Rheological Behavior and Sensitivity of Wood-Derived Bio-Oil Modified Asphalt Binders

Abstract

:Featured Application

Abstract

1. Introduction

2. Objective

- (1)

- To develop a new, environmentally friendly, and sustainable asphalt material for road engineering.

- (2)

- To systematically study the high-temperature performance of bio-asphalt binders.

- (3)

- To determine the changes of complex modulus and rutting factors of bio-asphalts at a wide range of loading frequencies.

3. Materials and Test Program

3.1. Materials and Preparation of Bio-Asphalt Binder

3.1.1. Materials

3.1.2. Preparation of Bio-Asphalt Binders

3.2. Test methods and Master Curve Generation Method

3.2.1. Conventional Test Method

3.2.2. Temperature Sweep Test Method

3.2.3. Frequency Sweep Test Method

3.2.4. Master Curve Generation Method

3.2.5. Fourier-Transform Infrared Spectroscopy

4. Results and Discussion

4.1. Conventional Tests

4.2. Temperature Sweep Test

4.3. Temperature Sensitivity Analysis

4.4. Frequency Sweep Test

4.5. Master Curve Generation

4.6. Functional Group Compositions Analysis

5. Conclusions

- (1)

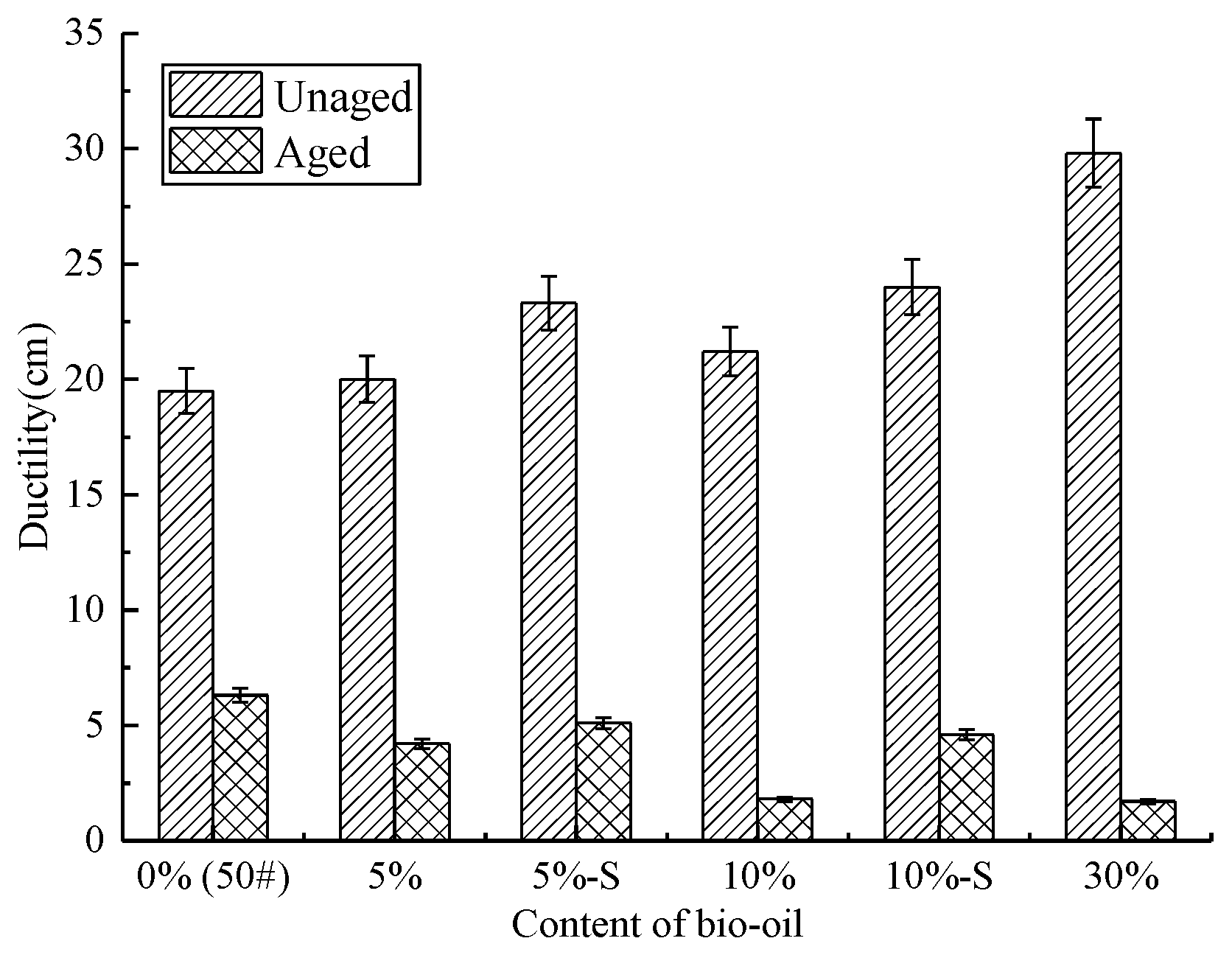

- With an increase of bio-oil content, penetration and ductility of unaged bio-asphalt increased gradually; the anti-cracking performance increased slightly; the softening point decreased, while the anti-rutting ability of unaged bio-asphalt decreased. For the RTFO-aged asphalt, the residual penetration ratio and the softening point difference were large, indicating that the bio-asphalt underwent a certain degree of aging after heating. The content of bio-oil had a significant effect on the mass loss of the bio-asphalt.

- (2)

- For the unaged and RTFO-aged bio-asphalts with 5% bio-oil, 5%-S, and 10%-S, the results indicated that the penetration, softening point, ductility, residual penetration ratio, mass loss, and other indicators, could meet the requirements of 50# grade asphalt.

- (3)

