Effects of Intraspecific Competition and Larval Size on Bioconversion of Apple Pomace Inoculated with Black Soldier Fly

Abstract

1. Introduction

2. Materials and Methods

2.1. Soldier Flies

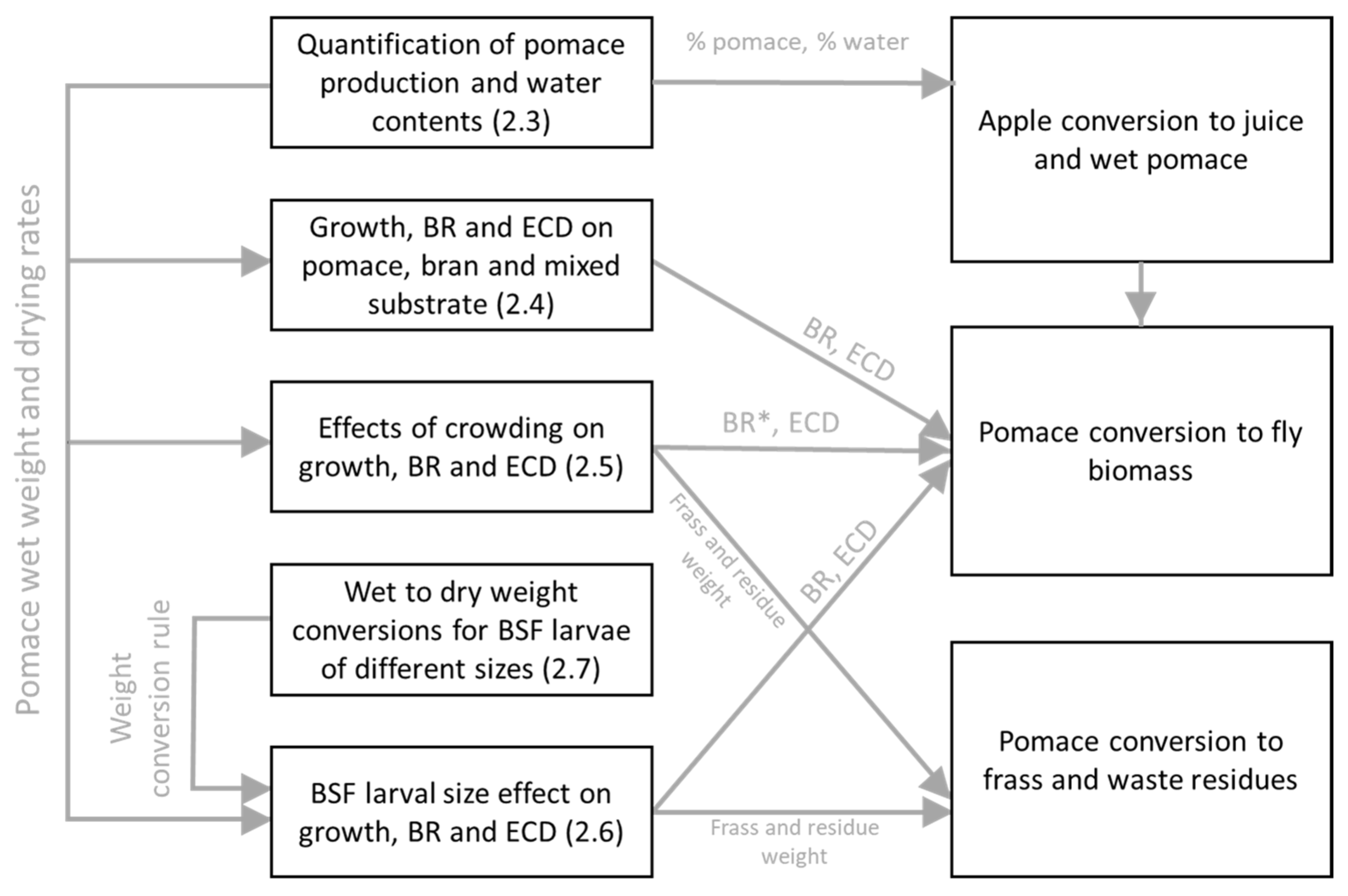

2.2. Rationale and Standardization of Experiments

2.3. Pomace Preparation and Quantification

2.4. Effects of Mixed Pomace–Wheat Bran on Growth and Conversion Efficiency

2.5. Effects of Inoculation Density on Growth and Conversion Efficiency

2.6. Conversion Efficiency Based on Larval Size Categories

2.7. Calculating Conversion Efficiencies

2.8. Statistical Analyses

3. Results

3.1. Apple Pomace Produced during Juicing

3.2. Effects of Mixed Substrate on Growth and Conversion Efficiency

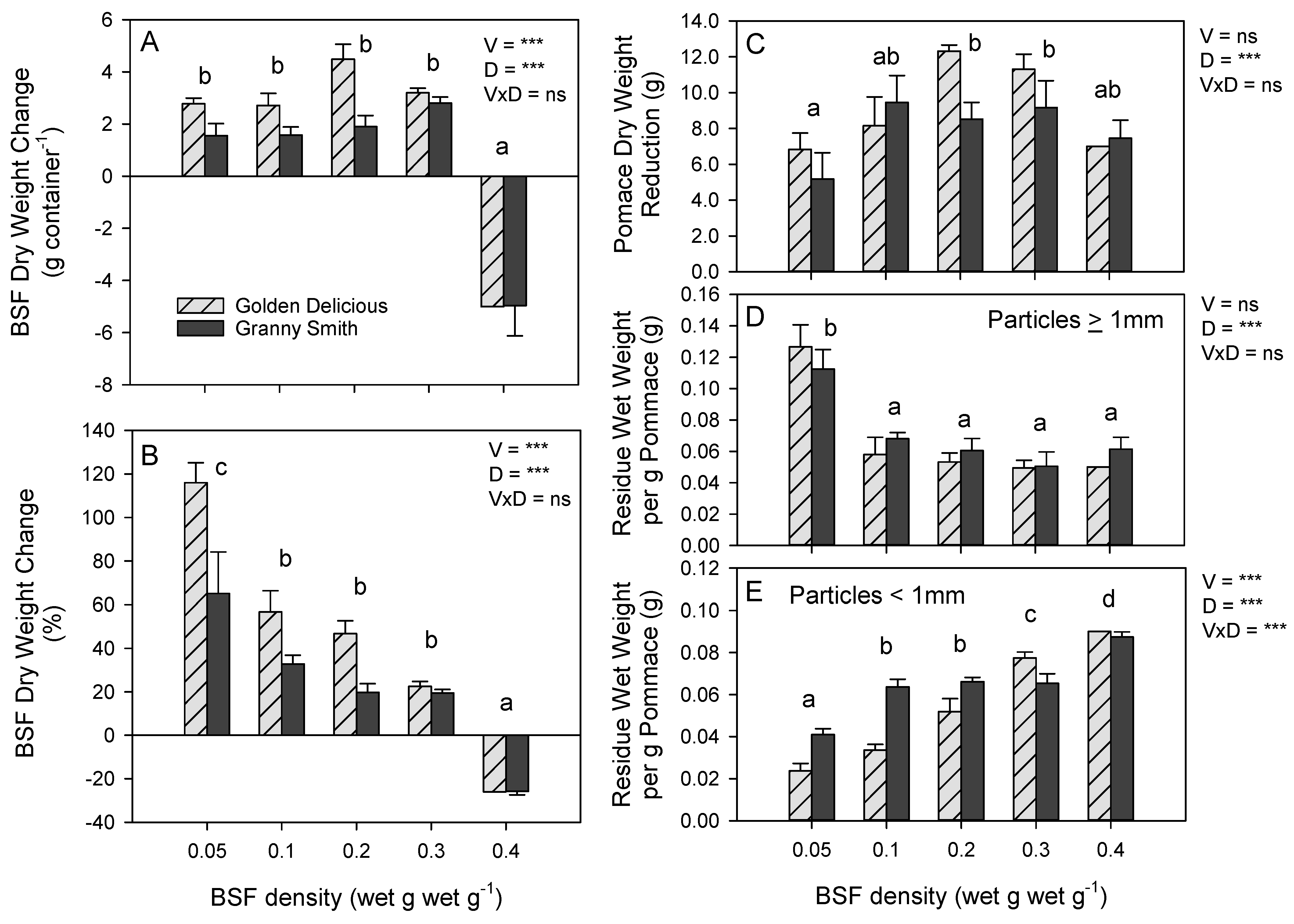

3.3. Effects of Inoculation Density on Growth and Conversion Efficiency

3.4. Effect of Starting BSF Larval Size on Conversion Efficiency

4. Discussion

4.1. BSF Intraspecific Competition on Apple Pomace

4.2. Growth Rates and Bioconversion Efficiencies as a Function of BSF Larval Size

4.3. Potential of BSF-Based Waste Reduction in Apple Orchards

