Study of the Influence of TiB Content and Temperature in the Properties of In Situ Titanium Matrix Composites

Abstract

:1. Introduction

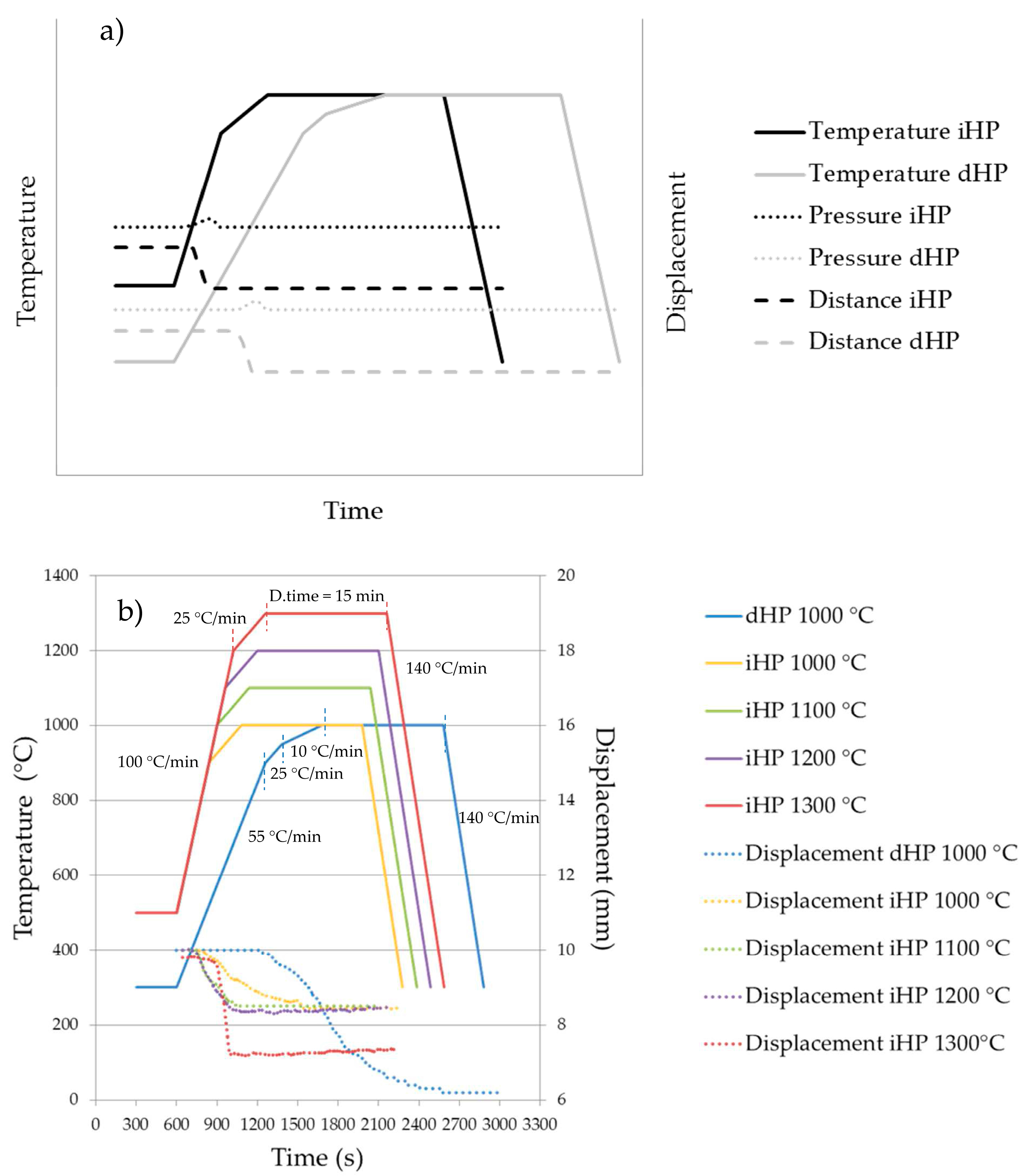

