Experimental Study on Erosion Modeling of Architectural Red Sandstone under the Action of the Natural Environment

Abstract

:1. Introduction

2. Test Materials and Programs

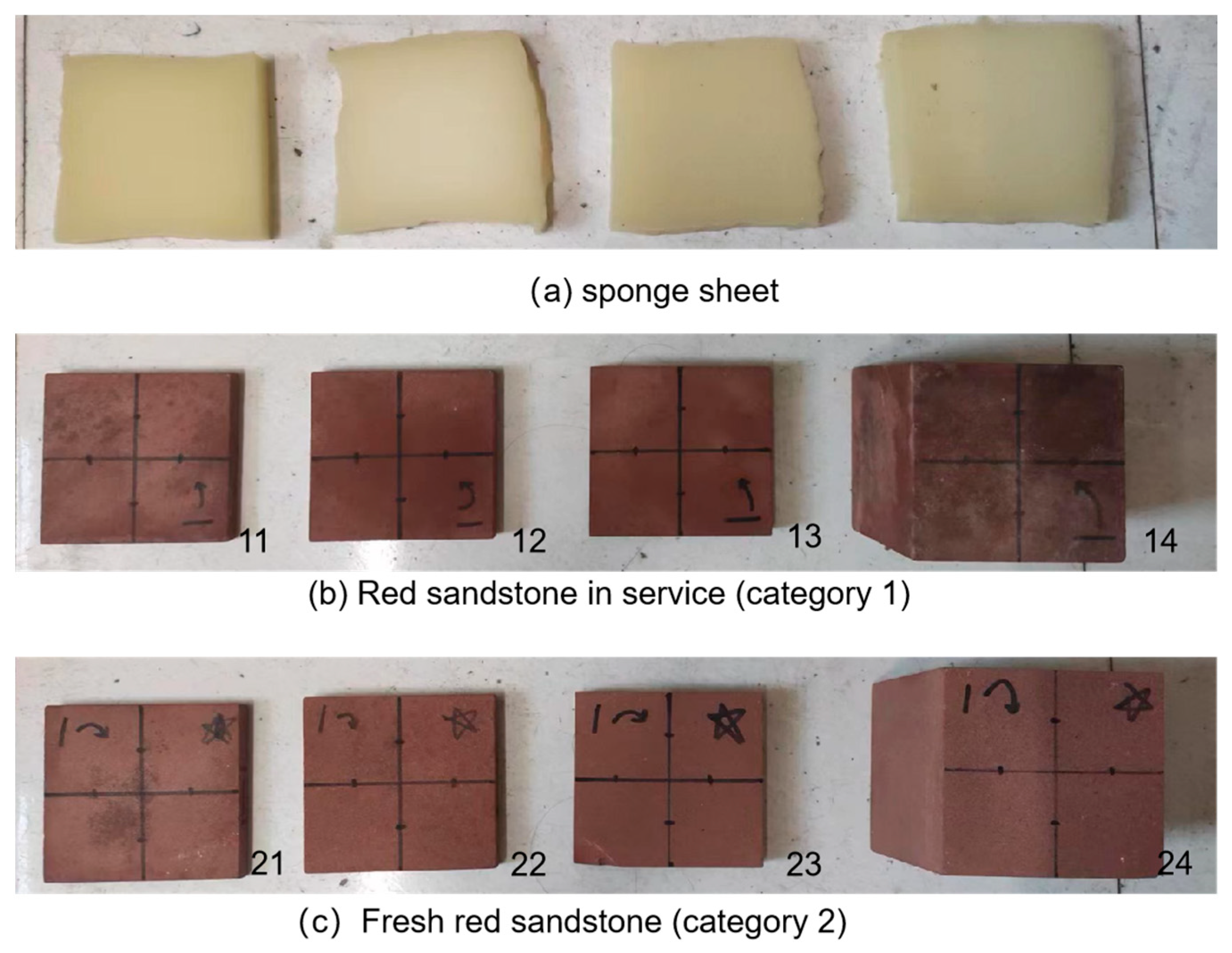

2.1. Specimen Selection and Preparation

2.2. Experimental Programme and Test Methods

3. Test Results and Discussion

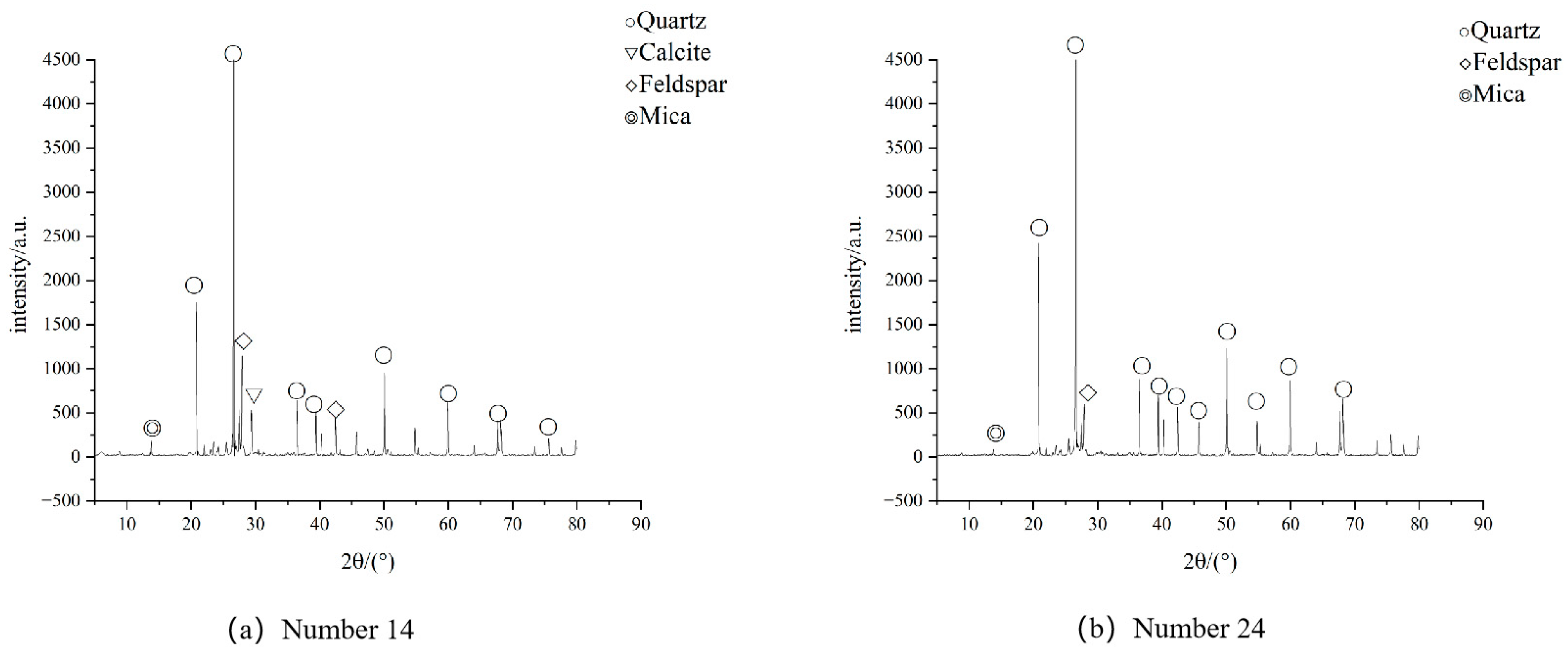

3.1. Microtest Analyses of Fresh Red Sandstone and In-Service Sandstone

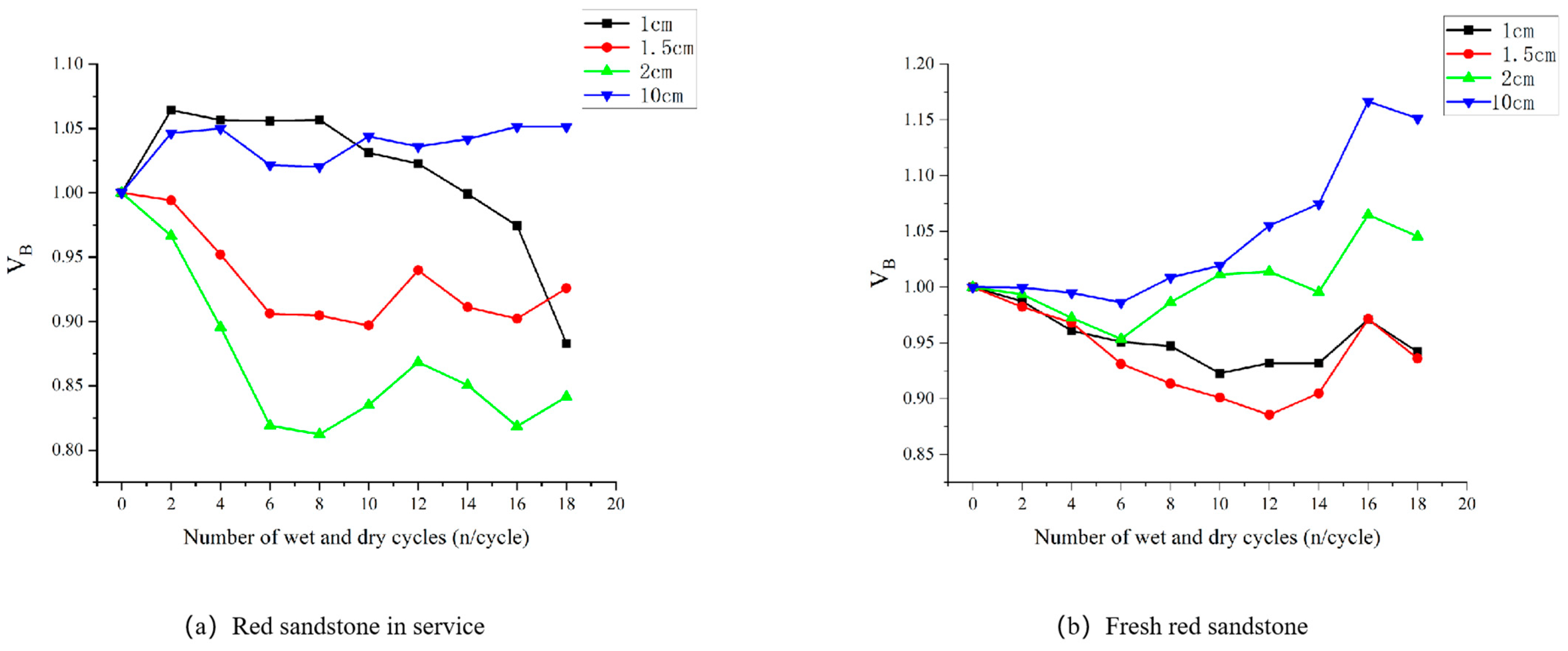

3.2. Study of Ultrasonic Velocity and Cut-Off Points of Different Erosion Stages in Red Sandstone Specimens

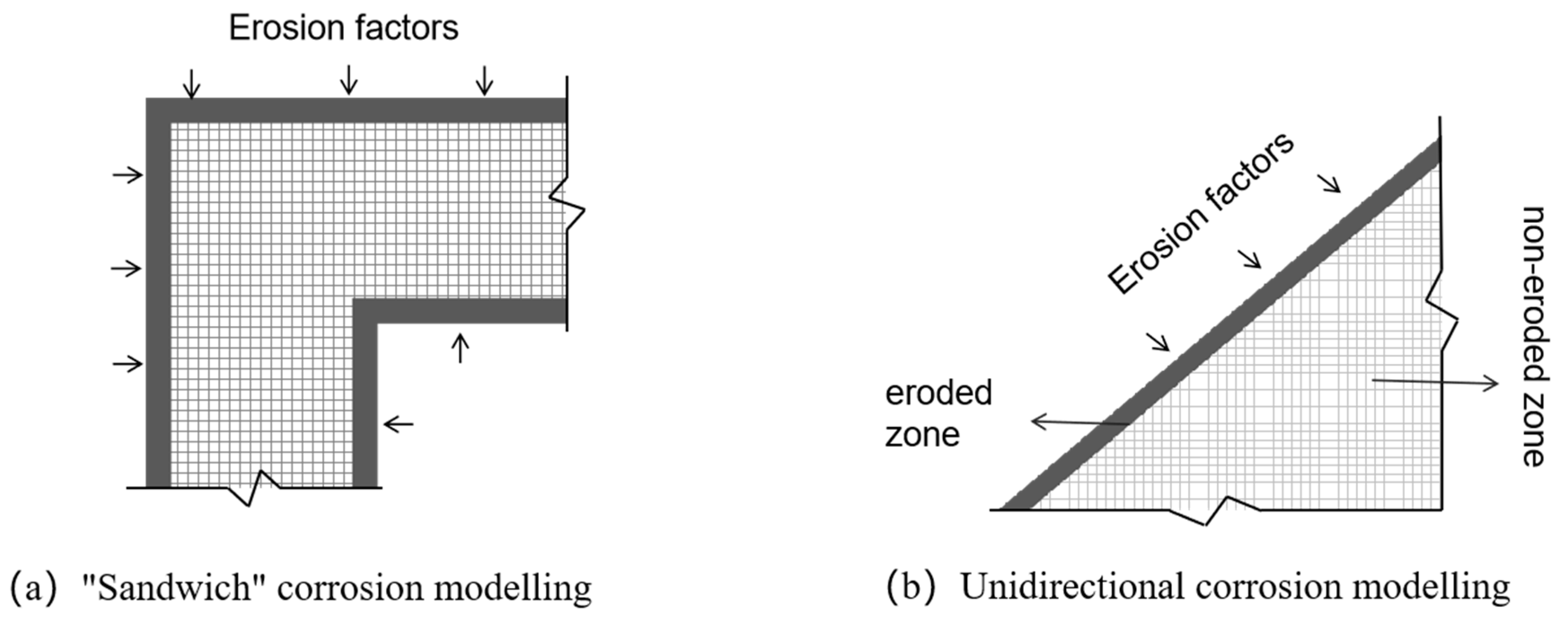

3.2.1. Erosion Modeling of Red Sandstone Specimens Subjected to Unidirectional Acidic Wet and Dry Cycles

3.2.2. Change Rule of Ultrasonic Velocity in Red Sandstone Specimens