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MMR. Global Apple Juice Market: Industry Analysis and Forecast (2021–2027) by Nature, Type, Form End-Use and Region. Maximize Market Research. Available online: www.maximizemarketresearch.com/market-report/global-apple-juice-market/43253/ (accessed on 15 September 2022).

- FAOSTAT. Crops and Livestock Products. Food and Agriculture Organization of the United Nations: Rome, Italy. Available online: www.fao.org/faostat/en/#data/QCL (accessed on 15 September 2022).

- Bhushan, S.; Kalia, K.; Sharma, M.; Singh, B.; Ahuja, P.S. Processing of apple pomace for bioactive molecules. Crit. Rev. Biotechnol. 2008, 28, 285–296. [Google Scholar] [CrossRef]

- Bortolini, D.G.; Benvenutti, L.; Demiate, I.M.; Nogueira, A.; Alberti, A.; Zielinski, A.A.F. A new approach to the use of apple pomace in cider making for the recovery of phenolic compounds. LWT 2020, 126, 109316. [Google Scholar] [CrossRef]

- Jackson, L.S.; Beacham-Bowden, T.; Keller, S.E.; Adhikari, C.; Taylor, K.T.; Chirtel, S.J.; Merker, R.I. Apple quality, storage, and washing treatments affect patulin levels in apple cider. J. Food Prot. 2003, 66, 618–624. [Google Scholar] [CrossRef]

- Wilczyński, K.; Kobus, Z.; Dziki, D. Effect of press construction on yield and quality of apple juice. Sustainability 2019, 11, 3630. [Google Scholar] [CrossRef]