2. Materials and Experimental Procedures

3. Results and Discussion

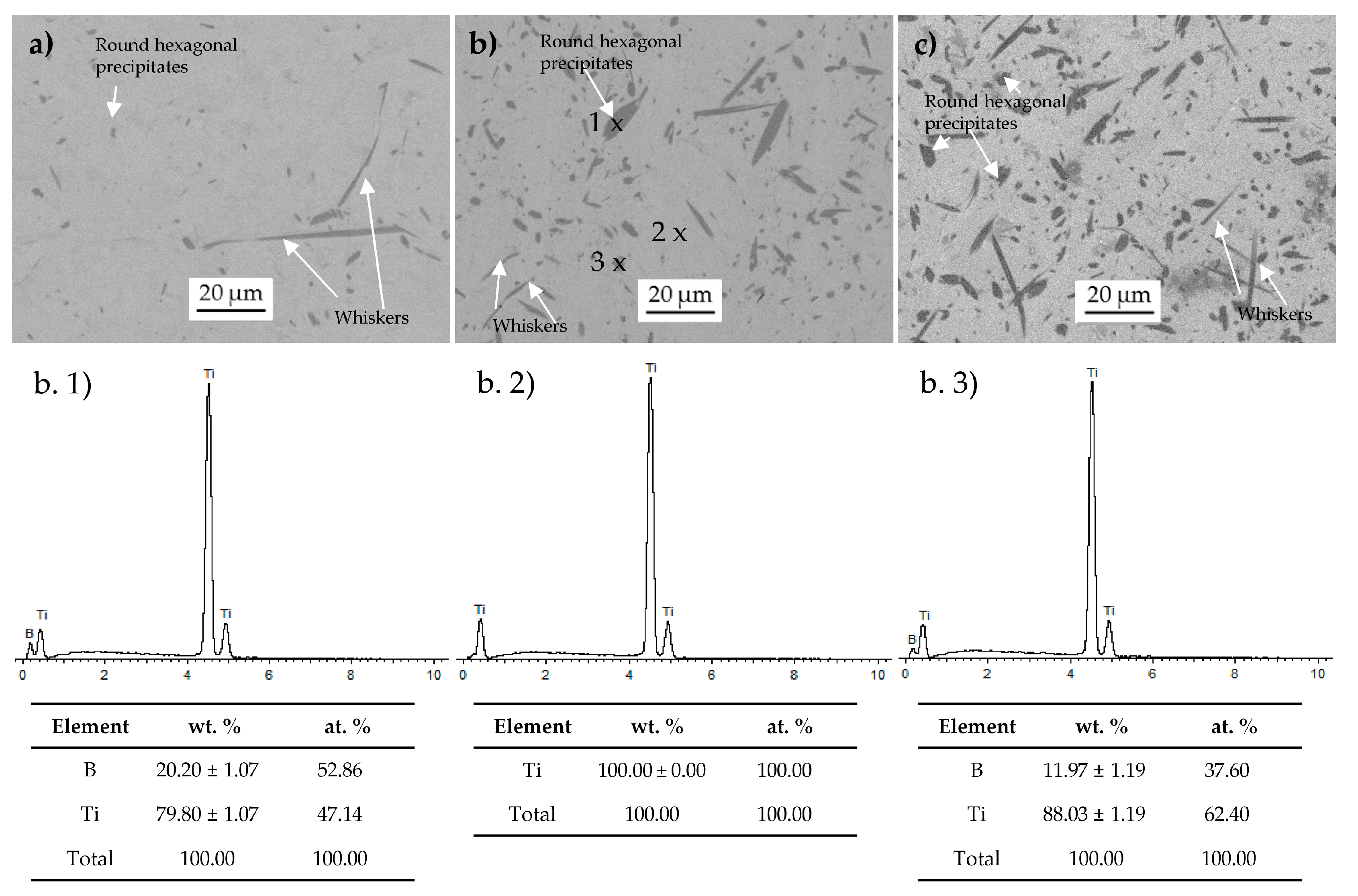

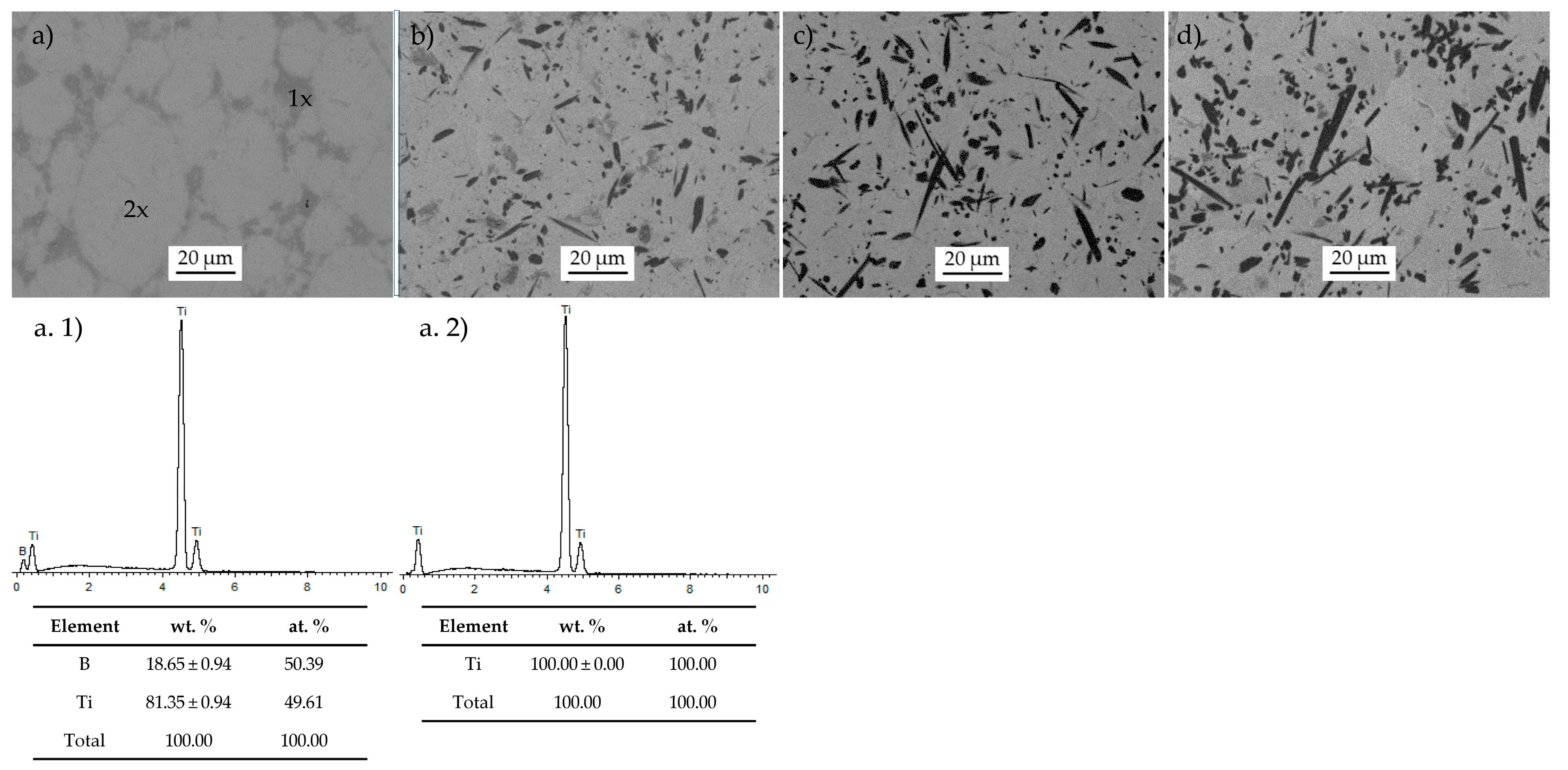

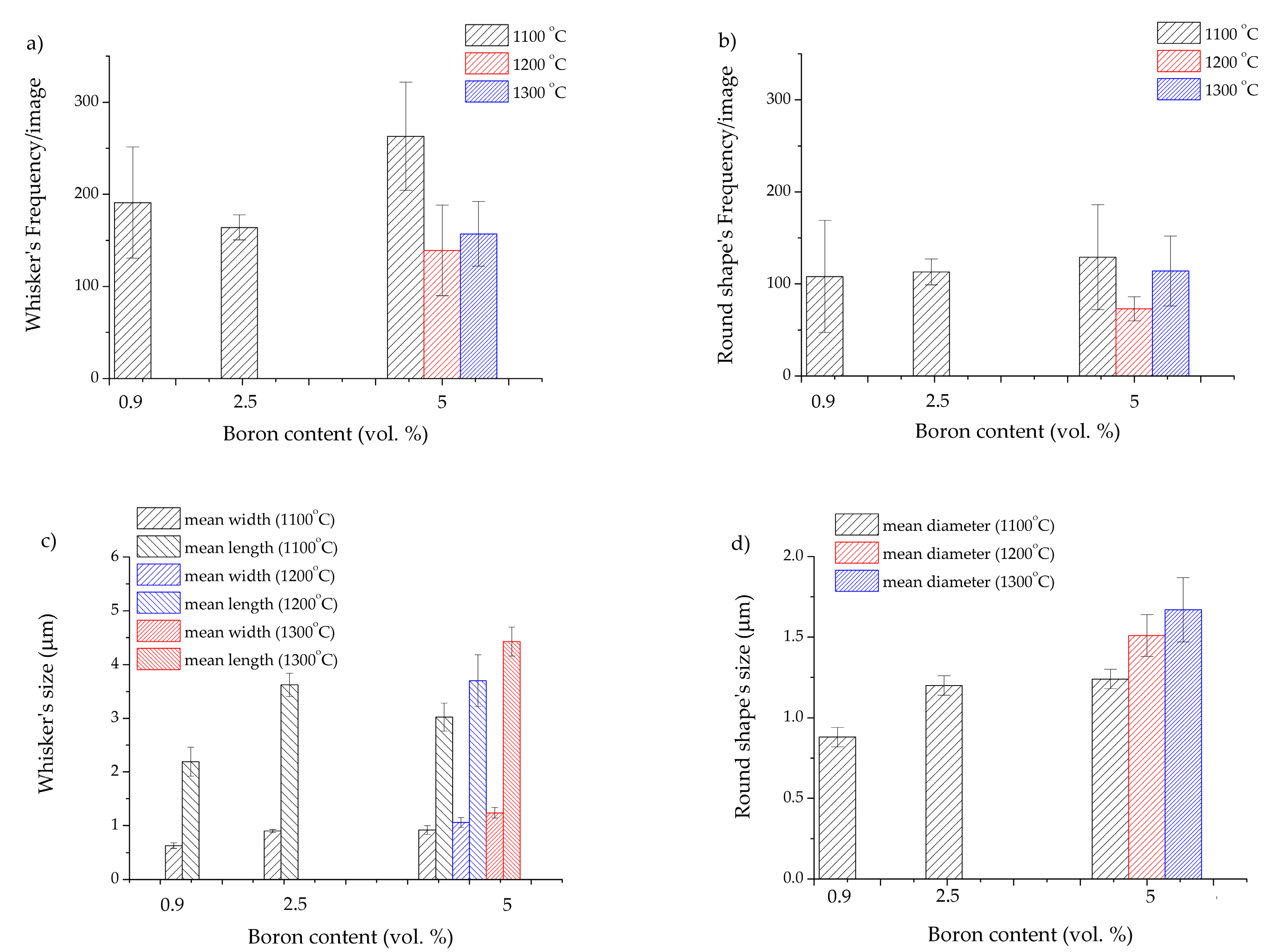

