The Microstructural Characterization and Mechanical Properties of 5 vol. % (TiBw + TiCp)/Ti Composite Produced by Open-Die Forging

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

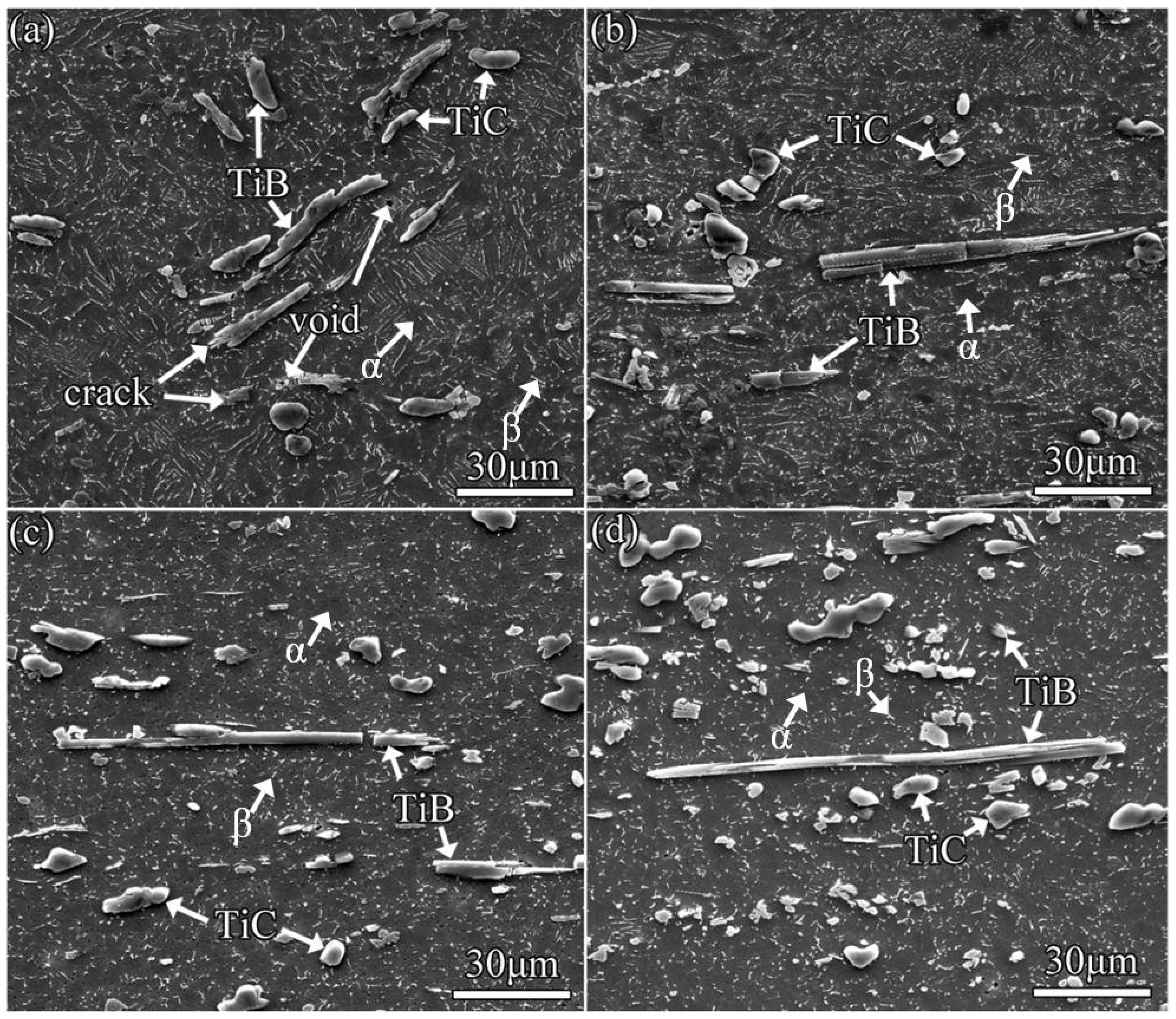

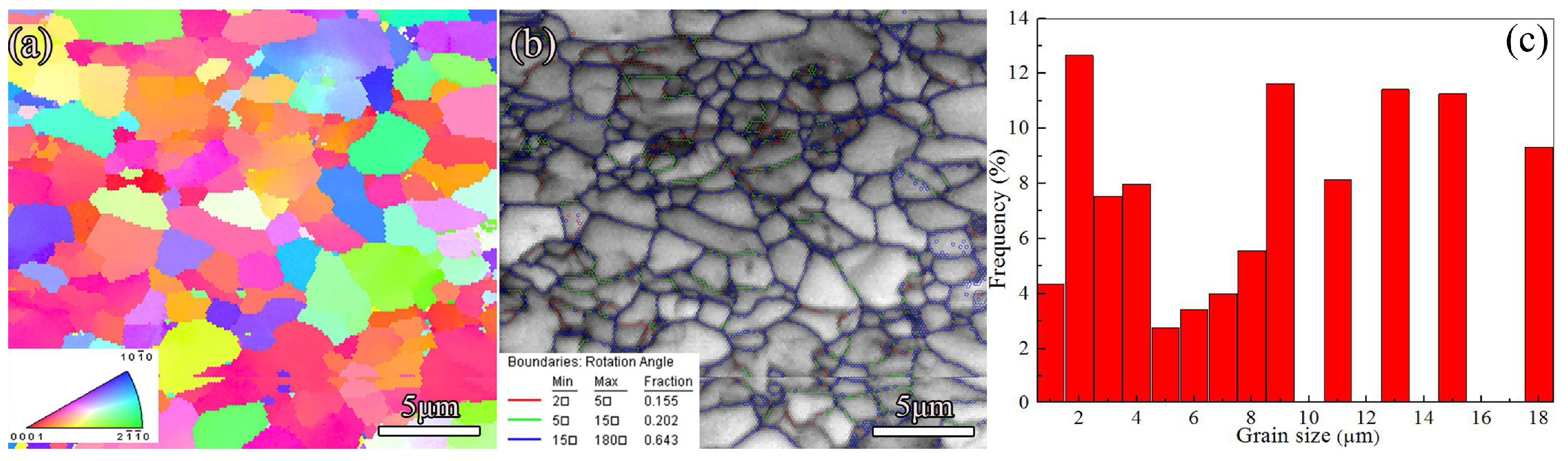

3.1. Microstructure

3.2. Tensile Properties

3.3. Fracture Morphology

4. Discussion

4.1. Microstructure

4.2. Tensile Properties

5. Conclusions

- The as-forged 5 vol. % (TiBw + TiCp)/Ti pancake exhibits inhomogeneous microstructure, with residual transformed β microstructure and microvoids near the randomly distributed TiBw and TiCp existing in the peripheral area.

- The microstructure in the centre area consists of dominant DRX grains plus some refined subgrains and dislocations. The grain size ranges between 1 μm and 7 μm. Moreover, the TiBw and TiCp are uniformly distributed within the matrix.

- Overall, the tensile properties of the composite samples taken from the central area of the pancake are better than those of the samples taken from the peripheral area. Grain refinement strengthening and load-carrying capacity of TiBw and TiCp independently or collectively dominate the strengthening mechanism.

Author Contributions

Funding

Conflicts of Interest

References

- Huang, L.Q.; Qian, M.; Liu, Z.M.; Nguyen, V.T.; Yang, L.; Wang, L.H.; Zou, J. In situ preparation of TiB nanowires for high-performance Ti metal matrix nanocomposites. J. Alloys Compd. 2018, 735, 2640–2645. [Google Scholar] [CrossRef]