- Dhillon, G.S.; Kaur, S.; Brar, S.K. Perspective of apple processing wastes as low-cost substrates for bioproduction of high value products: A review. Renew. Sustain. Energy Rev. 2013, 27, 789–805. [Google Scholar] [CrossRef]

- Ojha, S.; Bußler, S.; Schlüter, O.K. Food waste valorisation and circular economy concepts in insect production and processing. Waste Manag. 2020, 118, 600–609. [Google Scholar] [CrossRef]

- Martín-Ríos, C.; Demen-Meier, C.; Gössling, S.; Cornuz, C. Food waste management innovations in the foodservice industry. Waste Manag. 2018, 79, 196–206. [Google Scholar] [CrossRef]

- Otles, S.; Despoudi, S.; Bucatariu, C.; Kartal, C. Food waste management, valorization, and sustainability in the food industry. In Food Waste Recovery; Galanakis, C.M., Ed.; Academic Press: San Diego, CA, USA, 2015; pp. 3–23. [Google Scholar]

- Surendra, K.C.; Tomberlin, J.K.; van Huis, A.; Cammack, J.A.; Heckmann, L.-H.L.; Khanal, S.K. Rethinking organic wastes bioconversion: Evaluating the potential of the black soldier fly (Hermetia illucens (L.)) (Diptera: Stratiomyidae) (BSF). Waste Manag. 2020, 117, 58–80. [Google Scholar] [CrossRef]

- Zhang, J.; Tomberlin, J.; Cai, M.; Xiao, X.; Zheng, L.; Yu, Z.N. Research and industrialisation of Hermetia illucens L. in China. J. Insects Food Feed 2020, 6, 5–12. [Google Scholar] [CrossRef]

