Temperature and Particle Size Influence on the High Cycle Fatigue Behavior of the SiC Reinforced 2124 Aluminum Alloy

Abstract

:1. Introduction

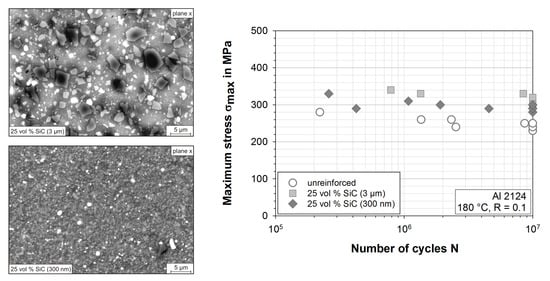

2. Materials and Methods

2.1. Material

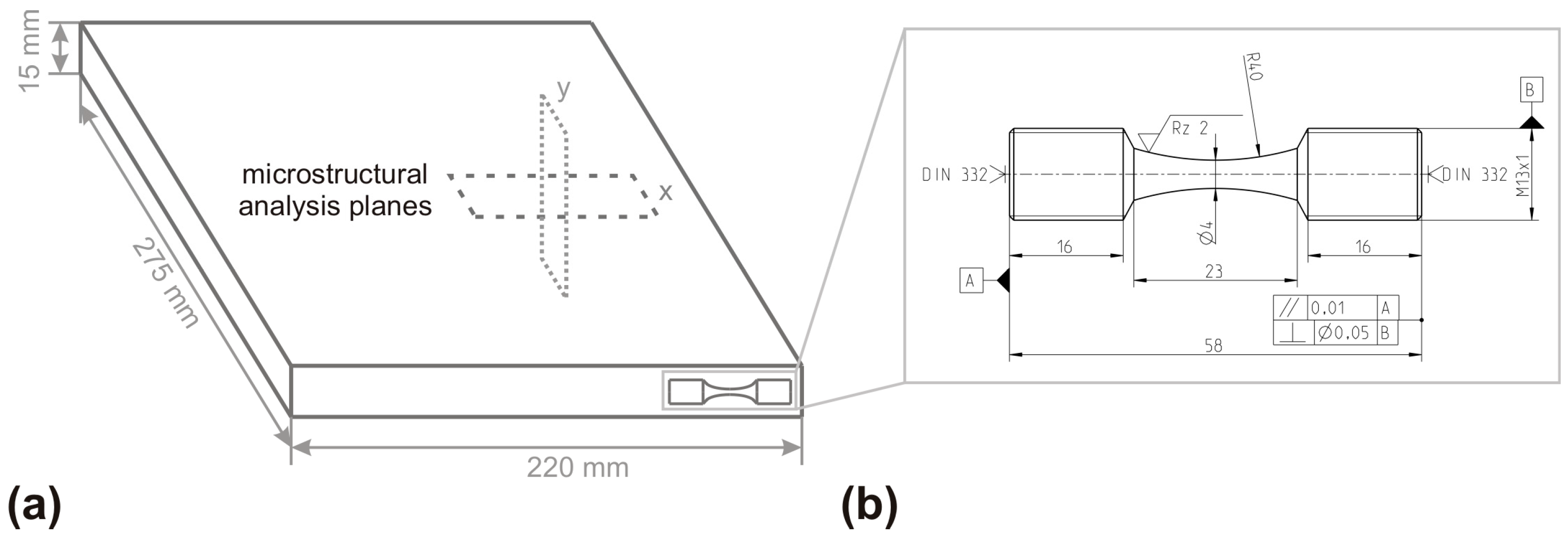

2.2. Methods of Mechanical Testing and Electron Microscopy

3. Results and Discussion

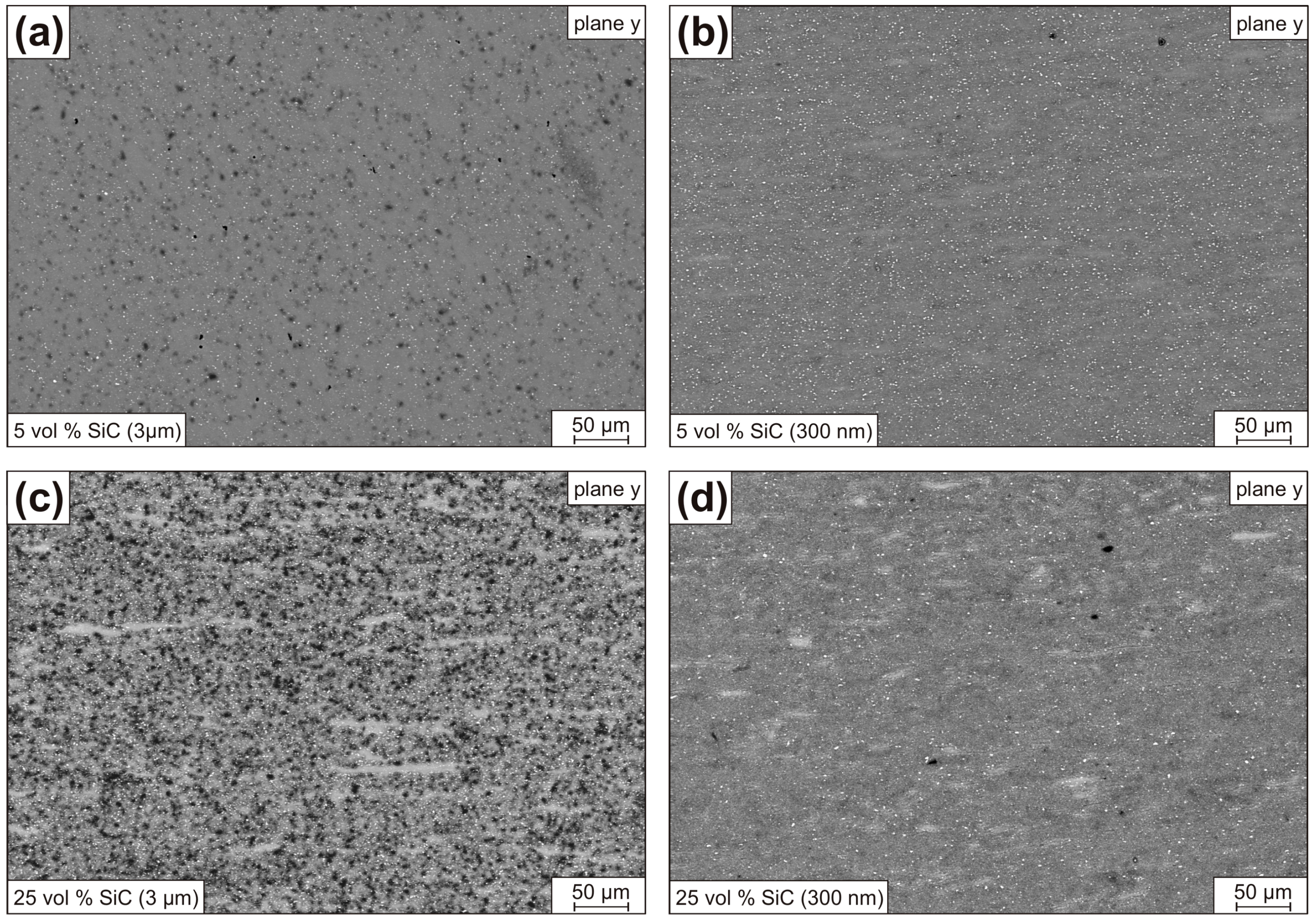

