Investigation on Friction and Wear of Cold Rolled High Strength Steel against an AISI52100 Counterpart

Abstract

:1. Introduction

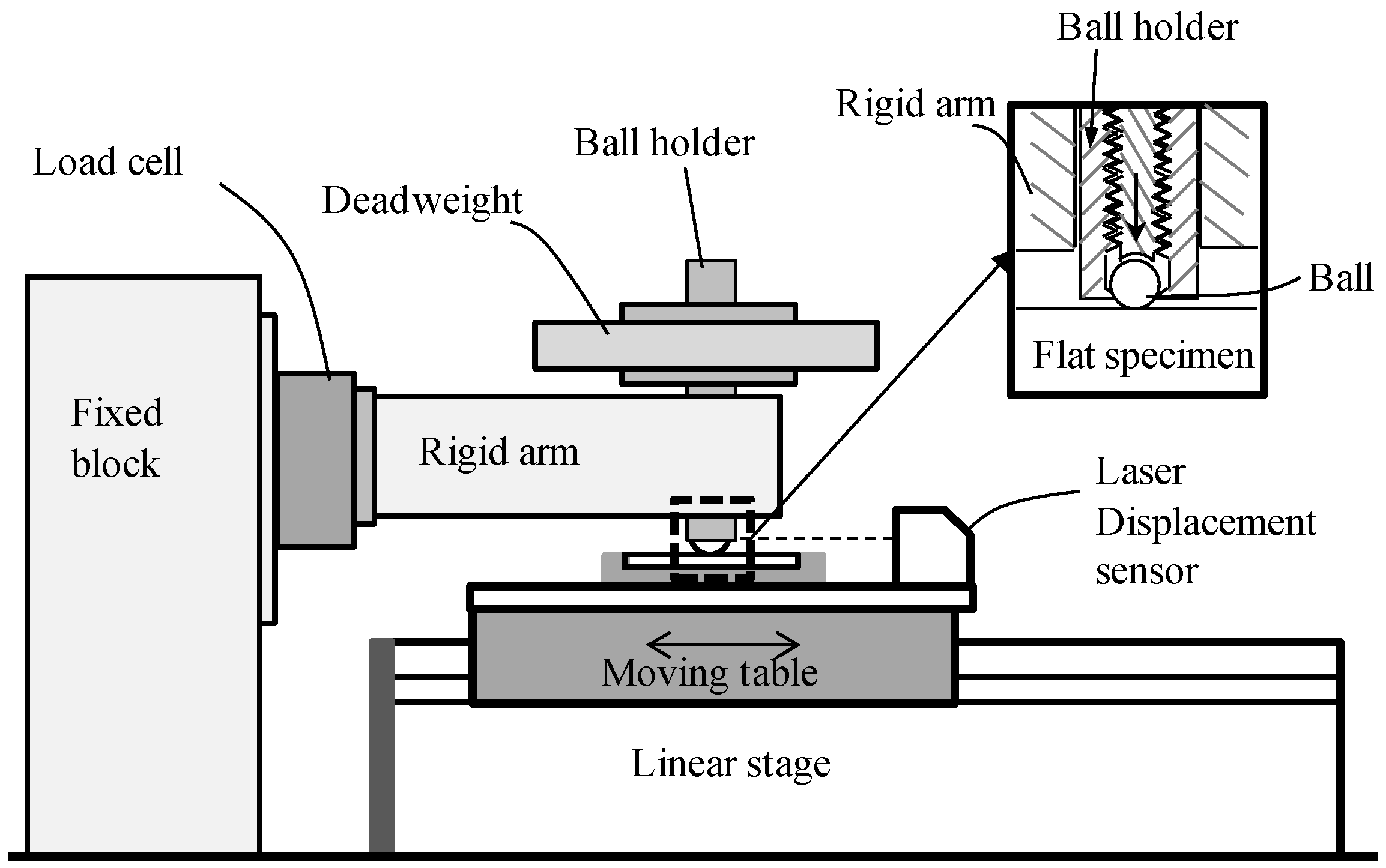

2. Materials and Methods