- Dortmans, B.; Egger, J.; Diener, S.; Zurbrügg, C. Black Soldier Fly Biowaste Processing: A Step-by-Step Guide, 2nd ed.; Eawag: Dübendorf, Switzerland, 2022. [Google Scholar]

- Zurbrügg, C.; Dortmans, B.; Fadhila, A.; Verstappen, B.; Diener, S. From pilot to full scale operation of a waste-to-protein treatment facility. Detritus 2018, 1, 18. [Google Scholar]

- Oliveira, F.R.; Doelle, K.; Smith, R.P. External morphology of Hermetia illucens Stratiomyidae: Diptera (L.1758) based on electron microscopy. Annu. Res. Rev. Biol. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Barragan-Fonseca, K.B.; Dicke, M.; van Loon, J.J. Nutritional value of the black soldier fly (Hermetia illucens L.) and its suitability as animal feed—A review. J. Insects Food Feed 2017, 3, 105–120. [Google Scholar] [CrossRef]

- Franco, A.; Scieuzo, C.; Salvia, R.; Petrone, A.M.; Tafi, E.; Moretta, A.; Schmitt, E.; Falabella, P. Lipids from Hermetia illucens, an innovative and sustainable source. Sustainability 2021, 13, 10198. [Google Scholar] [CrossRef]

- Guil-Guerrero, J.L.; Sánchez-Muros, M.J.; Fabrikov, D.; Rodríguez-Lozano, B.; González-Fernández, M.J.; Lyashenko, S.; Barroso, F.G. Hermetia illucens larvae as a living bioreactor for simultaneous food by-products recycling and useful oil production. J. Am. Oil Chem. Soc. 2020, 97, 717–727. [Google Scholar] [CrossRef]

- Borkent, S.; Hodge, S. Glasshouse evaluation of the black soldier fly waste product HexaFrass™ as an organic fertilizer. Insects 2021, 12, 977. [Google Scholar] [CrossRef]

- Lopes, I.G.; Yong, J.W.H.; Lalander, C. Frass derived from black soldier fly larvae treatment of biodegradable wastes. A critical review and future perspectives. Waste Manag. 2022, 142, 65–76. [Google Scholar] [CrossRef]

- Anyega, A.O.; Korir, N.K.; Beesigamukama, D.; Changeh, G.J.; Nkoba, K.; Subramanian, S.; Van Loop, J.J.A.; Dicke, M.; Tanga, C.M. Black soldier fly-composted organic fertilizer enhances growth, yield, and nutrient quality of three key vegetable crops in Sub-Saharan Africa. Front. Plant Sci. 2021, 12, 680312. [Google Scholar] [CrossRef]

- Mediha, Y.-A.; Eljack, R.; Schrimsher, C.; Beck, B.H. Use of dietary frass from black soldier fly larvae, Hermetia illucens, in hybrid tilapia (Nile x Mozambique, Oreocromis niloticus x O. mozambique) diets improves growth and resistance to bacterial diseases. Aquaculture Rep. 2020, 17, 100373. [Google Scholar]

- Mediha, Y.-A.; Eljack, R.; Beck, B.H. Nutritional value of frass from black soldier fly larvae, Hermetia illucens, in a channel catfish, Ictalurus punctatus, diet. Aquaculture Nutr. 2020, 26, 812–819. [Google Scholar]

- Hopkins, I.; Newman, L.P.; Gill, H.; Danaher, J. The influence of food waste rearing substrates on black soldier fly larvae protein composition: A systematic review. Insects 2021, 12, 608. [Google Scholar] [CrossRef]

- Meneguz, M.; Schiavone, A.; Gai, F.; Dama, A.; Lussiana, C.; Renna, M.; Gasco, L. Effect of rearing substrate on growth performance, waste reduction efficiency and chemical composition of black soldier fly (Hermetia illucens) larvae. J. Sci. Food Agric. 2018, 98, 5776–5784. [Google Scholar] [CrossRef] [PubMed]

