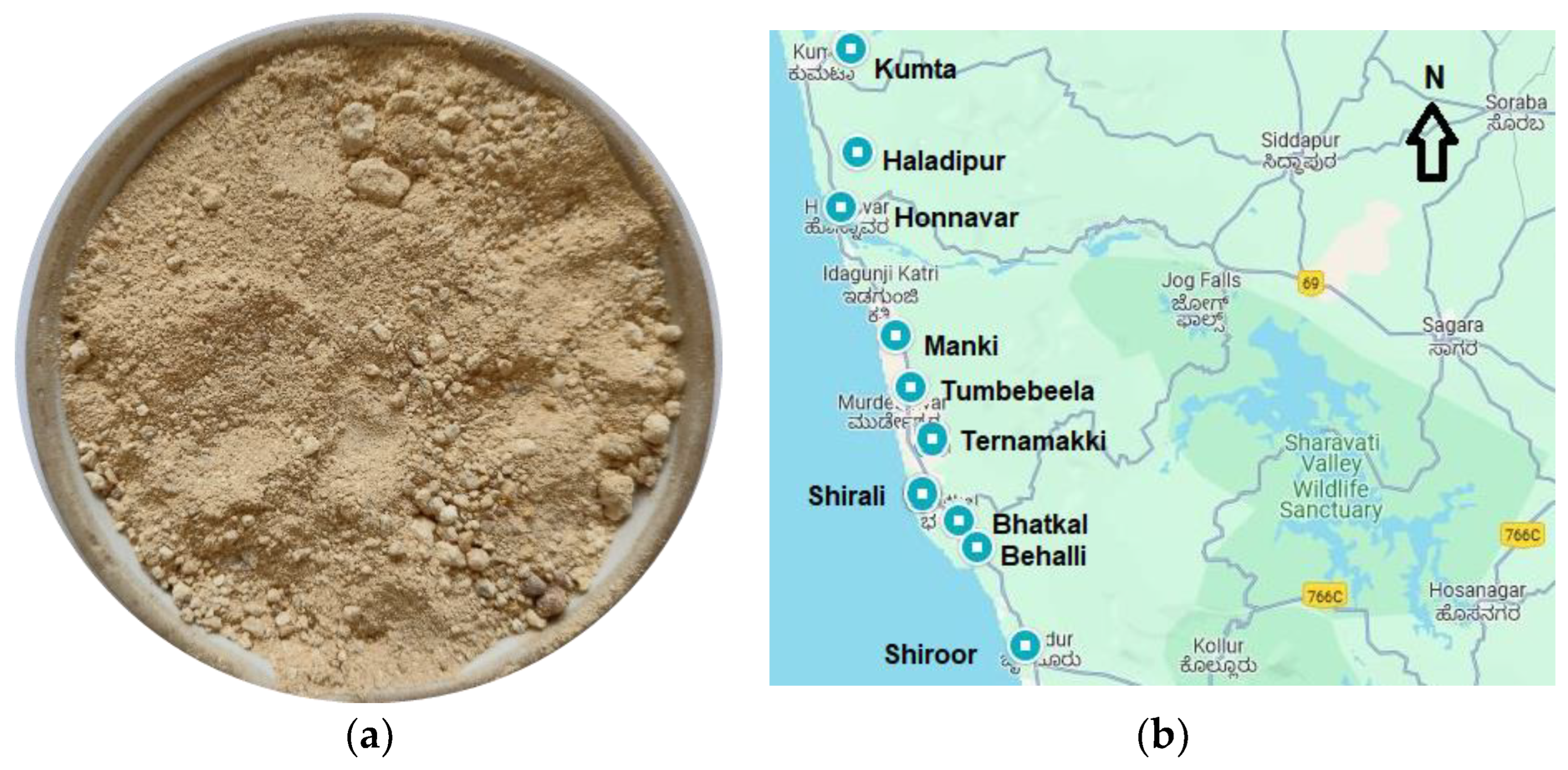

Correlation of Geotechnical and Mineralogical Properties of Lithomargic Clays in Uttara Kannada Region of South India

