Assessment of Thermal Stresses in Asphalt Mixtures at Low Temperatures Using the Tensile Creep Test and the Bending Beam Creep Test

Abstract

1. Introduction

1.1. Background

1.2. Objectives

2. Materials and Methods

2.1. Materials

2.1.1. Bitumen

2.1.2. Asphalt Mixtures

2.2. Methods

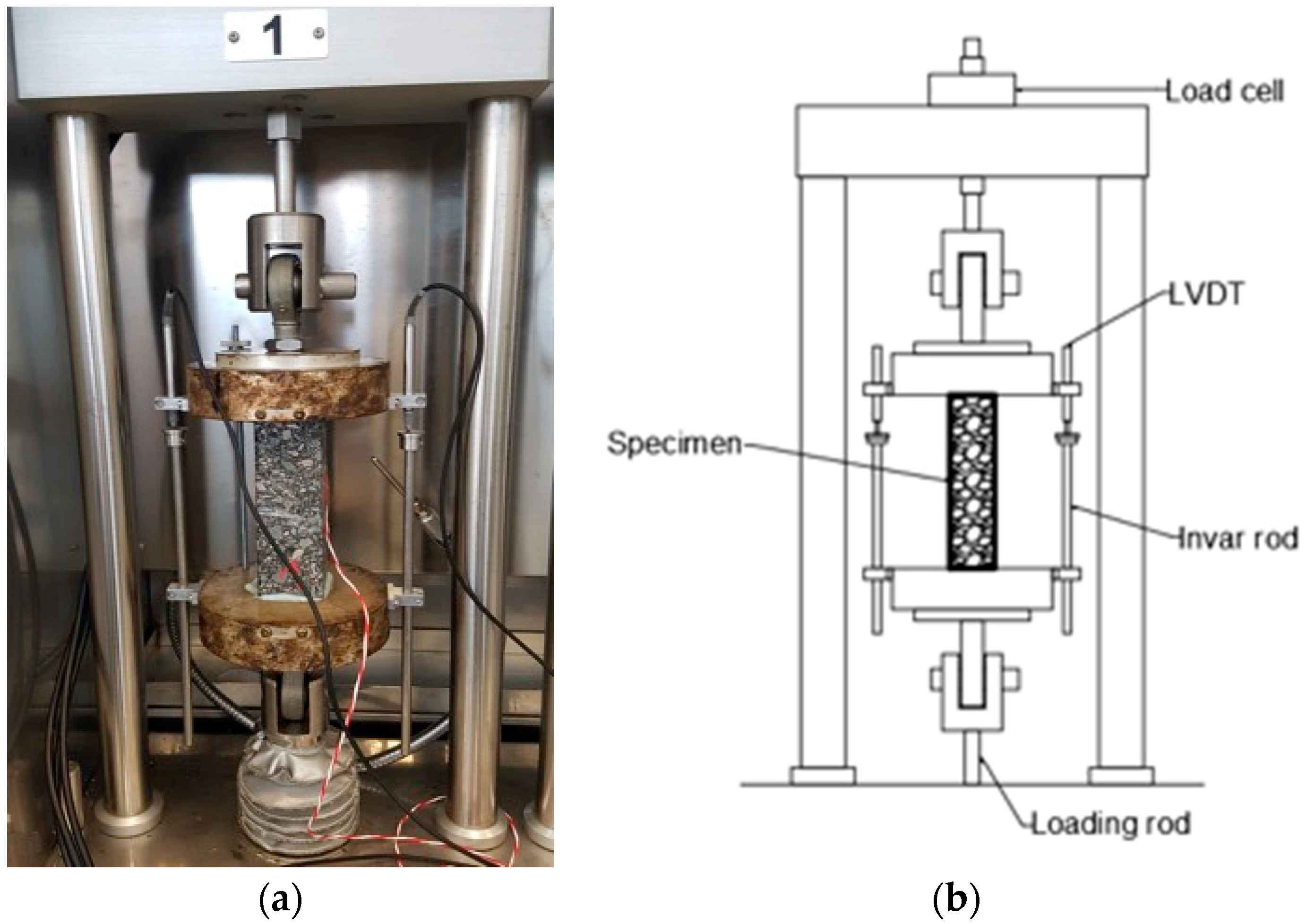

2.2.1. Tensile Creep Test (TCT)

2.2.2. Bending Beam Creep Test (BBCT)

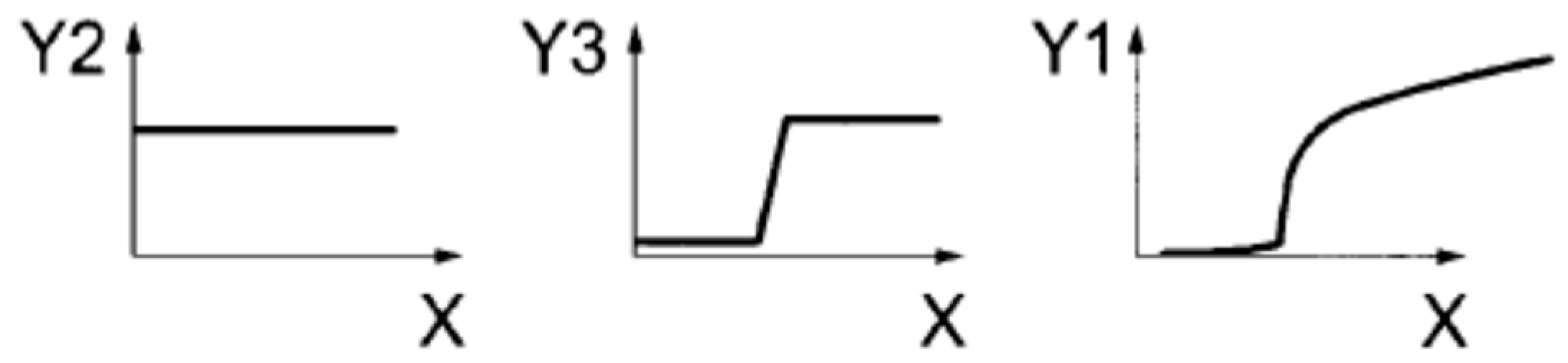

2.3. Method of Calculation of Rheological Properties

3. Results and Discussion

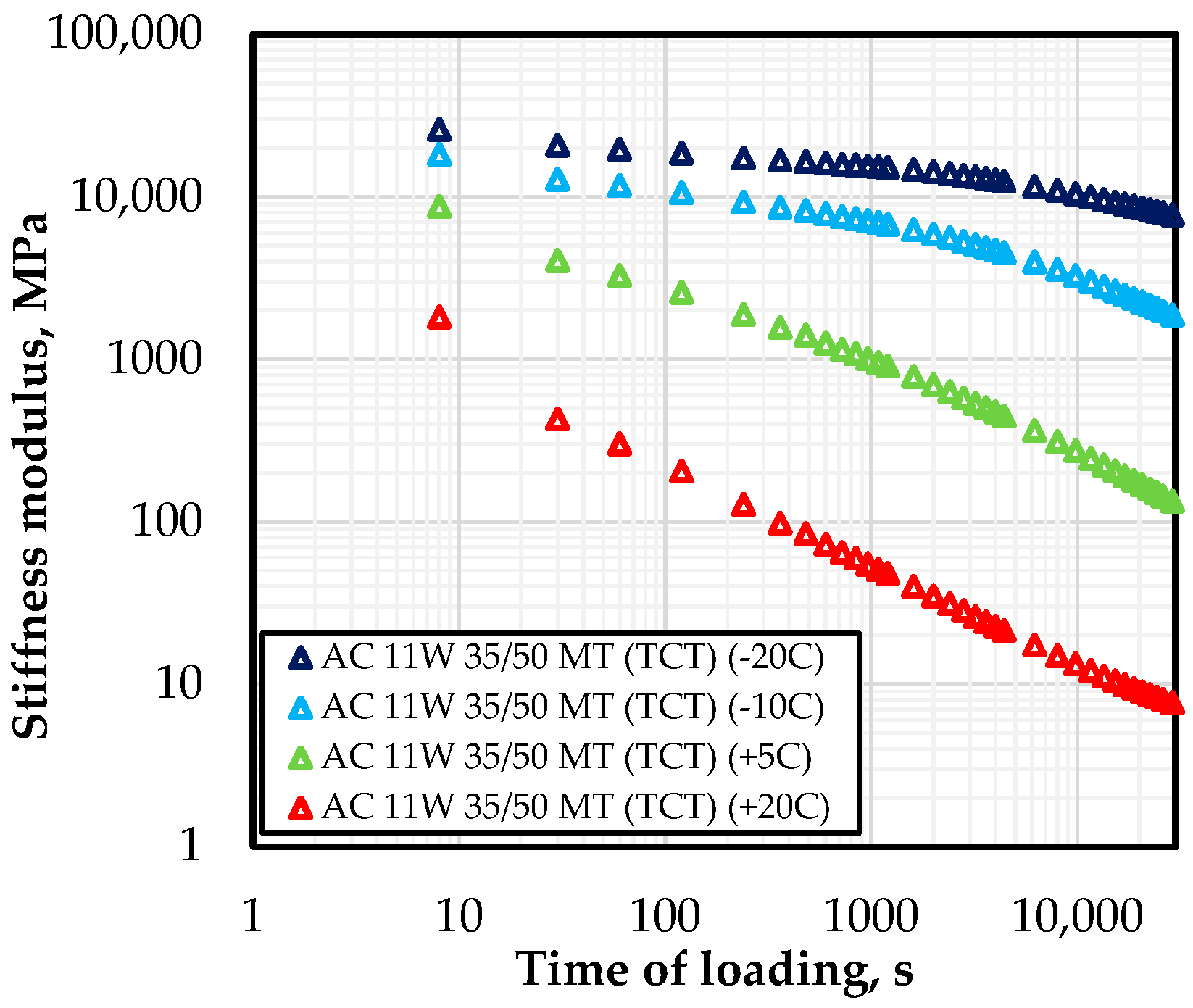

3.1. Stiffness Modulus

3.2. Burgers’ Model Parameters

3.3. Master Curve Parameters

3.4. Comparison of the TCT and BBCT Results

4. Thermal Stress Analysis

5. Summary and Conclusions

- According to different creep test methods applied in the study, lower strain values of creep curves were obtained for the Tensile Creep Test (TCT) than for the Bending Beam Creep Test (BBCT), especially at lower temperatures.

- Stiffness curves derived from both creep tests (BBCT and TCT) differ at all the tested temperatures – both in terms of shape and values. For low temperatures (−10 °C and lower) results obtained from the TCT presented higher values of stiffness modulus. The situation is opposite at temperatures higher than 0 °C, where the results obtained from the BBCT present higher values.