- Tjong, S.C.; Mai, Y.M. Processing-structure-property aspects of particulate and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 2008, 68, 583–601. [Google Scholar] [CrossRef]

- Huang, L.Q.; Wang, L.H.; Qian, M.; Zou, J. High tensile-strength and ductile titanium matrix composites strengthened by TiB nanowires. Scr. Mater. 2017, 141, 133–137. [Google Scholar] [CrossRef]

- Montealegre-Meléndez, I.; Arévalo, C.; Pérez-Soriano, E.M.; Kitzmantel, M.; Neubauer, E. Microstructural and XRD analysis and study of the properties of the system Ti-TiAl-B4C processed under different operational conditions. Metals 2018, 8, 367. [Google Scholar] [CrossRef]

- Zhang, C.J.; Kong, F.T.; Xiao, S.L.; Zhao, E.T.; Xu, L.J.; Chen, Y.Y. Evolution of microstructure and tensile properties of in situ titanium matrix composites with volume fraction of (TiB + TiC) reinforcements. Mater. Sci. Eng. A 2012, 548, 152–160. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, J.; Qu, W.; Su, Y.; Yu, Z. Microstructure Evolution of TiC particles in situ, synthesized by laser cladding. Materials 2017, 10, 281. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.J.; Geng, L.; Peng, H.X. In situ (TiBw + TiCp)/Ti6Al4V composites with a network reinforcement distribution. Mater. Sci. Eng. A 2010, 527, 6723–6727. [Google Scholar] [CrossRef]