3. Results and Discussion

4. Conclusions

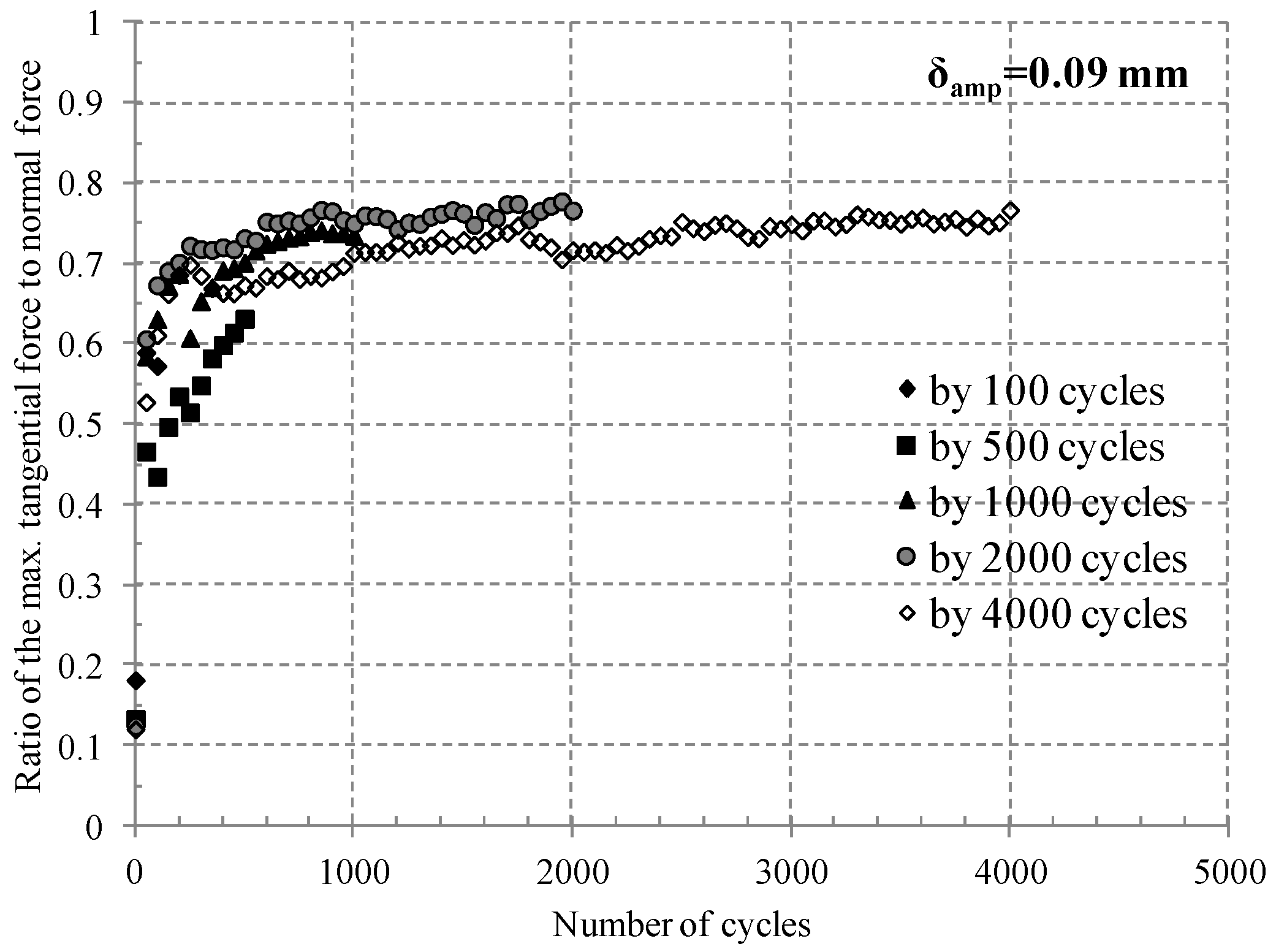

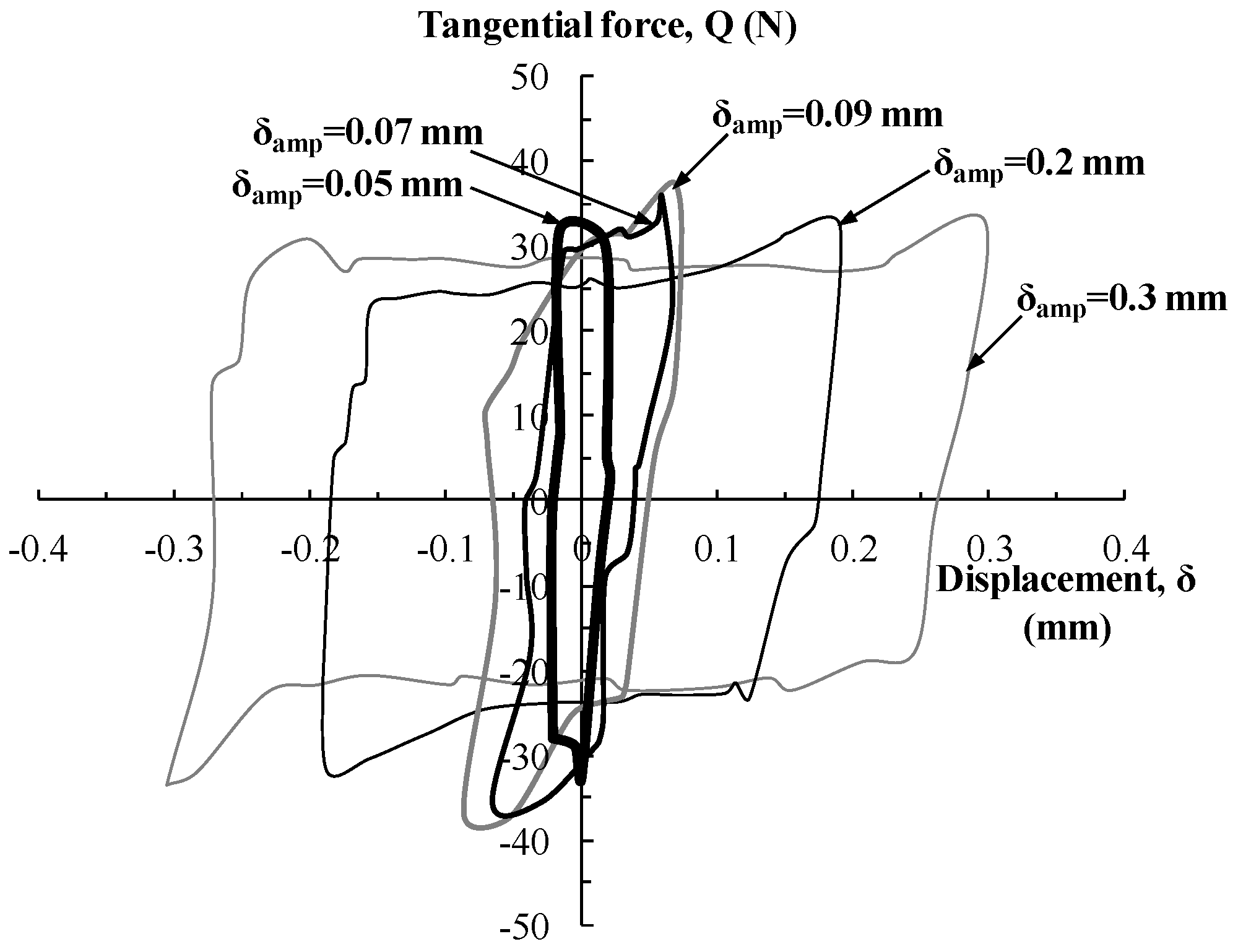

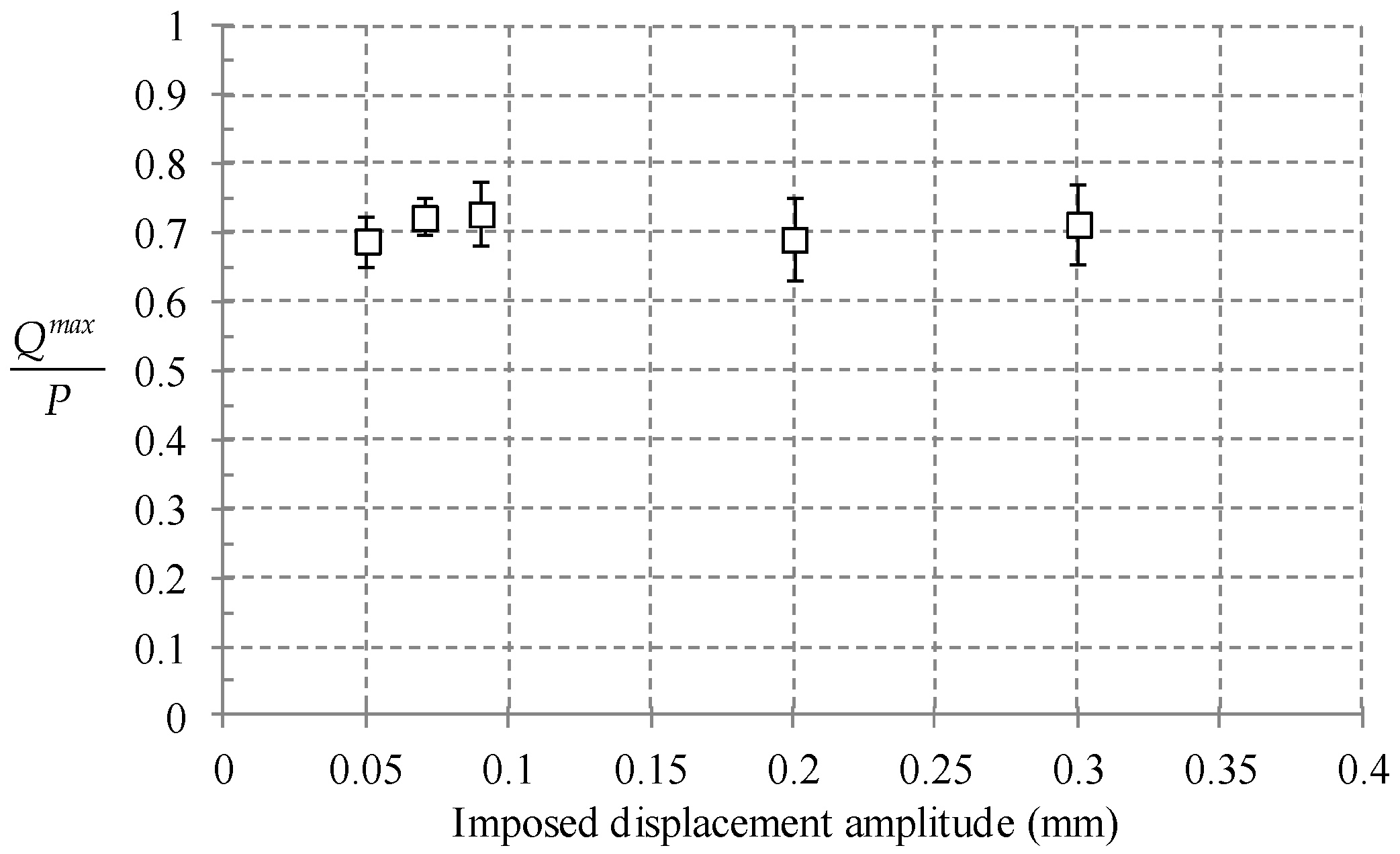

- The ratio of the maximum tangential to normal force was independent of the imposed displacement amplitude (between 0.05 mm and 0.3 mm). The ratio between the cold rolled high strength steel and AISI52100 steel was determined to be about 0.72 in dry conditions.

