Effect of Tempering Temperatures on Tensile Properties and Rotary Bending Fatigue Behaviors of 17Cr2Ni2MoVNb Steel

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

3.1. Microstructural Characterization

3.2. Hardness

3.3. Tensile Properties

3.3.1. Tensile Strength

3.3.2. Fracture Analysis

3.4. Fatigue Characteristics

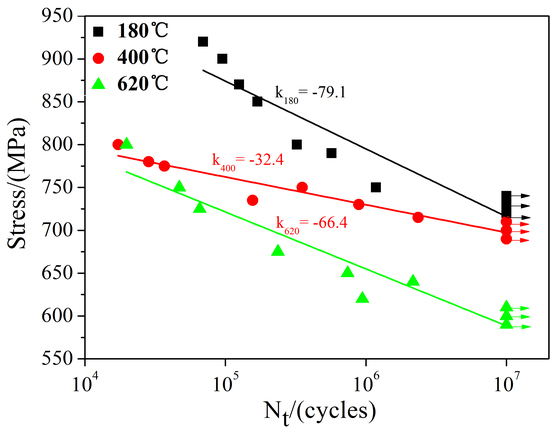

3.4.1. S-N Curve

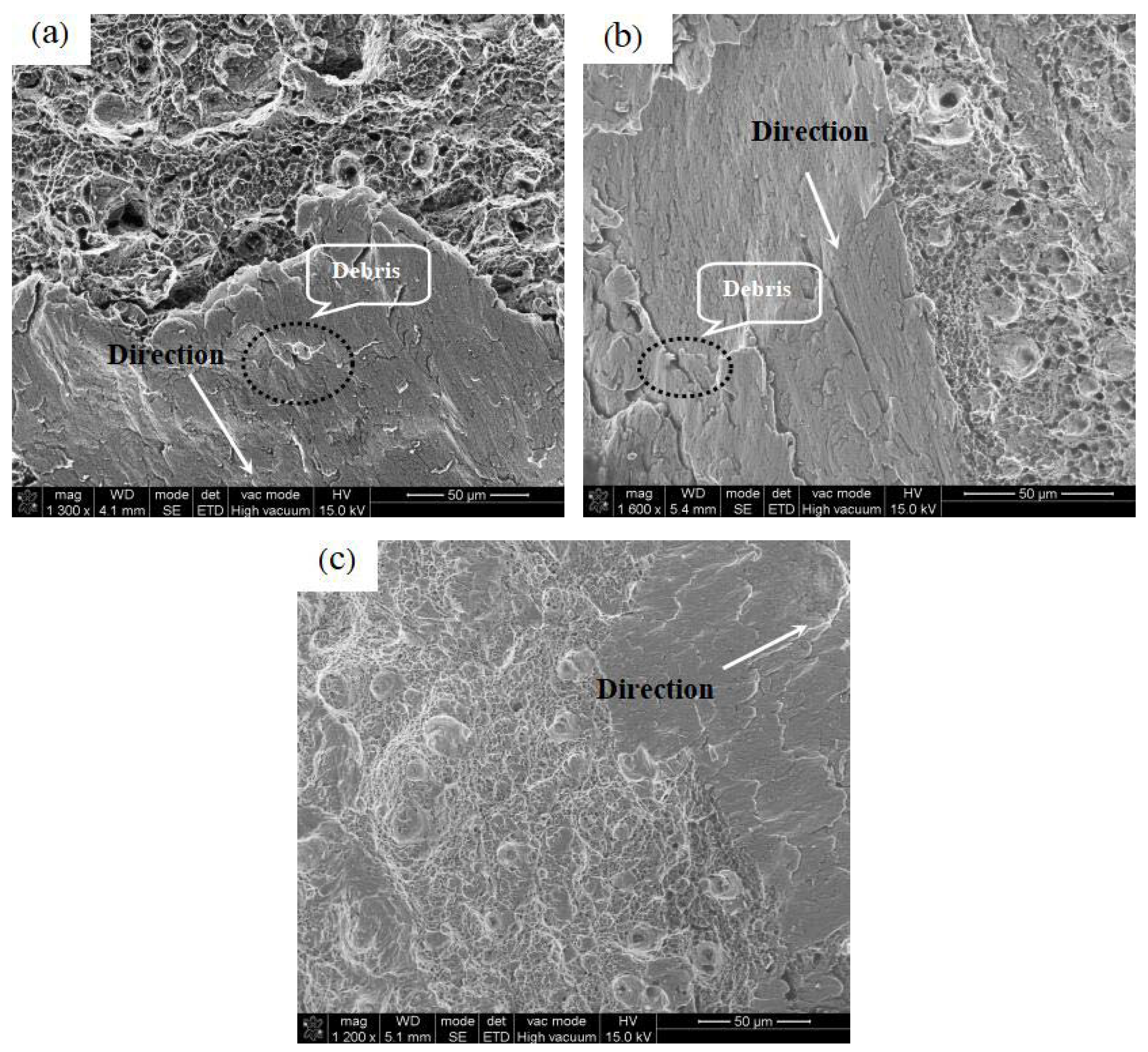

3.4.2. Fractography

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, Y.H.; Wang, M.Q.; Chen, J.C.; Dong, H. Microstructure and mechanical properties of gear steels after high temperature carburization. J. Iron Steel Res. Int. 2013, 20, 140–145. [Google Scholar] [CrossRef]

- Gurudas, M.; Kumar, T.N.; Kumar, G.S. Enhancement of mechanical properties in bainitic steel processed from different austenitization temperatures. Steel Res. Int. 2017, 2, 87–92. [Google Scholar]

- Morave, J.M.; Mantovani, D. Biodegradable metals for cardiovascular stent application: Interests and new opportunities. Int. J. Mol. Sci. 2011, 12, 4250–4270. [Google Scholar] [CrossRef] [PubMed]

- Schinhammer, M.; Hänzi, A.; Löffle, J.; Uggowitzer, P.J. Design strategy for biodegradable Fe-based alloys for medical applications. Acta Biomater. 2010, 6, 1705–1713. [Google Scholar] [CrossRef] [PubMed]

- Francis, A.; Yang, Y.; Virtanen, S.; BoccacciniIron, A.R. Iron and iron-based alloys for temporary cardiovascular applications. J. Mater. Sci. Mater. Med. 2015, 26, 138–154. [Google Scholar] [CrossRef] [PubMed]

- Pereloma, E.V.; Scott, R.I.; Smith, R.M. Effect of Cr on strain ageing behaviour of low carbon steel. Mater. Sci. 2007, 24, 539–543. [Google Scholar]

- Yang, Z.; Cong, D.Y.; Sun, X.M.; Nie, Z.H.; Wang, Y.D. Enhanced cyclability of elastocaloric effect in boron-microalloyed NiMn-In magnetic shape memory alloys. Acta Mater. 2017, 127, 33–42. [Google Scholar] [CrossRef]