- Master curves determined on the basis of the TCT results showed higher values of stiffness modulus for temperatures <0 °C and lower for temperatures >0°C in comparison to those determined from the BBCT.

- “Branching” modification of the Richards model correctly described the master curves determined from the BBCT results. In the case of the TCT results, master curves presented some discrepancies and a new model should be determined.

- The Arrhenius shift factor function presented reliable results for both tests (BBCT and TCT). In the case of the WLF shift factor function, the BBCT results showed significantly decreased values at temperatures higher than 0 °C.

- Results of thermal stress calculations indicated that higher reliability was obtained for the viscoelastic Monismith method based on the TCT results. The highest agreement with the TSRST results was also obtained for the Monismith method based on the TCT results.

- No clear relationships were obtained between the failure temperatures predicted from different methods of thermal stress calculation. The highest agreement was obtained for the viscoelastic Monismith method calculated based on the TCT results, for which 2 of 4 cases were the determined values of failure temperature in good agreement with the TSRST results.

- The main limitation of the study was related to the methodology of the TCT method. The test method was applied and conducted according to the European standard EN 12697-46. In the TCT, the time of loading is long (8 h) and an additional measurement period of 2 h is also recommended after unloading. The authors have come to the opinion that the time of loading can be shortened, but this issue requires further research.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jung, D.; Vinson, T.S. Thermal Stress Restrained Specimen Test to Evaluate Low-Temperature Cracking of Asphalt-Aggregate Mixtures; Transportation Research Record No. 1417; Transportation Research Board; National Academy Press: Washington, DC, USA, 1993; pp. 12–20. [Google Scholar]

- Judycki, J. A new viscoelastic method of calculation of low-temperature thermal stresses in asphalt layers of pavements. Int. J. Pavement Eng. 2016, 19, 24–36. [Google Scholar] [CrossRef]

- Vinson, T.S.; Janoo, V.C.; Haas, R.C.G. Low Temperature and Thermal Fatigue Cracking; Summary Report No SR-OSU-A-003A-89-1; Strategic Highway Research Program, National Research Council: Washington, DC, USA, 1989.