Abstract

1. Introduction

2. Materials and Methods

2.1. Geotechnical Characterization of Soil

2.2. Mineralogical Characterization of Soil

2.3. Correlation Analysis

3. Results and Discussion

3.1. Geotechnical Properties of Soil Samples

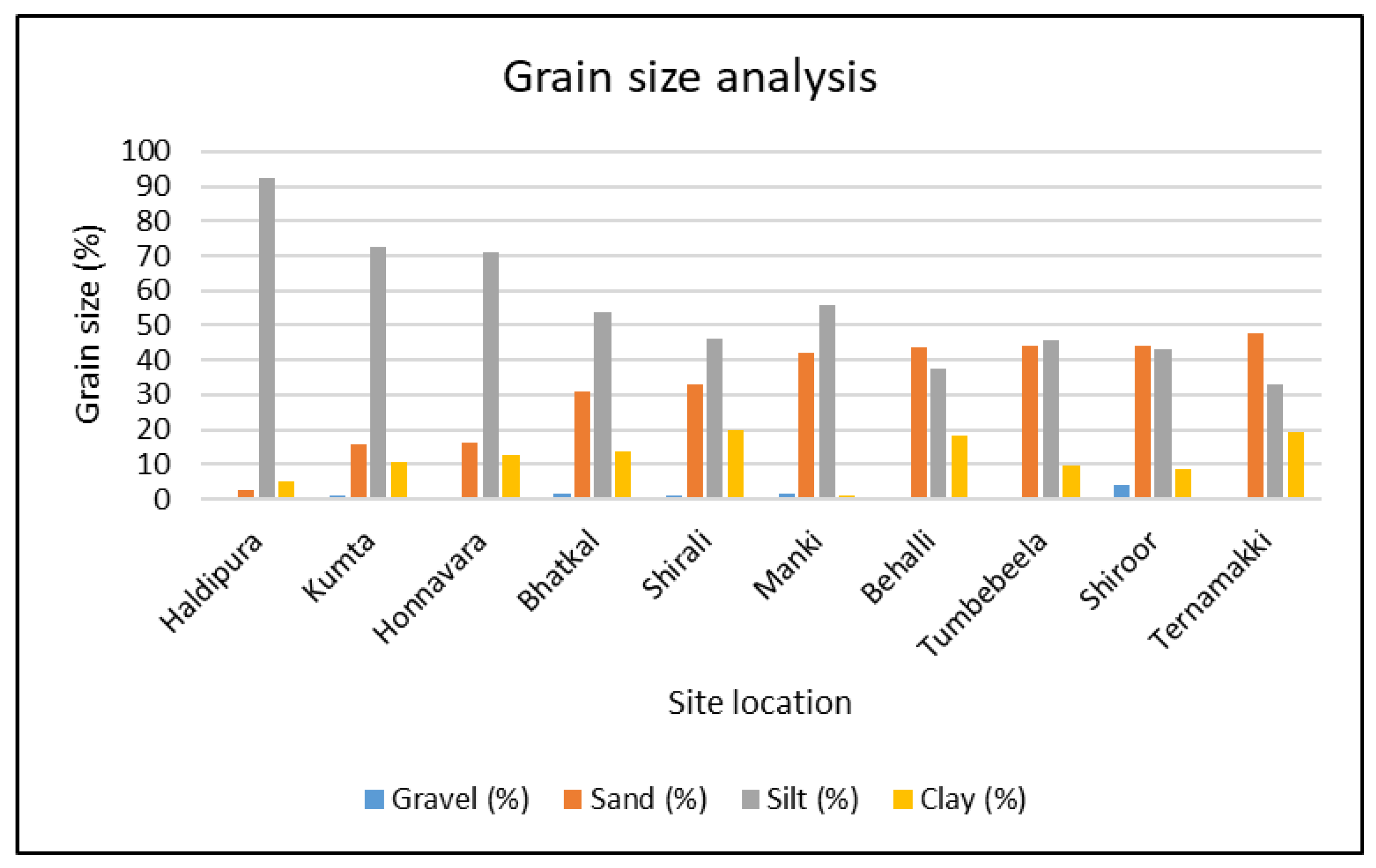

3.1.1. Index Properties

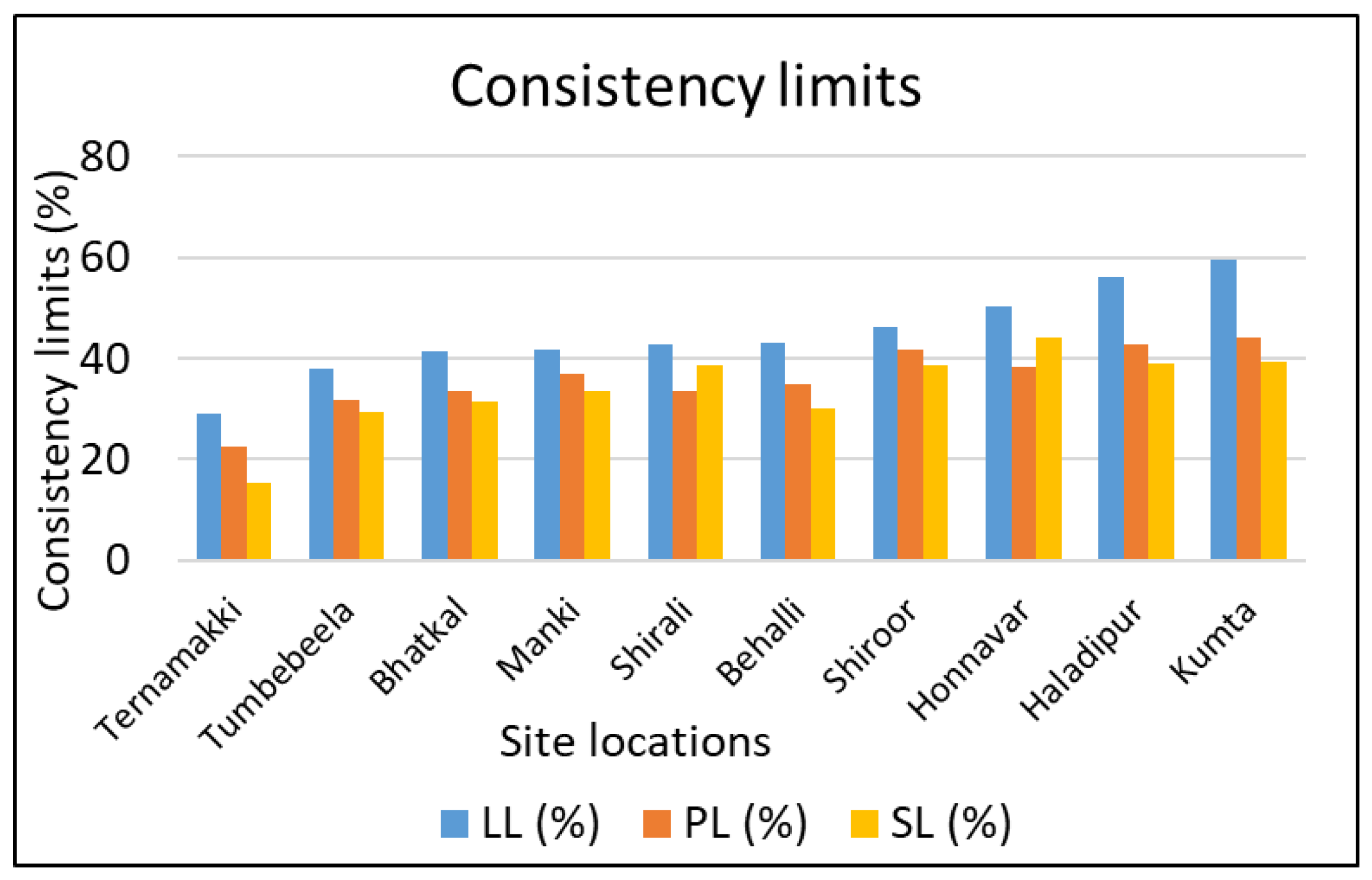

3.1.2. Consistency Limits of Soil Samples

3.1.3. Standard Proctor Compaction Test

3.1.4. Modified Proctor Compaction Test