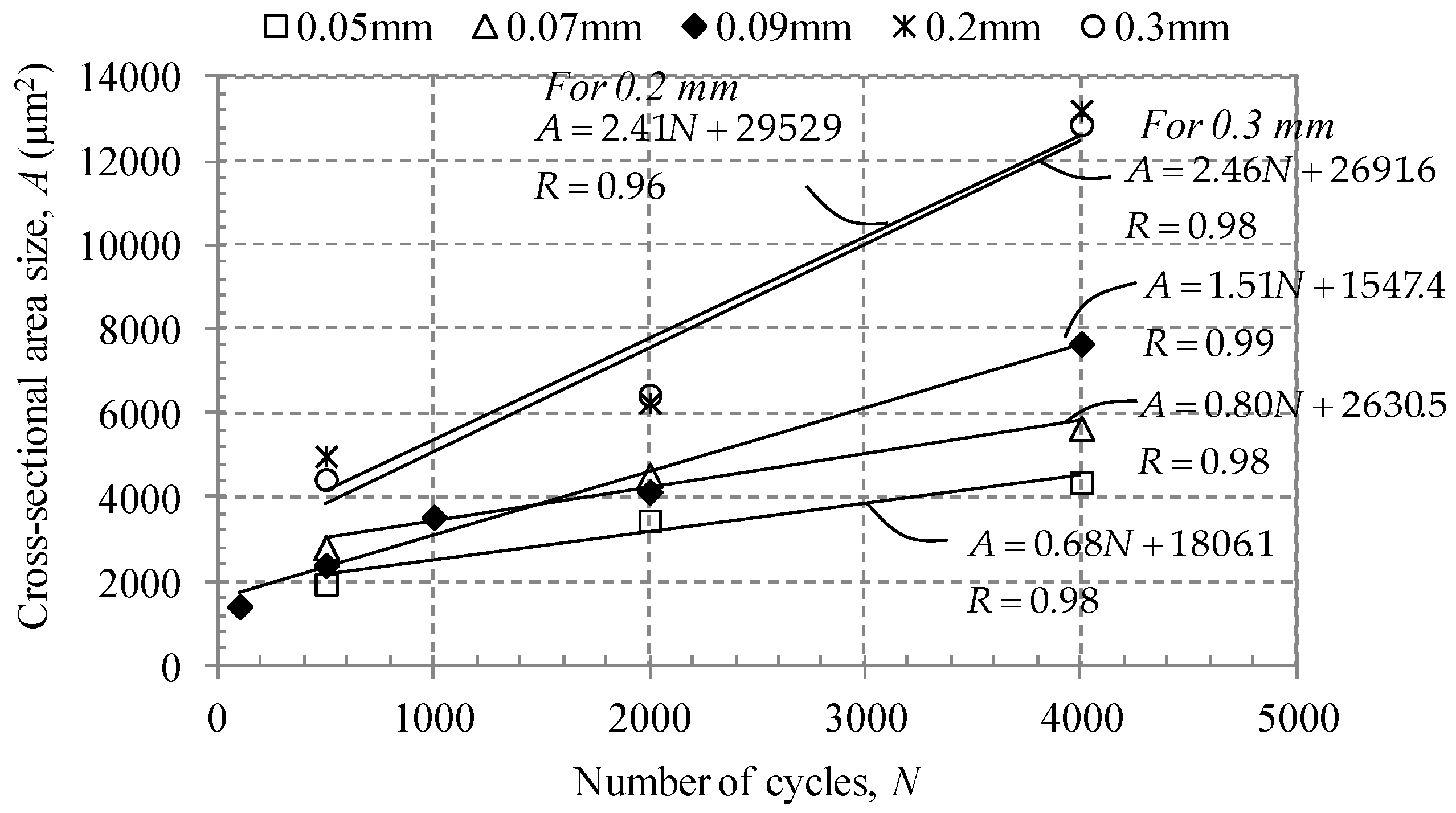

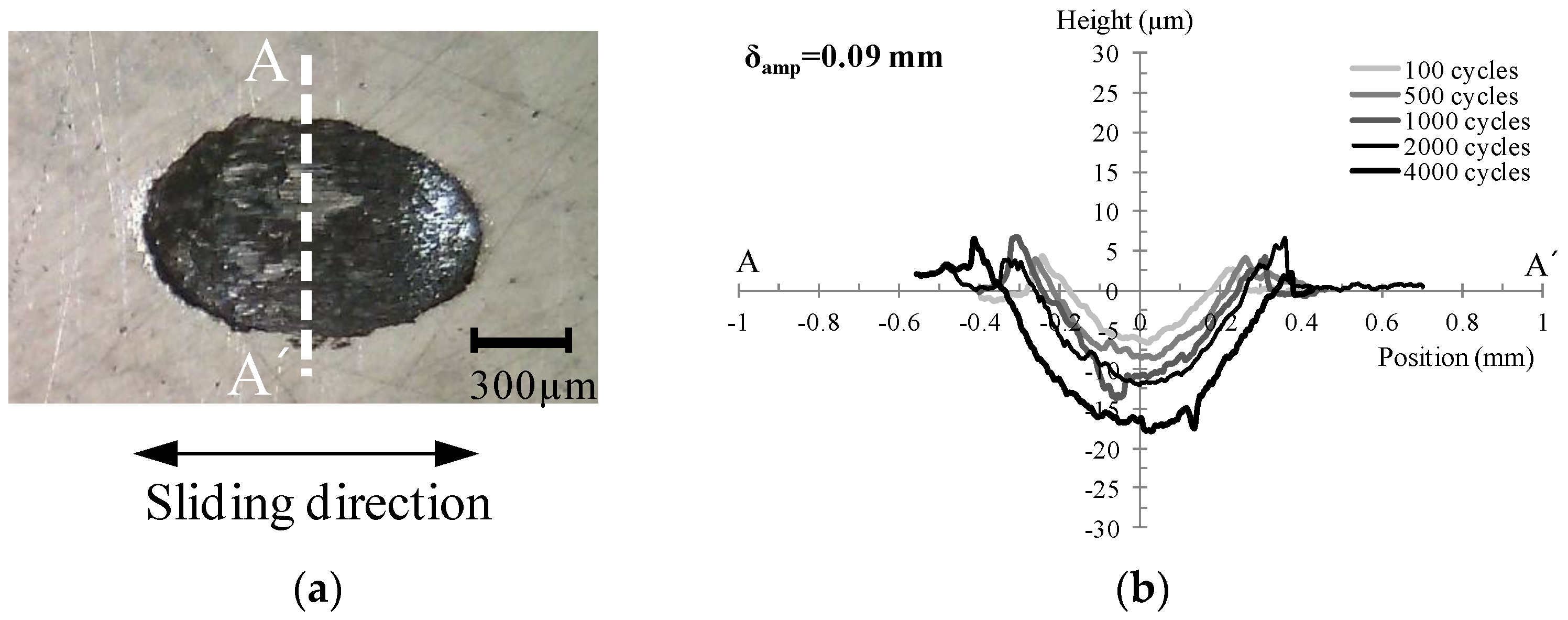

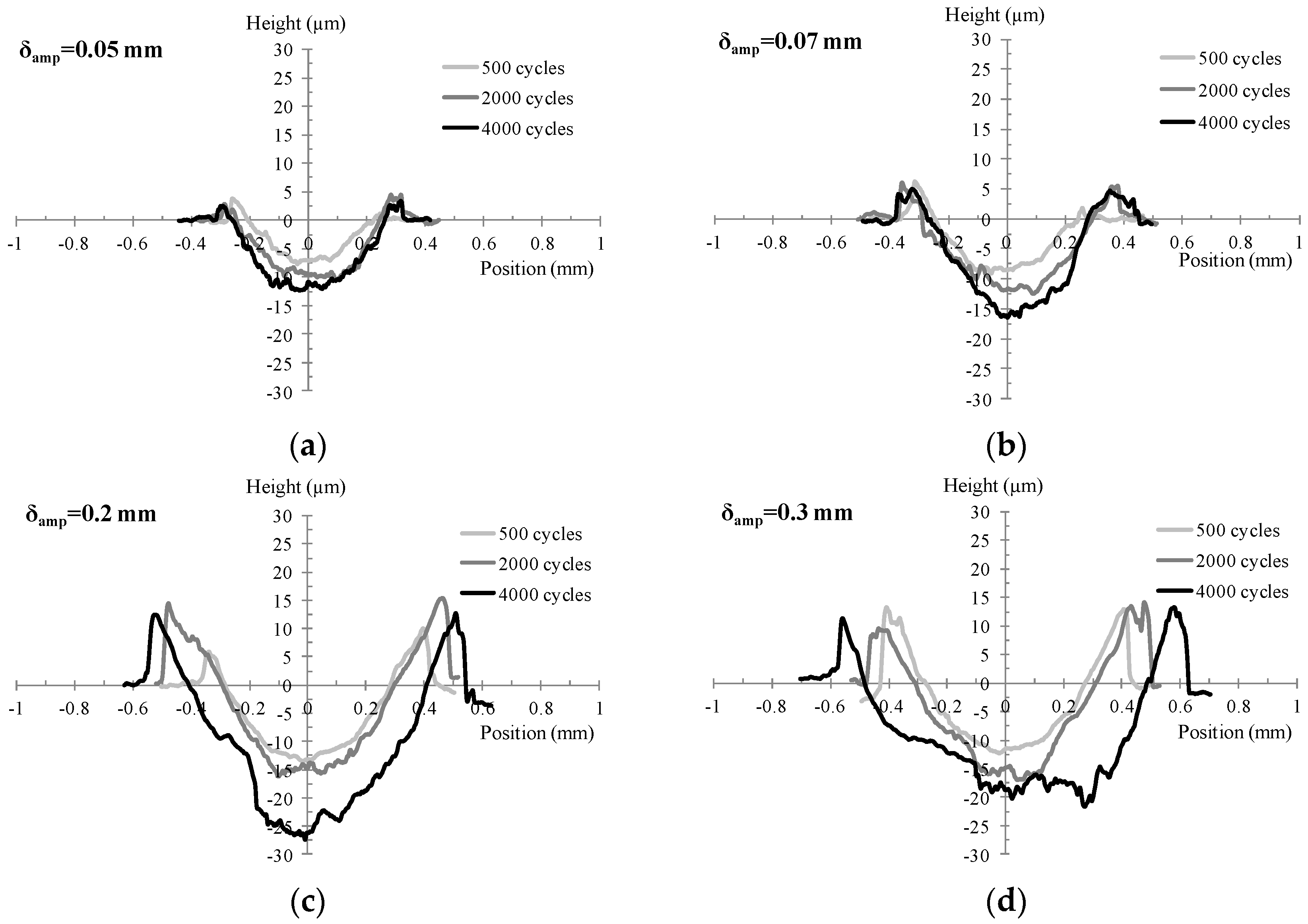