- Chia, S.Y.; Tanga, C.M.; Osuga, I.M.; Mohamed, S.A.; Khamis, F.M.; Salifu, D.; Sevgan, S.; Fiaboe, K.K.M.; Niassy, S.; Van Loope, J.J.A. Effects of waste stream combinations from brewing industry on performance of Black Soldier Fly, Hermetia illucens (Diptera: Stratiomyidae). PeerJ 2018, 6, e5885. [Google Scholar] [CrossRef] [PubMed]

- Jucker, C.; Leonardi, M.; Rigamonti, I.; Lupi, D.; Savoldelli, S. Brewery’s waste streams as a valuable substrate for Black Soldier Fly Hermetia illucens (Diptera: Stratiomyidae). J. Entomol. Acarol. Res. 2019, 51, 87–94. [Google Scholar] [CrossRef]

- Scala, A.; Cammack, J.A.; Salvia, R.; Scieuzo, C.; Franco, A.; Bufo, S.A.; Tomberlin, J.K.; Falabella, P. Rearing substrate impacts growth and macronutrient composition of Hermetia illucens (L.) (Diptera: Stratiomyidae) larvae produced at an industrial scale. Sci. Rep. 2020, 10, 19448. [Google Scholar] [CrossRef] [PubMed]

- Broeckx, L.; Frooninckx, L.; Slegers, L.; Berrens, S.; Noyens, I.; Goossens, S.; Verheyen, G.; Wuys, A.; Van Miert, S. Growth of Black Soldier Fly larvae reared on organic side-streams. Sustainability 2021, 13, 12953. [Google Scholar] [CrossRef]

- Ribeiro, N.; Costa, R.; Ameixa, O.M.C.C. The influence of non-optimal rearing conditions and substrates on the performance of the Black Soldier Fly (Hermetia illucens). Insects 2022, 13, 639. [Google Scholar] [CrossRef]

- Dzepe, D.; Nana, P.; Fotso, A.; Tchuinkam, T.; Djouaka, R. Influence of larval density, substrate moisture content and feedstock ratio on life history traits of black soldier fly larvae. J. Insects Food Feed 2020, 6, 133–140. [Google Scholar] [CrossRef]

- Jones, B.M.; Tomberlin, J.K. Impact of Larval Competition on Life-History Traits of the Black Soldier Fly (Diptera: Stratiomyidae). Ann. Entomol. Soc. Am. 2019, 112, 505–510. [Google Scholar] [CrossRef]

- Opare, L.; Holm, S.; Esperk, T. Temperature-modified density effects in the black soldier fly: Low larval density leads to large size, short development time and high fat content. J. Insects Food Feed 2022, 8, 783–802. [Google Scholar] [CrossRef]

- Barragan-Fonseca, K.B.; Dicke, M.; van Loon, J.J.A. Influence of larval density and dietary nutrient concentration on performance, body protein, and fat contents of black soldier fly larvae (Hermetia illucens). Entomol. Exp. Appl. 2018, 166, 761–770. [Google Scholar] [CrossRef]

- Hecke, K.; Herbinger, K.; Veberič, R.; Trobec, M.; Toplak, H.; Štamper, F.; Keppel, H.; Grill, D. Sugar-, acid- and phenol contents in apple cultivars from organic and integrated fruit cultivation. Eur. J. Clin. Nutr. 2006, 60, 1136–1140. [Google Scholar] [CrossRef]

- Visser, T.; Schaap, A.A.; De Vries, D.P. Acidity and sweetness in apple and pear. Euphytica 1968, 17, 153–167. [Google Scholar] [CrossRef]

- Visser, T.; Verhaegh, J.J. Inheritance and selection of some fruit characters of apple. I. Inheritance of low and high acidity. Euphytica 1978, 27, 753–760. [Google Scholar] [CrossRef]

- Parra Paz, A.S.; Carrejo, N.S.; Gómez Rodríguez, C.H. Effects of larval density and feeding rates on the bioconversion of vegetable waste using Black Soldier Fly larvae Hermetia illucens (L.), (Diptera: Stratiomyidae). Waste Biomass Valorization 2015, 6, 1059–1065. [Google Scholar] [CrossRef]