- Zhang, W.C.; Wang, M.M.; Chen, W.Z.; Feng, Y.J.; Yu, Y. Preparation of TiBw/Ti-6Al-4V composite with an inhomogeneous reinforced structure by a canned hot extrusion process. J. Alloys Compd. 2016, 669, 79–80. [Google Scholar] [CrossRef]

- Li, S.F.; Kondoh, K.; Imai, H.; Chen, B.; Jia, L.; Umeda, J. Microstructure and mechanical properties of P/M titanium matrix composites reinforced by in-situ synthesized TiC-TiB. Mater. Sci. Eng. A 2015, 628, 75–83. [Google Scholar] [CrossRef]

- Tabrizi, S.G.; Sajjadi, S.A.; Babakhani, A.; Lu, W. Influence of spark plasma sintering and subsequent hot rolling on microstructure and flexural behavior of in-situ TiB and TiC reinforced Ti6Al4V composite. Mater. Sci. Eng. A 2015, 624, 271–278. [Google Scholar] [CrossRef]

- Sheydaeian, E.; Toyserkani, E. A new approach for fabrication of titanium-titanium boride periodic composite via additive manufacturing and pressureless sintering. Composites Part B 2018, 138, 140–148. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Tan, C.; Liu, H.; Lin, P. Microstructure and tensile properties of TiCp/Ti6Al4V titanium matrix composites manufactured by laser melting deposition. J. Mater. Proc. Technol. 2018, 252, 524–536. [Google Scholar] [CrossRef]

- Mu, X.N.; Cai, H.N.; Zhang, H.M.; Fan, Q.B.; Wang, F.C.; Zhang, Z.H.; Ge, Y.X.; Shi, R.; Wu, Y.; Wang, Z.; et al. Uniform dispersion and interface analysis of nickel coated graphene nanoflakes/pure titanium matrix composites. Carbon 2018, 137, 146–155. [Google Scholar] [CrossRef]

- Zhang, C.J.; Zhang, S.Z.; Lin, P.; Hou, Z.P.; Kong, F.T.; Chen, Y.Y. Thermomechanical processing of (TiB + TiC)/Ti matrix composites and effects on microstructure and tensile properties. J. Mater. Res. 2016, 31, 1244–1253. [Google Scholar] [CrossRef]

- Chandravanshi, V.K.; Sarkar, R.; Ghosal, P.; Kamat, S.V.; Nandy, T.K. Effect of minor additions of boron on microstructure and mechanical properties of as-cast near α titanium alloy. Metall. Mater. Trans. A 2010, 41, 936–946. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing and properties of titanium-titanium boride (TiBw) matrix composites—A review. J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Imayev, V.; Gaisin, R.; Gaisina, E.; Imayev, R.; Fecht, H.J.; Pyczak, F. Effect of hot forging on microstructure and tensile properties of Ti-TiB based composites produced by casting. Mater. Sci. Eng. A 2014, 609, 34–41. [Google Scholar] [CrossRef]

- Bhat, R.B.; Tamirisakandala, S.; Miracle, D.B.; Ravi, V.A. Thermomechanical response of a powder metallurgy Ti-6Al-4V alloy modified with 2.9 pct boron. Metall. Mater. Trans. A 2005, 36, 845–857. [Google Scholar]

- Liu, B.; Li, Y.P.; Matsumoto, H.; Liu, Y.B.; Liu, Y.; Tang, H.P.; Chiba, A. Thermomechanical response of particulate-reinforced powder metallurgy titanium matrix composites-A study using processing map. Mater. Sci. Eng. A 2010, 527, 4733–4741. [Google Scholar] [CrossRef]

- Huang, D.M.; Wang, H.L.; Chen, X.; Chen, Y.; Guo, H. Influence of forging process on microstructure and mechanical properties of large section Ti-6.5Al-1Mo-1V-2Zr alloy bars. Trans. Nonferrous Met. Soc. China 2013, 23, 2276–2282. [Google Scholar] [CrossRef]

- Niu, H.Z.; Kong, F.T.; Chen, Y.Y. Microstructure characterization and tensile properties of β phase containing TiAl pancake. J. Alloys Compd. 2011, 509, 10179–10184. [Google Scholar] [CrossRef]