- Pucci, T.; Dumont, A.-G.; Di Benedetto, H. Thermomechanical and Mechanical Behaviour of Asphalt Mixtures at Cold Temperature: Road and Laboratory Investigations. Road Mater. Pavement Des. 2004, 5, 45–72. [Google Scholar] [CrossRef]

- Pszczola, M.; Judycki, J. Comparison of calculated and measured thermal stresses in asphalt concrete. Balt. J. Road Bridge Eng. 2015, 10, 39–45. [Google Scholar] [CrossRef]

- Pszczola, M.; Szydlowski, C. Influence of Bitumen Type and Asphalt Mixture Composition on Low-Temperature Strength Properties According to Various Test Methods. Materials 2018, 11, 2118. [Google Scholar] [CrossRef] [PubMed]

- Bai, M. Investigation of low-temperature properties of recycling of SBS modified asphalt binder. Constr. Build. Mater. 2017, 150, 766–773. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.B.; Bańkowski, W.; Radziszewski, P.; Sarnowski, M. Thermal and Fatigue Evaluation of Asphalt Mixtures Containing RAP Treated with a Bio-Agent. Appl. Sci. 2017, 7, 216. [Google Scholar] [CrossRef]

- Sybilski, D.; Bańkowski, W.; Mirski, K.; Hododecka, R.; Wróbel, A. Rubber-bitumen granulate for asphalt pavements—Laboratory comparative analysis. In Proceedings of the 5th International Conference on Bituminous Mixtures and Pavements, Thessaloniki, Greece, 1–3 June 2011; pp. 1413–1421. [Google Scholar]

- Pszczoła, M.; Jaczewski, M.; Szydłowski, C.; Judycki, J.; Dołżycki, B. Evaluation of low temperature properties of rubberized asphalt mixtures. Procedia Eng. 2017, 172, 897–904. [Google Scholar] [CrossRef]

- Zhao, L.; Xu, G.; Zhang, M. Low-temperature creep properties for fibre-asphalt mixtures. In Proceedings of the Institution of Civil Engineers-Transport; Thomas Telford Ltd.: London, UK, 2017; Volume 170, pp. 152–157. [Google Scholar] [CrossRef]

- Mackiewicz, P. Thermal stress analysis of joined plane in concrete pavements. Appl. Therm. Eng. 2014, 73, 1169–1176. [Google Scholar] [CrossRef]

- Chaubane, B.; Tia, M. Analysis and verification of thermal-gradient effects on concrete pavement. J. Transp. Eng. 1995, 121, 75–81. [Google Scholar] [CrossRef]

- Muki, R.; Sternberg, E. On transient thermal stresses in viscoelastic materials with temperature-dependent properties. J. Appl. Mech. 1961, 28, 193–207. [Google Scholar] [CrossRef]

- Lee, E.H.; Rogers, T.G. Solution of viscoelastic stress analysis problems using measured creep or relaxation functions. J. Appl. Mech. 1963, 30, 127–133. [Google Scholar] [CrossRef]

- Humpreys, J.S.; Martin, C.J. Determination of transient thermal stresses in a slab with temperature-dependent viscoelastic properties. Trans. Soc. Rheol. 1963, 7, 155–169. [Google Scholar] [CrossRef]

- Monismith, C.L.; Secor, G.A.; Secor, K.E. Temperature Induced Stresses and Deformations in Asphalt Concrete. J. Assoc. Asphalt Paving Technol. 1965, 34, 248–285. [Google Scholar]

- Wittmann, F.H.; Knappe, O.W.; Schuhbauer, A. Temperature induced stresses in concrete. Cem. Concr. Res. 1978, 8, 703–710. [Google Scholar] [CrossRef]

- Wittmann, F.H.; Schwanke, H. Influence of composition on temperature induced stresses in asphalt concrete mixtures. Cem. Concr. Res. 1979, 9, 497–500. [Google Scholar] [CrossRef]

- Marasteanu, M.; Zofka, A.; Turos, M.; Li, X.; Velasquez, R.; Xue, L.; Buttlar, W.G.; Paulino, G.; Braham, A.; Dave, E.; et al. Investigation of Low Temperature Cracking in Asphalt Pavements. A Transportation Pooled Fund Study; Report No MN/RC 2007-43; University of Minnesota: Minneapolis, MN, USA, 2007. [Google Scholar]

- Apeagyei, A.K.; Dave, E.V.; Buttler, W.G. Effect of cooling rate of thermal cracking of asphalt concrete pavements. J. Assoc. Asphalt Paving Technol. 2008, 77, 709–738. [Google Scholar]

- Marasteanu, M.; Buttlar, W.; Bahia, H.; Williams, C. Investigation of Low Temperature Cracking in Asphalt Pavements, National Pooled Fund Study—Phase II; Report No MN/RC 2012-23; University of Minnesota: Minneapolis, MN, USA, 2012. [Google Scholar]