- Adjavon, F.J.M.A.; Li, X.; Hu, B.; Dong, L.; Zeng, H.; Li, C.; Hu, W. Adult House Fly (Diptera: Muscidae) response to Black Soldier Fly (Diptera: Stratiomyidae) associated substrates and potential volatile organic compounds identification. Environ. Entomol. 2021, 50, 1037–1044. [Google Scholar] [CrossRef]

- Bradley, S.W.; Sheppard, D.C. House fly oviposition inhibition by larvae of Hermetia illucens, the black soldier fly. J. Chem. Ecol. 1984, 10, 853–859. [Google Scholar] [CrossRef]

- Sheppard, C. House Fly and Lesser Fly control utilizing the Black Soldier Fly in manure management systems for caged laying hens. Environ. Entomol. 1983, 12, 1439–1442. [Google Scholar] [CrossRef]

- Miranda, C.D.; Cammack, J.A.; Tomberlin, J.K. Interspecific competition between the House Fly, Musca domestica L. (Diptera: Muscidae) and Black Soldier Fly, Hermetia illucens (L.) (Diptera: Stratiomyidae) when reared on poultry manure. Insects 2019, 10, 440. [Google Scholar] [CrossRef]

- Diener, S.; Zurbrügg, C.; Tockner, K. Conversion of organic material by black soldier fly larvae: Establishing optimal feeding rates. Waste Manag. Res. 2009, 27, 603–610. [Google Scholar] [CrossRef]

- Yang, F.; Tomberlin, J.K. Comparing selected life-history traits of Black Soldier Fly (Diptera: Stratiomyidae) larvae produced in industrial and bench-top-sized containers. J. Insect Sci. 2020, 20, 25. [Google Scholar] [CrossRef]

- Ten Eyck, L.; Gehring, D. The Hop Grower’s Handbook: The Essential Guide for Sustainable, Small-Scale Production for Home and Market; Chelsea Green Publishing: White River Junction, VT, USA, 2016. [Google Scholar]

| Processing Parameters | Bramley Apple (11) 2 | Golden Delicious (14) 2 | Granny Smith (13) 2 | F-Variety 3 |

|---|---|---|---|---|

| Water content of whole apple (%) | 84.36 ± 0.41 b | 82.48 ± 0.53 a | 81.71 ± 0.18 a | 10.300 *** |

| Juice volume (mL 1000 g−1) | 599.64 ± 4.11 | 587.46 ± 10.73 | 595.25 ± 6.41 | 0.578 |

| Juice weight (wet g 1000 g−1) 1 | 679.22 ± 5.20 a | 698.27 ± 5.19 a | 735.25 ± 6.14 b | 25.230 *** |

| Pomace weight (wet g 1000 g−1) 1 | 306.26 ± 6.34 b | 295.34 ± 5.57 b | 261.73 ± 5.96 a | 14.972 *** |

| Pomace water content (%) | 71.20 ± 0.50 | 70.05 ± 0.55 | 70.83 ± 0.48 | 1.280 |

| Weight lost in processing (wet g 1000 g−1) | 50.81 ± 8.73 b | 23.73 ± 7.08 a | 12.56 ± 4.99 a | 7.433 *** |

| Juice (% of wet weight of whole apple) | 67.92 ± 0.52 a | 69.83 ± 0.52 a | 73.52 ± 0.61 b | 25.232 *** |

| Pomace (% of wet weight of whole apple) | 30.63 ± 0.63 b | 29.53 ± 0.56 b | 26.17 ± 0.60 a | 14.963 *** |

| Processing waste with juicer (%) | 5.08 ± 0.87 b | 2.37 ± 0.71 a | 1.26 ± 0.50 a | 7.437 *** |

| Dry weight of whole apple (dry g/1000 wet g) | 156.36 ± 4.11 a | 175.21 ± 5.28 b | 182.93 ± 1.80 b | 10.299 *** |

| Dry weight of pomace (dry g/1000 wet g) | 88.36 ± 2.93 b | 88.71 ± 2.88 b | 76.34 ± 2.16 a | 7.014 *** |

