A Novel Polymer Concrete Composite with GFRP Waste: Applications, Morphology, and Porosity Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polymer Concrete Composite Constituents and Manufacturing Method

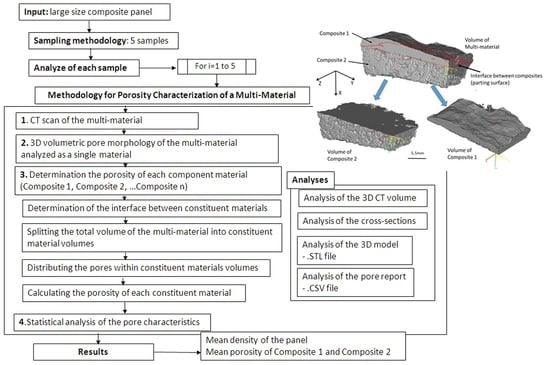

2.2. Method for Determining the Porosity of a Large Size Panel Comprised of a Novel Multi-Material Composite

- CT scan of polymer concrete composite samples;

- A 3D volumetric pore morphology of the multi-material composite analyzed as a single material;

- Determination of the porosity of each component material;

- Statistical analysis of pore characteristics.

- Determination of the interface between the constituent materials;

- Splitting the total volume of the multi-material into constituent material volumes;

- Distributing the pores within the constituent material volumes;

- Calculating the porosity of each constituent material.

2.3. Method for Determining the Panel Density

- Using five samples from gathered from the large panel based on the sampling methodology:

- Find the volumes of the samples using CT analysis;

- Weigh the samples using a precision digital scale (Figure 4b);

- Calculate the density of each sample;

- Determine the mean density of the panel.

3. Results and Discussions

3.1. Porosity Analysis of the Multi-Material Composite

- Based on the numerical CT results, the following parameters were calculated (Table 2):

- Total volume of the multi-material composite (Vmat);

- Volume of composites 1 and 2 (Vmat 1 and Vmat 2);

- Pores volume (Vpore1 and Vpore2) within composites 1 and 2;

- Porosity of composites 1 (Pmat1) and 2 (Pmat2).

3.2. Statistical Analysis of the Pore Characteristics

- Few pores having a regular shape (Sp > 0.5);

- Most of the pores having an irregular shape (0.2 < Sp < 0.5);

- Very few pores having an elongated shape (Sp < 0.2).

3.3. Microstructure Analysis

4. Conclusions

- The density of the new material proposed is 33.46% lower than that of the marble used as a datum model. The panel mass for the datum model (marble) was 15 kg, whereas the measured mass of the proposed material was 9.3 kg;

- The ornamental panels used for building cladding must have a pleasant appearance, yet also have the lowest possible mass and best possible resistance to external factors. A further study will investigate the mechanical characteristics of the proposed material;

- The proposed polymer concrete composite includes a large amount of GFRP waste (30%), and thus helps to protect the environment with regards to sustainable development;

- The new methodology proposed for CT analysis indicated results with a mean value of 0.146% for the porosity of composite 1 and 31.3% for composite 2. The porosity of composite 2 of the proposed multi-material offers advantages for building construction, such as being a lightweight material and providing good adhesive connection abilities. The porosity of composite 1 was observed as being lower than the porosity of the marble;

- The mean porosity of a large panel can be obtained as an arithmetic mean of the determined porosities across all five samples cut from the panel, based on a sampling method;

- The homogeneous distribution of the pores within the multi-material composite for all samples was shown. Most pores detected by CT analysis were shown to be of an irregular shape, which was later confirmed by microstructure analysis;

- The CT analysis only focused on the porosity investigation. The constituents of the composite material were investigated based only on SEM analysis. The surface morphology indicates constituents in a homogenous material, where a good connection between the surface layer material and structural composite material was detected.