3.3. A Study of the Demarcation Points of Different Erosion Stages of Red Sandstone Specimens

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fatoric, S.; Seekamp, E. Are cultural heritage and resources threatened by climate change? A systematic literature review. Clim. Chang. 2017, 142, 227–254. [Google Scholar] [CrossRef]

- Herring, R.; Dyer, K.; Martin, F.; Ward, C. The increasing importance of leading edge erosion and a review of existing protection solutions. Renew. Sustain. Energy Rev. 2019, 115, 109382. [Google Scholar] [CrossRef]

- Wei, J.; Chen, Q.; Du, J.; Liu, K.; Jiang, K. Study on the Durability of Acid Rain Erosion-Resistant Asphalt Mixtures. Materials 2022, 15, 1849. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Gu, L.; Li, W.; Zhang, Q. Effect of acid rain on economic loss of concrete structures in Hangzhou, China. Int. J. Low-Carbon Technol. 2019, 14, 89–94. [Google Scholar] [CrossRef]

- Wang, Y.; Niu, D.; Song, Z. Effect of Acid Rain Erosion on Steel Fiber Reinforced Concrete. J. Wuhan Univ. Technol. 2017, 32, 121–128. [Google Scholar] [CrossRef]

- Tang, W.; Davidson, C.I.; Finger, S.; Vance, K. Erosion of limestone building surfaces caused by wind-driven rain: 1. Field measurements. Atmos. Environ. 2004, 38, 5589–5599. [Google Scholar] [CrossRef]

- Tang, W.; Davidson, C.I. Erosion of limestone building surfaces caused by wind-driven rain: 2. Numerical modeling. Atmos. Environ. 2004, 38, 5601–5609. [Google Scholar] [CrossRef]

- Erkal, A.; Ayala, D.D.; Sequeira, L. Assessment of wind-driven rain impact, related surface erosion and surface strength reduction of historic building materials. Build. Environ. 2012, 57, 336–348. [Google Scholar] [CrossRef]

- Striani, R.; Cappai, M.; Casnedi, L.; Esposito Corcione, C.; Pia, G. Coating’s influence on wind erosion of porous stones used in the Cultural Heritage of Southern Italy: Surface characterisation and resistance. Case Stud. Constr. Mater. 2022, 17, e1501. [Google Scholar] [CrossRef]

- Esteban-Cantillo, O.J.; Menendez, B.; Quesada, B. Climate change and air pollution impacts on cultural heritage building materials in Europe and Mexico. Sci. Total Environ. 2024, 921, 170945. [Google Scholar] [CrossRef]

- Vidal, F.; Vicente, R.; Mendes Silva, J. Review of environmental and air pollution impacts on built heritage: 10 questions on corrosion and soiling effects for urban intervention. J. Cult. Herit. 2019, 37, 273–295. [Google Scholar] [CrossRef]

