Synthesis and Characterization of Copper-Based Composites Reinforced by CuZrAlNiTi Amorphous Particles with Enhanced Mechanical Properties

Abstract

:1. Introduction

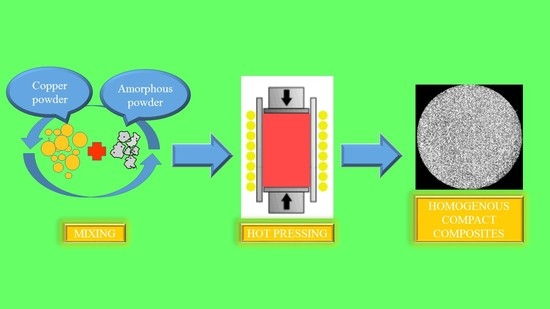

2. Experimental Procedures

3. Results and Discussion

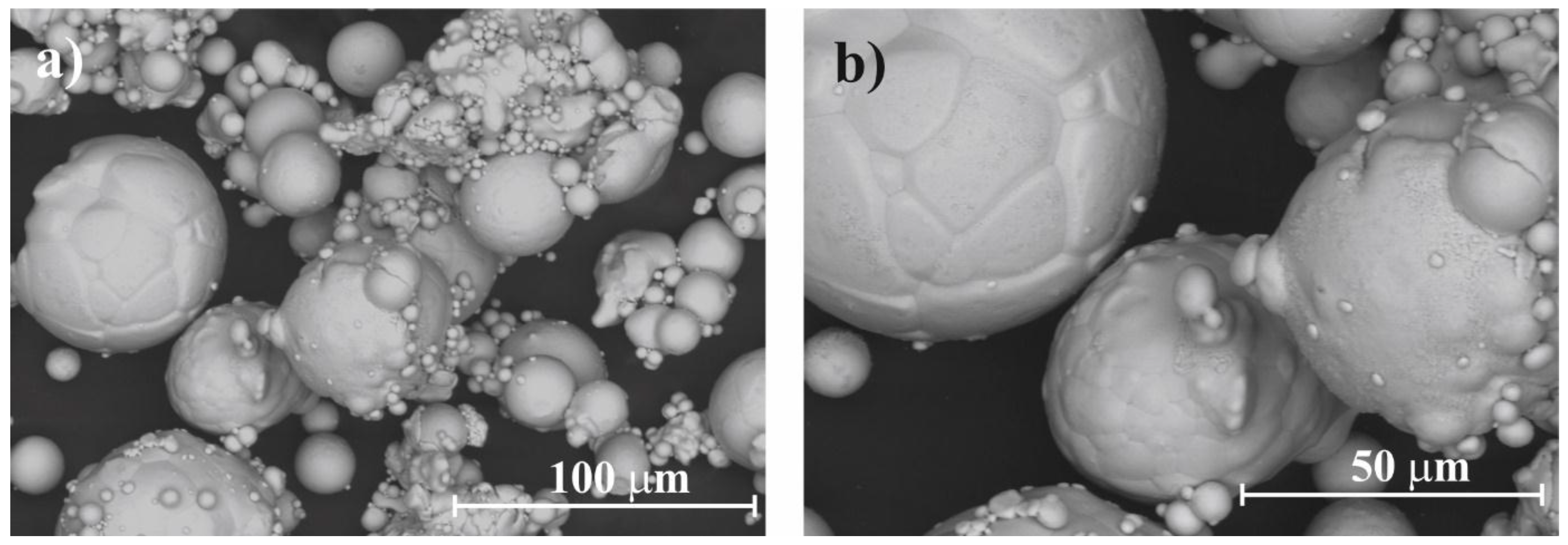

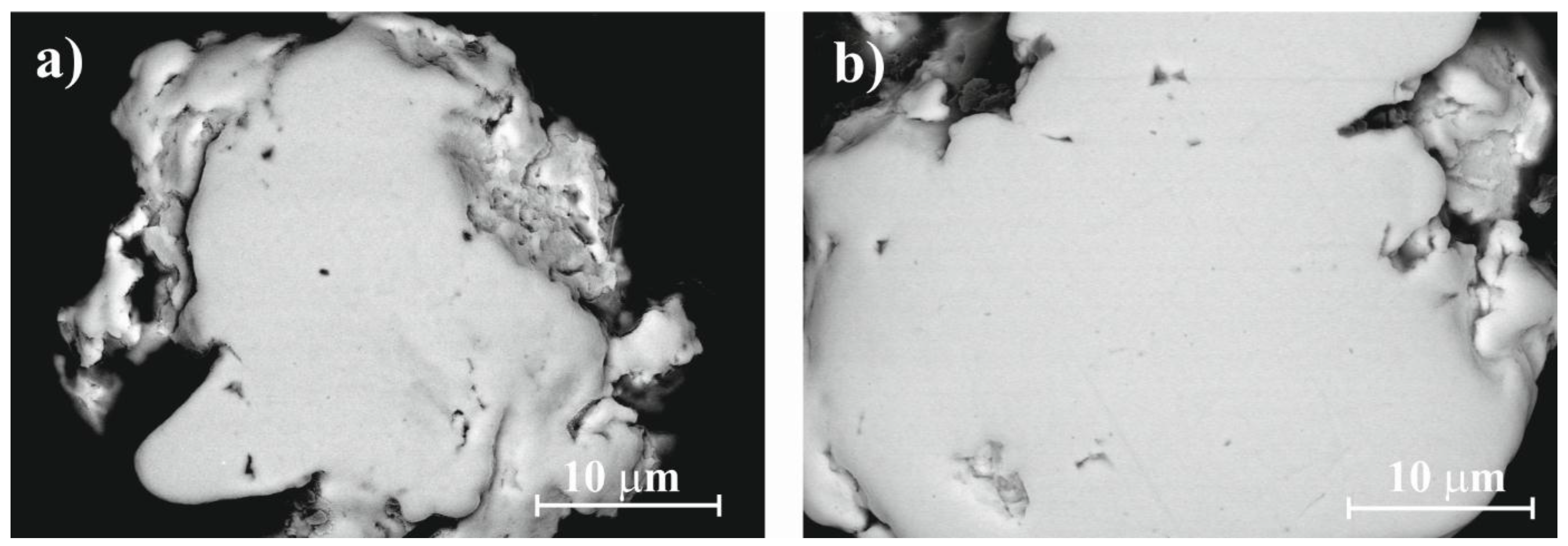

3.1. Analysis of the Initial Powders

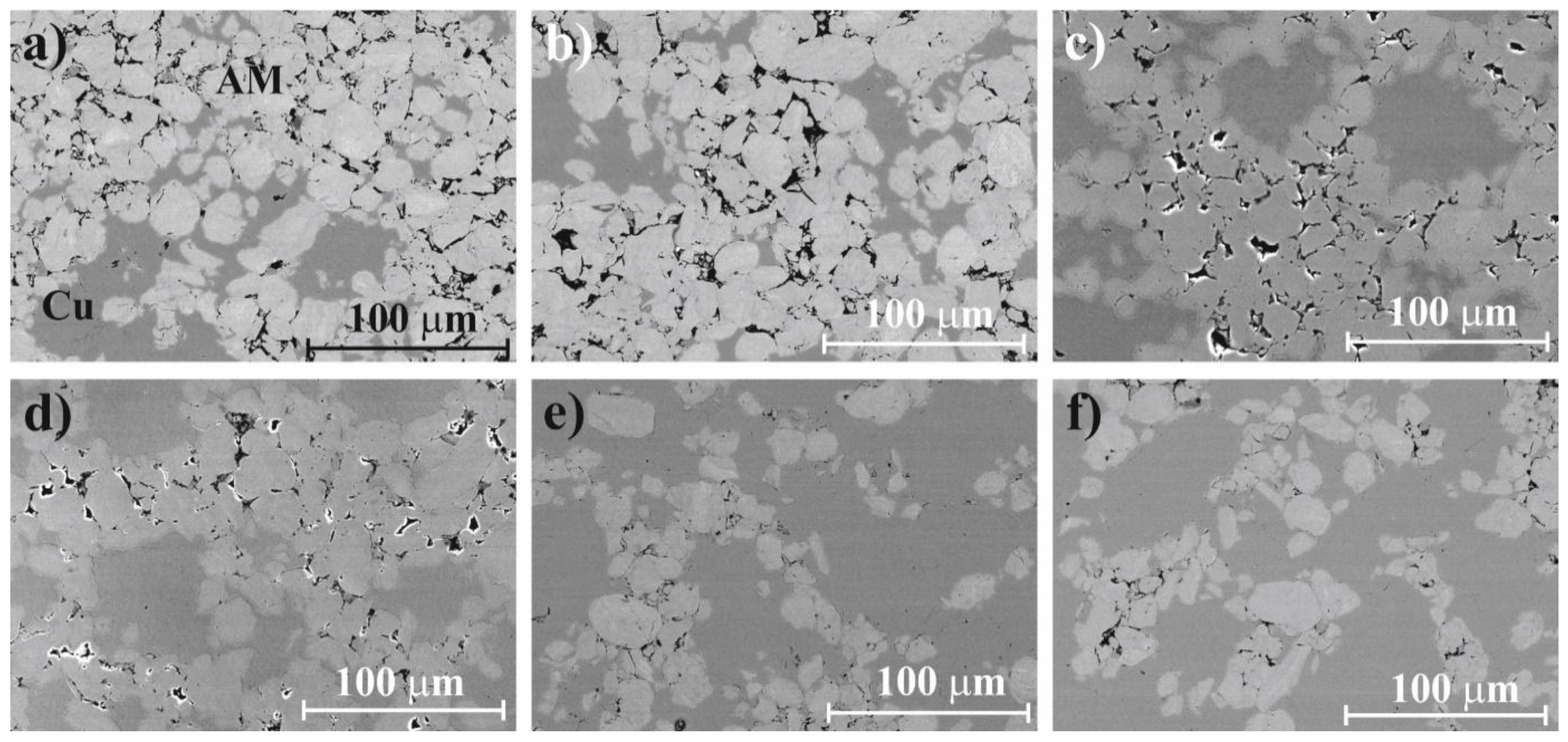

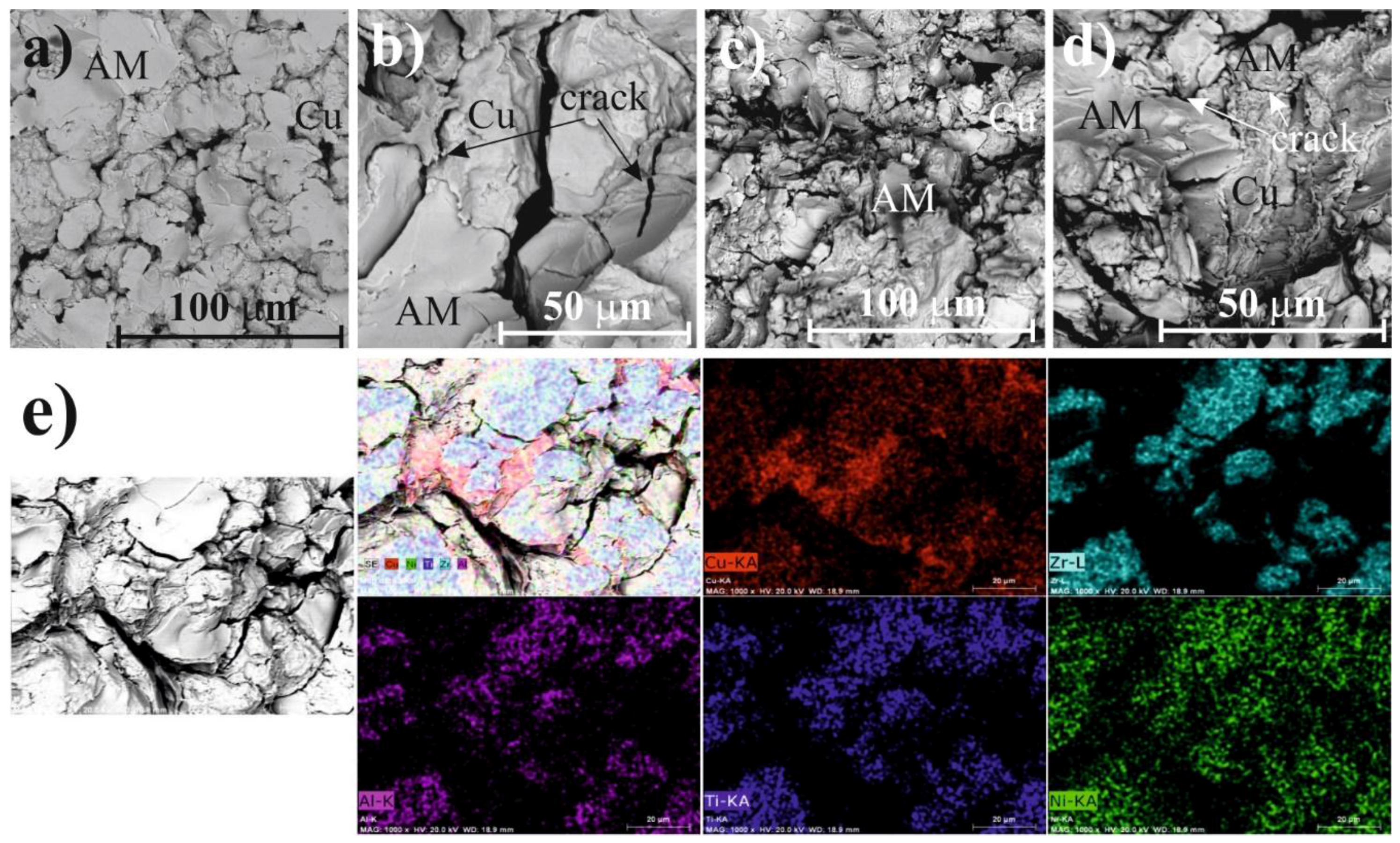

3.2. Effect of the Amorphous-to-Crystalline Ratio on the Microstructure

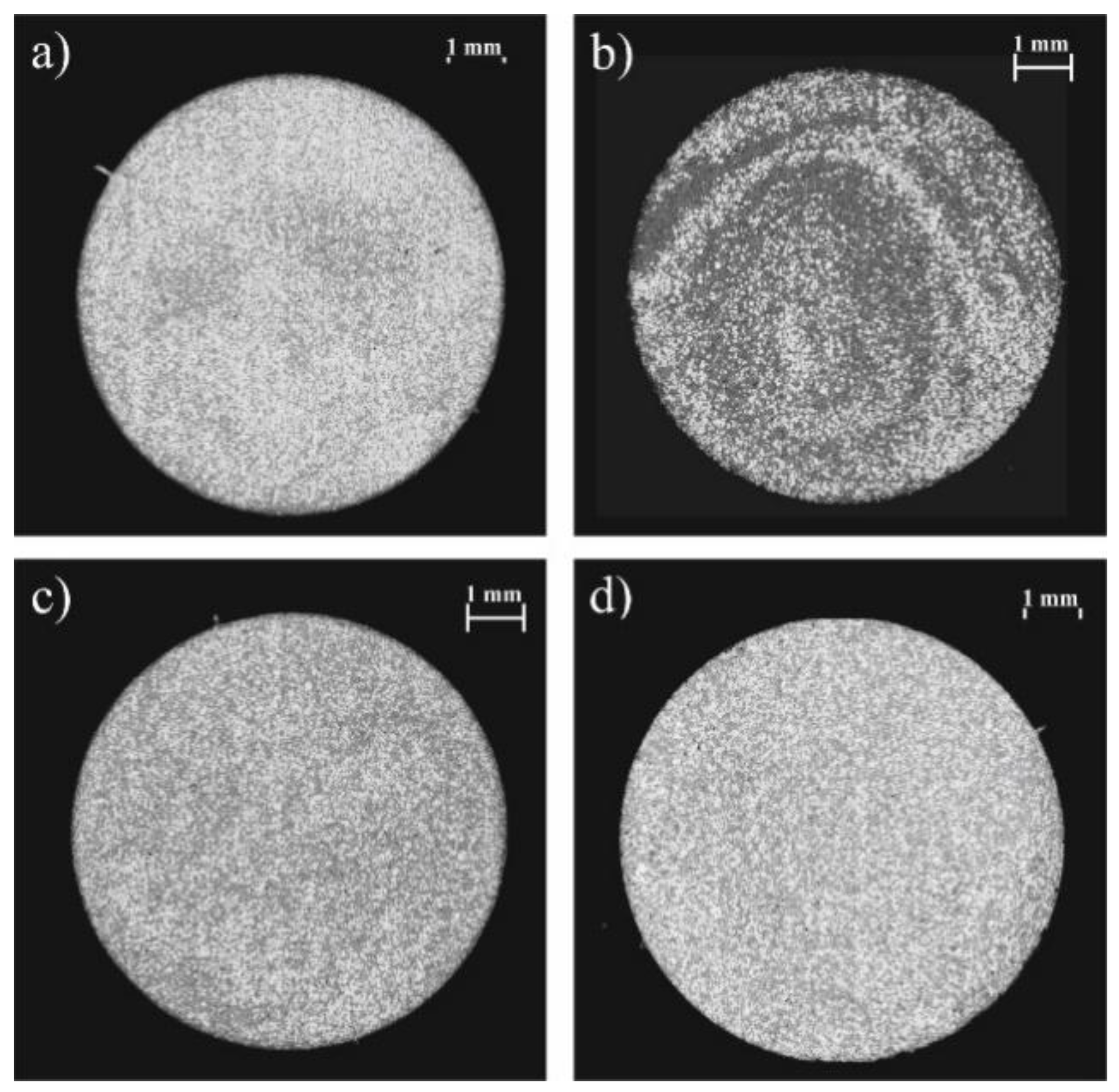

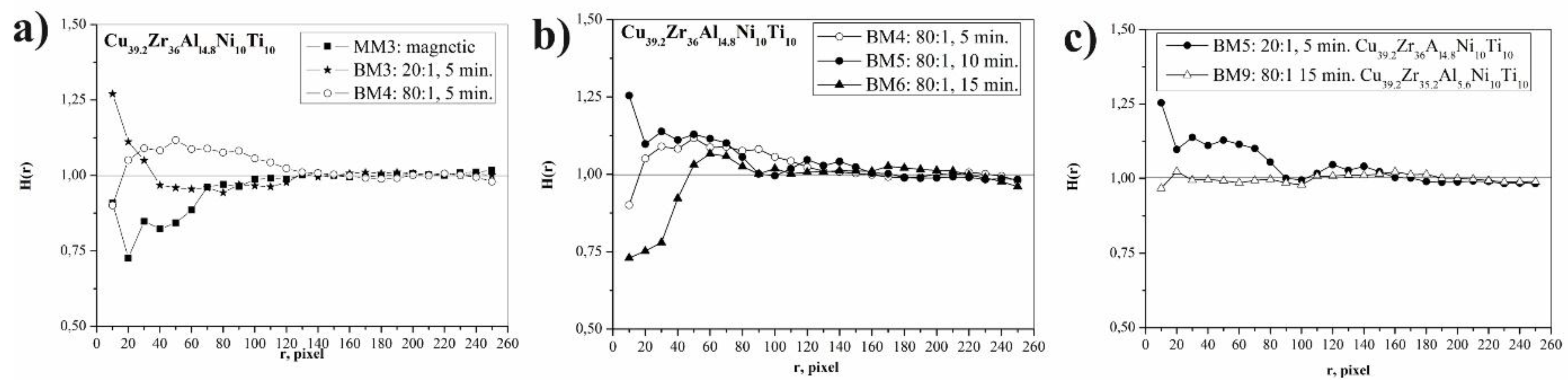

3.3. Effect of Mixing on the Homogeneity

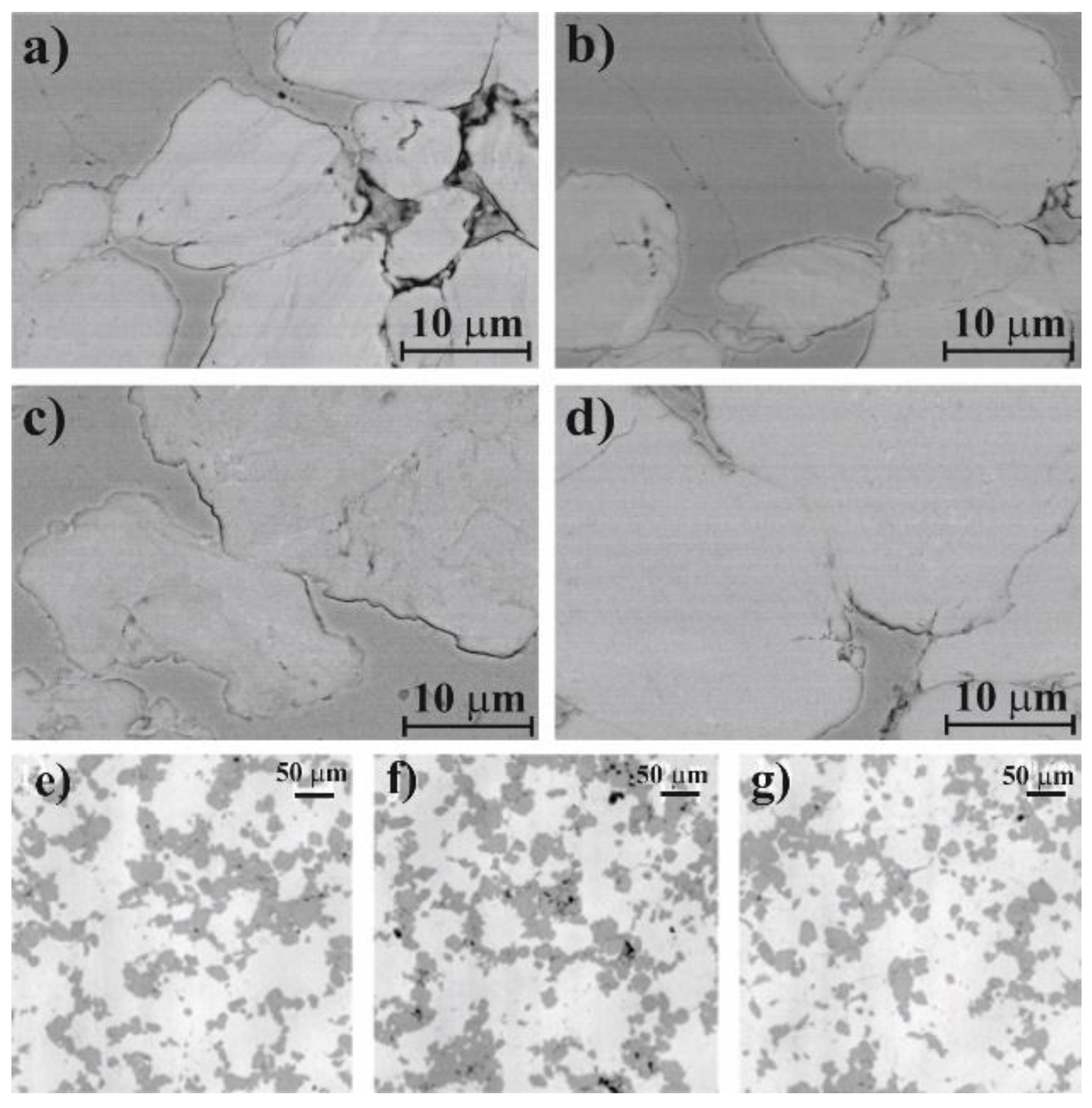

3.4. Microstructure after Consolidation