3.1. Microstructure

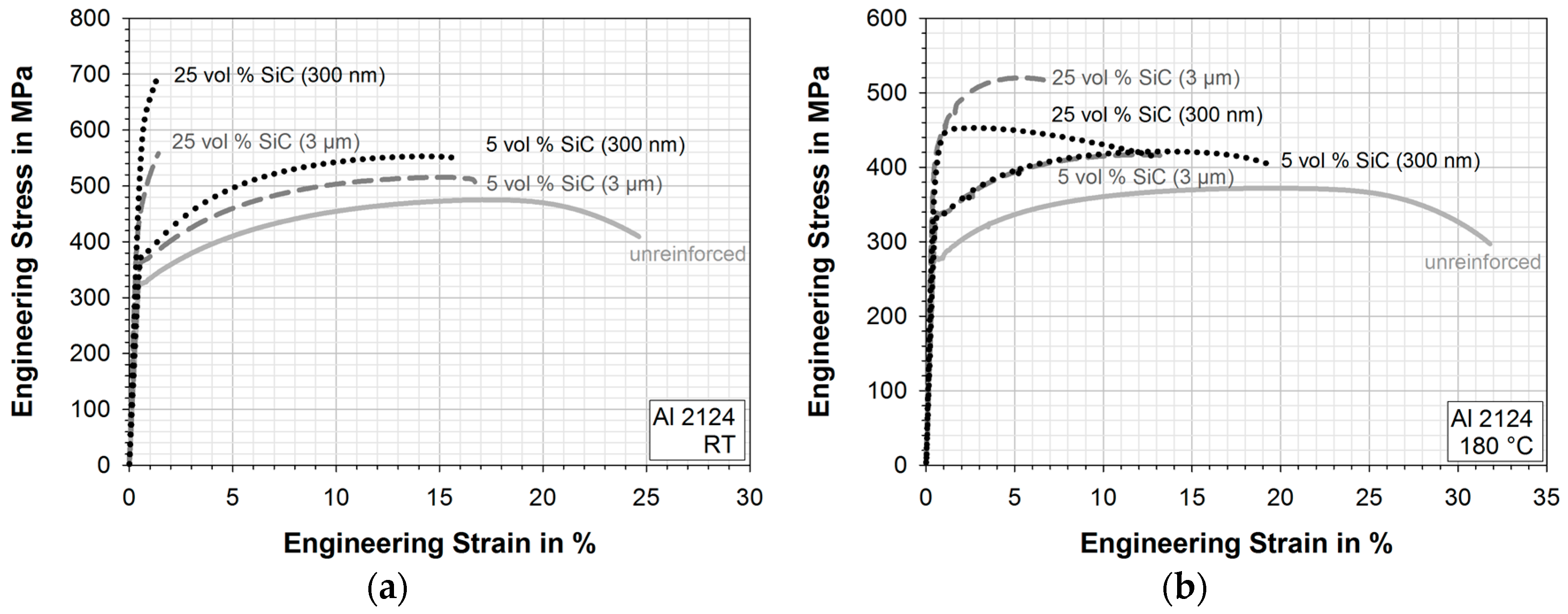

3.2. Tensile Testing

3.3. High Cycle Fatigue Behavior

4. Conclusions

- Generally, the tensile and the fatigue strength of the unreinforced and the reinforced material decrease with an increase in temperature. This is attributed to the increasing influence of the lower matrix strength, regardless of the particle volume fraction and the particle size.

- Particulate reinforcement leads to an increase in tensile strength and a loss in ductility. A high particle volume fraction enhances this effect. At room temperature, a decrease in particle size leads to a further increase in tensile strength, whereas at 180 °C, the tensile strength is not affected by a decreased particle size, nevertheless, the ductility increases.