- Sesana, E.; Gagnon, A.S.; Ciantelli, C.; Cassar, J.A.; Hughes, J.J. Climate change impacts on cultural heritage: A literature review. WIREs Clim. Chang. 2021, 12, e710. [Google Scholar] [CrossRef]

- Tanaka, H.; Inoue, M.; Ishikawa, T.; Nakayama, T. Simulating study of atmospheric corrosion of steels in a coastal industrial zone: Effect of SO32− on the formation of β-FeOOH rust particles synthesized from FeCl3 solutions. Corros. Sci. 2016, 112, 241–245. [Google Scholar] [CrossRef]

- Janfeshan Araghi, H.; Nikbin, I.M.; Rahimi Reskati, S.; Rahmani, E.; Allahyari, H. An experimental investigation on the erosion resistance of concrete containing various PET particles percentages against sulfuric acid attack. Constr. Build. Mater. 2015, 77, 461–471. [Google Scholar] [CrossRef]

- Lindgren, M.; Siljander, S.; Suihkonen, R.; Pohjanne, P.; Vuorinen, J. Erosion–corrosion resistance of various stainless steel grades in high-temperature sulfuric acid solution. Wear 2016, 364–365, 10–21. [Google Scholar] [CrossRef]

- Wang, X.; Wang, W.; Liu, Q.; Wang, S.; Luo, H.; Ji, S.; Zhu, J. Effects of metakaolin on sulfate and sulfuric acid resistance of grouting restoration materials. Constr. Build. Mater. 2022, 349, 128714. [Google Scholar] [CrossRef]

- Liu, P.; Chen, Y.; Yu, Z.; Lu, Z. Effect of sulfate solution concentration on the deterioration mechanism and physical properties of concrete. Constr. Build. Mater. 2019, 227, 116641. [Google Scholar] [CrossRef]

- Kawamoto, T. Deformation and fracturing behaviour of discontinuous rock mass damage mechanics theory. Int. J. Numer. Anal. Methods Geomech. 1988, 12, 1–30. [Google Scholar] [CrossRef]

- Jung, Y.S. Advancement of Erosion Testing, Modeling, and Design of Concrete Pavement Subbase Layers. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2010. [Google Scholar]

- Pan, H.; Si, X.; Zhao, Q. Damage evolution model of early disturbed concrete under sulfate attack and its experimental verification. Dyna-Bilbao 2018, 93, 52–59. [Google Scholar] [CrossRef]

- Du, B.; Bai, H.; Zhai, M.; He, S. Experimental Study on Dynamic Compression Characteristics of Red Sandstone under Wetting-Drying Cycles. Adv. Civ. Eng. 2020, 2020, 6688202. [Google Scholar] [CrossRef]

- Sun, W.; Du, B.; Cheng, Q. Experimental Study of the Dynamic Mechanical Behavior and Degradation Mechanism of Red Sandstone in Acid Dry-Wet Cycles. Geofluids 2023, 2023, 5541567. [Google Scholar] [CrossRef]

- Dong, Q.; Sun, X.; Lei, N.; Liu, B. Effect of Dry-Wet Cycling on the Degradation Characteristics and Mechanisms of Red Sandstone. Geofluids 2023, 2023, 9950331. [Google Scholar] [CrossRef]

- Zhang, J.J. Study of the Fissures, Volume Change and Permeability of Expansive Soil under Wetting and Drying Cycles. Master’s Dissertation, South China University of Technology, Guangzhou, China, 2010. [Google Scholar]

- Zhang, X.; Qian, C.; Chen, H.; Liang, C.; Kang, W. Calculation of Expansion Stresses and Strains in Concrete under Sulfate Crystallization Attack in Dry-Wet Cycles Environments. J. Mater. Civ. Eng. 2021, 33. [Google Scholar] [CrossRef]

- Guo, J.; Liu, P.; Wu, C.; Wang, K. Effect of Dry-Wet Cycle Periods on Properties of Concrete under Sulfate Attack. Appl. Sci. 2021, 11, 888. [Google Scholar] [CrossRef]

- Wang, K.; Xu, G.; Li, S.; Ge, C. Geo-environmental characteristics of weathering deterioration of red sandstone relics: A case study in Tongtianyan Grottoes, Southern China. Bull. Eng. Geol. Environ. 2018, 77, 1515–1527. [Google Scholar] [CrossRef]