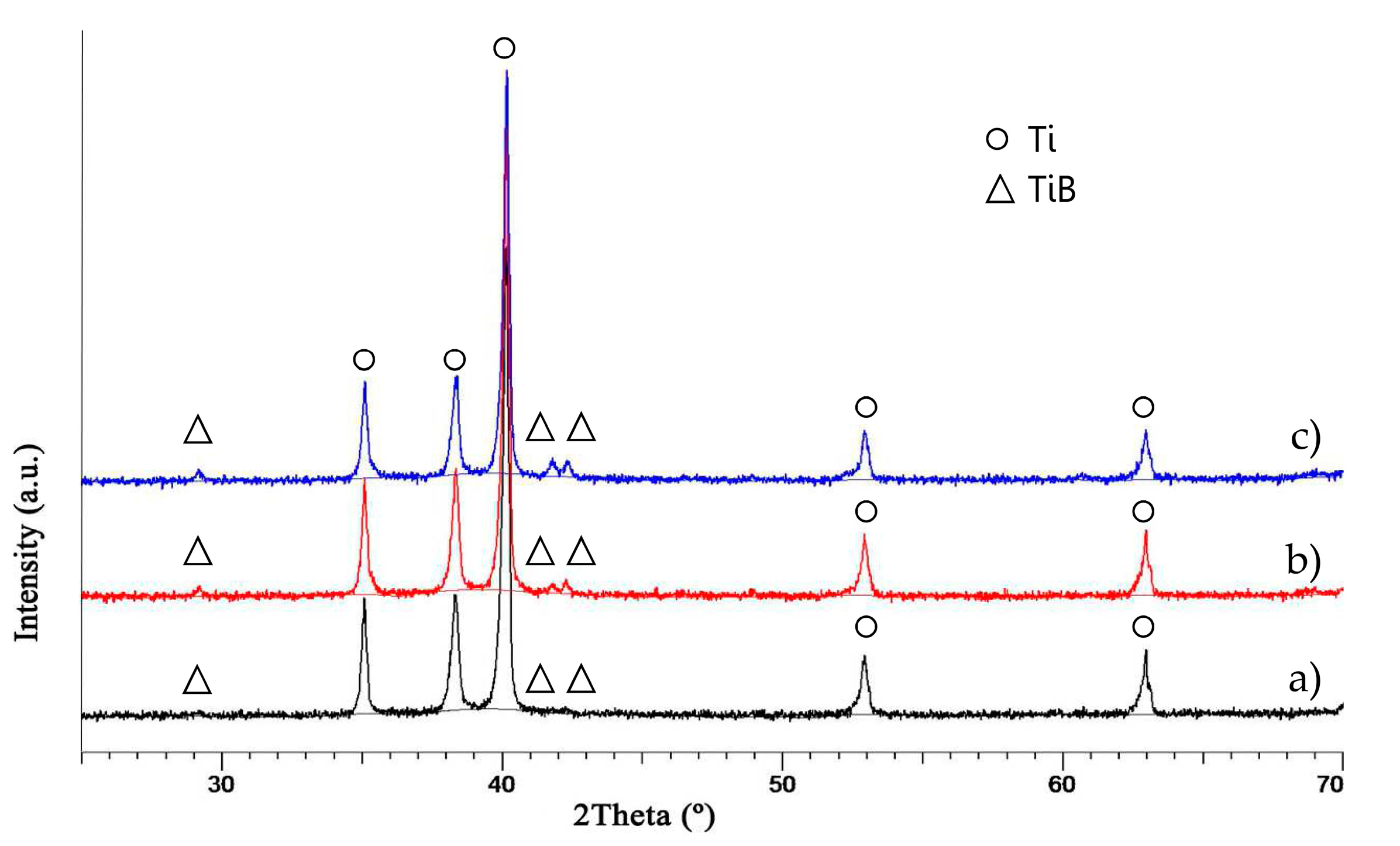

3.1. Microstructural Study and XRD Analysis

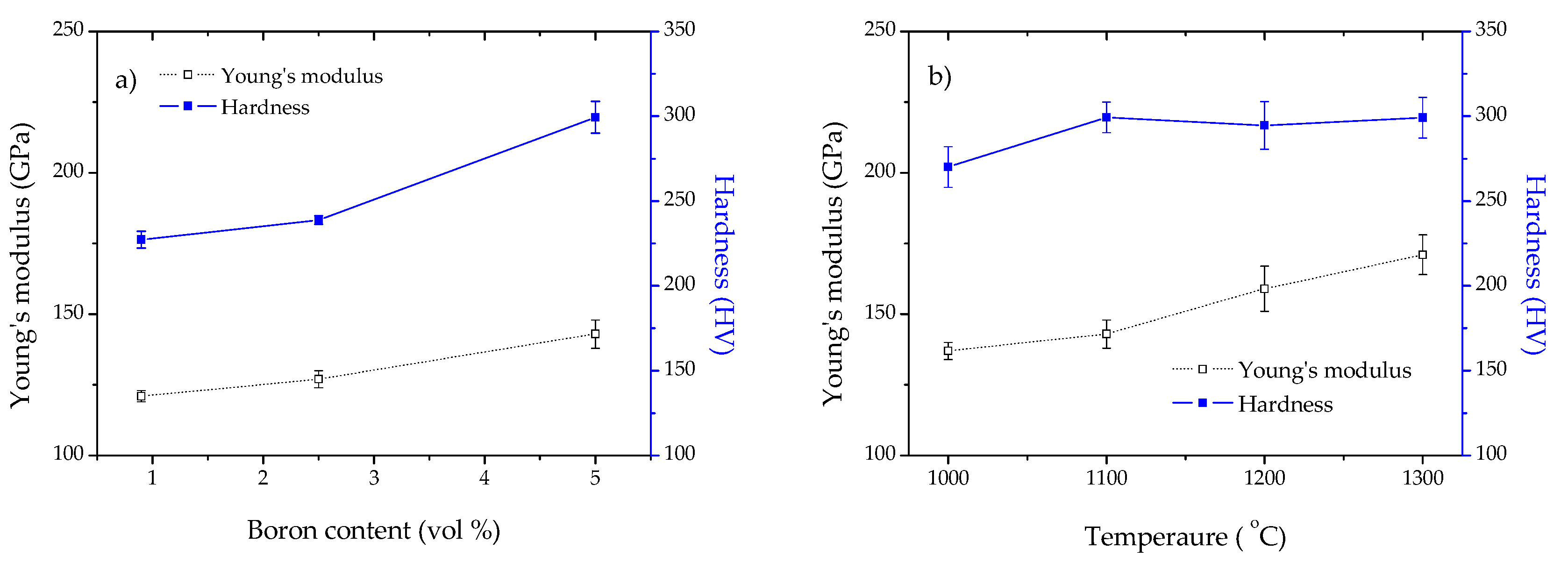

3.2. Density, Hardness, Young’s Modulus, and Mechanical Properties

4. Conclusions

- -

- High densification composites are produced. The influence of the in situ formed TiB and processing conditions on the material behaviour is verified.