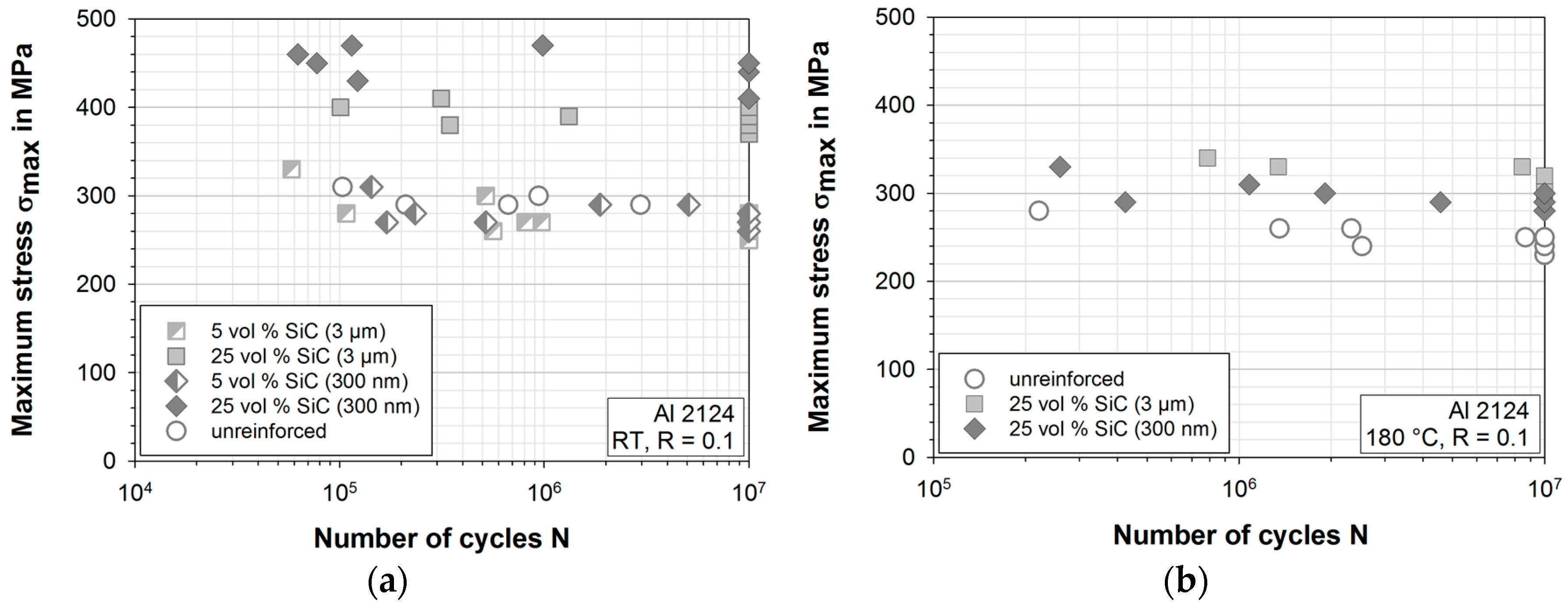

- The room temperature fatigue strength of the reinforced conditions with 5 vol % SiC in 3 μm and 300 nm size was minor in comparison to the unreinforced alloy. Supposedly the local stress concentrations induced by the reinforcement component lead to an early formation of initial cracks.

- The beneficial effect of an increased particle volume fraction and a decreased particle size on the fatigue strength could be confirmed for room temperature. The condition with 25 vol % particle fraction and 300 nm size exhibited the highest fatigue strength. Whereas, at 180 °C, reinforcement with 25 vol % SiC particles leads also to a significant increase in fatigue strength when compared to the unreinforced alloy, but the percentage increase was minor for the 300 nm particles if compared to the 3 μm particles.

- The combination of 25 vol % SiC particle fraction with 3 μm size proved to be most suitable for a major fatigue performance at room temperature and at 180 °C. It is assumed, that the interparticle spacing for this combination of particle size and fraction is large enough to impede dislocation movement and still small enough to limit void formation. Therefore, the fatigue strength was improved by 40% in comparison to the unreinforced alloy at both testing temperatures.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Doel, T.J.A.; Bowen, P. Tensile properties of particulate-reinforced metal matrix composites. Compos. Part A Appl. Sci. Manuf. 1996, 27, 655–665. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Cocomazzi, R.; Troiani, E. Room and high temperature tensile tests on the AA6061/10vol.%Al2O3p and AA7005/20vol.%Al2O3p composites. Mater. Sci. Eng. Technol. 2003, 34, 370–374. [Google Scholar] [CrossRef]

- Ceschini, L.; Minak, G.; Morri, A. Tensile and fatigue properties of the AA6061/20vol.% Al2O3p and AA7005/10vol.% Al2O3p composites. Compos. Sci. Technol. 2006, 66, 333–342. [Google Scholar] [CrossRef]

- Hall, J.N.; Jones, J.W.; Sachdev, A.K. Particle size, volume fraction and matrix strength effects on fatigue behavior and particle fracture in 2124 aluminum-SiCp composites. Mater. Sci. Eng. A 1994, 183, 69–80. [Google Scholar] [CrossRef]