| Pomace (% of dry weight of whole apple) | 56.83 ± 2.20 b | 51.27 ± 2.32 b | 41.81 ± 1.33 a | 13.627 *** |

| Water content of exposed pomace after 7 days at 28 °C (% of pomace) 4 | 51.78 ± 0.30 b | 45.19 ± 1.46 a | 45.96 ± 0.44 a | 16.884 *** |

| Parameters | Apple Pomace 3 | Pomace + Bran 3 | Bran 3 | F-Values 4 |

|---|---|---|---|---|

| Water content (% of substrate) 1 | 73.34 | 57.18 | 32.74 | |

| Substrate weight lost in controls (% of substrate) | 3.26 ± 0.32 | 6.93 ± 0.22 | 5.10 ± 1.13 | 3.294 |

| BSF survival (%) | 88.33 ± 5.43 | 98.33 ± 1.67 | 98.33 ± 1.67 | 2.857 |

| BSF weight gain (dry mg container−1) | 22.50 ± 3.68 a | 59.88 ± 10.79 b | 40.50 ± 3.94 ab | 7.213 ** |

| Average BSF weight gain (dry mg larva−1) | 2.53 ± 0.34 a | 5.93 ± 1.03 b | 4.10 ± 0.36 ab | 6.670 ** |

| Larval growth rate (dry mg larva−1 day−1) 2 | 0.36 ± 0.05 a | 0.85 ± 0.15 b | 0.59 ± 0.05 ab | 6.712 ** |

| Residue dry weight (dry g container−1) | 7.90 ± 0.04 a | 18.99 ± 0.19 b | 30.76 ± 0.26 c | 3703.810 *** |

| Efficiency of conversion of ingested food (%) 2 | 5.52 ± 0.95 | 2.41 ± 0.36 | 1.46 ± 0.19 | 2.455 |

| Bioconversion rate (%) 2 | 0.27 ± 0.04 b | 0.28 ± 0.05 b | 0.12 ± 0.01 a | 5.176 * |

| Variety | Starting BSF Density (wet g g−1) 1 | Residue (Dry g) 2 | Larval Growth Rate (Dry mg Larva−1 Day−1) 2,3 | Efficiency of Conversion of Digested Food (ECD) (%) 2,3 | Bioconversion Rate (BR) (%) 2,3 |

|---|---|---|---|---|---|

| Golden Delicious | 0.05 | 13.30 ± 1.25 b | 0.40 ± 0.03 b | 11.23 ± 0.37 | 7.33 ± 0.59 a |

| 0.10 | 7.7 ± 1.11 a | 0.39 ± 0.07 b | 9.54 ± 1.53 | 7.43 ± 1.10 a | |

| 0.20 | 9.32 ± 0.52 a | 0.64 ± 0.08 b | 15.61 ± 2.09 | 10.17 ± 2.13 a | |

| 0.30 | 10.85 ± 0.41 ab | 0.46 ± 0.03 b | 12.37 ± 0.56 | 8.70 ± 0.36 a | |

| 0.40 | 10.48 ab | −0.71 a | −18.51 | −13.33 b | |

| Granny Smith | 0.05 | 12.18 ± 0.28 b | 0.22 ± 0.07 b | 6.61 ± 1.72 | 4.33 ± 1.17 a |

| 0.10 | 10.08 ± 0.65 a | 0.23 ± 0.04 b | 7.07 ± 1.47 | 4.93 ± 1.10 a | |

| 0.20 | 10.36 ± 0.64 a | 0.27 ± 0.06 b | 7.55 ± 1.52 | 4.33 ± 1.17 a | |

| 0.30 | 10.53 ± 0.31 ab | 0.40 ± 0.03 b | 9.87 ± 0.76 | 7.19 ± 0.54 a | |

| 0.40 | 10.36 ± 0.14 ab | −0.71 ± 0.17 a | −27.28 ± 6.62 | −17.37 ± 4.15 b | |

| F-variety (V) 4 | 0.519 | 7.244 ** | 7.787 ** | ||

| F-density (D) 4 | 8.531 *** | 33.492 *** | 28.939 *** | ||

| VxD 4 | 1.911 | 1.418 | 3.942 ** | 0.603 |

| Parameter | BSF Size 1 Category | F-Values 2 | |||

|---|---|---|---|---|---|

| Small | Medium | Medium Large | Large | ||

| Number of larvae per wet g | 370.33 ± 18.93 | 123.00 ± 9.55 | 44.38 ± 1.99 | 23.5 ± 0.72 | |