- Tabatabaee, H.; Velasquez, R.; Bahia, H.U. Modeling thermal stress in asphalt mixtures undergoing glass transition and physical hardening. Transp. Res. Rec. J. Transp. Res. Board 2012, 2296, 106–114. [Google Scholar] [CrossRef]

- Hajj, E.Y.; Souliman, M.; Alavi, M.Z.; Salazar, L.L. Influence of hydrogreen bioasphalt on viscoelastic properties of reclaimed asphalt mixtures. Transp. Res. Rec. J. Transp. Res. Board 2013, 2371, 13–22. [Google Scholar] [CrossRef]

- Farrar, M.J.; Hajj, E.Y.; Planche, J.-P.; Alavi, M.Z. A method to estimate the thermal stress build-up in an asphalt mixture from a single-cooling event. Road Mater. Pavement Des. 2013, 14 (Suppl. 1), 201–211. [Google Scholar] [CrossRef]

- AASHTO. Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures MEPDG; Final Report; RA, Inc.: Champaign, IL, USA, 2004. [Google Scholar]

- AASHTO PP 42-02. Standard Practice for Determination of Low-Temperature Performance Grade (PG) of Asphalt Binders; AASHTO Provisional Standards; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2005. [Google Scholar]

- ASTM D6816-11. Standard Practice for Determining Low-Temperature Performance Grade of Asphalt Binders; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Hills, J.F.; Brien, D. The fracture of bitumen and asphalt mixes by temperature induced stresses. J. Assoc. Asphalt Paving Technol. 1966, 35, 294–309. [Google Scholar]

- Burgers, B.A.; Kopvillem, O.; Young, F.D.; Ste. Anne Test-relationships between predicted fracture temperatures and low temperature field performance. J. Assoc. Asphalt Paving Technol. 1971, 40, 148–193. [Google Scholar]

- Christianson, J.T.; Murray, D.W.; Anderson, K.O. Stress prediction and low temperature fracture susceptibility of asphalt concrete pavements. J. Assoc. Asphalt Paving Technol. 1972, 41, 494–523. [Google Scholar]

- Haas, R.C.G. A Method for Designing Asphalt Pavements to Minimize Low-Temperature Shrinkage Cracking; Asphalt Institute Research Report 73-1; The Asphalt Institute: College Park, MD, USA, 1973. [Google Scholar]

- Janoo, V.; Bayer, J.; Walsh, M. Thermal Stress Measurements in Asphalt Concrete; CRREL Report 93-10; US Army Corps of Engineers, Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1993. [Google Scholar]

- Kliewer, J.E.; Zeng, H.; Vinson, T.S. Aging and low-temperature cracking of asphalt concrete mixture. J. Cold Reg. Eng. 1996, 10, 134–148. [Google Scholar] [CrossRef]

- Qian, G.; Zheng, J.; Wang, Q. Calculating Thermal Stresses of Asphalt Pavement in Environmental Conditions. Prceedings of the Symposium on Pavement Mechanics and Materials, Blacksburg, VA, USA, 3–6 June 2007; pp. 78–87. [Google Scholar] [CrossRef]

- Gajewski, M.; Langlois, P.-A. Prediction of Asphalt Concrete Low-Temperature Cracking Resistance on the Basis of Different Constitutive Models. Procedia Eng. 2014, 91, 81–86. [Google Scholar] [CrossRef]

- Akentuna, M.; Kim, S.S.; Nazzal, M.; Abbas, A.R.; Arefin, M.S. Study of the thermal stress development of asphalt mixtures using the Asphalt Concrete Cracking Device (ACCD). Constr. Build Mater. 2016, 114, 416–422. [Google Scholar] [CrossRef]

- Yavuzturk, C.; Ksaibati, K. Assessment of Thermal Stresses in Asphalt Pavements Due to Environmental Conditions; University of Wyoming: Laramie, WY, USA, 2006. [Google Scholar]

- Pszczola, M.; Jaczewski, M.; Rys, D.; Jaskula, P.; Szydlowski, C. Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test. Materials 2018, 11, 100. [Google Scholar] [CrossRef] [PubMed]

- Jaczewski, M.; Judycki, J.; Jaskula, P. Asphalt concrete subjected to long-time loading at low temperatures-Deviations from the time-temperature superposition principle. Constr. Build. Mater. 2019, 202, 426–439. [Google Scholar] [CrossRef]

- Pszczoła, M.; Judycki, J. Testing of low temperature behaviour of asphalt mixtures in bending creep test. In Proceedings of the 7th International RILEM Symposium on Advanced Testing and Characterization of Bituminous Materials: Advanced Testing and Characterization of Bituminous Materials, Rhodes, Greece, 11 May 2009; pp. 303–312. [Google Scholar]