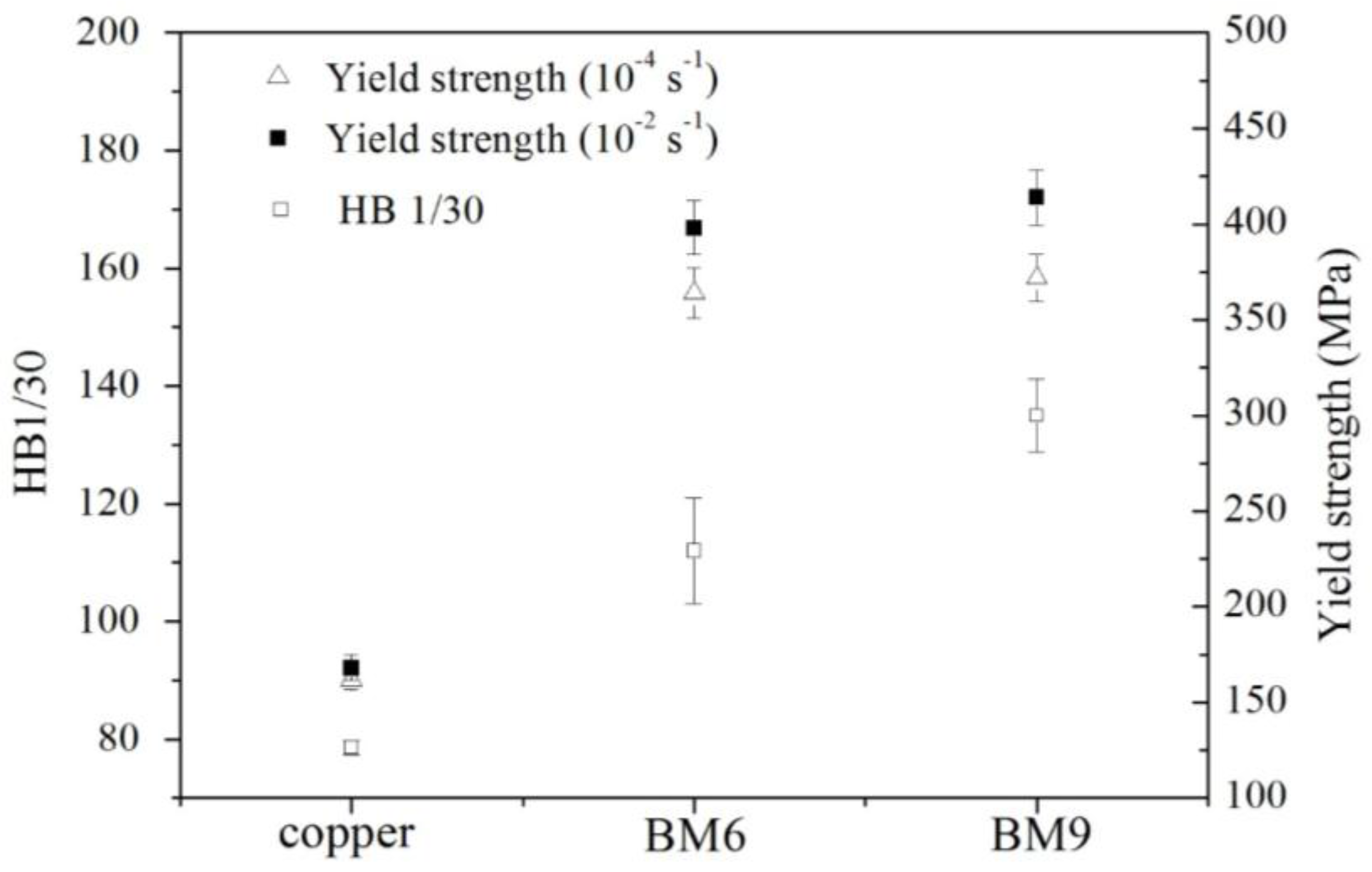

3.5. Mechanical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Marques, P.W.B.; Chaves, J.M.; Silva, P.S.; Florêncio, O.; Moreno-Gobbi, A.; Aliaga, L.C.R.; Botta, W.J. Mechanical spectroscopy study on the Cu54Zr40Al6 amorphous matrix alloy at low temperature. J. Alloys Compd. 2015, 621, 319–323. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Bachaga, T.; Daly, R.; Escoda, L.; Suñol, J.J.; Khitouni, M. Amorphization of Al50(Fe2B)30Nb20 mixture by mechanical alloying. J. Metall. Mater. Trans. A 2013, 44, 4718–4724. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Kumar, S.; Scudino, S.; Murty, B.S.; Eckert, J. Fabrication and Response of Al70Y16Ni10Co4 Glass Reinforced Metal Matrix Composites. Mater. Manuf. Process. 2011, 26, 1242–1247. [Google Scholar] [CrossRef]

