Strain Rate Dependence of Material Strength in AA5xxx Series Aluminum Alloys and Evaluation of Their Constitutive Equation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen

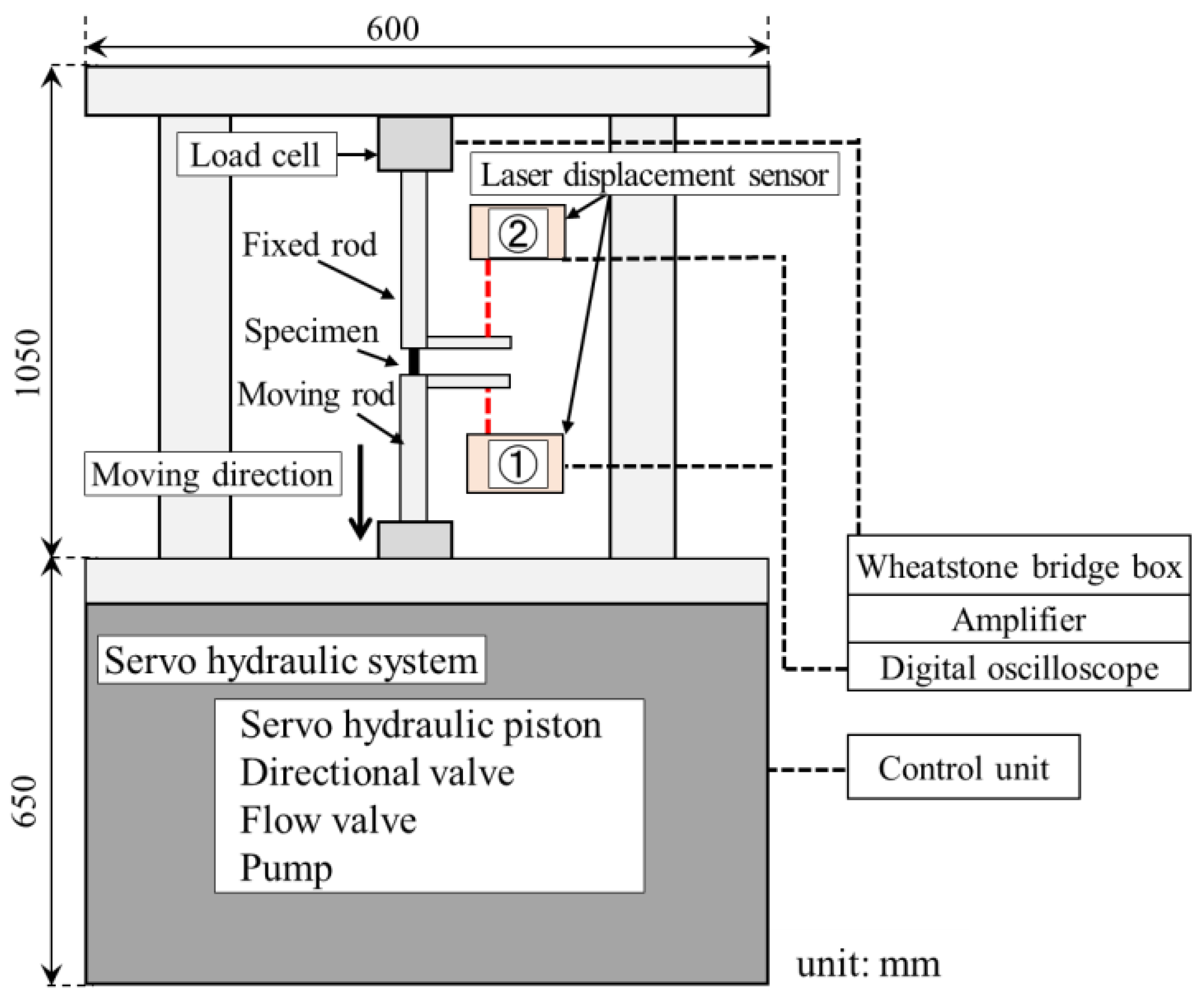

2.2. Tensile Test

2.2.1. Quasi-Static Test

2.2.2. Dynamic Test

2.2.3. Impact Test

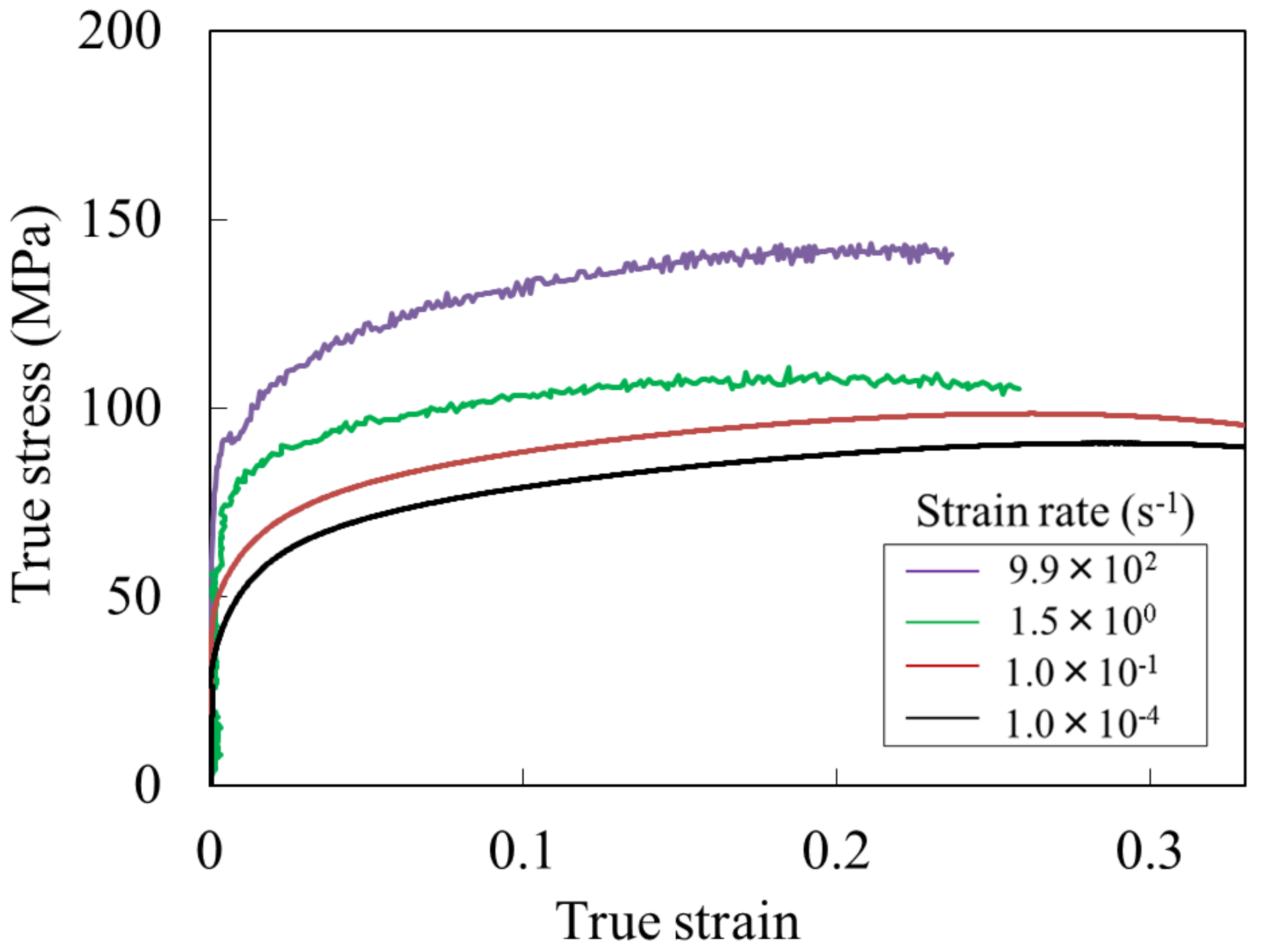

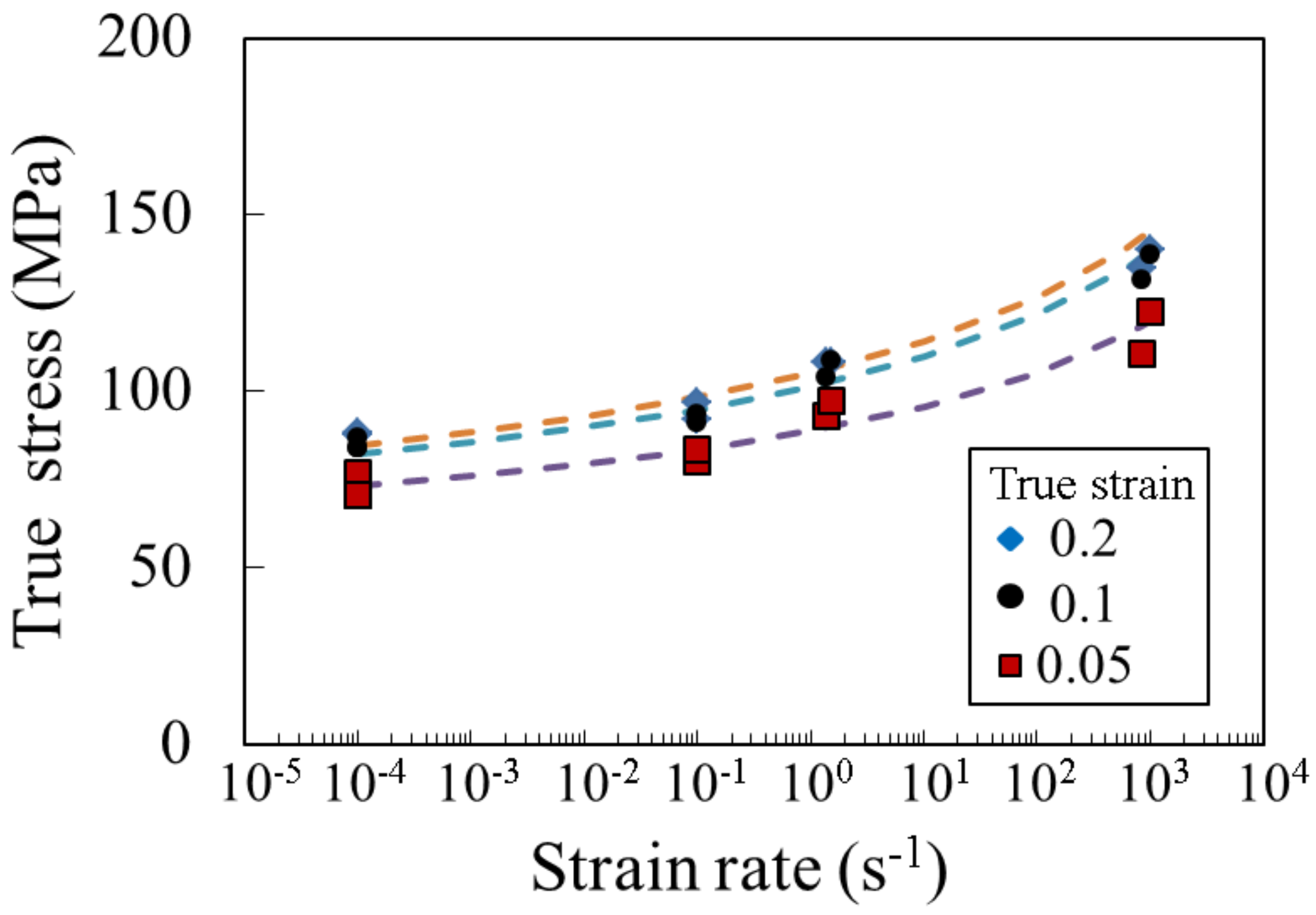

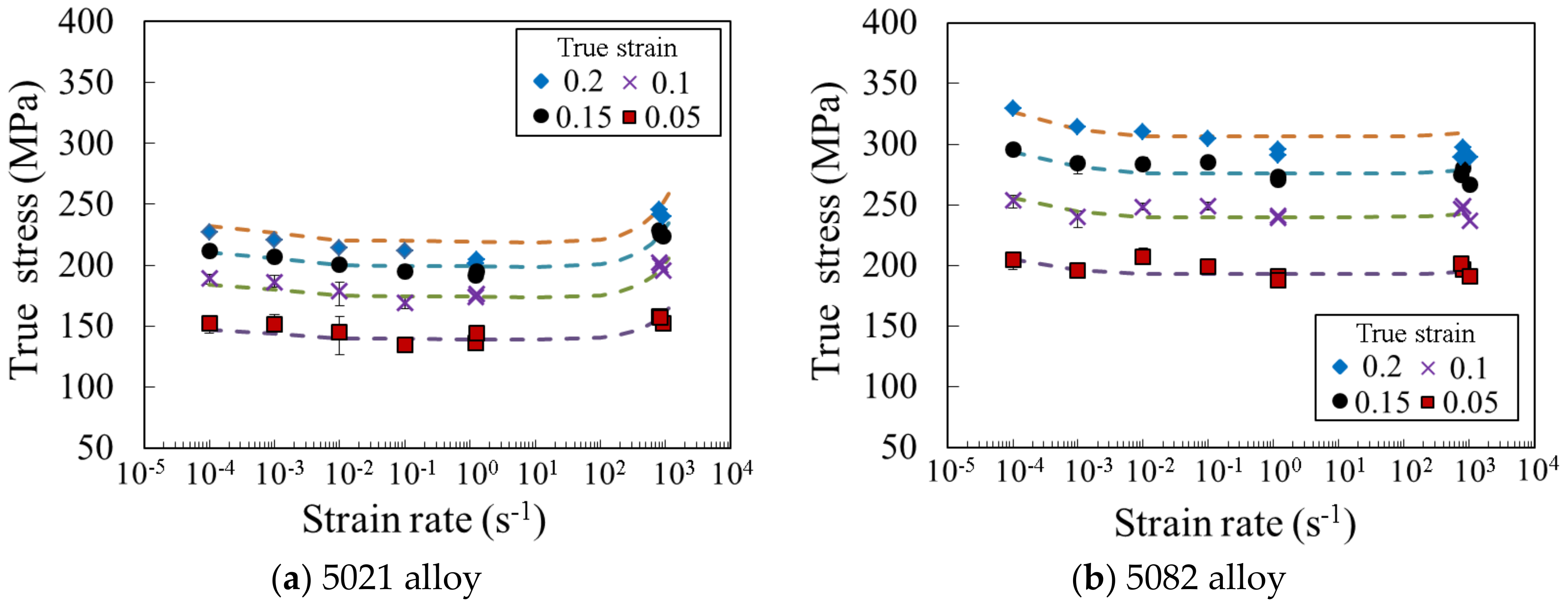

3. Results

4. Discussion