- The phase angle, complex modulus, and rutting factors decreased gradually with the increase of temperature for the unaged and RTFO-aged asphalts, which indicated that the high-temperature performances of bio-asphalt decreased with increasing temperature. The sequence of the phase angle, complex modulus, and rutting factors with different contents of bio-oil showed different changes, which were caused by the aging of the bio-oil.

- (4)

- The temperature sensitivity of both the unaged and RTFO-aged asphalts did not display regularity. The temperature sensitivity of unaged bio-asphalt was lower than that of the matrix asphalt. When the bio-oil content was higher than 10%, the temperature sensitivity of RTFO-aged bio-asphalt was higher than that of the matrix asphalt. The temperature sensitivity of RTFO-aged bio-asphalt with 5% content bio-oil was the smallest.

- (5)

- According to the frequency sweep test, the phase angle, storage modulus, loss modulus, and complex modulus of the unaged and RTFO-aged bio-asphalts and the matrix asphalt changed greatly with the change of frequency, at the lower frequency. When the frequency was greater than 5Hz, the viscoelastic curve stabilized gradually. As the temperature increased, the phase angle increased gradually, and the storage modulus, the loss modulus, and the complex modulus decreased gradually, while the viscous component of the bio-asphalt increased. This was consistent with the results of the temperature sweep.

- (6)

- According to the mater curve analysis, the complex modulus and rutting factors of bio-asphalt with 5% content bio-oil and 50# matrix asphalt increased with the increase of frequency, from the low frequency to the high-frequency range. Unaged bio-asphalt with 5% bio-oil content in the lower frequency range had considerable rutting resistance compared to the matrix asphalt. In contrast, at the higher frequency range, the complex modulus and rutting factors of bio-asphalt with 5% bio-oil were lower than those of the 50# base asphalt, which was superior to matrix asphalt in low-temperature anti-cracking performance. The RTFO-aged bio-asphalt with 5% bio-oil had a higher resistance to rutting than the matrix asphalt at the low and high-frequency ranges.

