth of the densified layer (mm) | 0.61 | 0.78 | 1.12 | 0.65 |

| Temperature (°C) | RT | 100 | 200 | 300 |

|---|---|---|---|---|

| Rolling pressure (kN) | 45.40 | 42.83 | 40.29 | 45.47 |

| Temperature (°C) | RT | 100 | 200 | 300 |

|---|---|---|---|---|

| Strach depth (μm) | 0.3 | 0.30 | 0.29 | 0.32 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Li, D.; Peng, J.; Wang, T.; Yan, B.; Lu, W. The Effect of Rolling Temperature on the Microstructure and Mechanical Properties of Surface-Densified Powder Metallurgy Fe-Based Gears Prepared by the Surface Rolling Process. Metals 2017, 7, 420. https://doi.org/10.3390/met7100420

Chen D, Li D, Peng J, Wang T, Yan B, Lu W. The Effect of Rolling Temperature on the Microstructure and Mechanical Properties of Surface-Densified Powder Metallurgy Fe-Based Gears Prepared by the Surface Rolling Process. Metals. 2017; 7(10):420. https://doi.org/10.3390/met7100420

Chicago/Turabian StyleChen, Di, Dekai Li, Jingguang Peng, Taolei Wang, Biao Yan, and Wei Lu. 2017. "The Effect of Rolling Temperature on the Microstructure and Mechanical Properties of Surface-Densified Powder Metallurgy Fe-Based Gears Prepared by the Surface Rolling Process" Metals 7, no. 10: 420. https://doi.org/10.3390/met7100420