- Wang, Q.W.; Li, C.S.; Chen, J.; Tu, X.Y. Effects of heat input on microstructure and mechanical properties of Fe-2Cr-Mo-0.12C steel. Mater. Sci. Technol. 2018, 34, 538–546. [Google Scholar] [CrossRef]

- Wang, M.Q.; Jie, S.; Han, D. Microstructure and mechanical properties of V-Nb microalloyed steel for heavy-duty gear. Trans. Mater. 2007, 28, 18–23. (In Chinese) [Google Scholar]

- Xiao, F.R.; Cao, Y.B.; Qiao, G.Y.; Zhang, X.B.; Bo, L. Effect of Nb solute and NbC precipitates on dynamic or static recrystallization in Nb steels. J. Iron Steel Res. Int. 2012, 19, 52–56. [Google Scholar] [CrossRef]

- Chen, S.L.; Geng, K. Effect of heat treatment on mechanical properties of Cr-Ni-Mo carburized gear steel. Spec. Steel 2002, 23, 20–22. (In Chinese) [Google Scholar]

- Wu, D.; Wang, F.M.; Cheng, J.; Li, C.R. Effects of Nb and tempering time on carbide precipitation behavior and mechanical properties of Cr-Mo-V Steel for brake discs. Steel Res. Int. 2018, 89. [Google Scholar] [CrossRef]

- Hong, Y.S.; Lei, Z.Q.; Sun, C.Q.; Zhao, A.G. Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels. Int. J. Fatigue 2014, 58, 144–152. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of steel flow stresses at high temperatures and strain rates. Metall. Trans. A 1991, 7, 1545–1558. [Google Scholar] [CrossRef]

- Mohammad, J.K.; Mohammad, A. Evaluation of high-cycle bending fatigue and fracture behaviors in EN-GJS700-2 ductile cast iron of crankshafts. Eng. Fail. Anal. 2018, 85, 189–200. [Google Scholar]

- Shendy, B.R.; Yoozbashi, M.N.; Avishan, B.; Yazdani, S. An investigation on rotating bending fatigue behavior of nanostructured low-temperature bainitic steel. Acta Metall. 2014, 27, 233–238. [Google Scholar] [CrossRef]