- (7)

- Chemical reactions occurred when the 50# base asphalt was mixed with bio-oil.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Bostancioğlu, M.; Oruç, Ş. Effect of furfural-derived thermoset furan resin on the high-temperature performance of bitumen. Road Mater. Pavement Des. 2014, 16, 227–237. [Google Scholar] [CrossRef]

- Cavaca, L.A.S.; Afonso, C.A.M. Oleuropein: A Valuable Bio-Renewable Synthetic Building Block. Eur. J. Org. Chem. 2018, 2018, 581–589. [Google Scholar] [CrossRef]

- Pereira, P.; Pais, J. Main flexible pavement and mix design methods in Europe and challenges for the development of an European method. J. Traffic Transp. Eng. Engl. Ed. 2017, 4, 316–346. [Google Scholar] [CrossRef]

- Mohammad, L.; Elseifi, M.; Cooper, S.; Challa, H.; Naidoo, P. Laboratory Evaluation of Asphalt Mixtures That Contain Biobinder Technologies. Transp. Res. Rec. J. Transp. Res. Board 2013, 2371, 58–65. [Google Scholar] [CrossRef]

- Cuadri, A.A.; García-Morales, M.; Navarro, F.J.; Partal, P. Processing of bitumens modified by a bio-oil-derived polyurethane. Fuel 2014, 118, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; You, Z.; Dai, Q. Performance evaluation of asphalt binder modified by bio-oil generated from waste wood resources. Int. J. Pavement Res. Technol. 2013, 6, 431–439. [Google Scholar]

- Fini, E.H.; Al-Qadi, I.L.; You, Z.; Zada, B.; Mills-Beale, J. Partial replacement of asphalt binder with bio-binder: Characterisation and modification. Int. J. Pavement Eng. 2012, 13, 515–522. [Google Scholar] [CrossRef]

- Fini, E.H.; Hosseinnezhad, S.; Oldham, D.J.; Chailleux, E.; Gaudefroy, V. Source dependency of rheological and surface characteristics of bio-modified asphalts. Road Mater. Pavement Des. 2016, 18, 408–424. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical Characterization of Biobinder from Swine Manure: Sustainable Modifier for Asphalt Binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Fini, E.H.; Oldham, D.J.; Abu-Lebdeh, T. Synthesis and Characterization of Biomodified Rubber Asphalt: Sustainable Waste Management Solution for Scrap Tire and Swine Manure. J. Environ. Eng. 2013, 139, 1454–1461. [Google Scholar] [CrossRef]

- Fini, E.H.; Yang, S.-H.; Xiu, S. Characterization and Application of Manure-Based Bio-binder in Asphalt Industry. Transp. Res. Board 2010, 2010, 10–2871. [Google Scholar]

- Mills-Beale, J.; You, Z.; Fini, E.; Zada, B.; Lee, C.H.; Yap, Y.K. Aging Influence on Rheology Properties of Petroleum-Based Asphalt Modified with Biobinder. J. Mater. Civ. Eng. 2014, 26, 358–366. [Google Scholar] [CrossRef]

- Raouf, M.; Williams, R. Temperature and Shear Susceptibility of a Nonpetroleum Binder as a Pavement Material. Transp. Res. Rec. J. Transp. Res. Board 2010, 2180, 9–18. [Google Scholar] [CrossRef]

- Raouf, M.A.; Williams, R.C. Determination of Pre-Treatment Procedure Required for Developing Bio-Binders from Bio-Oils. In Proceedings of the 2009 Mid-Continent Transportation Research Symposium, Ames, IA, USA, 20–21 August 2009. [Google Scholar]

- Tang, S.; Williams, R.C. Antioxidant Effect of Bio-Oil Additive ESP on Asphalt Binder. In Proceedings of the 2009 Mid-Continent Transportation Research Symposium, Ames, IA, USA, 20–21 August 2009. [Google Scholar]

