Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Instruments

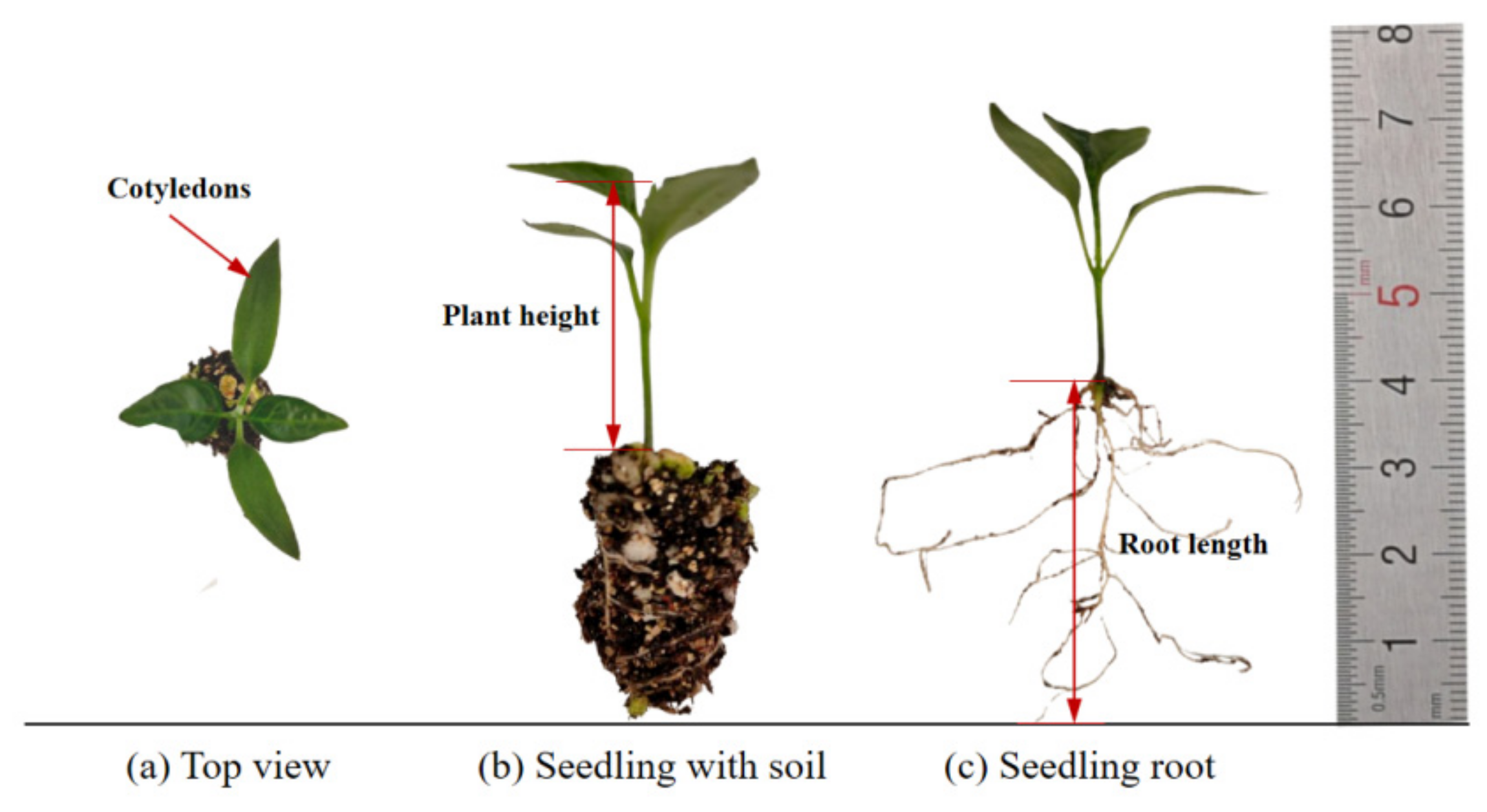