- Zofka, A.; Marasteanu, M.O.; Turos, M. Determination of asphalt mixture creep compliance at low temperatures using thin beam specimens. Transp. Res. Rec. J. Transp. Res. Board 2008, 2057, 134–139. [Google Scholar] [CrossRef]

- Zofka, A.; Marasteanu, M.O.; Turos, M. Investigation of asphalt mixture creep compliance at low temperatures. Road Mater. Pavement Des. 2011, 9, 269–285. [Google Scholar] [CrossRef]

- Judycki, J.; Jaskula, P.; Dolzycki, B.; Pszczola, M.; Jaczewski, M.; Rys, D.; Stienss, M. Investigation of low-temperature cracking in newly constructed high-modulus asphalt concrete base course of a motorway pavement. Road Mater. Pavement Des. 2015, 16, 362–388. [Google Scholar] [CrossRef]

- CEN–EN 12591. Bitumen and Bituminous Binders—Specifications for Paving Grade Bitumens; European Committee for Standardization CEN: Brussels, Belgium, 2009. [Google Scholar]

- CEN–EN 14023. Bitumen and Bituminous Binders—Specifications Framework for Polymer Modified Bitumens; European Committee for Standardization CEN: Brussels, Belgium, 2010. [Google Scholar]

- CEN–EN 13108-1. Bituminous Mixtures—Material Specifications—Part 1: Asphalt Concrete; European Committee for Standardization CEN: Brussels, Belgium, 2016. [Google Scholar]

- Szymanski, D. Assessment of the Low-Temperature Properties of Asphalt Mixtures Based on the TSRST, UTST and TCT Test Results. Master’s Thesis, Gdansk University of Technology, Gdańsk, Poland, 2018. (In Polish). [Google Scholar]

- CEN–EN 12697-46. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part: 46: Low Temperature Cracking and Properties by Uniaxial Tension Tests; European Committee for Standardization CEN: Brussels, Belgium, 2012. [Google Scholar]

- CEN–EN 12697-33. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 33: Specimen Prepared by Roller Compactor; European Committee for Standardization CEN: Brussels, Belgium, 2007. [Google Scholar]

- Judycki, J. Bending Test of Asphaltic Mixtures under Statical Loading. In Design and Quality Control of Bituminous Mixes, Proceedings of the 4th International Symposium on the Role of Mechanical Tests for the Characterization, Budapest, Hungary, 23–25 October 1990; Book Series: RILEM Proceedings; Taylor & Francis: Oxfordshire, UK, 1990; Volume 8, pp. 207–227. [Google Scholar]

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1980. [Google Scholar]

- Rowe, G.M.; Sharrock, M.J. Alternate shift factor relationship for describing the temperature dependency of the visco-elastic behaviour of asphalt materials. Transp. Res. Rec. 2011, 2207, 125–135. [Google Scholar] [CrossRef]

- Jaczewski, M.; Judycki, J.; Jaskuła, P. Modelling of Asphalt Mixes under Long Time Creep at Low Temperatures. Transp. Res. Procedia 2016, 14, 3527–3535. [Google Scholar] [CrossRef]

- Mejłun, Ł.; Judycki, J.; Dołżycki, B. Comparison of Elastic and Viscoelastic Analysis of Asphalt Pavement at High Temperature. Procedia Eng. 2017, 172, 746–753. [Google Scholar] [CrossRef]

- Cholewińska, M.; Iwański, M.; Mazurek, G. The impact of ageing on the bitumen stiffness modulus using the cam model. Balt. J. Road Bridge Eng. 2018, 13, 34–39. [Google Scholar] [CrossRef]

- Judycki, J. Non-linear viscoelastic behaviour of conventional and modified asphaltic concrete under creep. Mater. Struct. 1992, 25, 95–101. [Google Scholar] [CrossRef]

| Type of Bitumen | |||||

|---|---|---|---|---|---|

| Property | 35/50 | 50/70 | 70/100 | 45/80-55 | |

| Penetration at 25 °C, 0.1 mm, acc. to PN-EN 1426 | Original | 45 | 54 | 81 | 60 |

| RTFOT | 28 | 40 | 48 | 40 | |

| R&B Temperature, °C, acc. to PN-EN 1427 | Original | 53.0 | 50.8 | 47.8 | 68.6 |