5. Patent

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ribeiro, M.C.S.; Dinis, M.L.; Castro, A.C.M.; Fiúza, A.; Ferreira, A.J.M.; Meixedo, J.P.; Alvim, M.R. On the recyclability of glass fiber reinforced thermoset polymeric composites towards the sustainability of polymers’ industry. Int. J. Waste Resour. 2016, 6. [Google Scholar] [CrossRef] [Green Version]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61. [Google Scholar] [CrossRef] [Green Version]

- Meira Castro, A.C.; Ribeiro, M.C.S.; Santos, J.; Meixedo, J.P.; Silva, F.J.G.; Fiúza, A.; Dinis, M.L.; Alvim, M.R. Sustainable waste recycling solution for the glass fibre reinforced polymer composite materials industry. Con. Build. Mat. 2013, 45, 87–94. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, S.; Umar, A.; Masood, A.; Gupta, N.; Iqbal, M. Properties of normal concrete, self-compacting concrete and glass fibre-reinforced self-compacting concrete: An experimental study. Plast. Impact Mech. 2017, 173, 807. [Google Scholar] [CrossRef]

- Aliabdo, A.; Abd Elmoaty, A.; Aboshama, A. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866. [Google Scholar] [CrossRef]

- Shokrieh, M.; Rezvani, S.; Mosalmani, R. Mechanical behavior of polyester polymer concrete under low strain rate loading conditions. Polym. Test. 2017, 63, 596. [Google Scholar] [CrossRef]

- Zegardło, B.; Szeląg, M.; Ogrodnik, P.; Bombik, A. Physico-mechanical properties and microstructure of polymer concrete with recycled glass aggregate. Materials 2018, 11, 1213. [Google Scholar] [CrossRef] [Green Version]

- Sathiyamurthy, S.; Syed Abu Thaheer, A.; Jayabal, S. Mechanical behaviours of calcium carbonate impregnated short coir fibre-reinforced polyester composites. Proc. IMechE Part L J. Materials Des. Appl. 2012, 226, 52–60. [Google Scholar] [CrossRef]

- Sultana, R.; Akter, R.; Alam, M.Z.; Qadir, M.R.; Begum, M.H.A.; Gafur, M.A. Preparation and characterization of sand reinforced polyester composites. IJET IJENS 2013, 13, 111–118. [Google Scholar]

- Yildizel, S.A. Mechanical performance of glass fiber reinforced composites made with gypsum, expanded perlite and silica sand. Rom. J. Mater. 2018, 48, 229–235. [Google Scholar]

- ASTM D4404-18, Standard Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion Porosimetry; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 25 January 2020). [CrossRef]

- Kritikos, M.; Buranský, I.; Buranská, E.; Mojžiš, M. Evaluation of accuracy of seamless steel tube scanning by industrial computed tomography. MATEC Web Conf. 2019, 299, 04009. [Google Scholar] [CrossRef] [Green Version]

- ASTM E1441-19, Standard Guide for Computed Tomography (CT); ASTM International: West Conshohocken, PA, USA, 2019; Available online: www.astm.org (accessed on 27 January 2020). [CrossRef]

- Carmignato, S. Accuracy of industrial computed tomography measurements: Experimental results from an international comparison. CIRP Ann. Manuf. Technol. 2012, 61, 491–494. [Google Scholar] [CrossRef]

- Kruth, J.P.; Bartscher, M.; Carmignato, S.; Schmitt, R.; De Chiffre, L.; Weckenmann, A. Computed tomography for dimensional metrology. CIRP Ann. Manuf. Technol. 2011, 60, 821–842. [Google Scholar] [CrossRef]

- De Chiffre, L.; Carmignato, S.; Kruth, J.P.; Schmitt, R.; Weckenmann, A. Industrial applications of computed tomography. CIRP Ann. Manuf. Technol. 2014, 63, 655. [Google Scholar] [CrossRef]

- Villarraga-Gómez, H.; Lee, C.B.; Smith, S.T. Dimensional metrology with X-ray CT: A comparison with CMM measurements on internal features and compliant structures. Precis. Eng. 2018, 51, 291–307. [Google Scholar] [CrossRef]