- Chawla, N.; Andres, C.; Jones, J.W.; Allison, J.E. Effect of SiC volume fraction and particle size on the fatigue resistance of a 2080 Al/SiC composite. Metall. Mater. Trans. A 1998, 29, 2843–2854. [Google Scholar] [CrossRef]

- Chawla, N.; Allison, J.E. Fatigue of Particle Reinforced Materials. In Encyclopedia of Materials: Science and Technology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 2967–2971. [Google Scholar]

- Llorca, J. Fatigue of particle-and whisker-reinforced metal-matrix composites. Prog. Mater. Sci. 2002, 47, 283–353. [Google Scholar] [CrossRef]

- Furukawa, M.; Wang, J.; Horita, Z.; Nemoto, M.; Ma, Y.; Langdon, T.G. An investigation of strain hardening and creep in an Al-6061/Al2O3 metal matrix composite. Metall. Mater. Trans. A 1995, 26, 633–639. [Google Scholar] [CrossRef]

- Li, Y.; Langdon, T.G. Creep behavior of an Al-6061 metal matrix composite reinforced with alumina particulates. Acta Mater. 1997, 45, 4797–4806. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. The high-temperature creep behaviour of aluminium-matrix composites reinforced with SiC, Al2O3 and TiB2 particles. Compos. Sci. Technol. 1997, 57, 697–702. [Google Scholar] [CrossRef]

- Park, B.G.; Crosky, A.G.; Hellier, A.K. High cycle fatigue behaviour of microsphere Al2O3–Al particulate metal matrix composites. Compos. Part B Eng. 2008, 39, 1257–1269. [Google Scholar] [CrossRef]

- Chawla, N.; Habel, U.; Shen, Y.-L.; Andres, C.; Jones, J.W.; Allison, J.E. The Effect of Matrix Microstructure on the Tensile and Fatigue Behavior of SiC Particle-Reinforced 2080 AI Matrix Composites. Metall. Mater. Trans. A 2000, 31, 531–540. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Mattingly, J. Influence of heat treatment on the tensile properties and fracture behaviour of an aluminium alloy-ceramic particle composite. J. Mater. Sci. 1993, 28, 611–620. [Google Scholar] [CrossRef]

- Romanova, V.A.; Balokhonov, R.R.; Schmauder, S. The influence of the reinforcing particle shape and interface strength on the fracture behavior of a metal matrix composite. Acta Mater. 2009, 57, 97–107. [Google Scholar] [CrossRef]

- Zhang, P.; Li, F. Effect of particle characteristics on deformation of particle reinforced metal matrix composites. Trans. Nonferrous Met. Soc. China 2010, 20, 655–661. [Google Scholar] [CrossRef]

- Xue, Z.; Huang, Y.; Li, M. Particle size effect in metallic materials: A study by the theory of mechanism-based strain gradient plasticity. Acta Mater. 2002, 50, 149–160. [Google Scholar] [CrossRef]

- Huang, M.; Li, Z. Size effects on stress concentration induced by a prolate ellipsoidal particle and void nucleation mechanism. Int. J. Plast. 2005, 21, 1568–1590. [Google Scholar] [CrossRef]

- Köhler, L.; Hockauf, K.; Lampke, T. Influence of Particulate Reinforcement and Equal-Channel Angular Pressing on Fatigue Crack Growth of an Aluminum Alloy. Metals (Basel) 2015, 5, 790–801. [Google Scholar] [CrossRef]

- Shyong, J.H.; Derby, B. The deformation characteristics of SiC particulate-reinforced aluminium alloy 6061. Mater. Sci. Eng. A 1995, 197, 11–18. [Google Scholar] [CrossRef]

- Shin, C.S.; Huang, J.C. Effect of temper, specimen orientation and test temperature on the tensile and fatigue properties of SiC particles reinforced PM 6061 Al alloy. Int. J. Fatigue 2010, 32, 1573–1581. [Google Scholar] [CrossRef]

- Papakyriacou, M.; Mayer, H.; Stanzl-Tschegg, S.; Groschl, M. Fatigue properties of Al2O3-particle-reinforced 6061 aluminium alloy in the high-cycle regime. Int. J. Fatigue 1996, 18, 475–481. [Google Scholar] [CrossRef]