- Wang, Z.; Tan, J.; Sun, B.A.; Scudino, S.; Prashanth, K.G.; Zhang, W.W.; Li, Y.Y.; Eckert, J. Fabrication and mechanical properties of Al-based metal matrix composites reinforced with Mg65Cu20Zn5Y10 metallic glass particles. Mater. Sci. Eng. A 2014, 600, 53–58. [Google Scholar] [CrossRef]

- Dastgerdi, J.N.; Marquis, G.; Anbarlooie, B.; Sankaranarayanan, S.; Gupta, M. Microstructure-sensitive investigation on the plastic deformation and damage initiation of amorphous particles reinforced composites. Compos. Struct. 2016, 142, 130–139. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Sahu, S.; Sankaranarayanan, S.; Gupta, S.; Gupta, M. Development of novel Mg–Ni60Nb40 amorphous particle reinforced compo sites with enhanced hardness and compressive response. Mater. Des. 2014, 53, 849–855. [Google Scholar]

- Sankaranarayanan, S.; Shankar, V.H.; Jayalakshmi, S.; Bau, N.Q.; Gupta, M. Development of high performance magnesium composites using Ni50Ti50 metallic glass reinforcement and microwave sintering approach. J. Alloys Compd. 2015, 627, 192–199. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Aljerf, M.; Li, Y.; Braccini, M.; Yavari, A.R.; Inoue, A. Cu-based metallic glass particle additions to significantly improve overall compressive properties of an Al alloy. Compos. Part A 2010, 41, 1551–1557. [Google Scholar] [CrossRef]

