Influence of Extrusion Temperature on the Aging Behavior and Mechanical Properties of an AA6060 Aluminum Alloy

Abstract

:1. Introduction

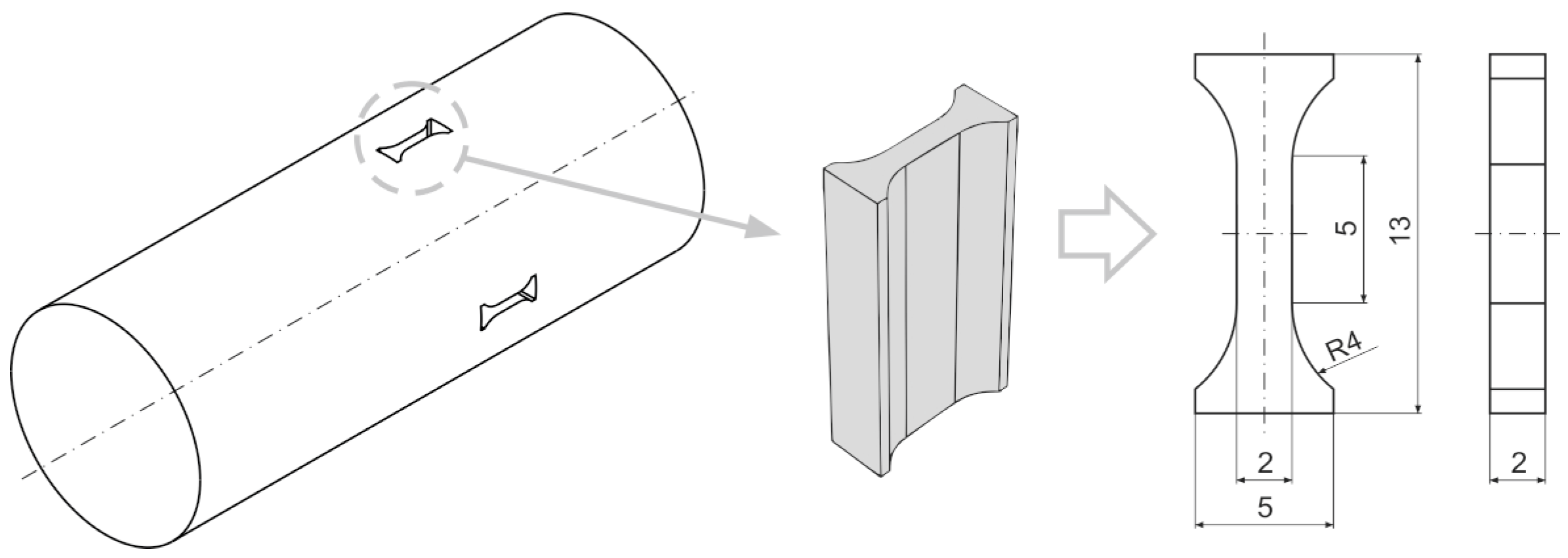

2. Materials and Methods

3. Results and Discussion

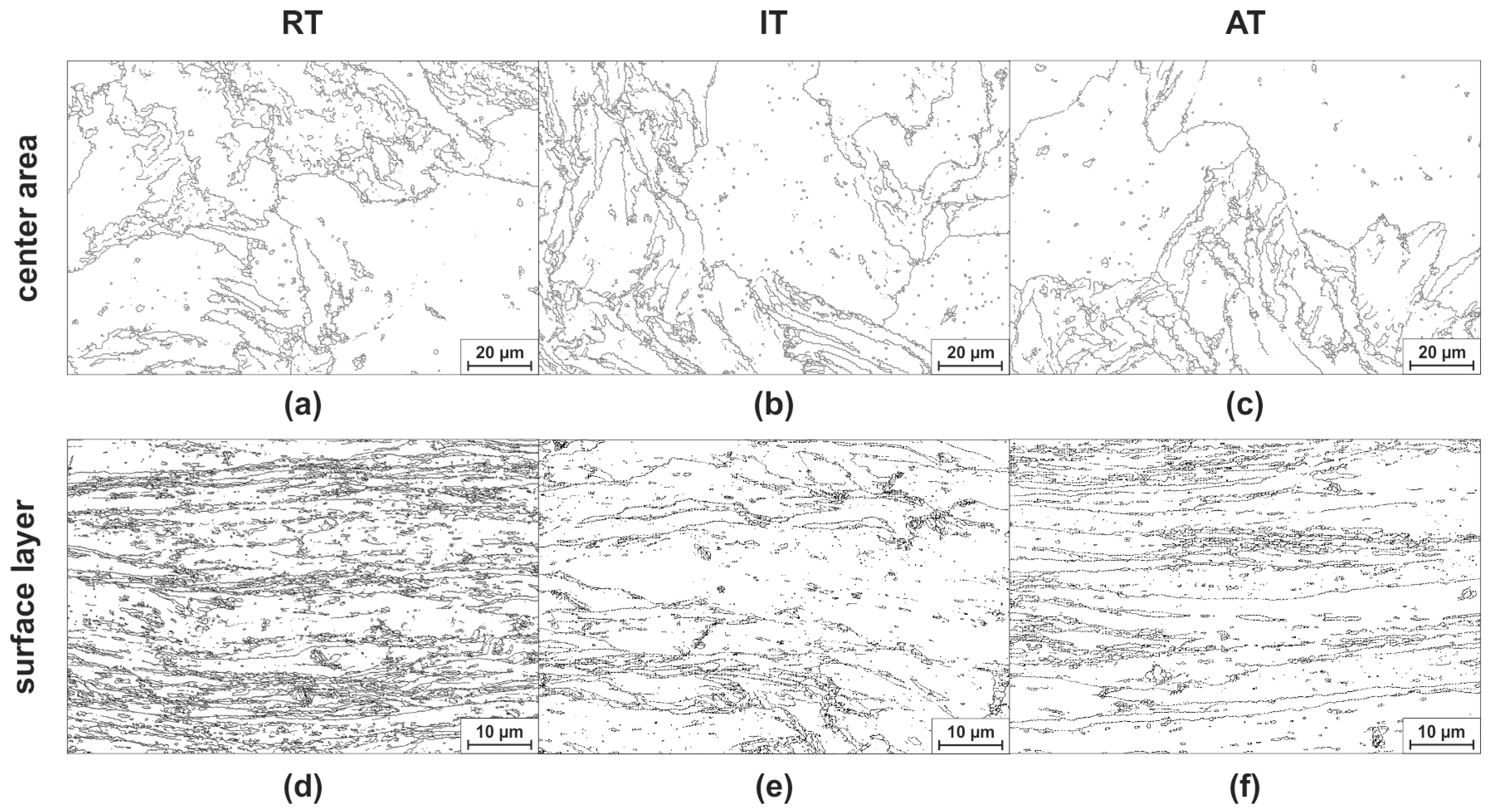

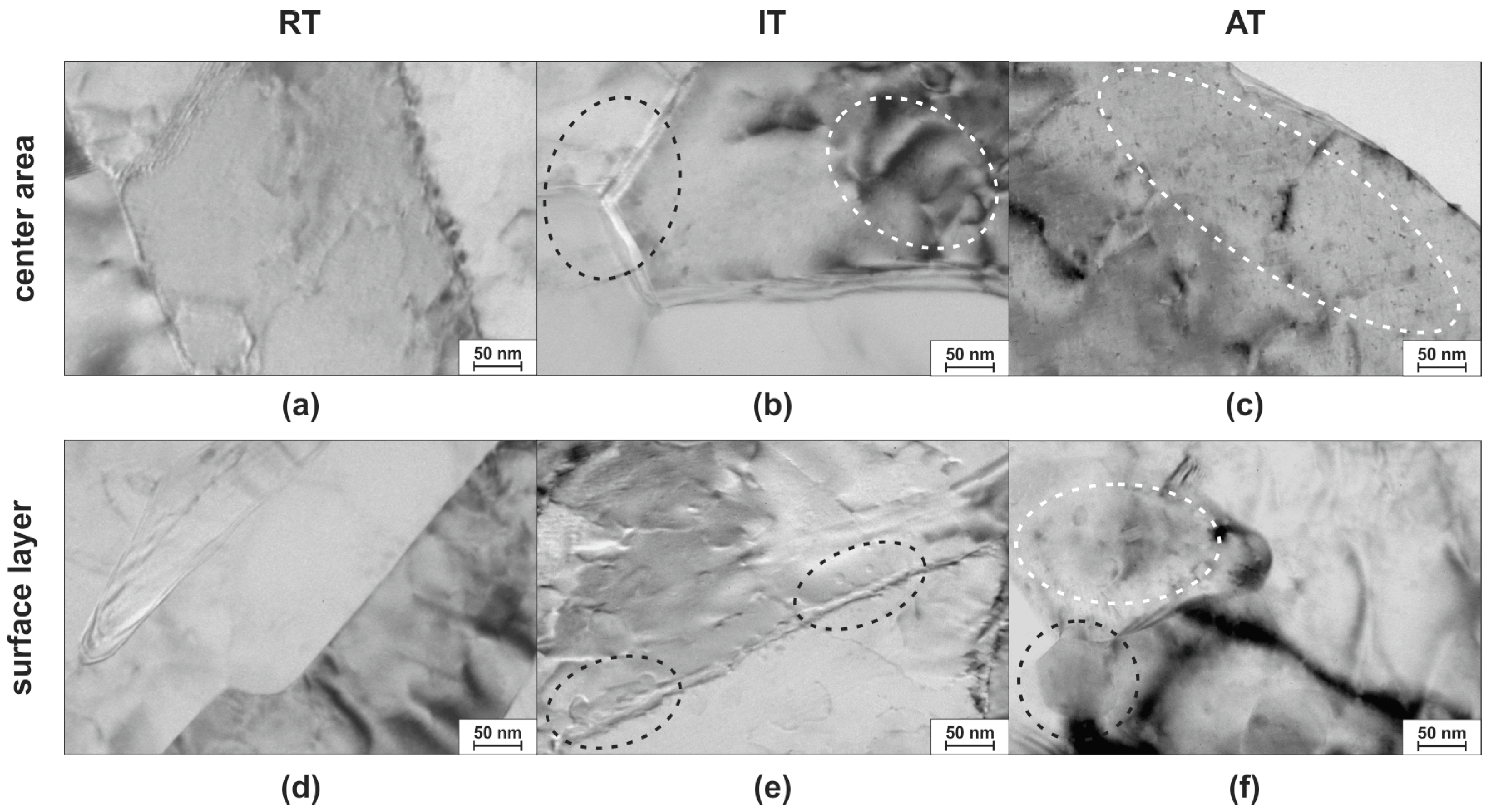