- Yang, Y.; Song, L.; Wang, J.; Yue, L.; Shi, E.; Wang, Z.; Yang, T. Impact of Acid, Salt, and Wetting-Drying Cycles on Weathering Deterioration of the Red Sandstone Used for Leshan Giant Buddha China. Int. J. Archit. Herit. 2024, 13, 123–149. [Google Scholar] [CrossRef]

- Wen, C.P.; Yuan, X.Q. Hyperbolic Consolidation Creep Model of Weathered Red Sandstone Coarse-Grained Soil Under the Wet and Dry Cycles Conditions. Geotech. Geol. Eng. 2022, 40, 5103–5113. [Google Scholar] [CrossRef]

- Basu, A.; Aydin, A. Evaluation of ultrasonic testing in rock material characterization. Geotech. Test. J. 2006, 29, 117–125. [Google Scholar] [CrossRef]

- Hou, H.; Hu, D.; Zhou, H.; Lu, J.; Zhang, F. A chemo-mechanical coupling model for concrete lining subjected to external sulfate attack. Eur. J. Environ. Civ. Eng. 2021, 25, 2674–2691. [Google Scholar] [CrossRef]

- Liao, K.; Zhang, Y.; Zhang, W.; Wang, Y.; Zhang, R. Modeling constitutive relationship of sulfate-attacked concrete. Constr. Build. Mater. 2020, 260, 119902. [Google Scholar] [CrossRef]

- Min, H.; Sui, L.; Xing, F.; Tian, H.; Zhou, Y. An effective transport model of sulfate attack in concrete. Constr. Build. Mater. 2019, 216, 365–378. [Google Scholar] [CrossRef]

- Zhou, X.; Shen, F.; Berto, F. Experimental study on triaxial creep behavior of red sandstone under different pore pressures based on ultrasonic measurement. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 2388–2402. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, L.; Liu, Z.; Wu, N. Experimental Study on Mechanical Properties and Deterioration Mechanism of Red Sandstone from the Panjiatuo Landslide under Action of Acidic Drying-Wetting Cycles. Appl. Sci. 2023, 13, 5955. [Google Scholar] [CrossRef]

- Tang, Z.C.; Zhang, Q.Z.; Zhang, Y. Cyclic Drying-Wetting Effect on Shear Behaviors of Red Sandstone Fracture. Rock Mech. Rock Eng. 2021, 54, 2595–2613. [Google Scholar] [CrossRef]

- Cao, R.; Fang, L.; Qiu, X.; Lin, H.; Li, X.; Li, W. Damage deterioration mechanism and damage constitutive modelling of red sandstone under cyclic thermal-cooling treatments. Arch. Civ. Mech. Eng. 2022, 22, 188. [Google Scholar] [CrossRef]

| Serial Number | Main Substances | Micro-Distribution |

|---|---|---|

| 14 | Quartz, feldspar, and mica | Overall smooth with no obvious defects, cracks, or other defects |

| 24 | Quartz, feldspar, mica, and calcite | Significant increase in defects such as granularity, flocculation, holes, etc. |