- Swarr, T.; Krauss, G. The effect of structure on the deformation of as-quenched and tempered martensite in a Fe-0.2 pct C alloy. Metall. Trans. A 1976, 7, 41–48. [Google Scholar] [CrossRef]

- Tomita, Y.; Okabayashi, K. Effect of microstructure on strength and toughness of heat-treated low alloy structural steels. Matall. Trans. A 1986, 17, 1203–1207. [Google Scholar] [CrossRef]

- Stasko, R.; Adrian, H.; Adrian, A. Effect of nitrogen and vanadium on austenite grain groeth of a low alloy steel. Mater. Charact. 2006, 5, 340–347. [Google Scholar] [CrossRef]

- Long, S.L.; Liang, Y.L.; Jiang, Y.; Liang, Y.; Yang, M. Effect of quenching temperature on martensite multi-level microstructures and properties of strengh and toughness in 20CrNi2Mo steel. Mater. Sci. Eng. A 2016, 676, 38–47. [Google Scholar] [CrossRef]

- Morito, S.; Tanaka, H.; Konishi, R.; Furuhara, T.; Maki, T. The morphology and crystallography of lath martensite in Fe-C. Acta Mater. 2003, 51, 1789–1799. [Google Scholar] [CrossRef]

- Chang, Y.L.; Chen, P.Y.; Tsai, Y.T.; Yang, J.R. Crystallographic analysis of lenticular martensite in Fe-1.0C-17Cr stainless steel by electron backscatter diffraction. Mater. Charact. 2016, 113, 17–25. [Google Scholar] [CrossRef]

- Wang, C.F.; Wang, M.Q.; Dong, H. In-situ observation of deformation and fracture process for lath martensite steel. J. Iron Steel Res. 2012, 24, 38–43. (In Chinese) [Google Scholar]

- Li, Y.Q. Microstructure and strain fatigue dislocation structure of 7075 RRA Aluminum alloy. Rare Met. 2001, 20, 52–57. [Google Scholar]

- Phung, N.L.; Favier, V.; Ranc, N.; Valès, F.; Mughrabi, H. Very high cycle fatigue of copper: Evolution, morphology and locations of surface slip markings. Int. J. Fatigue 2014, 3, 63–68. [Google Scholar] [CrossRef] [Green Version]

- Neumann, P. Coarse slip model of fatigue. Acta Metall. 1969, 17, 1219–1225. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Al | Cu | Mo | V | Nb | Mg | S | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.188 | 0.015 | 0.40 | 1.83 | 1.63 | 0.048 | 0.01 | 0.31 | 0.093 | 0.059 | 0.007 | 0.001 | 0.009 |

| Samples Label | Quenching Temperature | Quenching Method | Tempering Temperature | Tempering Method |

|---|---|---|---|---|

| 1 | 860 °C × 1 h | oil | 180 °C × 2 h | water |

| 2 | 860 °C × 1 h | oil | 400 °C × 2 h | water |

| 3 | 860 °C × 1 h | oil | 620 °C × 2 h | water |

| Sample Label | Temperature (°C) | 2% YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|---|

| 1 | 180 | 1362 | 1456 | 13.76 |

| 2 | 400 | 1288 | 1341 | 12.48 |

| 3 | 620 | 964 | 1019 | 14.8 |

| Element | Weight % | ||

|---|---|---|---|

| A | B | C | |

| C | 7.81 | 4.99 | 2.41 |

| O | 19.23 | 32.54 | 33.45 |

| Mg | 0.63 | 1.15 | 1.21 |

| Al | 21.2 | 24.66 | 25.34 |

| Cr | 1 | 1.47 | 1.62 |

| Fe | 50.13 | 35.19 | 35.97 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, S.-G.; Zhang, Y.-L.; Lai, F.-Q.; Li, X.-Q. Effect of Tempering Temperatures on Tensile Properties and Rotary Bending Fatigue Behaviors of 17Cr2Ni2MoVNb Steel. Metals 2018, 8, 507. https://doi.org/10.3390/met8070507

Qu S-G, Zhang Y-L, Lai F-Q, Li X-Q. Effect of Tempering Temperatures on Tensile Properties and Rotary Bending Fatigue Behaviors of 17Cr2Ni2MoVNb Steel. Metals. 2018; 8(7):507. https://doi.org/10.3390/met8070507

Chicago/Turabian StyleQu, Sheng-Guan, Ya-Long Zhang, Fu-Qiang Lai, and Xiao-Qiang Li. 2018. "Effect of Tempering Temperatures on Tensile Properties and Rotary Bending Fatigue Behaviors of 17Cr2Ni2MoVNb Steel" Metals 8, no. 7: 507. https://doi.org/10.3390/met8070507