- Huang, L.J.; Zhang, Y.Z.; Geng, L.; Wang, B.; Ren, W. Hot compression characteristics of TiBw/Ti6Al4V composites with novel network microstructure using processing maps. Mater. Sci. Eng. A 2013, 580, 242–249. [Google Scholar] [CrossRef]

- Zhou, W.; Ge, P.; Zhao, Y.Q. Finite element analysis of temperature field in forging process of Ti-1023 alloy. Hot Work. Technol. 2009, 38, 21–24. [Google Scholar]

- Roy, S.; Suwas, S. The influence of temperature and strain rate on the deformation response and microstructural evolution during hot compression of a titanium alloy Ti-6Al-4V-0.1B. J. Alloys Compd. 2013, 548, 110–125. [Google Scholar]

- Srinivasan, R.; Bennett, M.D.; Tamirsakandala, S. Rolling of plates and sheets from as-cast Ti-6Al-4V-0.1B. J. Mater. Eng. Perform. 2008, 18, 390–398. [Google Scholar] [CrossRef]

- Armstrong, R.; Codd, I.; Douthwaite, R.M.; Petch, N.J. The plastic deformation of polycrystalline aggregates. Philos. Mag. 1962, 7, 45–58. [Google Scholar] [CrossRef]

- Xiao, L.; Lu, W.J.; Qin, J.N. High-temperature tensile properties of in situ-synthesized titanium matrix composites with strong dependence on strain rates. J. Mater. Res. 2008, 23, 3066–3074. [Google Scholar] [CrossRef]

- Boehlert, C.J.; Tamirisakandala, S.; Curtin, W.A.; Miracle, D.B. Assessment of in situ TiB whisker tensile strength and optimization of TiB-reinforced titanium alloy design. Scr. Mater. 2009, 61, 245–248. [Google Scholar] [CrossRef]

- Ma, F.C.; Lu, W.J.; Qin, J.N.; Zhang, D. Strengthening mechanisms of carbon element in in situ TiC/Ti-1100 composites. J. Mater. Sci. 2006, 41, 5395–5398. [Google Scholar] [CrossRef]

- Zhang, C.J.; Kong, F.T.; Xu, L.J.; Zhao, E.T.; Xiao, S.L.; Chen, Y.Y. Temperature dependence of tensile properties and fracture behavior of as rolled TiB/Ti composite sheet. Mater. Sci. Eng. A 2012, 556, 962–969. [Google Scholar] [CrossRef]

| Sampling Points | 25 °C | 60 °C | 650 °C | 700 °C | ||||

|---|---|---|---|---|---|---|---|---|

| σb (MPa) | δ (%) | σb (MPa) | δ (%) | σb (MPa) | δ (%) | σb (MPa) | δ (%) | |

| near periphery | 1023.7 | 1.82 | 657.6 | 5.86 | 610.9 | 10.1 | 493.9 | 15.3 |

| near centre | 1192.1 | 3.13 | 701.9 | 7.78 | 621.8 | 14.3 | 480.5 | 18.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.; Lü, Z.; Zhang, C.; Zhang, S.; Zhang, H.; Lin, P.; Cao, P. The Microstructural Characterization and Mechanical Properties of 5 vol. % (TiBw + TiCp)/Ti Composite Produced by Open-Die Forging. Metals 2018, 8, 485. https://doi.org/10.3390/met8070485

Han J, Lü Z, Zhang C, Zhang S, Zhang H, Lin P, Cao P. The Microstructural Characterization and Mechanical Properties of 5 vol. % (TiBw + TiCp)/Ti Composite Produced by Open-Die Forging. Metals. 2018; 8(7):485. https://doi.org/10.3390/met8070485

Chicago/Turabian StyleHan, Jianchao, Zhidan Lü, Changjiang Zhang, Shuzhi Zhang, Hongzhou Zhang, Peng Lin, and Peng Cao. 2018. "The Microstructural Characterization and Mechanical Properties of 5 vol. % (TiBw + TiCp)/Ti Composite Produced by Open-Die Forging" Metals 8, no. 7: 485. https://doi.org/10.3390/met8070485

APA StyleHan, J., Lü, Z., Zhang, C., Zhang, S., Zhang, H., Lin, P., & Cao, P. (2018). The Microstructural Characterization and Mechanical Properties of 5 vol. % (TiBw + TiCp)/Ti Composite Produced by Open-Die Forging. Metals, 8(7), 485. https://doi.org/10.3390/met8070485