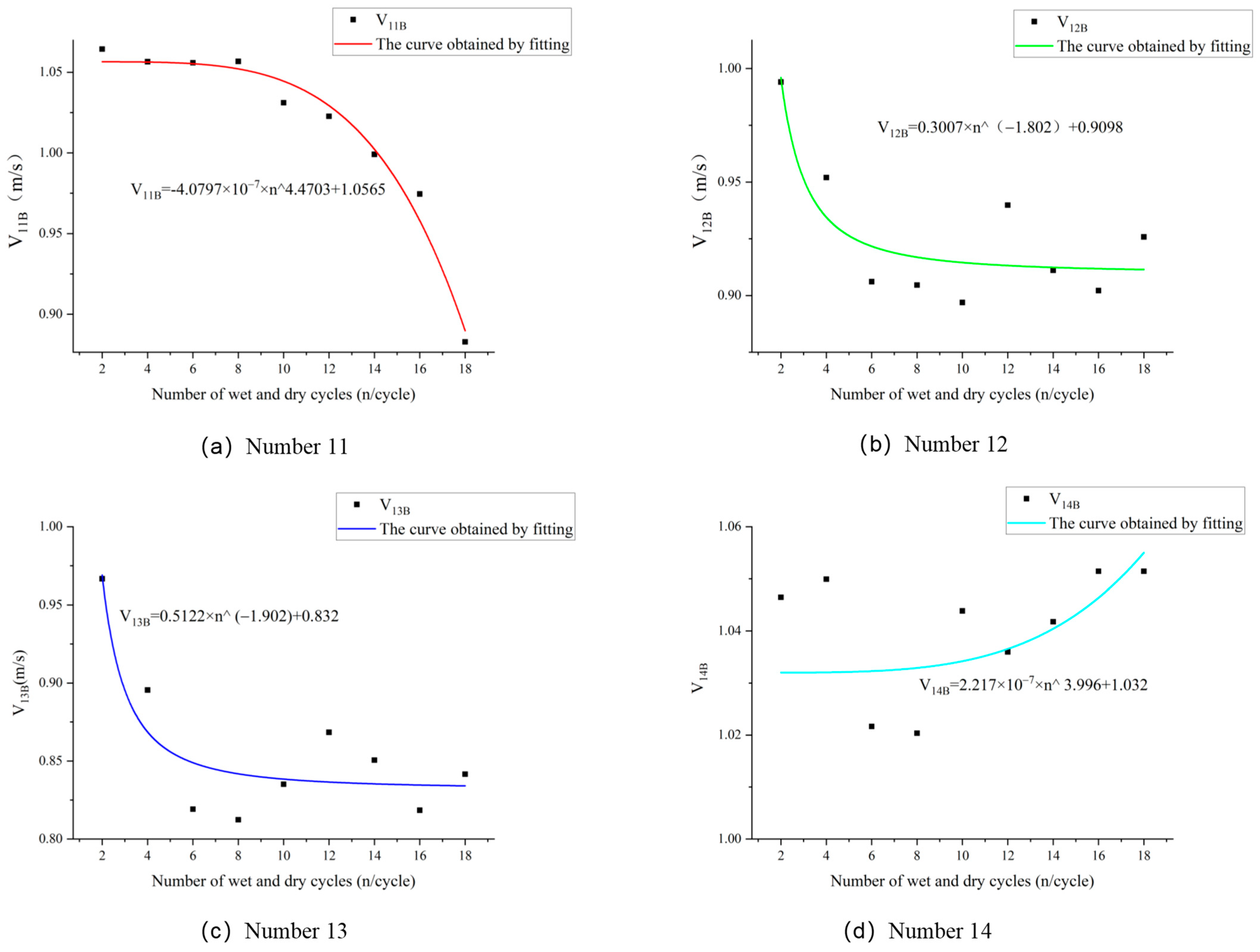

| Specimen Number | Fit a Function Model | R2 |

|---|---|---|

| 11 | H1(1, n) = -4.0797 × 10−7 × n^ 4.4703 + 1.0565 | 0.9767 |

| 12 | H1(1.5, n) = 0.3007 × n^ (−1.802) + 0.9098 | 0.7649 |

| 13 | H1(2, n) = 0.5122 × n^ (−1.902) + 0.832 | 0.7898 |

| 14 | H1(10, n) = 2.217 × 10−7 × n^ 3.996 + 1.032 | 0.5636 |

| Specimen Number | Fit a Function Model | R2 |

|---|---|---|

| 21 | H2(1, n) = 0.1461 × n^ (−1.58) + 0.9394 | 0.5734 |

| 22 | H2(1.5, n) = 0.1815 × n^ (−1.348) + 0.9115 | 0.4569 |

| 23 | H2(2, n) = 1.109 × 10−4 × n^ 2.288 + 0.9742 | 0.6945 |

| 24 | H2(10, n) = 1.325 × 10−4 × n^ 2.508 + 0.9869 | 0.9258 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, S.; Zhang, J.; Zhang, H.; Li, R.; Ao, T.; Cao, K. Experimental Study on Erosion Modeling of Architectural Red Sandstone under the Action of the Natural Environment. Buildings 2024, 14, 1168. https://doi.org/10.3390/buildings14041168

Zeng S, Zhang J, Zhang H, Li R, Ao T, Cao K. Experimental Study on Erosion Modeling of Architectural Red Sandstone under the Action of the Natural Environment. Buildings. 2024; 14(4):1168. https://doi.org/10.3390/buildings14041168

Chicago/Turabian StyleZeng, Shuisheng, Jun Zhang, Huanlin Zhang, Rutian Li, Tao Ao, and Kunpeng Cao. 2024. "Experimental Study on Erosion Modeling of Architectural Red Sandstone under the Action of the Natural Environment" Buildings 14, no. 4: 1168. https://doi.org/10.3390/buildings14041168