- -

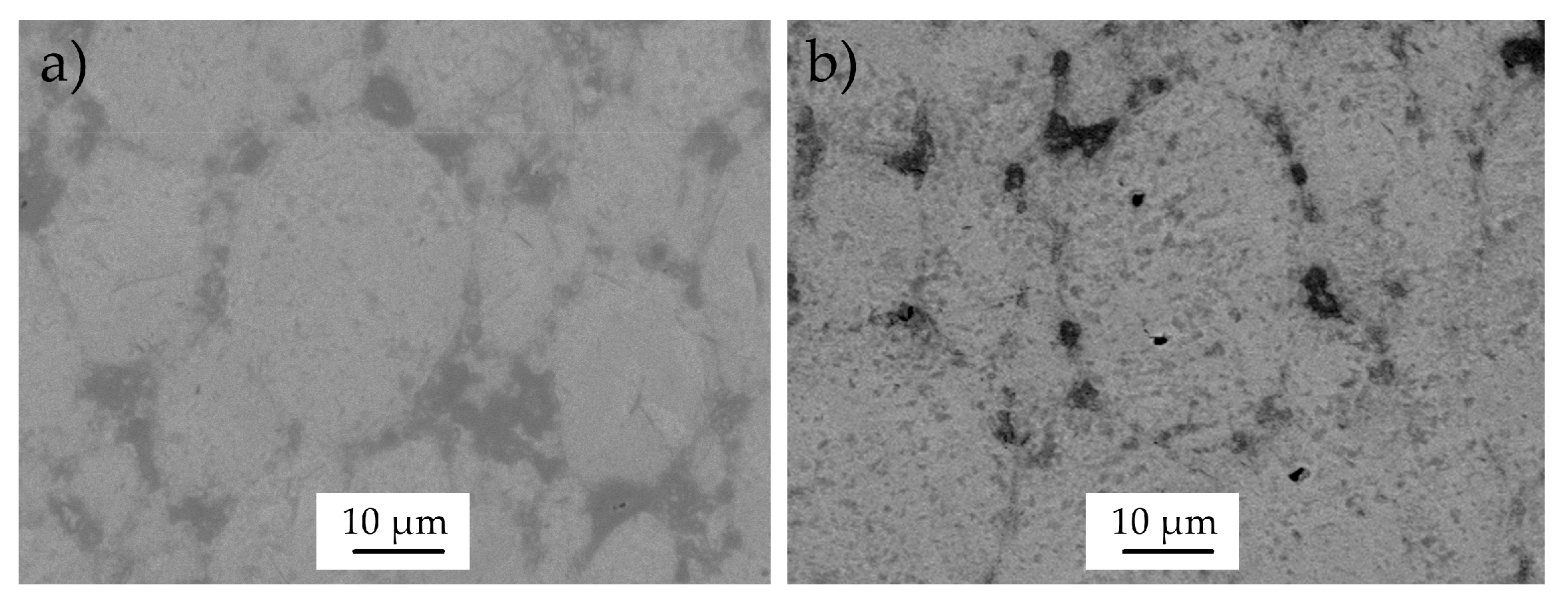

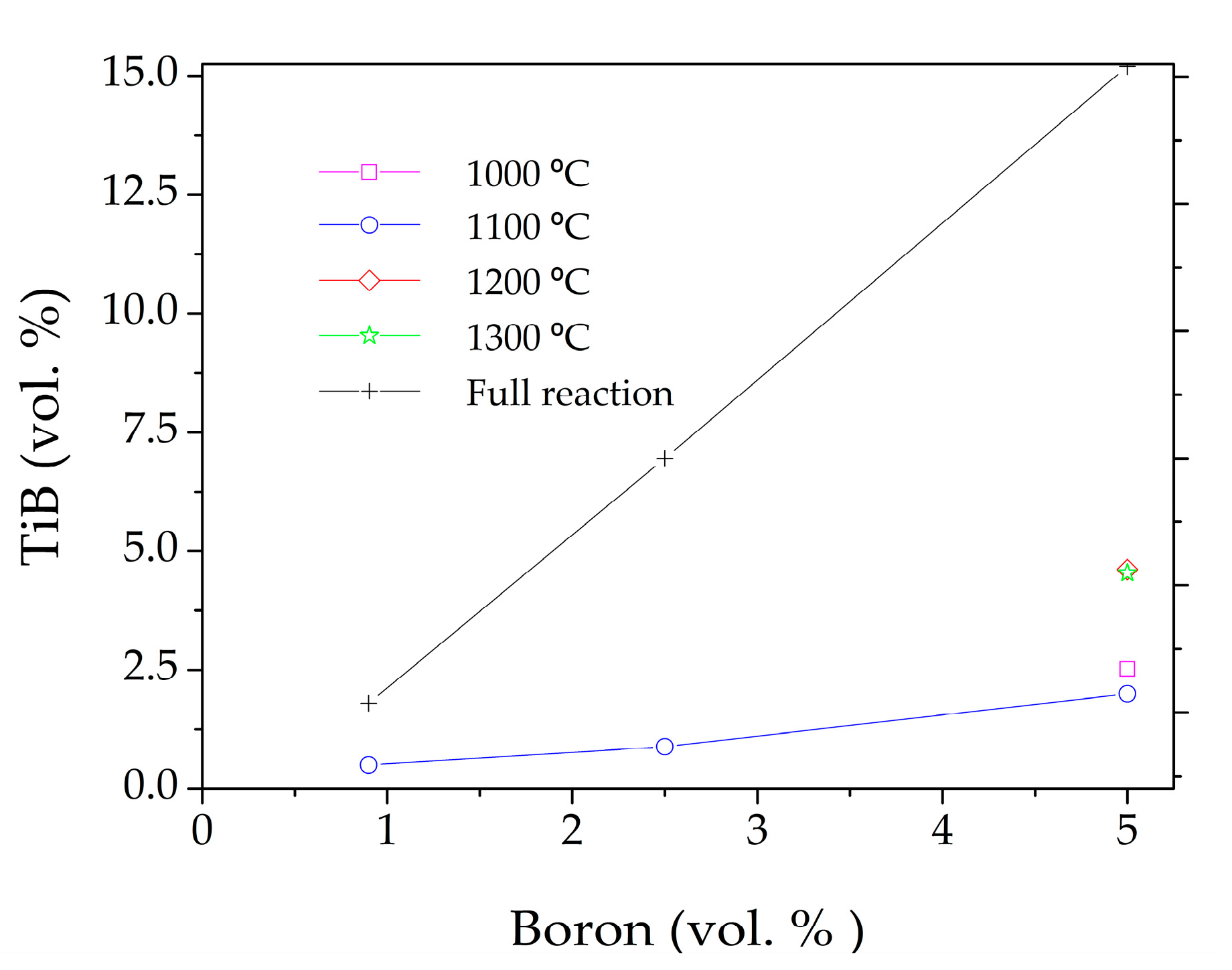

- The microstructural study reveals changes in the composites depending on the operational temperatures. In the range of 1000 to 1100 °C, the location of the precipitates and the boron particles evolves from the grain boundaries into the matrix. Up to 1100 °C, two different morphologies of TiB precipitates have been considered: whiskers and round hexagonal shapes. Increasing the temperature promotes a gradual growth of the TiB phases. At the same composite composition, the TiB precipitates remained relatively constant even if the temperature rose from 1200 to 1300 °C.

- -

- Relating to the boron addition, variations of the sizes of these secondary phases were also observed. Although the addition of more boron involved greater formation of precipitates, the proportions between the boron content and the TiB formed were lower at the highest boron content in the starting mixture. The formed TiB and the boron particles significantly contributed to the hardening and stiffness effects. Increasing the temperature helped to increase the stiffness of the composites more than its hardness.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ravi Chandran, K.S.; Panda, K.B.; Sahay, S.S. TiBw-reinforced Ti composites: Processing, properties, application prospects, and research needs. JOM 2004, 56, 42–48. [Google Scholar] [CrossRef]

- Kondoh, K. 16–Titanium metal matrix composites by powder metallurgy (PM) routes. In Titanium Powder Metallurgy; Elsevier: Amsterdam, The Netherlands, 2015; pp. 277–297. [Google Scholar]