3.1.5. Unconfined Compressive Strength Test (UCS)

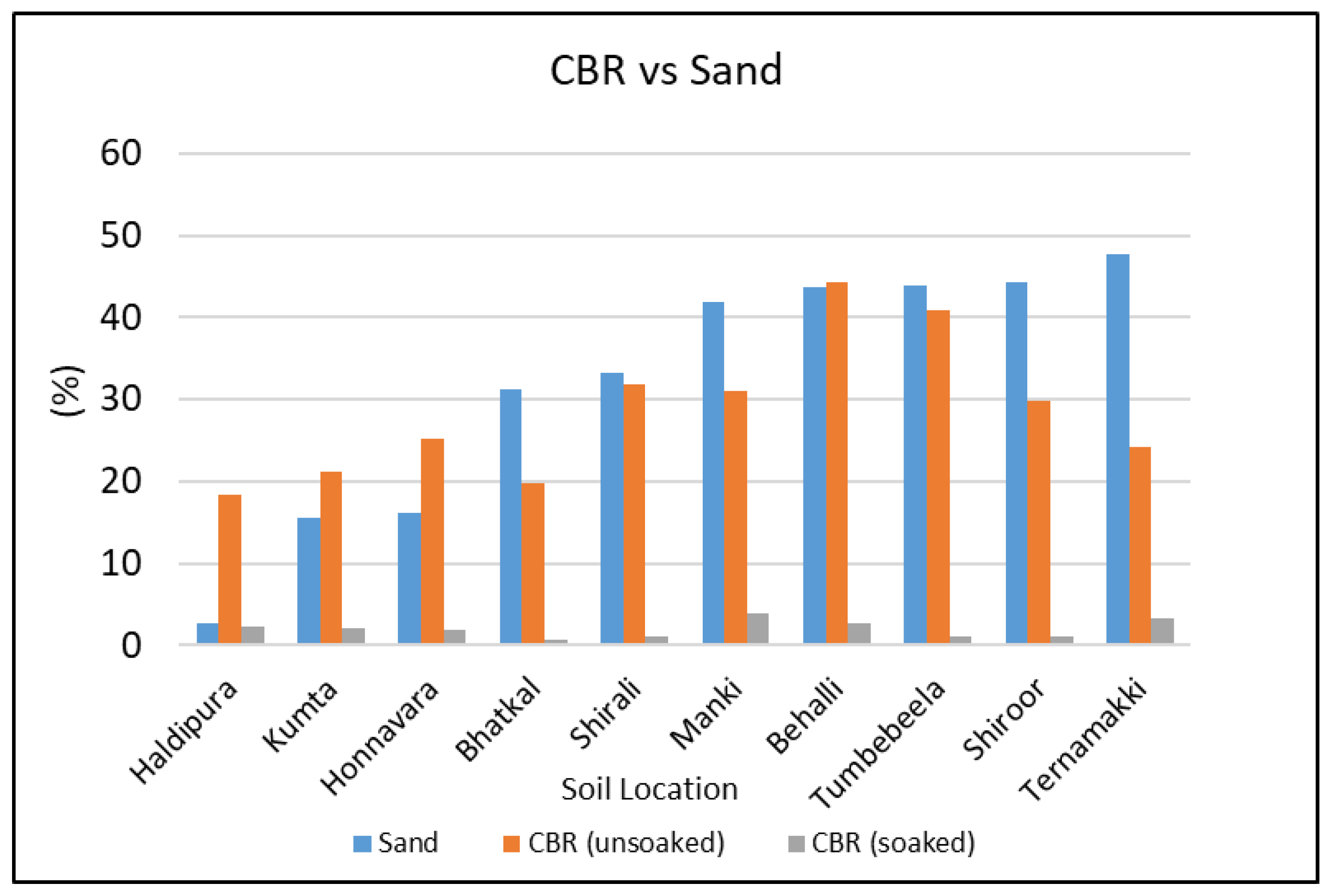

3.1.6. California Bearing Ratio (CBR) Test

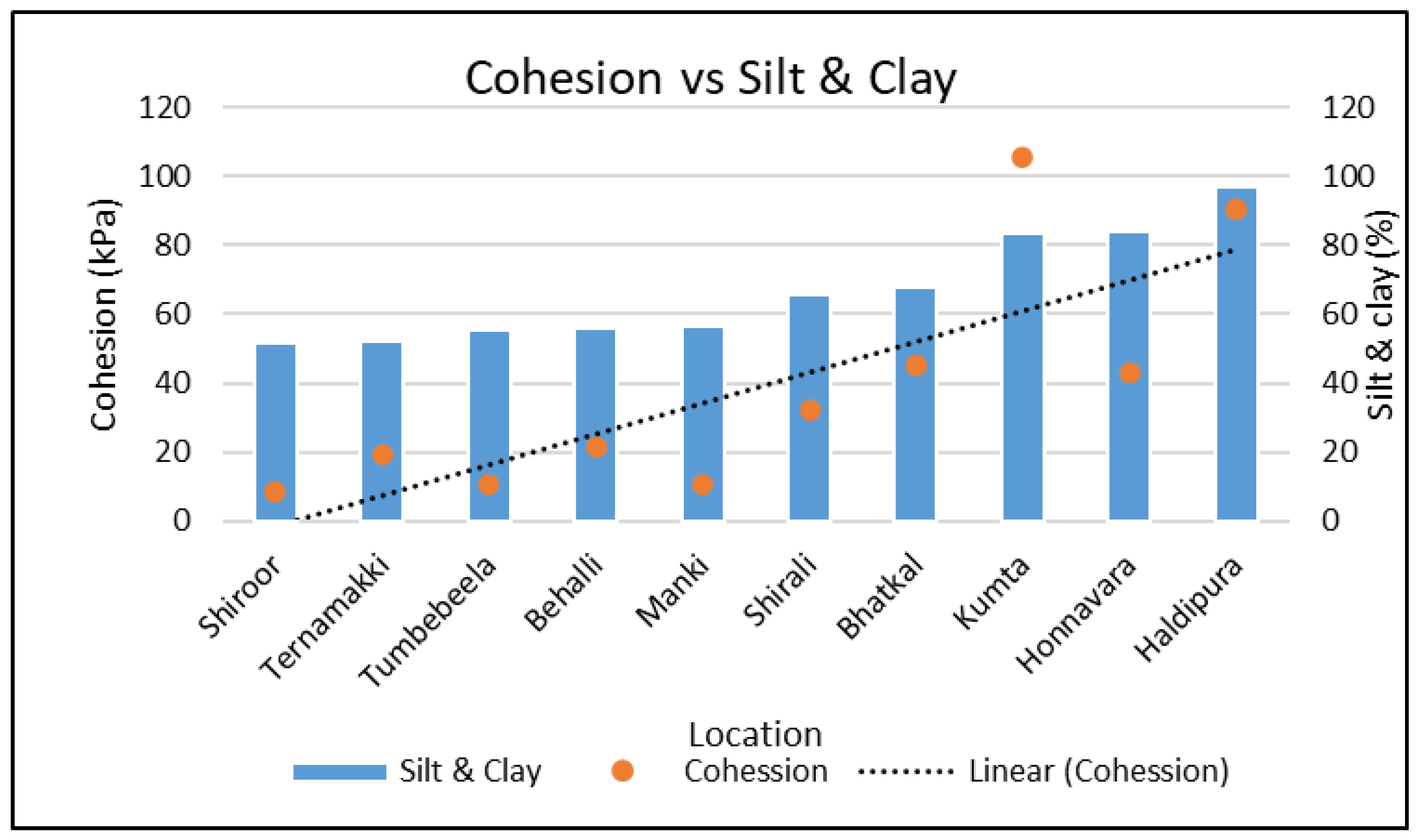

3.1.7. Triaxial Compression Test

3.2. Mineralogical Properties

3.3. Correlation of Geotechnical and Mineralogical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khandali, S.D.; Devaraju, T.C. Laterite-bauxite of Paduvari plateau, South Kanara, Karnataka State. J. Geol. Soc. India 1987, 30, 255–266. [Google Scholar]