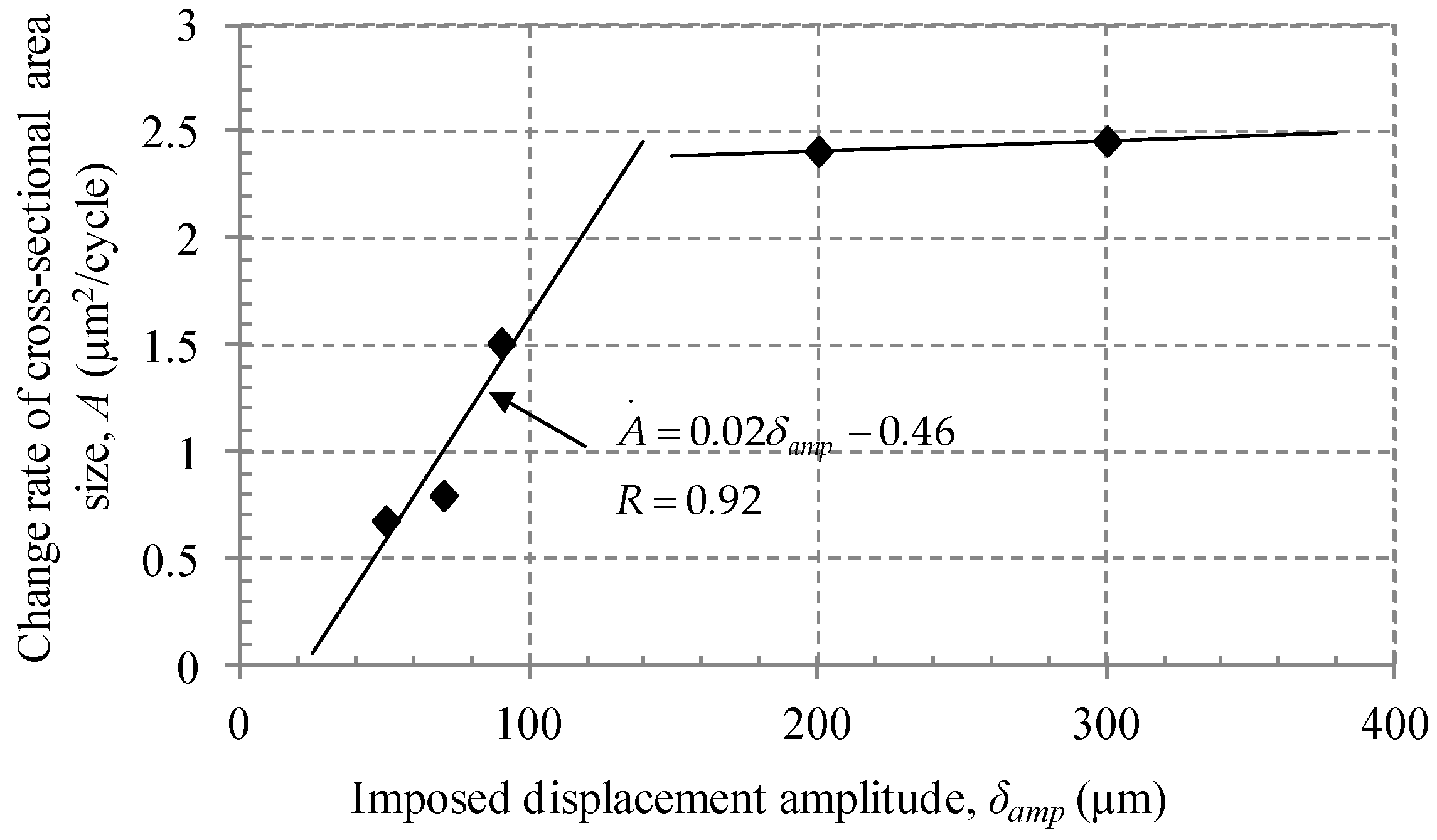

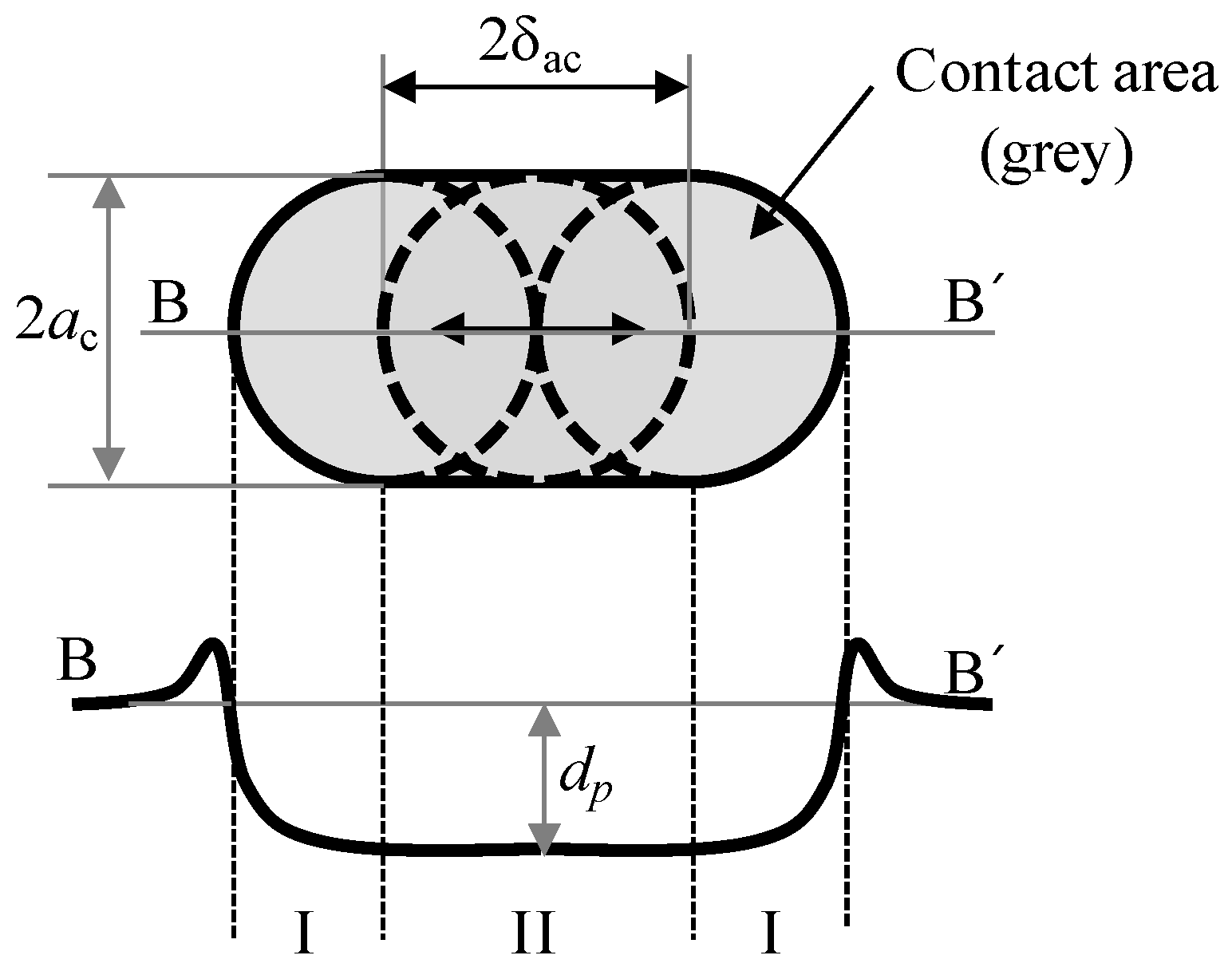

- The cross-sectional area size of the wear scar increased as the number of cycles increased. The growth rate of the cross-sectional area size increased according to imposed displacement amplitude up to 0.09 mm.