4.1. Previous Studies on Serration Theory [17]

4.2. Effect of Strain Rate on Serration Behavior

4.3. Positive Strain Rate of Flow Stress

4.4. Negative Strain Rate of Flow Stress

4.4.1. Effect of Mg Content

4.4.2. Effect of Mn Content

4.4.3. Influence of Temperature Increase Caused by Adiabatic Heating in Impact Test

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huh, H.; Ahn, K.; Lim, J.H.; Kim, H.W.; Park, L.J. Evaluation of dynamic hardening models for BCC, FCC, and HCP metals at a wide range of strain rates. J. Mater. Proc. Technol. 2014, 214, 1326–1340. [Google Scholar] [CrossRef]

- Hopkinson, B. A method of measuring the pressure produced in the detonation of high explosives or by the impact of bullets. Philos. Trans. R. Soc. Lond. A 1914, 213, 437–456. [Google Scholar] [CrossRef]

- Kolsky, H. An investigation of the mechanical properties of materials at very high rates of loading. Proc. Phys. Soc. Sect. B. 1949, 62, 676–700. [Google Scholar] [CrossRef]

- Reed, J.M.; Walter, M.E. Observations of serration characteristics and acoustic emission during serrated flow of an Al-Mg alloy. Mater. Sci. Eng. A 2003, 359, 1–10. [Google Scholar] [CrossRef]

- Fan, G.J.; Wang, G.Y.; Choo, H.; Liaw, P.K.; Park, Y.S.; Han, B.Q.; Lavernia, E.J. Deformation behavior of an ultrafine-grained Al–Mg alloy at different strain rates. Scr. Mater. 2005, 52, 929–933. [Google Scholar] [CrossRef]