- Garcea, S.C.; Wang, Y.; Withers, P.J. X-ray computed tomography of polymer composites. Compos. Sci. Technol. 2018, 156, 305. [Google Scholar] [CrossRef]

- Crupi, V.; Epasto, G.; Guglielmino, E. Computed tomography analysis of damage in composites subjected to impact loading. Frat. Integrità Strutt. 2011, 17, 32–41. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Chen, F. Defects characterization in CFRP using X-ray computed tomography. Polym. Polym. Compos. 2016, 24, 149. [Google Scholar] [CrossRef]

- Liaptsis, G.; Clarke, A.L.; Nithiarasu, P. High resolution X-ray volumetric inspection of large planar amples using SART based computed laminography. In In Proceedings of the 56th Annual Conference of The British Institute of Non-Destructive Testing, Telford, UK, 5–7 September 2017. [Google Scholar]

- Grębowski, K.; Rucka, M.; Wilde, K. Non-destructive testing of a sport tribune under synchronized crowd-induced excitation using vibration analysis. Materials 2019, 12, 2148. [Google Scholar] [CrossRef] [Green Version]

- Nikishkov, Y.; Airoldi, L.; Makeev, A. Measurement of voids in composites by X-ray Computed Tomography. Compos. Sci. Technol. 2013, 89, 89–97. [Google Scholar] [CrossRef]

- Guessasma, S.; Nouri, H.; Roger, F. Microstructural and mechanical implications of microscaled assembly in droplet-based multi-material additive manufacturing. Polymers 2017, 9, 372. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sabău, E.; Bâlc, N.; Bere, P. Method and composite material for ornamental synthetic panels manufacturing. RO 130062, International Classification C04B 14/36 (2006.01), 2017. [Google Scholar]

- Sabău, E. Recycling of polymeric composite materials. In Product Lifecycle Management—Terminology and Applications; Udroiu, R., Bere, P., Eds.; IntechOpen: London, UK, 2018; pp. 103–121. [Google Scholar] [CrossRef] [Green Version]

- Wahab, G.M.A.; Gouda, M.; Ibrahim, G. Study of physical and mechanical properties for some of Eastern Desert dimension marble and granite utilized in building decoration. Ain Shams Eng. J. 2019, 10, 907. [Google Scholar] [CrossRef]

- Krolczyk, J.B.; Legutko, S. Devices and equipment for mixing granular materials in industry. Appl. Mech. Mater. 2015, 809–810, 742–747. [Google Scholar] [CrossRef]

- VGSTUDIO. Available online: https://www.volumegraphics.com/de/produkte/vgstudio.html (accessed on 2 May 2019).

- Minitab. Getting Started with Minitab 17. Available online: https://www.minitab.com (accessed on 15 May 2019).

- Udroiu, R.; Braga, I.C.; Nedelcu, A. Evaluating the quality surface performance of additive manufacturing systems: Methodology and a material jetting case study. Materials 2019, 12, 995. [Google Scholar] [CrossRef] [Green Version]

- Plessis, A.; Sperling, P.; Beerlink, A.; Tshabalala, L.; Hoosain, S.; Mathe, N.; Rouxa, S.G. Standard method for micro CT-based additive manufacturing quality control 2: Density measurement. MethodsX 2018, 5, 1117. [Google Scholar] [CrossRef]

- Chung, S.Y.; Lehmann, C.; Abd Elrahman, M.; Stephan, D. Pore characteristics and their effects on the material properties of foamed concrete evaluated using micro-CT images and numerical approaches. Appl. Sci. 2017, 7, 550. [Google Scholar] [CrossRef] [Green Version]