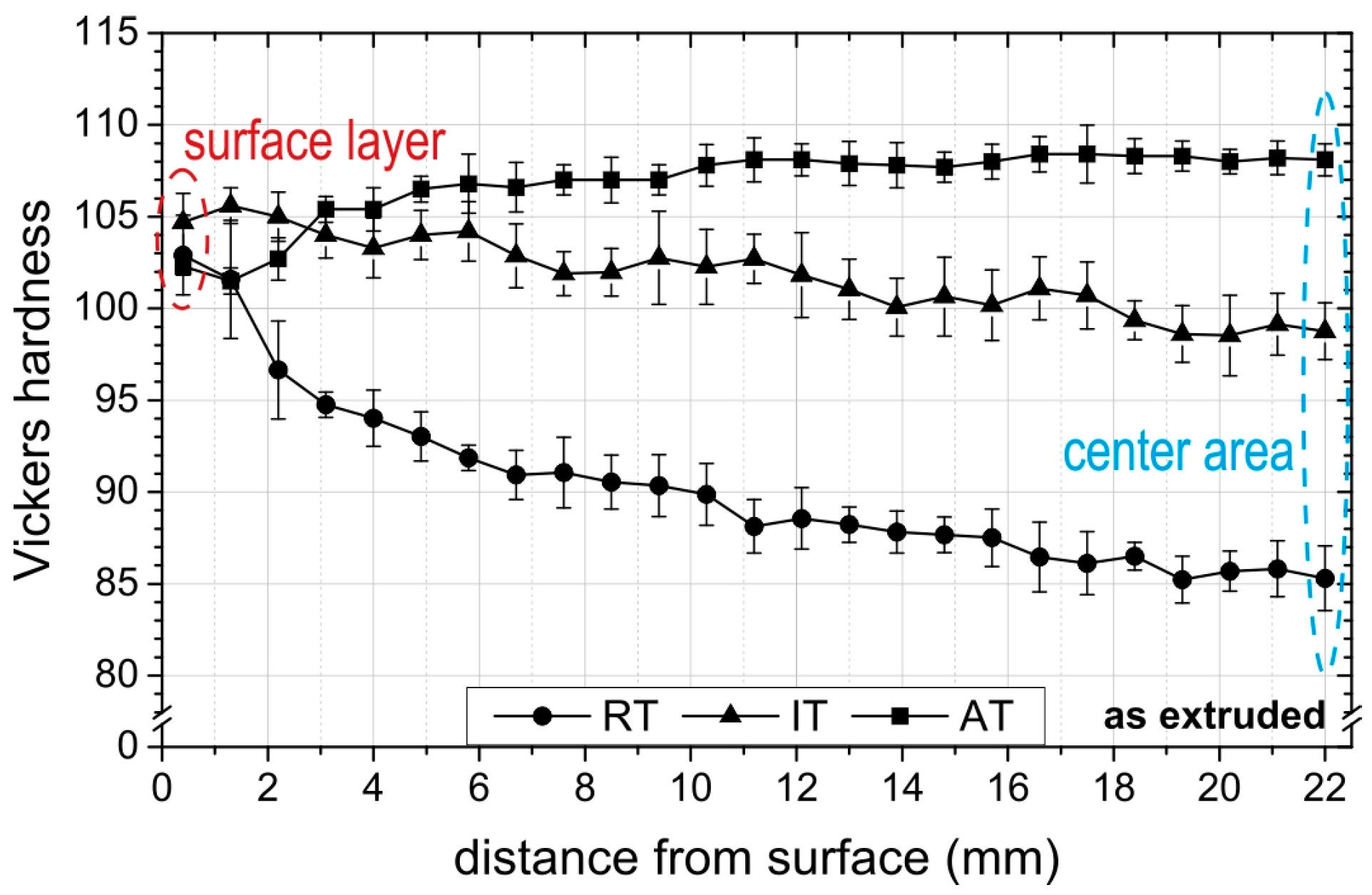

3.1. Microstructural and Mechanical Characterization of the as-Extruded Material

3.2. Aging Behavior of Cold and Hot Extruded Materials

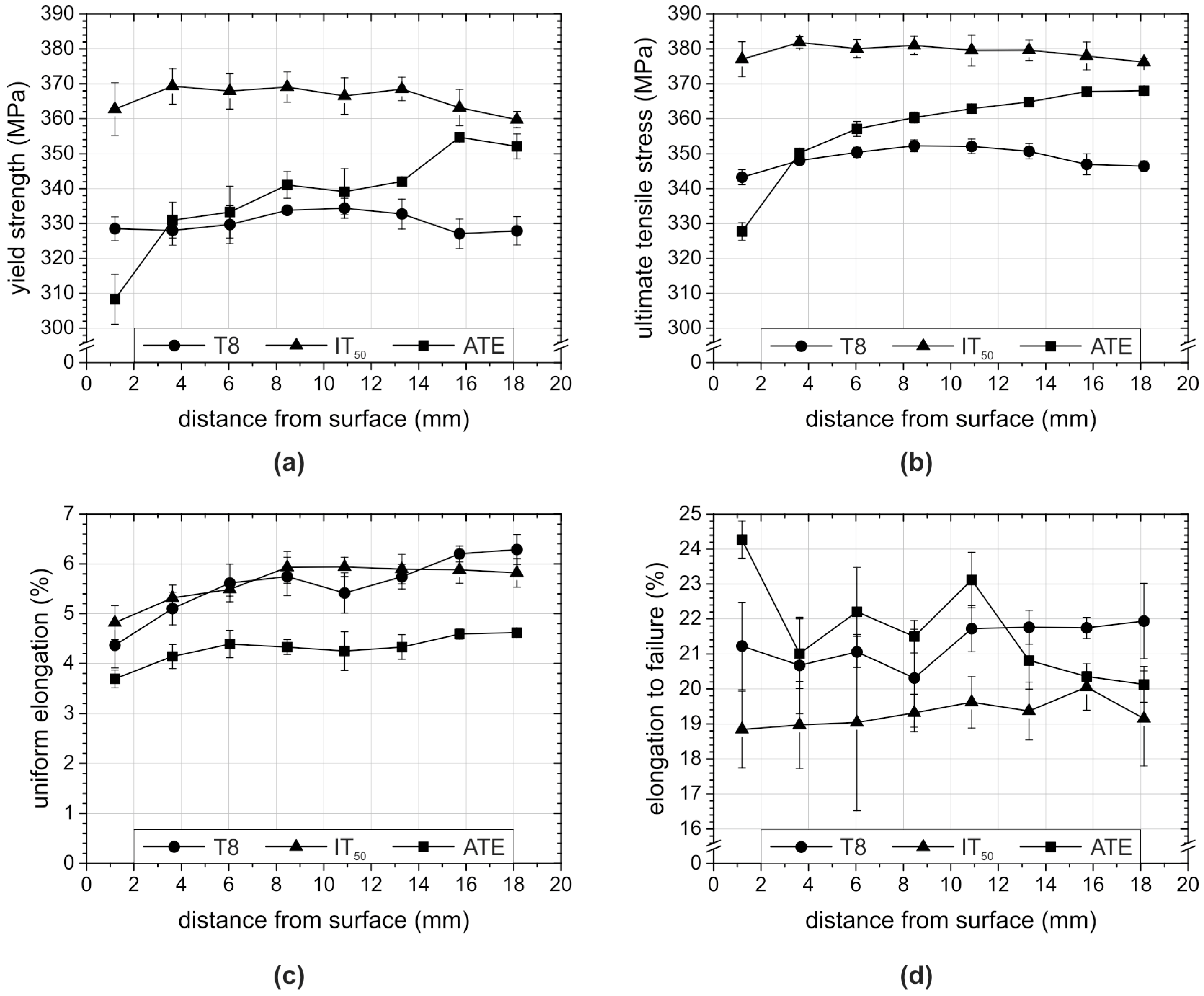

3.3. Microstructural and Mechanical Characterization of Optimized Material Conditions

4. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sheppard, T. Extrusion of Aluminium Alloys; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1999; ISBN 978-0412590702. [Google Scholar]

- Atkinson, A.; Taylor, R.I. The diffusion of Ni in the bulk and along dislocations in NiO single crystals. Philos. Mag. A 1979, 39, 581–595. [Google Scholar] [CrossRef]

- Staab, T.E.M.; Haaks, M.; Modrow, H. Early precipitation stages of aluminum alloys—The role of quenched-in vacancies. Appl. Surf. Sci. 2008, 255, 132–135. [Google Scholar] [CrossRef]

- Frint, P.; Hockauf, M.; Halle, T.; Strehl, G.; Lampke, T.; Wagner, M.F.-X. Microstructural Features and Mechanical Properties after Industrial Scale ECAP of an Al-6060 Alloy. Mater. Sci. Forum 2011, 667–669, 1153–1158. [Google Scholar] [CrossRef]

- Frint, P.; Hockauf, M.; Halle, T.; Wagner, M.F.-X.; Lampke, T. The role of backpressure during large scale equal-channel angular pressing. Materwiss. Werkst. 2012, 43, 668–672. [Google Scholar] [CrossRef]