- Zheng, R.; Yang, H.; Liu, T.; Ameyama, K.; Ma, C. Microstructure and mechanical properties of aluminum alloy matrix composites reinforced with Fe-based metallic glass particles. Mater. Des. 2014, 53, 512–518. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, H.Y.; Wang, Y.X.; Wang, Q.D.; Ye, B.; Ding, W.J. Microstructure and mechanical properties of hypoeutectic Al-Si composite reinforced with TiCN nanoparticles. Mater. Des. 2016, 95, 545–554. [Google Scholar] [CrossRef]

- Zhou, D.; Zeng, W.; Zhang, D. A feasible ultrafine grained Cu matrix composite microstructure for achieving high strength and high electrical conductivity. J. Alloys Compd. 2016, 682, 590–593. [Google Scholar] [CrossRef]

- Ziemnicka-Sylwester, M. The Cu matrix cermets remarkably strengthened by TiB2 “in situ” synthesized via self-propagating high temperature synthesis. Mater. Des. 2014, 53, 758–765. [Google Scholar] [CrossRef]

- Wang, F.; Li, Y.; Yamanaka, K.; Wakon, K.; Harata, K.; Chiba, A. Influence of two-step ball-milling condition on electrical and mechanical properties of TiC-dispersion-strengthened Cu alloys. Mater. Des. 2014, 64, 441–449. [Google Scholar] [CrossRef]

- Wang, F.; Li, Y.; Wang, X.; Koizumi, Y.; Kenta, Y.; Chiba, A. In-situ fabrication and characterization of ultrafine structured Cu-TiC composites with high strength and high conductivity by mechanical milling. J. Alloys Compd. 2016, 657, 122–132. [Google Scholar] [CrossRef]

- Wensley, C.A. Processing and Properties of Amorphous NiW Reinforced Crystalline Ni Matrix Composites. Master’s Thesis, Virginia Tech, Blacksburg, VA, USA, 2005. [Google Scholar]

- Thakur, S.K.; Paramsothy, M.; Gupta, M. Improving tensile and compressive strengths of magnesium by blending it with aluminium. Mater. Sci. Technol. 2010, 26, 115–120. [Google Scholar] [CrossRef]

- Carvalho, O.; Buciumeanu, M.; Soares, D.; Silva, F.S.; Miranda, G. Evaluation of CNT Dispersion Methodology Effect on Mechanical Properties of an AlSi Composite. J. Mater. Eng. Perf. 2015, 24, 2535–2545. [Google Scholar] [CrossRef]

- Öksüz, K.E.; Şimşir, M.; Şahin, Y. Characterization of Diamond Impregnated B4C/Fe-Co MMC. In Proceedings of the Euro International Powder Metallurgy Congress and Exhibition, Euro PM 2011, Barcelona, Spain, 9–12 October 2011.