| Size range (number per wet g) | 300–460 | 100–160 | 40–60 | 20–30 | |

| Survival (%) | 88.02 ± 3.36 a | 95.74 ± 1.89 ab | 98.86 ± 1.40 b | 96.44 ± 1.74 ab | 4.448 * |

| Weight of survivors (dry g container−1) | 0.86 ± 0.03 b | 0.73 ± 0.12 ab | 0.58 ± 0.08 ab | 0.52 ± 0.06 a | 3.767 * |

| Larval growth rate (g day−1) | 0.12 ± 0.01 b | 0.10 ± 0.02 ab | 0.08 ± 0.01 ab | 0.07 ± 0.01 a | 4.132 * |

| Dry weight gain (dry g container−1) | 0.86 ± 0.03 b | 0.73 ± 0.12 ab | 0.57 ± 0.08 ab | 0.50 ± 0.06 a | 4.017 * |

| Percentage weight gain (conainer−1) | 180.00 ± 9.51 c | 166.67 ± 11.16 b | 91.67 ± 7.49 a | 58.33 ± 6.01 a | 48.480 *** |

| Weight of frass (wet g container−1) | 3.88 ± 0.08 b | 3.00 ± 0.45 ab | 2.67 ± 0.42 ab | 2.17 ± 0.17 a | 5.061 ** |

| Weight of larger (>1 mm) residue particles (wet g container−1) | 11.38 ± 0.49 | 10.67 ± 0.71 | 12.33 ± 0.56 | 12.33 ± 0.42 | 2.116 |

| Residue moisture content (% water) | 35.29 ± 4.85 | 42.18 ± 7.10 | 21.87 ± 5.04 | 26.16 ± 4.16 | 2.85 |

| Residue weight (dry g container−1) | 10.22 ± 1.02 | 8.15 ± 1.35 | 11.89 ± 1.35 | 10.79 ± 0.90 | 1.78 |

| Efficiency of conversion of ingested food (%) 3 | 5.23 ± 0.41 b | 4.27 ± 0.45 ab | 3.69 ± 0.33 ab | 3.07 ± 0.28 a | 5.087 ** |

| Bioconversion rate (%) 3 | 3.17 ± 0.12 b | 2.69 ± 0.45 ab | 2.10 ± 0.28 ab | 1.86 ± 0.22 a | 4.061 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horgan, F.G.; Launders, M.; Mundaca, E.A.; Crisol-Martínez, E. Effects of Intraspecific Competition and Larval Size on Bioconversion of Apple Pomace Inoculated with Black Soldier Fly. Agriculture 2023, 13, 452. https://doi.org/10.3390/agriculture13020452

Horgan FG, Launders M, Mundaca EA, Crisol-Martínez E. Effects of Intraspecific Competition and Larval Size on Bioconversion of Apple Pomace Inoculated with Black Soldier Fly. Agriculture. 2023; 13(2):452. https://doi.org/10.3390/agriculture13020452

Chicago/Turabian StyleHorgan, Finbarr G., Michael Launders, Enrique A. Mundaca, and Eduardo Crisol-Martínez. 2023. "Effects of Intraspecific Competition and Larval Size on Bioconversion of Apple Pomace Inoculated with Black Soldier Fly" Agriculture 13, no. 2: 452. https://doi.org/10.3390/agriculture13020452

APA StyleHorgan, F. G., Launders, M., Mundaca, E. A., & Crisol-Martínez, E. (2023). Effects of Intraspecific Competition and Larval Size on Bioconversion of Apple Pomace Inoculated with Black Soldier Fly. Agriculture, 13(2), 452. https://doi.org/10.3390/agriculture13020452