- Yang, S.H.; Suciptan, T. Rheological behavior of Japanese cedar-based biobinder as partial replacement for bituminous binder. Constr. Build. Mater. 2016, 114, 127–133. [Google Scholar] [CrossRef]

- Wang, H.; Gao, J.; You, Z.; Tian, Y. Advances in bio-binder application on road pavement. J. Wu Han Univ. Technol. 2014, 36, 57–60. (In Chinese) [Google Scholar]

- Gao, J.; Wang, H.; You, Z.; Yang, X. Gray relational entropy analysis of high temperature performance of bio-asphalt binder and its mixture. Int. J. Pavement Res. Technol. 2018. [Google Scholar] [CrossRef]

- Wang, H.; Gao, J.; Zhao, X.; You, Z.; Tian, Y. Rheological Properties on Bio-binder based on DSR and RV. J. Hu Nan Univ. Nat. Sci. 2015, 42, 26–33. (In Chinese) [Google Scholar]

- He, M.; Cao, D.; Zhang, H.; Song, Z.; Wu, X. Research on Conventional Performance of Modified Bio-Asphalt. J. Highw. Transp. Res. Dev. Engl. Ed. 2015, 9, 1–6. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Hasan, M.R.M. Research on properties of bio-asphalt binders based on time and frequency sweep test. Constr. Build. Mater. 2018, 160, 786–793. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Jiang, X.; You, Z.; Yang, X.; Ye, M. Thermal Storage Stability of Bio-Oil Modified Asphalt. J. Mater. Civ. Eng. 2018, 30, 04018054. [Google Scholar] [CrossRef]

- Li, H.; Xia, S.; Li, Y.; Ma, P.; Zhao, C. Stability evaluation of fast pyrolysis oil from rice straw. Chem. Eng. Sci. 2015, 135, 258–265. [Google Scholar] [CrossRef]

- Alsbou, E.; Helleur, B. Accelerated Aging of Bio-oil from Fast Pyrolysis of Hardwood. Energy Fuels 2014, 28, 3224–3235. [Google Scholar] [CrossRef]

| Content of Bio-Oil | Content of Bio-Oil | Mean Difference | Standard Error | Significance | 95% Confidence Interval | |