- Karabulut, S.; Gökmen, U.; Çinici, H. Study on the mechanical and drilling properties of AA7039 composites reinforced with Al2O3/B4C/SiC particles. Compos. Part B Eng. 2016, 93, 43–55. [Google Scholar] [CrossRef]

- Tomolya, K.; Janovszky, D.; Sycheva, A.; Sveda, M.; Ferenczi, T.; Roosz, A. Peculiarities of ball-milling induced crystalline amorphous transformation in Cu-Zr-Al-Ni-Ti alloys. Intermetallics 2015, 65, 117–121. [Google Scholar] [CrossRef] [Green Version]

- Qiu, W.T.; Pang, Y.; Xiao, Z.; Li, Z. Preparation of W-Cu alloy with high density and ultrafine grains by mechanical alloying and high pressure sintering. Int. J. Refract. Met. Hard Mater. 2016, 61, 91–97. [Google Scholar] [CrossRef]

- Gácsi, Z.; Kovács, J.; Pieczonka, T. Characterisation of particle arrangement using the radial distribution function. In Proceedings of the 3rd International Powder Metallurgy Conference, Ankara, Turkey, 4–8 September 2002; pp. 542–551.

- Wang, Z.; Georgarakis, K.; Nakayama, K.S.; Li, Y.; Tsarkov, A.A.; Xie, G.; Dudinał, D.; Louzguine-Luzgin, D.V.; Yavari, A.R. Microstructure and mechanical behavior of metallic glass fiber reinforced Al alloy matrix composites. Sci. Rep. 2016, 6, 24384. [Google Scholar] [CrossRef] [PubMed]

- Kolednik, O.; Unterweger, K. The ductility of metal matrix composites—Relation to local deformation behavior and damage evolution. Eng. Fract. Mech. 2008, 75, 3663–3676. [Google Scholar] [CrossRef]

| Samples | Composition of Amorphous Powder (at %) | Mixing Techniques | Copper Powder (wt %) | Parameters of Mixing |

|---|---|---|---|---|

| MM1 | Cu39.2Zr36Al4.8Ni10Ti10 | Magnetic | 30 | 1000 rpm |

| MM2 | Magnetic | 40 | 1000 rpm | |

| MM3 | Magnetic | 50 | 1000 rpm | |

| UM1 | Ultrasonic | 30 | 10 kHz | |

| UM2 | Ultrasonic | 40 | 10 kHz | |

| BM1 | Ball-milling | 30 | 20:1, 5 min | |

| BM2 | Ball-milling | 40 | 20:1, 5 min | |

| BM3 | Ball-milling | 50 | 20:1, 5 min | |

| BM4 | Ball-milling | 50 | 80:1, 5 min | |

| BM5 | Ball-milling | 50 | 80:1, 10 min | |

| BM6 | Ball-milling | 50 | 80:1, 15 min | |

| BM7 | Cu39.2Zr35.2Al5.6Ni10Ti10 | Ball-milling | 30 | 80:1, 15 min |

| BM8 | Ball-milling | 40 | 80:1, 15 min | |

| BM9 | Ball-milling | 50 | 80:1, 15 min |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomolya, K.; Sycheva, A.; Sveda, M.; Arki, P.; Miko, T.; Roosz, A.; Janovszky, D. Synthesis and Characterization of Copper-Based Composites Reinforced by CuZrAlNiTi Amorphous Particles with Enhanced Mechanical Properties. Metals 2017, 7, 92. https://doi.org/10.3390/met7030092

Tomolya K, Sycheva A, Sveda M, Arki P, Miko T, Roosz A, Janovszky D. Synthesis and Characterization of Copper-Based Composites Reinforced by CuZrAlNiTi Amorphous Particles with Enhanced Mechanical Properties. Metals. 2017; 7(3):92. https://doi.org/10.3390/met7030092

Chicago/Turabian StyleTomolya, Kinga, Anna Sycheva, Maria Sveda, Peter Arki, Tamas Miko, Andras Roosz, and Dora Janovszky. 2017. "Synthesis and Characterization of Copper-Based Composites Reinforced by CuZrAlNiTi Amorphous Particles with Enhanced Mechanical Properties" Metals 7, no. 3: 92. https://doi.org/10.3390/met7030092