- Picu, R.C.; Vincze, G.; Ozturk, F.; Gracio, J.J.; Barlat, F.; Maniatty, A.M. Strain rate sensitivity of the commercial aluminum alloy AA5182-O. Mater. Sci. Eng. A 2005, 390, 334–343. [Google Scholar] [CrossRef]

- Coër, J.; Manach, P.Y.; Laurent, H.M.; Oliveira, C.; Menezes, L.F. Piobert–Lüders plateau and Portevin–Le Chatelier effect in an Al–Mg alloy in simple shear. Mech. Res. Commun. 2013, 48, 1–7. [Google Scholar] [CrossRef]

- Cai, Y.; Yang, S.; Fu, S.; Zhang, D.; Zhang, Q. Investigation of Portevin–Le Chatelier band strain and elastic shrinkage in Al-based alloys associated with Mg contents. J. Mater. Sci. Technol. 2017, 33, 580–586. [Google Scholar] [CrossRef]

- Brindley, B.J.; Worthington, P.J. Serrated yielding in Aluminium-3% Magnesium. Acta Metall. 1969, 17, 1357–1361. [Google Scholar] [CrossRef]

- Eremin, V.I. Effect of sample cross-section geometry and loading type on low temperature unstable plastic deformation. Scr. Metall. Mat. 1991, 25, 2215–2219. [Google Scholar] [CrossRef]

- Zhu, S.M.; Nie, J.F. Serrated flow and tensile properties of a Mg–Y–Nd alloy. Scr. Mater. 2004, 50, 51–55. [Google Scholar] [CrossRef]

- Garat, V.; Cloue, J.-M.; Poquillon, D.; Andrieu, E. Influence of Portevin–Le Chatelier effect on rupture mode of alloy 718 specimens. J. Nuclear Mater. 2008, 375, 95–101. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Li, J.; Yuan, B.; Wu, R.; Fan, J.; Wang, B. Serration behavior in Pd77.5Cu6Si16.5 Alloy. Metals 2016, 6, 191. [Google Scholar] [CrossRef]

- Rusinek, A.; Rodríguez-Martínez, J.A. Thermo-viscoplastic constitutive relation for aluminium alloys, modeling of negative strain rate sensitivity and viscous drag effects. Mater. Des. 2009, 30, 4377–4390. [Google Scholar] [CrossRef]

- Kabirian, F.; Khan, A.S.; Pandey, A. Negative to positive strain rate sensitivity in 5xxx series aluminum alloys: Experiment and constitutive modeling. Int. J. Plast. 2014, 55, 232–246. [Google Scholar] [CrossRef]

- Huskins, E.L.; Cao, B.; Ramesh, K.T. Strengthening mechanisms in an Al–Mg alloy. Mater. Sci. Eng. A. 2010, 527, 1292–1298. [Google Scholar] [CrossRef]

- Kami, T.; Yamada, H.; Ogasawara, N. Dynamic behaviour of Al-Mg aluminum alloy at a wide range of strain rates. EPJ Web Conf. (accepted).

- Yamada, H.; Tsurudome, M.; Miura, N.; Horikawa, K.; Ogasawara, N. Ductility loss of 7075 aluminum alloys affected by interaction of hydrogen, fatigue deformation, and strain rate. Mater. Sci. Eng. A 2015, 642, 194–203. [Google Scholar] [CrossRef]

- Khan, A.S.; Huang, S. Experimental and theoretical study of mechanical behavior of 1100 aluminum in the strain rate range 10−5−104 s−1. Int. J. Plast. 1992, 8, 397–424. [Google Scholar] [CrossRef]

- Huang, S.; Khan, A.S. Modeling the mechanical behaviour of 1100-0 aluminum at different strain rates by the bodner-partom model. Int. J. Plast. 1992, 8, 501–517. [Google Scholar] [CrossRef]

- McCormigk, P.G. A model for the Portevin-Le Chatelier effect in substitutional alloys. Acta Metall. 1972, 20, 351–354. [Google Scholar] [CrossRef]

- Kubin, L.P.; Estrin, Y. Evolution of dislocation densities and the critical conditions for the Portevin-Le Châtelier effect. Acta Metall. Mater. 1990, 38, 697–708. [Google Scholar] [CrossRef]