- Nayak, D.; Sarvade, P.G.; Udaya Shankara, H.N.; Pai, J.B. Mineralogical Characterization of Lithomargic Clay Deposits along the Coastal Belt of Udupi Region of South India. J. Compos. Sci. 2023, 7, 170. [Google Scholar] [CrossRef]

- Bhagyashree; Udayashankar, H.N.; Sarvade, P.G.; Kavyashree. Correlation of Mineralogical and Geotechnical Properties of Laterite Soils of Coastal Karnataka, India. Civ. Eng. Archit. 2023, 11, 3334–3346. [Google Scholar] [CrossRef]

- Lakkimsetti, B.; Nayak, S. Experimental Investigation and Performance Evaluation of Lithomargic Clay Stabilized with Granulated Blast Furnace Slag and Calcium Chloride. Int. J. Geosynth. Ground Eng. 2022, 8, 12. [Google Scholar] [CrossRef]

- Amulya, S.; Ravi Shankar, A.U.; Praveen, M. Stabilisation of lithomargic clay using alkali-activated fly ash and ground granulated blast furnace slag. Int. J. Pavement Eng. 2020, 21, 1114–1121. [Google Scholar] [CrossRef]

- Nayak, S.; Sarvade, P.G. Effect of Cement and Quarry Dust on Shear Strength and Hydraulic Characteristics of Lithomargic Clay. Geotech. Geol. Eng. 2012, 30, 419–430. [Google Scholar] [CrossRef]

- Budihal, R.; Pujar, G. Major and trace elements geochemistry of laterites from the Swarnagadde plateau, Uttar Kannada district, Karnataka, India. J. Geosci. Geomat. 2018, 6, 12–20. Available online: http://pubs.sciepub.com/jgg/6/1/2 (accessed on 30 January 2024).

- Sekhar, D.C.; Nayak, S.; Preetham, H.K. Influence of Granulated Blast Furnace Slag and Cement on the Strength Properties of Lithomargic Clay. Indian Geotech. J. 2017, 47, 384–392. [Google Scholar] [CrossRef]

- Thomas, B.C.; Shivashankar, R.; Jacob, S.; Varghese, M.S. Erosion Studies on Lithomargic Clays. Indian Geotech. J. 2020, 50, 142–156. [Google Scholar] [CrossRef]

- Sarvade, P.G.; Nayak, D.; Sharma, A.; Gogoi, R.; Madhukar, S. Strength characteristics of randomly distributed coconut coir reinforced lithomargic clay. Int. J. Civ. Eng. Technol. 2017, 8, 1122–1134. [Google Scholar]

- Sarvade, P.G.; Nayak, D.; Sharma, A.; Gogoi, R.; Madhukar, S. Evaluation of strength characteristics of coconut coir mat reinforced lithomargic clay. Int. J. Civ. Eng. Technol. 2018, 9, 1168–1179. [Google Scholar]

- Narloch, P.; Woyciechowski, J.; Kotowski, J.; Wójcik, E. The effect of soil mineral composition on the compressive strength of cement stabilized rammed earth. Materials 2020, 13, 324. [Google Scholar] [CrossRef] [PubMed]

- Mason, B.; Carleton, B.M. Principles of Geochemistry; John Wiley & Sons: New York, NY, USA, 1982. [Google Scholar]

- Nayak, D.; Udayashankar, H.N.; Sarvade, P.G. Geotechnical Characterization of Lithomargic Clays of Uttara Kannada District, Karnataka. J. Xi’an Univ. Archit. Technol. 2021, 13, 1–21. [Google Scholar]

- Momade, F.; Gawu, S. Geochemical and Mineralogical Characteristics of Lithomargic Clay Types from Awaso Bauxite Deposit, Ghana: Implications for Possible Industrial Utilization. J. Sci. Technol. 2009, 29, 96–106. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behaviour; John Wiley & Sons: New York, NY, USA, 2005; Volume 3. [Google Scholar]