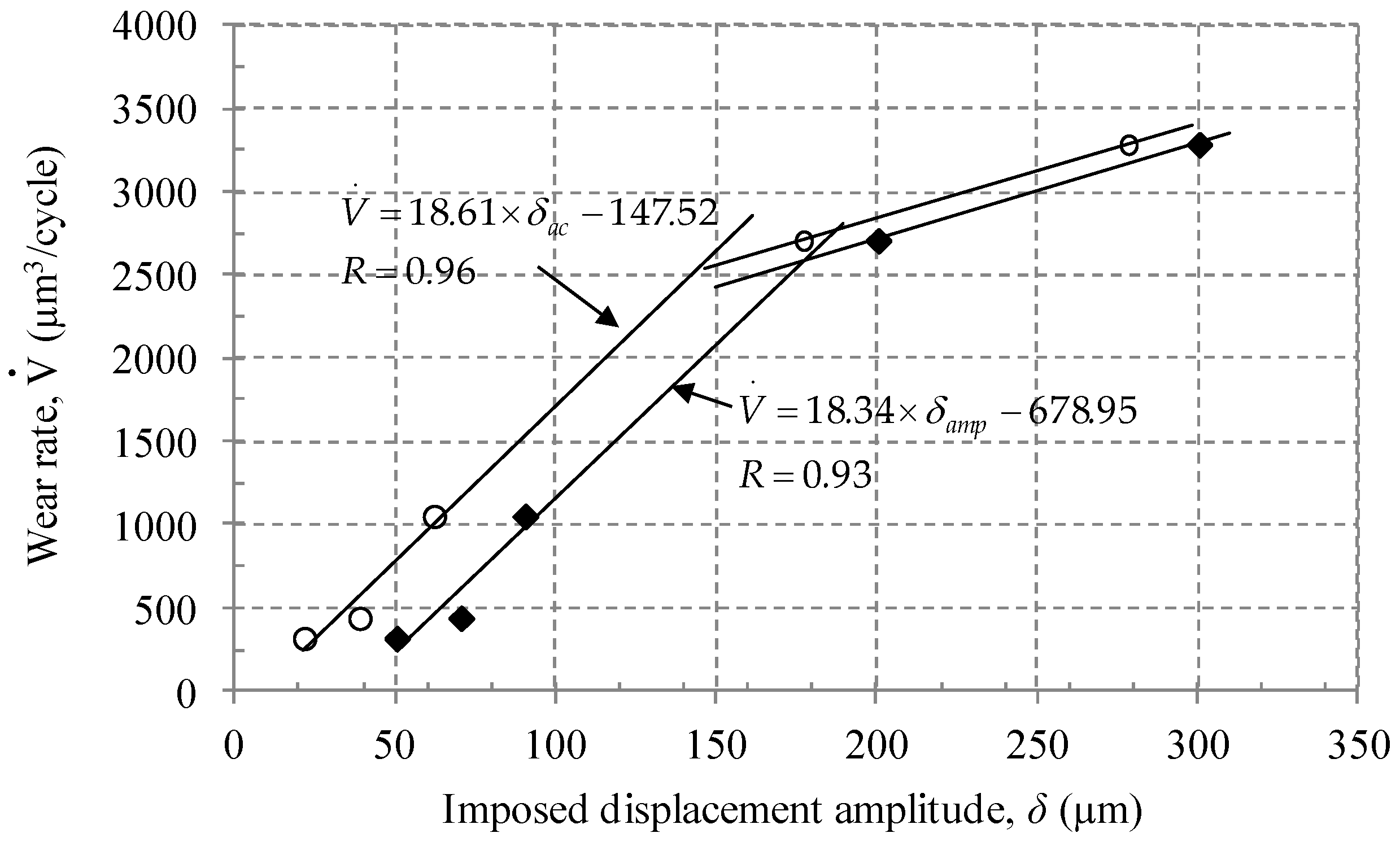

- The approximate wear volume on the cold rolled high strength steel specimen increased according to the number of cycles. A rapid increase in the wear rate occurred at imposed displacement amplitudes lower than 0.09 mm. The increase in the wear rate was found to transition from rapid to gradual between displacement amplitudes of 0.09 mm and 0.2 mm. In other words, the transition from fretting to reciprocal sliding regimes was identified between 0.09 mm and 0.2 mm.

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

Appendix B

References

- Hofmann, H.; Mattissen, D.; Schaumann, T.H. Advanced cold rolled steels for automotive applications. Steel. Res. Int. 2009, 80, 22–28. [Google Scholar] [CrossRef]

- Kuziak, R.; Kawalla, R.; Waengler, S. Advanced high strength steels for automotive industry. Arch. Civ. Mech. Eng. 2008, 8, 103–117. [Google Scholar] [CrossRef]

- Kim, K. A study of the frictional characteristics of metal and ceramic counterfaces against electro-deposited coatings for use on automotive seat rails. Wear 2014, 320, 62–67. [Google Scholar] [CrossRef]

- He, X.; Deng, C.; Zhang, X. Fretting behavior of SPR joining dissimilar sheets of titanium and copper alloys. Metals 2016, 6, 312. [Google Scholar] [CrossRef]

- Lavella, M. Contact properties and wear behavior of nickel based superalloy Rene 80. Metals 2016, 6, 159. [Google Scholar] [CrossRef]

- Waterhouse, R.B. ASM Handbook, Friction, Lubrication and Wear Technology, 1st ed.; ASM International: Materials Park, OH, USA, 1992; Volume 18, pp. 242–256. [Google Scholar]

- Bhushan, B. Introduction to Tribology, 1st ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2002. [Google Scholar]

- Vingsbo, O.; Soderberg, S. On fretting maps. Wear 1988, 126, 131–147. [Google Scholar] [CrossRef]

- Kim, K.; Korsunsky, A.M. Effect of imposed displacement and initial coating thickness on fretting behavior of a thermally sprayed coating. Wear 2011, 271, 1080–1085. [Google Scholar] [CrossRef]

- Hur, J.W.; Baek, S.Y.; Kim, K. Effect of displacement on kinetic frictional behavior between electro-deposited coating and AISI 52100 steel under fretting conditions. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2016, 230, 1172–1179. [Google Scholar] [CrossRef]