- Frint, S.; Hockauf, M.; Frint, P.; Wagner, M.F.-X. Scaling up Segal’s principle of Equal-Channel Angular Pressing. Mater. Des. 2016, 97, 502–511. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Sha, G.; Wang, Y.B.; Liao, X.Z.; Duan, Z.C.; Ringer, S.P.; Langdon, T.G. Influence of equal-channel angular pressing on precipitation in an Al–Zn–Mg–Cu alloy. Acta Mater. 2009, 57, 3123–3132. [Google Scholar] [CrossRef]

- Roven, H.J.; Liu, M.; Werenskiold, J.C. Dynamic precipitation during severe plastic deformation of an Al–Mg–Si aluminium alloy. Mater. Sci. Eng. A 2008, 483–484, 54–58. [Google Scholar] [CrossRef]

- Gubicza, J.; Schiller, I.; Chinh, N.Q.; Illy, J.; Horita, Z.; Langdon, T.G. The effect of severe plastic deformation on precipitation in supersaturated Al–Zn–Mg alloys. Mater. Sci. Eng. A 2007, 460–461, 77–85. [Google Scholar] [CrossRef]

- Cai, M.; Field, D.P.; Lorimer, G.W. A systematic comparison of static and dynamic ageing of two Al–Mg–Si alloys. Mater. Sci. Eng. A 2004, 373, 65–71. [Google Scholar] [CrossRef]

- Hirosawa, S.; Hamaoka, T.; Horita, Z.; Lee, S.; Matsuda, K.; Terada, D. Methods for designing concurrently strengthened severely deformed age-hardenable aluminum alloys by ultrafine-grained and precipitation hardenings. Metall. Mater. Trans. A 2013, 44, 3921–3933. [Google Scholar] [CrossRef]

- Hockauf, M.; Meyer, L.W.; Zillmann, B.; Hietschold, M.; Schulze, S.; Krüger, L. Simultaneous improvement of strength and ductility of Al–Mg–Si alloys by combining equal-channel angular extrusion with subsequent high-temperature short-time aging. Mater. Sci. Eng. A 2009, 503, 167–171. [Google Scholar] [CrossRef]

- Kim, W.J.; Kim, J.K.; Park, T.Y.; Hong, S.I.; Kim, D.I.; Kim, Y.S.; Lee, J.D. Enhancement of Strength and Superplasticity in a 6061 Al Alloy Processed by Equal-Channel-Angular-Pressing. Metall. Mater. Trans. A 2002, 33, 3155–3164. [Google Scholar] [CrossRef]

- Berndt, N.; Frint, P.; Böhme, M.; Wagner, M.F.-X. Microstructure and Mechanical Properties of an AA6060 Aluminum Alloy after Cold and Warm Extrusion. Mater. Sci. Eng. A 2017, 707, 717–724. [Google Scholar] [CrossRef]

- Frint, P.; Wagner, M.F.-X.; Weber, S.; Seipp, S.; Frint, S.; Lampke, T. An experimental study on optimum lubrication for large-scale severe plastic deformation of aluminum-based alloys. J. Mater. Process. Technol. 2017, 239, 222–229. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berndt, N.; Frint, P.; Wagner, M.F.-X. Influence of Extrusion Temperature on the Aging Behavior and Mechanical Properties of an AA6060 Aluminum Alloy. Metals 2018, 8, 51. https://doi.org/10.3390/met8010051

Berndt N, Frint P, Wagner MF-X. Influence of Extrusion Temperature on the Aging Behavior and Mechanical Properties of an AA6060 Aluminum Alloy. Metals. 2018; 8(1):51. https://doi.org/10.3390/met8010051

Chicago/Turabian StyleBerndt, Nadja, Philipp Frint, and Martin F.-X. Wagner. 2018. "Influence of Extrusion Temperature on the Aging Behavior and Mechanical Properties of an AA6060 Aluminum Alloy" Metals 8, no. 1: 51. https://doi.org/10.3390/met8010051