- Wang, C.; Xu, Y.; Han, E. Portevin-Le Chatelier effect of LA41 magnesium alloys. Front. Mater. Sci. China. 2007, 1, 105–108. [Google Scholar] [CrossRef]

- Salvado, F.C.; Teixeira-Dias, F.; Walley, S.M.; Lea, L.J.; Cardoso, J.B. A review on the strain rate dependency of the dynamic viscoplastic response of FCC metals. Prog. Mater. Sci. 2017, 88, 186–231. [Google Scholar] [CrossRef] [Green Version]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates, and high temperatures. Proc. 7th Inter. Symp. Ballist. 1983, 541–547. [Google Scholar]

- Mukai, T.; Ishikawa, K.; Higashi, K. Strength and ductility under dynamic loading in fine- grained IN905XL aluminum alloy. Metall. Mater. Trans. A 1995, 26A, 2521–2526. [Google Scholar] [CrossRef]

- The Japan Institute of Light Metals. Structures and Properties of Aluminum; The Japan Institute of Light Metals: Tokyo, Japan, 1991. [Google Scholar]

- Hayashi, T.; Yamaura, H.; Shigeru, O. Temperature measurement of metals under high velocity deformation. Proc. 20th Japan Cong. Mater. Res. 1977, 94–98. [Google Scholar]

- Zhao, K.; Fan, R. The effect of pulse electric current on the mechanical properties and fracture behaviors of aluminum alloy AA5754. J. Eng. Mater. Technol. 2016, 138, 041009. [Google Scholar] [CrossRef]

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al | Grain Size (μm) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1070 | 0.04 | 0.18 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 99.77 | 26 |

| 5005 | 0.16 | 0.29 | 0.03 | 0.02 | 0.76 | 0.00 | 0.01 | 0.01 | Bal. | 99 |

| 5021 | 0.13 | 0.27 | 0.07 | 0.25 | 2.28 | 0.03 | 0.03 | 0.03 | Bal. | 54 |

| 5082 | 0.11 | 0.20 | 0.03 | 0.14 | 4.50 | 0.06 | 0.02 | 0.01 | Bal. | 32 |

| 5182 | 0.09 | 0.20 | 0.05 | 0.34 | 4.40 | 0.02 | 0.03 | 0.02 | Bal. | 29 |

| A | B | n0 | n1 | C |

|---|---|---|---|---|

| 33 | 97 | 0.185 | −0.64 | 0 |

| Alloy | A | B | n0 | n1 | K1 | C1 | K2 | m2 |

|---|---|---|---|---|---|---|---|---|

| 5005 | 23.11 | 154.70 | 0.20 | −0.07 | 0.00016 | 0.00 | 0.00 | 0.00 |

| 5021 | 25.41 | 359.60 | 0.38 | 0.02 | 0.00016 | 1.06 | 693.62 | 1.09 |

| 5082 | 78.00 | 507.13 | 0.50 | 0.00009 | 0.00001 | 59.6 | 1358.60 | 4.38 |

| 5182 | 79.90 | 485.88 | 0.50 | 0.00 | 0.00013 | 1.03 | 599.89 | 0.28 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamada, H.; Kami, T.; Mori, R.; Kudo, T.; Okada, M. Strain Rate Dependence of Material Strength in AA5xxx Series Aluminum Alloys and Evaluation of Their Constitutive Equation. Metals 2018, 8, 576. https://doi.org/10.3390/met8080576

Yamada H, Kami T, Mori R, Kudo T, Okada M. Strain Rate Dependence of Material Strength in AA5xxx Series Aluminum Alloys and Evaluation of Their Constitutive Equation. Metals. 2018; 8(8):576. https://doi.org/10.3390/met8080576

Chicago/Turabian StyleYamada, Hiroyuki, Tsuyoshi Kami, Ryota Mori, Tomoyuki Kudo, and Minemitsu Okada. 2018. "Strain Rate Dependence of Material Strength in AA5xxx Series Aluminum Alloys and Evaluation of Their Constitutive Equation" Metals 8, no. 8: 576. https://doi.org/10.3390/met8080576