- Zadra, M.; Girardini, L. High-performance, low-cost titanium metal matrix composites. Mater. Sci. Eng. A 2014, 608, 155–163. [Google Scholar] [CrossRef]

- Campbell, F.C. Chapter 9: Metal matrix composites. In Manufacturing Technology for Aerospace Structural Materials; Elsevier Science: Oxford, UK, 2006; pp. 419–457. ISBN 978-1-85-617495-4. [Google Scholar]

- Kainer, K.U. Metal Matrix Composites; Wiley-VCH: Weinheim, Germany, 2006; ISBN 978-3-527-31360-0. [Google Scholar]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium Alloys for Aerospace Applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Sabahi Namini, A.; Azadbeh, M.; Shahedi Asl, M. Effect of TiB2 content on the characteristics of spark plasma sintered Ti–TiBw composites. Adv. Powder Technol. 2017, 28, 1564–1572. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. In-situ formation of novel TiC-particle-reinforced 316L stainless steel bulk-form composites by selective laser melting. J. Alloys Compd. 2017, 706, 409–418. [Google Scholar] [CrossRef]

- Attar, H.; Bönisch, M.; Calin, M.; Zhang, L.-C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium-titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Zhang, J.; Ke, W.; Ji, W.; Fan, Z.; Wang, W.; Wang, H. Microstructure and properties of in situ titanium boride (TiB)/titanium (TI) composites. Mater. Sci. Eng. A 2015, 648, 158–163. [Google Scholar] [CrossRef]

- Munir, K.S.; Zheng, Y.; Zhang, D.; Lin, J.; Li, Y.; Wen, C. Microstructure and mechanical properties of carbon nanotubes reinforced titanium matrix composites fabricated via spark plasma sintering. Mater. Sci. Eng. A 2017, 688, 505–523. [Google Scholar] [CrossRef]