- El Swaify, S.A.; Ahmed, S.; Swindale, L.D. Effects of adsorbed cations on physical properties of tropical red earths and tropical black earths. J. Soil Sci. 1970, 21, 188–198. [Google Scholar] [CrossRef]

- Smiles, D.E.; Smith, C.J. A survey of the cation content of piggery effluents and some consequences of their use to irrigate soils. Soil Res. 2004, 42, 231–246. [Google Scholar] [CrossRef]

- IS 2720 Part-4; Grain Size Analysis. Bureau of Indian Standards: New Delhi, India, 1985.

- IS 2720, Part-5; Determination of Liquid Limit and Plastic Limit. Bureau of Indian Standards: New Delhi, India, 1985.

- IS 2720, Part-3; Determination of Specific Gravity. Bureau of Indian Standards: New Delhi, India, 1980.

- IS 2720, Part-7; Determination of Water Content-Density Relation Using Light Compaction. Bureau of Indian Standards: New Delhi, India, 1980.

- IS 2720, Part-6; Determination of Shrinkage Factors. Bureau of Indian Standards: New Delhi, India, 1972.

- Mshali, M.R.; Visser, A.T. Influence of mica on unconfined compressive strength of a cement-treated weathered granite gravel. J. S. Afr. Inst. Civ. Eng. 2012, 54, 71–77. [Google Scholar]

- Nayak, D.; Sarvade, P.G.; Udaya Shankara, H.N.; Kumar, M.P. Mineralogical Analysis of Lithomargic Clay Deposits along the Coastal Belt of Uttara Kannada Region in South India. J. Adv. Res. Appl. Sci. Eng. Technol. 2024, 39, 117–134. [Google Scholar] [CrossRef]

- Kurnaz, T.F.; Kaya, Y. The Performance Comparison of the Soft Computing Methods on the Prediction of Soil Compaction Parameters. Arab. J. Geosci. 2020, 13, 159. [Google Scholar] [CrossRef]

- Karimpour-Fard, M.; Machado, S.L.; Falamaki, A.; Carvalho, M.F.; Tizpa, P. Prediction of Compaction Characteristics of Soils from Index Test’s Results. Iran. J. Sci. Technol. 2019, 43, 231–248. [Google Scholar] [CrossRef]

| Location | Specific Gravity (-) | Dry Unit Weight (kN/m3) | Field Moisture Content (%) |

|---|---|---|---|

| Shiroor | 2.43 | 14.81 | 18.13 |

| Behalli | 2.38 | 14.71 | 18.20 |

| Bhatkal | 2.40 | 14.91 | 19.90 |

| Shirali | 2.34 | 14.81 | 26.44 |

| Ternamakki | 2.48 | 15.20 | 12.63 |

| Tumbebeela | 2.39 | 14.61 | 15.33 |

| Manki | 2.45 | 14.52 | 21.07 |

| Honnavar | 2.43 | 14.03 | 24.42 |

| Haladipur | 2.51 | 14.12 | 23.38 |

| Kumta | 2.59 | 14.42 | 32.10 |

| Location | IO | Mc | CC | AO | Vmt | Fo | Bt | Ms | Dzt | Gb | Sill | Ort | Mu | Ka | Ill | Qtz | Mnt |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shiroor | - | 21 | 1 | 2 | 8 | 2 | 8 | 11 | 4 | 4 | 3 | 6 | 2 | 10 | 11 | 1 | 6 |

| Behalli | 1 | 13.9 | 1 | 3 | 10.9 | 2 | 7.9 | 9.9 | 5 | 4 | 3 | 4 | 2 | 10.9 | 9.9 | 3 | 8.9 |

| Bhatkal | 0.3 | 13.3 | 2 | 2 | 15.3 | 2 | 5.1 | 8.2 | 6.1 | 3.1 | 2 | 3.1 | 2 | 14.3 | 12.2 | 2 | 7.1 |