- Kamat, S.V.; Hirth, J.P.; Mehrabian, R. Mechanical properties of particulate-reinforced aluminum-matrix composites. Acta Metall. 1989, 37, 2395–2402. [Google Scholar] [CrossRef]

- Milan, M.T.; Bowen, P. Tensile and Fracture Toughness Properties of SiCp Reinforced Al Alloys: Effects of Particle Size, Particle Volume Fraction, and Matrix Strength. J. Mater. Eng. Perform. 2004, 13, 775–783. [Google Scholar] [CrossRef]

- Flom, Y.; Arsenault, R.J. Interfacial bond strength in an aluminium alloy 6061-SiC composite. Mater. Sci. Eng. 1986, 77, 191–197. [Google Scholar] [CrossRef]

- Mummery, P.; Derby, B. The influence of microstructure on the fracture behaviour of particulate metal matrix composites. Mater. Sci. Eng. A 1991, 135, 221–224. [Google Scholar] [CrossRef]

- Tokaji, K.; Shiota, H.; Kobayashi, K. Effect of particle size on fatigue behaviour in SiC particulate-reinforced aluminium alloy composites. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 281–288. [Google Scholar] [CrossRef]

- Bouafia, F.; Serier, B.; Bouiadjra, B.A.B. Finite element analysis of the thermal residual stresses of SiC particle reinforced aluminum composite. Comput. Mater. Sci. 2012, 54, 195–203. [Google Scholar] [CrossRef]

- Hadianfard, M.J.; Healy, J.; Mai, Y.-W. Temperature effect on fracture behaviour of an alumina particulate-reinforced 6061-aluminium composite. Appl. Compos. Mater. 1994, 1, 93–113. [Google Scholar] [CrossRef]

- Poza, P.; Llorca, J. Fracture toughness and fracture mechanisms of Al-Al2O3 composites at cryogenic and elevated temperatures. Mater. Sci. Eng. A 1996, 206, 183–193. [Google Scholar] [CrossRef]

- Han, N.L.; Wang, Z.G.; Zhang, G.D. Effect of reinforcement size on the elevated-temperature tensile properties and low-cycle fatigue behavior of particulate SiC/Al composites. Compos. Sci. Technol. 1997, 57, 1491–1499. [Google Scholar] [CrossRef]

- Vogelsang, M.; Aresenault, R.J.; Fisher, R.M. An In Situ HVEM Study of Dislocation Generation at Al/SiC Interfaces in Metal Matrix Composites. Metall. Trans. A 1986, 17A, 379–389. [Google Scholar] [CrossRef]

- Knowles, A.J.; Jiang, X.; Galano, M.; Audebert, F. Microstructure and mechanical properties of 6061 Al alloy based composites with SiC nanoparticles. J. Alloys Compd. 2014, 615, 401–405. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tokaji, K.; Kawamura, M. Fatigue behaviour of SiC-particulate-reinforced aluminium alloy composites with different particle sizes at elevated temperatures. Compos. Sci. Technol. 2008, 68, 2785–2791. [Google Scholar] [CrossRef]

- Biermann, H.; Kemnitzer, M.; Hartmann, O. On the temperature dependence of the fatigue and damage behaviour of a particulate-reinforced metal-matrix composite. Mater. Sci. Eng. A 2001, 319–321, 671–674. [Google Scholar] [CrossRef]

- Vyletel, G.M.; Allison, J.E.; Van, D.C.A. The effect of matrix microstructure on cyclic response and fatigue behavior of particle—Reinforced 2219 aluminum: Part I. room temperature behavior. Metall. Mater. Trans. A 1995, 26, 3143–3154. [Google Scholar] [CrossRef]

- Nieh, T.G.; Lesuer, D.R.; Syn, C.K. Tensile and Fatigue Properties of a 25 vol% SiC Particulate Reinforced 6090 Al Composite at 300 °C. Scr. Metall. Mater. 1995, 32, 707–712. [Google Scholar] [CrossRef]