|---|---|---|---|---|---|---|

| Lower Limit | Upper Limit | |||||

| 0% | 5% | −0.294000 * | 0.052726 | 0.001 | −0.41559 | −0.17241 |

| 10% | −1.180000 * | 0.052726 | 0.000 | −1.30159 | −1.05841 | |

| 30% | −3.836000 * | 0.052726 | 0.000 | −3.95759 | −3.71441 | |

| 5% | 0% | 0.294000 * | 0.052726 | 0.001 | 0.17241 | 0.41559 |

| 10% | −0.886000 * | 0.052726 | 0.000 | −1.00759 | −0.76441 | |

| 30% | −3.542000 * | 0.052726 | 0.000 | −3.66359 | −3.42041 | |

| 10% | 0% | 1.180000 * | 0.052726 | 0.000 | 1.05841 | 1.30159 |

| 5% | 0.886000 * | 0.052726 | 0.000 | 0.76441 | 1.00759 | |

| 30% | −2.656000 * | 0.052726 | 0.000 | −2.77759 | −2.53441 | |

| 30% | 0% | 3.836000 * | 0.052726 | 0.000 | 3.71441 | 3.95759 |

| 5% | 3.542000 * | 0.052726 | 0.000 | 3.42041 | 3.66359 | |

| 10% | 2.656000 * | 0.052726 | 0.000 | 2.53441 | 2.77759 | |

| Asphalt Type | Equation | R2 |

|---|---|---|

| 50#-base asphalt | ln(G*/sinδ) = −8.323lnT + 35.616 | 0.99991 |

| 5%-bio-asphalt | ln(G*/sinδ) = −8.230lnT + 34.876 | 0.99994 |

| 10%-bio-asphalt | ln(G*/sinδ) = −8.306lnT + 35.218 | 0.99964 |

| 30%-bio-asphalt | ln(G*/sinδ) = −7.598lnT + 31.966 | 0.99965 |

| Asphalt Type | Equation | R2 |

|---|---|---|

| 50#-base asphalt | ln(G*/sinδ) = −8.962lnT + 39.312 | 0.99907 |

| 5%-bio-asphalt | ln(G*/sinδ) = −8.526lnT + 37.570 | 0.99906 |

| 10%-bio-asphalt | ln(G*/sinδ) = −9.128lnT + 40.376 | 0.99848 |

| 30%-bio-asphalt | ln(G*/sinδ) = −8.989lnT + 39.882 | 0.99998 |

| Binder Types | Absorption Wave Number | Functional Groups | Class of Compounds [22,23,24] |

|---|---|---|---|

| 50# base asphalt | 788–842 | C-H plane bending | Aromatic compounds |

| 1024 | S=O | Sulfoxide | |

| 1379, 1452 | CH3 | Aliphatic compounds | |

| 1602 | C=C ring stretch | Aromatic compounds | |

| 2852, 2925 | C-H stretching | Alkanes | |

| 3421 | O-H stretching, N-H stretching | Polymeric O-H, water, NH2 | |

| Bio-oil | 763–827 | C-H plane bending | Aromatic compounds |

| 1097 | S=O | Sulfoxide | |

| 1263 | C-O stretching | Phenol, esters | |

| 1379, 1452 | CH3 | Aliphatic compounds | |

| 1519 | -NO2 stretching | Nitrogenous compounds | |

| 1602 | C=C ring stretch | Aromatic compounds | |

| 1706 | C=O stretching | Ketones, aldehydes, carboxylic acids | |

| 2852, 2924 | C-H stretching | Alkanes | |

| 3421 | O-H stretching, N-H stretching | Polymeric O-H, water, NH2 | |

| Bio-asphalt (50# base asphalt with 30% bio-oil) | 769–839 | C-H plane bending | Aromatic compounds |

| 1024 | S=O | Sulfoxide | |

| 1379, 1452 | CH3 | Aliphatic compounds | |

| 1519 | -NO2 stretching | Nitrogenous compounds | |

| 1602 | C=C ring stretch | Aromatic compounds | |

| 1706 | C=O stretching | Ketones, aldehydes, carboxylic acids | |

| 2852, 2952 | C-H stretching | Alkanes | |

| 3307 | O-H stretching, N-H stretching | Polymeric O-H, water, NH2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.; Wang, H.; You, Z.; Mohd Hasan, M.R.; Lei, Y.; Irfan, M. Rheological Behavior and Sensitivity of Wood-Derived Bio-Oil Modified Asphalt Binders. Appl. Sci. 2018, 8, 919. https://doi.org/10.3390/app8060919

Gao J, Wang H, You Z, Mohd Hasan MR, Lei Y, Irfan M. Rheological Behavior and Sensitivity of Wood-Derived Bio-Oil Modified Asphalt Binders. Applied Sciences. 2018; 8(6):919. https://doi.org/10.3390/app8060919

Chicago/Turabian StyleGao, Junfeng, Hainian Wang, Zhanping You, Mohd Rosli Mohd Hasan, Yong Lei, and Muhammad Irfan. 2018. "Rheological Behavior and Sensitivity of Wood-Derived Bio-Oil Modified Asphalt Binders" Applied Sciences 8, no. 6: 919. https://doi.org/10.3390/app8060919

APA StyleGao, J., Wang, H., You, Z., Mohd Hasan, M. R., Lei, Y., & Irfan, M. (2018). Rheological Behavior and Sensitivity of Wood-Derived Bio-Oil Modified Asphalt Binders. Applied Sciences, 8(6), 919. https://doi.org/10.3390/app8060919