| Shirali | 12.1 | 1 | 2 | 10.1 | 3 | 8.1 | 6.1 | 4 | 7.1 | 4 | 11.1 | 6.1 | 9.1 | 9.1 | 1 | 6.1 | |

| Ternamakki | - | 14.9 | 1 | 2 | 5 | 1 | 5 | 10.9 | 2 | 13.9 | 6.9 | 6.9 | 2 | 5.9 | 13.9 | 4 | 5 |

| Tumbebeela | - | 10.1 | 2 | 1 | 7.1 | 1 | 7.1 | 8.1 | 3 | 15.2 | 6.1 | 7.1 | 1 | 8.1 | 14.1 | 5.1 | 4 |

| Manki | 1 | 8.9 | 7.9 | 1 | 13.9 | 1 | 11.9 | 5.9 | 2 | 8.9 | 5.9 | 3 | 7.9 | 5.9 | 7.9 | 2 | 5 |

| Honnavar | 1 | 15.8 | 5 | 1 | 5.9 | 1 | 18.8 | 4 | 3 | 6.9 | 3 | 5 | 5.9 | 4 | 5 | 1 | 13.9 |

| Haladipur | - | 13 | 6 | 3 | 7 | 1 | 7 | 17 | 2 | 5 | 2 | 6 | 1 | 4 | 18 | 3 | 5 |

| Kumta | 1 | 10.8 | 5.9 | 2.9 | 12.7 | 2.9 | 4.9 | 6.9 | 4.9 | 6.9 | 2 | 5.9 | 2.9 | 10.8 | 9.8 | 2 | 6.9 |

| Property | Mineral | Positively Correlated | Negatively Correlated | Strength |

|---|---|---|---|---|

| Angle of internal friction | Microcline | Pos | Moderate | |

| Clay content | Calcite | Neg | Moderate | |

| Silt content | Calcite | Pos | Strong | |

| OMC (standard) | Calcite | Pos | Strong | |

| MDD (standard) | Calcite | Neg | Strong | |

| Sand content | Calcite | Neg | Moderate | |

| OMC (modified) | Gibbsite | Neg | Moderate | |

| MDD (modified) | Sillimanite | Pos | Moderate | |

| OMC (modified) | Sillimanite | Neg | Strong | |

| Liquid limit | Sillimanite | Neg | Moderate | |

| Plastic limit | Sillimanite | Neg | Moderate | |

| Cohesion | Sillimanite | Neg | Moderate | |

| Sand content | Sillimanite | Pos | Moderate | |

| MDD (standard) | Sillimanite | Pos | Moderate | |

| OMC (standard) | Sillimanite | Neg | Moderate | |

| Shrinkage limit | Quartz | Neg | Moderate |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nayak, D.; Sarvade, P.G.; Udayashankar, H.N.; Maddodi, B.S.; Kumar, M.P. Correlation of Geotechnical and Mineralogical Properties of Lithomargic Clays in Uttara Kannada Region of South India. Geosciences 2024, 14, 92. https://doi.org/10.3390/geosciences14040092

Nayak D, Sarvade PG, Udayashankar HN, Maddodi BS, Kumar MP. Correlation of Geotechnical and Mineralogical Properties of Lithomargic Clays in Uttara Kannada Region of South India. Geosciences. 2024; 14(4):92. https://doi.org/10.3390/geosciences14040092

Chicago/Turabian StyleNayak, Deepak, Purushotham G. Sarvade, H. N. Udayashankar, Balakrishna S. Maddodi, and M. Prasanna Kumar. 2024. "Correlation of Geotechnical and Mineralogical Properties of Lithomargic Clays in Uttara Kannada Region of South India" Geosciences 14, no. 4: 92. https://doi.org/10.3390/geosciences14040092

APA StyleNayak, D., Sarvade, P. G., Udayashankar, H. N., Maddodi, B. S., & Kumar, M. P. (2024). Correlation of Geotechnical and Mineralogical Properties of Lithomargic Clays in Uttara Kannada Region of South India. Geosciences, 14(4), 92. https://doi.org/10.3390/geosciences14040092