- Ozerov, M.N.; Stepanov, N.; Kolesnikov, A.; Sokolovsky, V.; Zherebtsov, S. Brittle-to-ductile transition in a Ti–TiB metal-matrix composite. Mater. Lett. 2017, 187, 28–31. [Google Scholar] [CrossRef]

- Jia, L.; Wang, X.; Chen, B.; Imai, H.; Li, S.; Lu, Z.; Kondoh, K. Microstructural evolution and competitive reaction behavior of Ti-B4C system under solid-state sintering. J. Alloys Compd. 2016, 687, 1004–1011. [Google Scholar] [CrossRef]

- Popov, V.A.; Shelekhov, E.V.; Prosviryakov, A.S.; Presniakov, M.Y.; Senatulin, B.R.; Kotov, A.D.; Khomutov, M.G. Particulate metal matrix composites development on the basis of in situ synthesis of TiC reinforcing nanoparticles during mechanical alloying. J. Alloys Compd. 2017, 707, 365–370. [Google Scholar] [CrossRef]

- Jiao, Y.; Huang, L.J.; Wang, S.; Li, X.T.; An, Q.; Cui, X.P.; Geng, L. Effects of first-scale TiBw on secondary-scale Ti5Si3 characteristics and mechanical properties of in-situ (Ti5Si3 + TiBw)/Ti6Al4V composites. J. Alloys Compd. 2017, 704, 269–281. [Google Scholar] [CrossRef]

- Ariza, E.; Montealegre-Meléndez, I.; Arévalo, C.; Kitzmantel, M.; Neubauer, E. Ti/B4C Composites Prepared by In Situ Reaction Using Inductive Hot Pressing. Key Eng. Mater. 2017, 742, 121–128. [Google Scholar] [CrossRef]

- Lu, L.; Fuh, J.Y.H.; Chen, Z.D.; Leong, C.C.; Wong, Y.S. In situ formation of TiC composite using selective laser melting. Mater. Res. Bull. 2000, 35, 1555–1561. [Google Scholar] [CrossRef]

- Hu, Y.; Zhao, B.; Ning, F.; Wang, H.; Cong, W. In-situ ultrafine three-dimensional quasi-continuous network microstructural TiB reinforced titanium matrix composites fabrication using laser engineered net shaping. Mater. Lett. 2017, 195, 116–119. [Google Scholar] [CrossRef]

- Oghenevweta, J.E.; Wexler, D.; Calka, A. Sequence of phase evolution during mechanically induced self-propagating reaction synthesis of TiB and TiB2 via magnetically controlled ball milling of titanium and boron powders. J. Alloys Compd. 2017, 701, 380–391. [Google Scholar] [CrossRef]

- Schmidt, J.; Boehling, M.; Burkhardt, U.; Grin, Y. Preparation of titanium diboride TiB2 by spark plasma sintering at slow heating rate. Sci. Technol. Adv. Mater. 2007, 8, 376–382. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, D.; Gabbitas, B.; Yang, F.; Matthews, S. Synthesis of a TiBw/Ti6Al4V composite by powder compact extrusion using a blended powder mixture. J. Alloys Compd. 2014, 606, 262–268. [Google Scholar] [CrossRef]

- Gorsse, S.; Petitcorps, Y.L.; Matar, S.; Rebillat, F. Investigation of the Young’s modulus of TiB needles in situ produced in titanium matrix composite. Mater. Sci. Eng. A 2003, 340, 80–87. [Google Scholar] [CrossRef]

- Lieberman, S.I.; Gokhale, A.M.; Tamirisakandala, S.; Bhat, R.B. Three-dimensional microstructural characterization of discontinuously reinforced Ti64–TiB composites produced via blended elemental powder metallurgy. Mater. Charact. 2009, 60, 957–963. [Google Scholar] [CrossRef]

- Bose, A.; Eisen, W.B. Hot Consolidation of Powders and Particulates; MPIF: Princeton, NJ, USA, 2003; ISBN 1-878954-495-4. [Google Scholar]

- Radhakrishna Bhat, B.V.; Subramanyam, J.; Bhanu Prasad, V.V. Preparation of Ti-TiB-TiC & Ti-TiB composites by in-situ reaction hot pressing. Mater. Sci. Eng. A 2002, 325, 126–130. [Google Scholar] [CrossRef]

- Montealegre-Meléndez, I. Development of Titanium Metal Matrix Composites via Powder Metallurgy; Technische Universitat Wien: Wien, Viena, 2009. [Google Scholar]

- Liu, B.X.; Huang, L.J.; Geng, L.; Wang, B.; Cui, X.P. Fracture behaviors and microstructural failure mechanisms of laminated Ti–TiBw/Ti composites. Mater. Sci. Eng. A 2014, 611, 290–297. [Google Scholar] [CrossRef]

- Arevalo, C.; Montealegre-Meléndez, I.; Ariza, E.; Kitzmantel, M.; Rubio-Escudero, C.; Neubauer, E. Influence of Sintering Temperature on the Microstructure and Mechanical Properties of In Situ Reinforced Titanium Composites by Inductive Hot Pressing. Materials 2016, 9, 919. [Google Scholar] [CrossRef] [PubMed]

- Montealegre-Meléndez, I.; Neubauer, E.; Arévalo, C.; Rovira, A.; Kitzmantel, M. Study of Titanium Metal Matrix Composites Reinforced by Boron Carbides and Amorphous Boron Particles Produced via Direct Hot Pressing. Key Eng. Mater. 2016, 704, 85–93. [Google Scholar] [CrossRef]