- Li, J.; Lu, Y.H. Effects of displacement amplitude on fretting wear behaviors and mechanism of Inconel 600 alloy. Wear 2013, 304, 223–230. [Google Scholar] [CrossRef]

- Landolt, D.; Mischler, S. Tribocorrosion of Passive Metals and Coatings, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 406–407. [Google Scholar]

- Sackfield, A.; Hills, D.A.; Nowell, D. Mechanics of Elastic Contacts, 1st ed.; Butterworth-Heinemann: Oxford, UK, 1993. [Google Scholar]

| Material | C | Mn | P | S | Si | Al | Cr |

|---|---|---|---|---|---|---|---|

| Cold rolled high strength steel | 0.18 | 1.5 | 0.08 | 0.03 | 0.3 | 0.02 | - |

| AISI52100 | 0.95–1.10 | 0.05 | 0.025 | 0.025 | 0.15–0.35 | - | 1.3–1.6 |

| Material | Elastic Modulus, GPa | Poisson’s Ratio | Vickers Hardness, HV |

|---|---|---|---|

| Cold rolled high strength steel | 205 | 0.28 | ~153 1 |

| AISI52100 | ~200 | 0.27–0.3 | 789 |

| Displacement Amplitude (mm) | : wear rate, N: number of cycles, C: constant | ||

|---|---|---|---|

| (µm3/cycle) | C (µm3) | R | |

| 0.05 | 320.05 | 6.08 × 105 | 0.99 |

| 0.07 | 441.07 | 1.19 × 106 | 0.96 |

| 0.09 | 1053.70 | 5.04 × 105 | 0.98 |

| 0.2 | 2711.00 | 1.11 × 106 | 0.95 |

| 0.3 | 3287.20 | 1.03 × 106 | 0.96 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hur, J.; Kim, K. Investigation on Friction and Wear of Cold Rolled High Strength Steel against an AISI52100 Counterpart. Metals 2017, 7, 90. https://doi.org/10.3390/met7030090

Hur J, Kim K. Investigation on Friction and Wear of Cold Rolled High Strength Steel against an AISI52100 Counterpart. Metals. 2017; 7(3):90. https://doi.org/10.3390/met7030090

Chicago/Turabian StyleHur, Jiwon, and Kyungmok Kim. 2017. "Investigation on Friction and Wear of Cold Rolled High Strength Steel against an AISI52100 Counterpart" Metals 7, no. 3: 90. https://doi.org/10.3390/met7030090

APA StyleHur, J., & Kim, K. (2017). Investigation on Friction and Wear of Cold Rolled High Strength Steel against an AISI52100 Counterpart. Metals, 7(3), 90. https://doi.org/10.3390/met7030090