- Li, C.; Ellyin, F. Fatigue damage and its localization in particulate metal matrix composites. Mater. Sci. Eng. A 1996, 214, 115–121. [Google Scholar] [CrossRef]

| Element | Al | Cu | Mg | Mn | Si | Fe | Cr | Ti | Zn | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| wt % | 91.25 | 4.9 | 1.8 | 0.9 | 0.2 | 0.3 | 0.1 | 0.15 | 0.25 | 0.15 |

| Condition of the 2124 Aluminum Alloy | Temperature | Yield Strength in MPa | Ultimate Tensile Strength in MPa | Uniform Elongation in % | Elongation to Failure in % |

|---|---|---|---|---|---|

| unreinforced | RT | 341 ± 35 | 471 ± 8 | 16.7 ± 1.0 | 24.8 ± 1.1 |

| 5 vol % SiC (3 μm) | RT | 358 ± 8 | 508 ± 9 | 14.0 ± 1.0 | 15.6 ± 0.8 |

| 25 vol % SiC (3 μm) | RT | 460 ± 6 | 573 ± 62 | 1.5 ± 1.2 | 1.5 ± 1.2 |

| 5 vol % SiC (300 nm) | RT | 378 ± 1 | 552 ± 1 | 13.3 ± 1 | 14.5 ± 1.0 |

| 25 vol % SiC (300 nm) | RT | 633 ± 10 | 727 ± 33 | 1.0 ± 0.4 | 1.0 ± 0.4 |

| unreinforced | 180 °C | 282 ± 15 | 380 ± 17 | 17.4 ± 1.6 | 28.1 ± 3.1 |

| 5 vol % SiC (3 μm) | 180 °C | 332 ± 4 | 413 ± 4 | 11.9 ± 0.5 | 13.5 ± 1.0 |

| 25 vol % SiC (3 μm) | 180 °C | 426 ± 6 | 529 ± 11 | 4.7 ± 0.4 | 6.0 ± 1.6 |

| 5 vol % SiC (300 nm) | 180 °C | 337 ± 5 | 423 ± 5 | 12.5 ± 0.3 | 18.8 ± 1.6 |

| 25 vol % SiC (300 nm) | 180 °C | 419 ± 4 | 458 ± 5 | 2.0 ± 0.3 | 13.1 ± 1.2 |

| Condition of the 2124 Aluminum Alloy | Temperature | Maximum Stress σmax in MPa | Reduction in Fatigue Limit in % 1 | Increase in Fatigue Limit in % 2 |

|---|---|---|---|---|

| Unreinforced | RT | 280 | - | - |

| 5 vol % SiC (3 μm) | RT | 250 | 10.7 | - |

| 25 vol % SiC (3 μm) | RT | 390 | - | 39.3 |

| 5 vol % SiC (300 nm) | RT | 270 | 3.6 | - |

| 25 vol % SiC (300 nm) | RT | 410 | - | 46.4 |

| Unreinforced | 180 °C | 230 | 17.9 | - |

| 25 vol % SiC (3 μm) | 180 °C | 320 | - | 39.1 |

| 25 vol % SiC (300 nm) | 180 °C | 280 | - | 21.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winter, L.; Hockauf, K.; Lampke, T. Temperature and Particle Size Influence on the High Cycle Fatigue Behavior of the SiC Reinforced 2124 Aluminum Alloy. Metals 2018, 8, 43. https://doi.org/10.3390/met8010043

Winter L, Hockauf K, Lampke T. Temperature and Particle Size Influence on the High Cycle Fatigue Behavior of the SiC Reinforced 2124 Aluminum Alloy. Metals. 2018; 8(1):43. https://doi.org/10.3390/met8010043

Chicago/Turabian StyleWinter, Lisa, Kristin Hockauf, and Thomas Lampke. 2018. "Temperature and Particle Size Influence on the High Cycle Fatigue Behavior of the SiC Reinforced 2124 Aluminum Alloy" Metals 8, no. 1: 43. https://doi.org/10.3390/met8010043

APA StyleWinter, L., Hockauf, K., & Lampke, T. (2018). Temperature and Particle Size Influence on the High Cycle Fatigue Behavior of the SiC Reinforced 2124 Aluminum Alloy. Metals, 8(1), 43. https://doi.org/10.3390/met8010043