| RTFOT | 57.8 | 57.8 | 53.4 | 67.4 | |

| Performance Grade, acc. to AASHTO M 320 | 70-16 | 64-22 | 58-22 | 70-22 | |

| Fraass Breaking Point Temperature, °C, acc. to PN-EN 12593 | Original RTFOT | −6 −3 | −14 −12 | −16 −10 | −16 −15 |

| Type of Mixtures | |||

|---|---|---|---|

| Asphalt Mixture | AC 11 S | AC 11 S | AC 11 W |

| Type of layer | wearing course | wearing course | binder course |

| Type of traffic | low traffic (LT) | medium traffic (MT) | medium traffic (MT) |

| Bitumen type | 70/100 | 50/70 45/80-55 | 35/50 |

| Binder content (% by mass) | 5.8 | 5.6 | 5.6 |

| Aggregate type | crushed gravel | crushed gneiss | crushed gneiss |

| Filler type | limestone | limestone | limestone |

| Sieve size (mm) | % Passing (by mass) | ||

| 16 | 100 | 100 | 100 |

| 11.2 | 97 | 98 | 98 |

| 8 | 83 | 77 | 83 |

| 5.6 | 71 | 62 | 65 |

| 4 | 60 | 52 | 54 |

| 2 | 40 | 39 | 43 |

| 0.125 | 11 | 11 | 12 |

| 0.063 | 8.0 | 7.2 | 7.4 |

| Test Temperature T, °C | Percentage of the Maximum Stress βt(T) Obtained from the UTST, % |

|---|---|

| +20 | 5 |

| +5 | 10 |

| −10 | 30 |

| −20 | 50 |

| −30 | 50 |

| Mixture Designation | Test Temperature T, °C | Burgers Model Parameters | |||

|---|---|---|---|---|---|

| E1, MPa | E2, MPa | η1, MPa·s | η2, MPa·s | ||

| AC 11S 70/100 LT | −20 | 24,601 | 60,649 | 620,381,505 | 83,584,308 |

| −10 | 12,516 | 6790 | 38,457,749 | 14,471,875 | |

| 5 | 2791 | 254 | 991,934 | 767,794 | |

| 20 | * | * | * | * | |

| AC 11S 50/70 MT | −20 | 24,656 | 115,183 | 827,458,047 | 90,290,579 |

| −10 | 13,737 | 7758 | 69,265,928 | 21,096,067 | |

| 5 | 4070 | 459 | 4,086,935 | 1,888,343 | |

| 20 | 629 | 14 | 353,051 | 62,056 | |

| AC 11S 45/80-55 MT | −30 | 29,941 | 98,166 | 2,381,475,542 | 91,889,789 |

| −20 | 19,307 | 19,490 | 195,406,816 | 28,798,508 | |

| −10 | 12,257 | 4123 | 21,890,814 | 10,897,801 | |

| 5 | 2762 | 239 | 3,205,784 | 1,009,562 | |

| AC 11W 35/50 MT | −20 | 21,772 | 28,228 | 600,059,352 | 75,959,661 |

| −10 | 13,004 | 8210 | 87,034,368 | 23,417,485 | |

| 5 | 4031 | 601 | 5,187,255 | 2,240,592 | |

| 20 | 749 | 16 | 453,536 | 85,500 | |

| Mixture Designation | Test Temperature T, °C | Burgers’ Model Parameters | |||

|---|---|---|---|---|---|

| E1, MPa | E2, MPa | η1, MPa·s | η2, MPa·s | ||

| AC 11S 70/100 LT | −20 | 38,503 | 4,517 | 588,962,264 | 2,007,996 |

| −10 | 34,090 | 2,948 | 60,779,274 | 624,963 | |

| 0 | 18,572 | 801 | 3,152,349 | 271,364 | |

| 10 | 6,168 | 151 | 397,640 | 41,598 | |

| AC 11S 50/70 MT | −20 | 46,106 | 5,024 | 595,720,702 | 470,341 |

| −10 | 34,208 | 3,350 | 79,945,328 | 490,828 | |

| 0 | 18,582 | 1,153 | 5,340,236 | 303,322 | |

| 10 | 5,129 | 175 | 467,638 | 49,697 | |

| AC 11S 45/80-55 MT | −20 | 45,953 | 4,676 | 487,685,841 | 588,195 |

| −10 | 30,444 | 3,149 | 53,177,748 | 437,444 | |

| 0 | 17,695 | 876 | 3,849,752 | 319,700 | |

| 10 | 5,134 | 167 | 478,026 | 47,128 | |

| Mixture Designation | Test Temperature T, °C | Richards Model Parameters (“Branching” Modification) | ||||