- Vecchio, I.; Schladitz, K.; Godehardt, M.; Heneka, M.J. Geometric Characterization of Particles in 3D with an Application to Technical Cleanliness; Fraunhofer-Institut Fur Techno- Und Wirtschaftsmathematik: Kaiserslautern, Germany, 2011; pp. 1–33. [Google Scholar]

| Voxel Size (μm) | 88 |

|---|---|

| Resolution | 1 k (1024 × 1024) |

| Number of projection | 1600 |

| Cu filter (mm) | 0 |

| Voltage (kV) | 160 |

| Current (μA) | 550 |

| Integration time (ms) | 1000 |

| Gain | 8× |

| Position from source (mm) | 330 |

| Measurement time (min) | 30 |

| Scatter radiation | off |

| Panel 1 | |||||||

|---|---|---|---|---|---|---|---|

| Sample | S1 | S2 | S3 | S4 | S5 | Mean | SD 1 |

| Vmulti_mat [mm3] | 7770 | 8350 | 7250 | 7180 | 7480 | 7606 | - |

| V mat 1 [mm3] | 2206 | 3156 | 2283 | 2445 | 2897 | 2597.4 | - |

| V mat 2 [mm3] | 5564 | 5194 | 4967 | 4735 | 4583 | 5008.6 | - |

| V pore 1 [mm3] | 3.93 | 4.01 | 2.67 | 2.85 | 5.39 | 3.77 | |

| V pore 2 [mm3] | 1890 | 1485 | 1443 | 1561 | 1494 | 1581.8 | - |

| P mat 1 [%] | 0.178% | 0.127% | 0.117% | 0.117% | 0.186% | 0.145% | 0.0003 |

| P mat 2 [%] | 33.97% | 28.59% | 29.05% | 32.97% | 32.60% | 31.44% | 0.024 |

| Mmulti-mat [g] | 13.335 | 15.031 | 12.536 | 12.216 | 12.041 | 13.032 | - |

| ρmulti-mat [g/cm3] | 1.716 | 1.8 | 1.729 | 1.701 | 1.730 | 1.735 | 0.038 |

| Samples | S1 | S2 | S3 | S4 | S5 | Mean | SD 1 |

|---|---|---|---|---|---|---|---|

| Panel 2 | |||||||

| P mat 1 [%] | 0.171% | 0.100% | 0.113% | 0.187% | 0.132% | 0.141% | 0.0003 |

| P mat 2 [%] | 31.49% | 28.62% | 33.92% | 30.81% | 29.64% | 30.90% | 0.0201 |

| ρmulti-mat [g/cm3] | 1.775 | 1.725 | 1.745 | 1.718 | 1.734 | 1.739 | 0.0223 |

| Panel 3 | |||||||

| P mat 1 [%] | 0.177% | 0.107% | 0.119% | 0.154% | 0.209% | 0.153% | 0.00041 |

| P mat 2 [%] | 33.19% | 28.44% | 31.96% | 33.34% | 30.86% | 31.56% | 0.02013 |

| ρmulti-mat [g/cm3] | 1.73 | 1.777 | 1.71 | 1.74 | 1.759 | 1.743 | 0.0258 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabău, E.; Udroiu, R.; Bere, P.; Buranský, I.; Miron-Borzan, C.-Ş. A Novel Polymer Concrete Composite with GFRP Waste: Applications, Morphology, and Porosity Characterization. Appl. Sci. 2020, 10, 2060. https://doi.org/10.3390/app10062060

Sabău E, Udroiu R, Bere P, Buranský I, Miron-Borzan C-Ş. A Novel Polymer Concrete Composite with GFRP Waste: Applications, Morphology, and Porosity Characterization. Applied Sciences. 2020; 10(6):2060. https://doi.org/10.3390/app10062060

Chicago/Turabian StyleSabău, Emilia, Razvan Udroiu, Paul Bere, Ivan Buranský, and Cristina-Ştefana Miron-Borzan. 2020. "A Novel Polymer Concrete Composite with GFRP Waste: Applications, Morphology, and Porosity Characterization" Applied Sciences 10, no. 6: 2060. https://doi.org/10.3390/app10062060