- Montealegre-Meléndez, I.; Neubauer, E.; Danninger, H. Consolidation of titanium matrix composites to maximum density by different hot pressing techniques. Mater. Sci. Eng. A 2010, 527, 4466–4473. [Google Scholar] [CrossRef]

- Davis, J.R. Nondestructive Evaluation and Quality Control. In ASM Handbook; ASM-International: Novelty, OH, USA, 1989. [Google Scholar]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Okulov, I.V.; Wendrock, H.; Bӧnisch, M.; Volegov, A.S.; Calin, M.; Eckert, J.; Dargusch, M.S. Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting. Mater. Sci. Eng. A 2017, 688, 20–26. [Google Scholar] [CrossRef]

- Wang, B.; Huang, L.J.; Geng, L.; Yu, Z.S. Modification of microstructure and tensile property of TiBw/near-α Ti composites by tailoring TiBw distribution and heat treatment. J. Alloys Compd. 2017, 690, 424–430. [Google Scholar] [CrossRef]

- Murray, J.L.; Liao, P.K.; Spear, K.E. The B-Ti (Boron-Titanium) System. Bull. Alloy Phase Diagr. 1986, 7, 550–551. [Google Scholar] [CrossRef]

- Yan, Z.; Chen, F.; Cai, Y.; Zheng, Y. Microstructure and mechanical properties of in-situ synthesized TiB whiskers reinforced titanium matrix composites by high-velocity compaction. Powder Technol. 2014, 267, 309–314. [Google Scholar] [CrossRef]

- Choi, B.J.; Kim, I.Y.; Lee, Y.Z.; Kim, Y.J. Microstructure and friction/wear behavior of (TiB + TiC) particulate-reinforced titanium matrix composites. Wear 2014, 318, 68–77. [Google Scholar] [CrossRef]

- Zhang, W.; Feng, Y.; Chen, W.; Yang, J. Effects of heat treatment on the microstructure and mechanical properties of in situ inhomogeneous TiBw/Ti6Al4V composite fabricated by pre-sintering and canned powder extrusion. J. Alloys Compd. 2017, 693, 1116–1123. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin, Germany, 2007. [Google Scholar]

- Leyends, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications, 1st ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar]

| Particle Size Distribution | Ti (µm) | Amorphous B (µm) |

|---|---|---|

| D10 | 11.88 | 0.74 |

| D50 | 28.13 | 2.44 |

| D90 | 51.42 | 14.51 |

| Amorphous B (vol %) | Temperature (°C) | Pressure (MPa) | Dwell Time (min) | Processing Method | Diameter (mm) |

|---|---|---|---|---|---|

| 0.9 | 1100 | 50 | 15 | iHP * | 20 |

| 2.5 | 1100 | 50 | 15 | iHP | 20 |

| 5 | 1000 | 50 | 15 | iHP | 20 |

| 5 | 1000 | 35 | 15 | dHP * | 80 |

| 5 | 1100 | 50 | 15 | iHP | 20 |

| 5 | 1200 | 50 | 15 | iHP | 20 |

| 5 | 1300 | 50 | 15 | iHP | 20 |

| Specimen | Temperature (°C) | Densification (%) |

|---|---|---|

| Ti + 0.9 vol % | 1100 | 96.61 |

| Ti + 2.5 vol % | 1100 | 98.10 |

| Ti + 5 vol % | 1000 | 98.42 |

| Ti + 5 vol % (dHP) | 1000 | 98.73 |

| Ti + 5 vol % | 1100 | 98.46 |

| Ti + 5 vol % | 1200 | 98.91 |

| Ti + 5 vol % | 1300 | 99.35 |

| Material | Tensile Properties | Bending Properties | ||||

|---|---|---|---|---|---|---|

| Ti + 5 vol % of B | Room temperature | 250 °C | Room temperature | |||

| σUTS (MPa) | ε (%) | σUTS (MPa) | ε (%) | σUBS (MPa) | ε (%) | |

| 780 | 1.94 | 533 | 6.18 | 1454.38 | 3.44 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arévalo, C.; Montealegre-Melendez, I.; Pérez-Soriano, E.M.; Ariza, E.; Kitzmantel, M.; Neubauer, E. Study of the Influence of TiB Content and Temperature in the Properties of In Situ Titanium Matrix Composites. Metals 2017, 7, 457. https://doi.org/10.3390/met7110457

Arévalo C, Montealegre-Melendez I, Pérez-Soriano EM, Ariza E, Kitzmantel M, Neubauer E. Study of the Influence of TiB Content and Temperature in the Properties of In Situ Titanium Matrix Composites. Metals. 2017; 7(11):457. https://doi.org/10.3390/met7110457

Chicago/Turabian StyleArévalo, Cristina, Isabel Montealegre-Melendez, Eva M. Pérez-Soriano, Enrique Ariza, Michael Kitzmantel, and Erich Neubauer. 2017. "Study of the Influence of TiB Content and Temperature in the Properties of In Situ Titanium Matrix Composites" Metals 7, no. 11: 457. https://doi.org/10.3390/met7110457

APA StyleArévalo, C., Montealegre-Melendez, I., Pérez-Soriano, E. M., Ariza, E., Kitzmantel, M., & Neubauer, E. (2017). Study of the Influence of TiB Content and Temperature in the Properties of In Situ Titanium Matrix Composites. Metals, 7(11), 457. https://doi.org/10.3390/met7110457