|---|---|---|---|---|---|---|

| Max | β | γ | δ | λ | ||

| AC 11S 70/100 LT | > −20 | 4.712 | −10.075 | −0.462 | 0.367 | 0.000615 |

| < −20 | 4.712 | −17.217 | −0.279 | 0.367 | 0.0000005 | |

| AC 11S 50/70 MT | >−20 | 4.789 | −9.735 | −0.451 | 0.441 | 0.000898 |

| < −20 | 4.789 | −16.478 | −0.196 | 0.441 | 0.000001 | |

| AC 11S 45/80-55 MT | >−20 | 4.823 | −9.584 | −0.421 | 1.175 | 0.000566 |

| −20 ÷ −30 | 4.823 | −10.698 | −0.366 | 0.823 | 0.000226 | |

| < −30 | 4.823 | −10.424 | −0.212 | 3.786 | 0.000066 | |

| AC 11W 35/50 MT | > −10 | 4.935 | −9.703 | −0.369 | 0.284 | 0.00055 |

| −10 ÷ −20 | 4.935 | −6.737 | −0.302 | 0.284 | 0.01074 | |

| < −20 | 4.935 | −11.818 | −0.213 | 0.284 | 0.00006 | |

| Mixture Designation | Test Temperature T, °C | Richards Model Parameters (“Branching” Modification) | ||||

|---|---|---|---|---|---|---|

| Max | β | γ | δ | λ | ||

| AC 11S 70/100 LT | >−10 | 4.766 | −9.066 | −0.428 | 1.327 | 0.000864 |

| −10 ÷ −20 | 4.766 | −9.560 | −0.498 | 3.246 | 0.000206 | |

| <−20 | 4.766 | −10.471 | −0.848 | 3.713 | 0.000066 | |

| AC 11S 50/70 MT | >−10 | 5.118 | −11.162 | −0.295 | 0.146 | 0.000090 |

| −10 ÷ −20 | 5.118 | −11.835 | −0.368 | 3.234 | 0.000014 | |

| <−20 | 5.118 | −12.737 | −0.703 | 3.815 | 0.000004 | |

| AC 11S 45/80-55 MT | >−10 | 4.764 | −10.941 | −0.429 | 1.358 | 0.000132 |

| −10 ÷ −20 | 4.764 | −11.643 | −0.482 | 3.209 | 0.000026 | |

| <−20 | 4.764 | −11.381 | −0.852 | 3.741 | 0.000025 | |

| Mixture Designation | TSRST | Thermal Stress Calculation Method (Data Source) | |||

|---|---|---|---|---|---|

| Hills & Brien (BBCT) | Hills & Brien (TCT) | Monismith (BBCT) | Monismith (TCT) | ||

| AC 11S 70/100 LT | −26.4 | −29.0 | −21.0 | −29.5 | −25.0 |

| AC 11S 50/70 MT | −25.7 | −26.5 | −19.5 | −27.5 | −23.5 |

| AC 11S 45/80-55 MT | −29.5 | <−30.0 | −28.5 | <−30.0 | −29.5 |

| AC 11W 35/50 MT | −22.3 | - | −20.5 | - | −25.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pszczola, M.; Jaczewski, M.; Szydlowski, C. Assessment of Thermal Stresses in Asphalt Mixtures at Low Temperatures Using the Tensile Creep Test and the Bending Beam Creep Test. Appl. Sci. 2019, 9, 846. https://doi.org/10.3390/app9050846

Pszczola M, Jaczewski M, Szydlowski C. Assessment of Thermal Stresses in Asphalt Mixtures at Low Temperatures Using the Tensile Creep Test and the Bending Beam Creep Test. Applied Sciences. 2019; 9(5):846. https://doi.org/10.3390/app9050846

Chicago/Turabian StylePszczola, Marek, Mariusz Jaczewski, and Cezary Szydlowski. 2019. "Assessment of Thermal Stresses in Asphalt Mixtures at Low Temperatures Using the Tensile Creep Test and the Bending Beam Creep Test" Applied Sciences 9, no. 5: 846. https://doi.org/10.3390/app9050846

APA StylePszczola, M., Jaczewski, M., & Szydlowski, C. (2019). Assessment of Thermal Stresses in Asphalt Mixtures at Low Temperatures Using the Tensile Creep Test and the Bending Beam Creep Test. Applied Sciences, 9(5), 846. https://doi.org/10.3390/app9050846