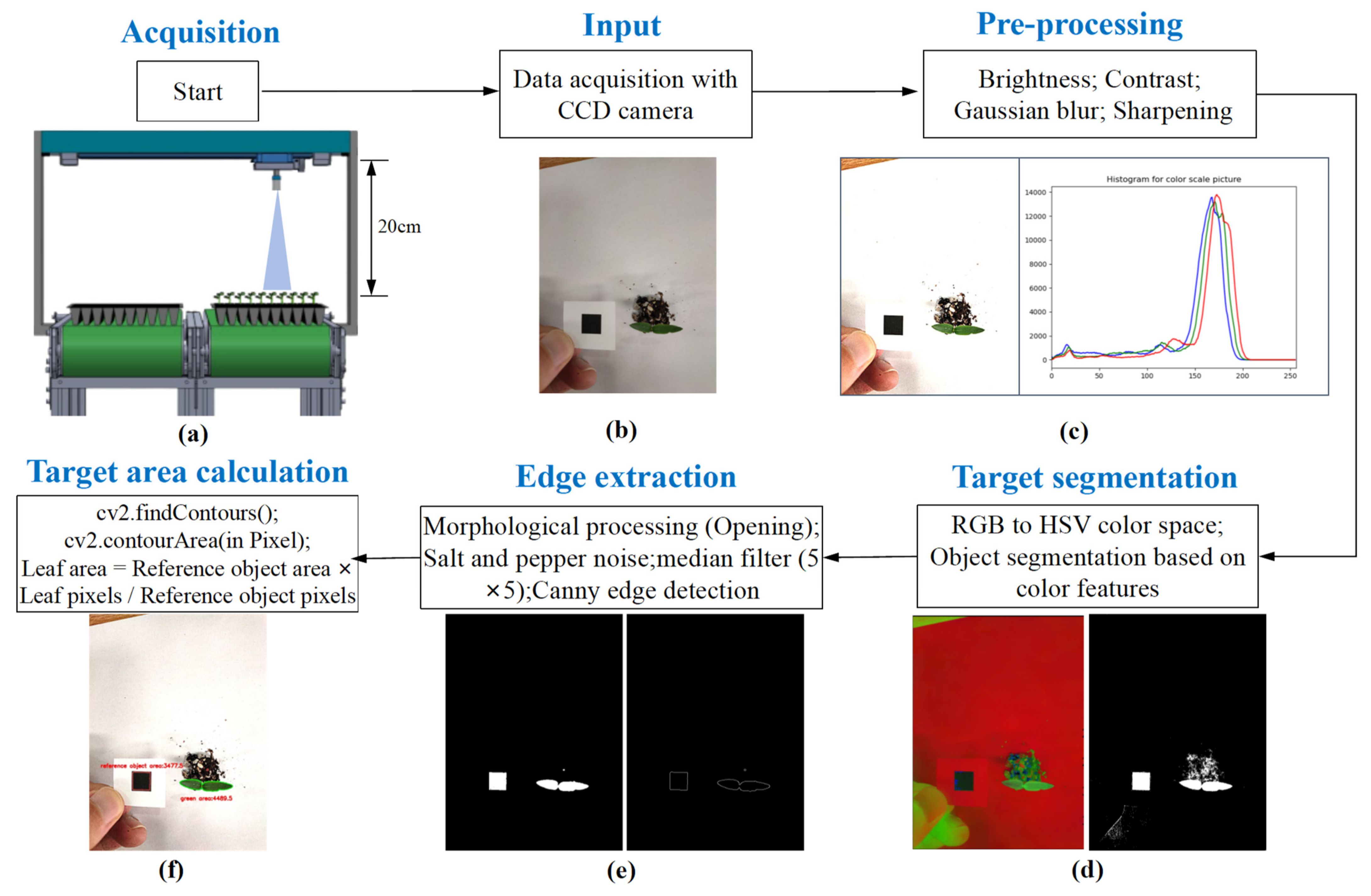

2.2. Test Methods for Plant Morphological Parameters

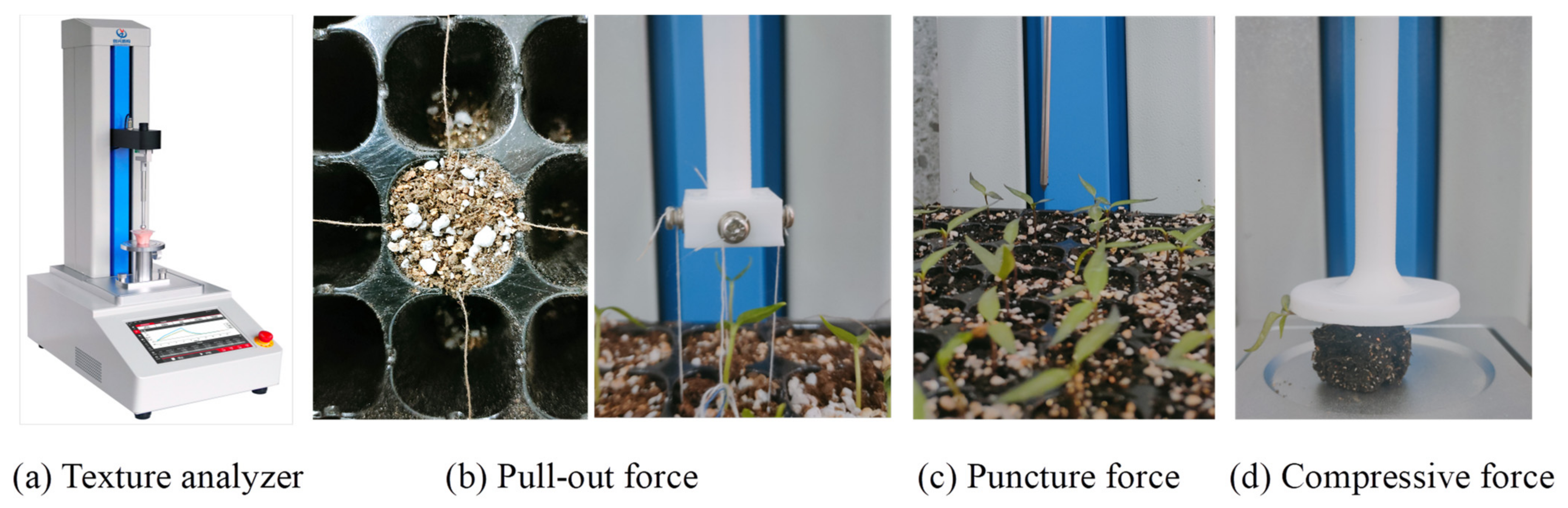

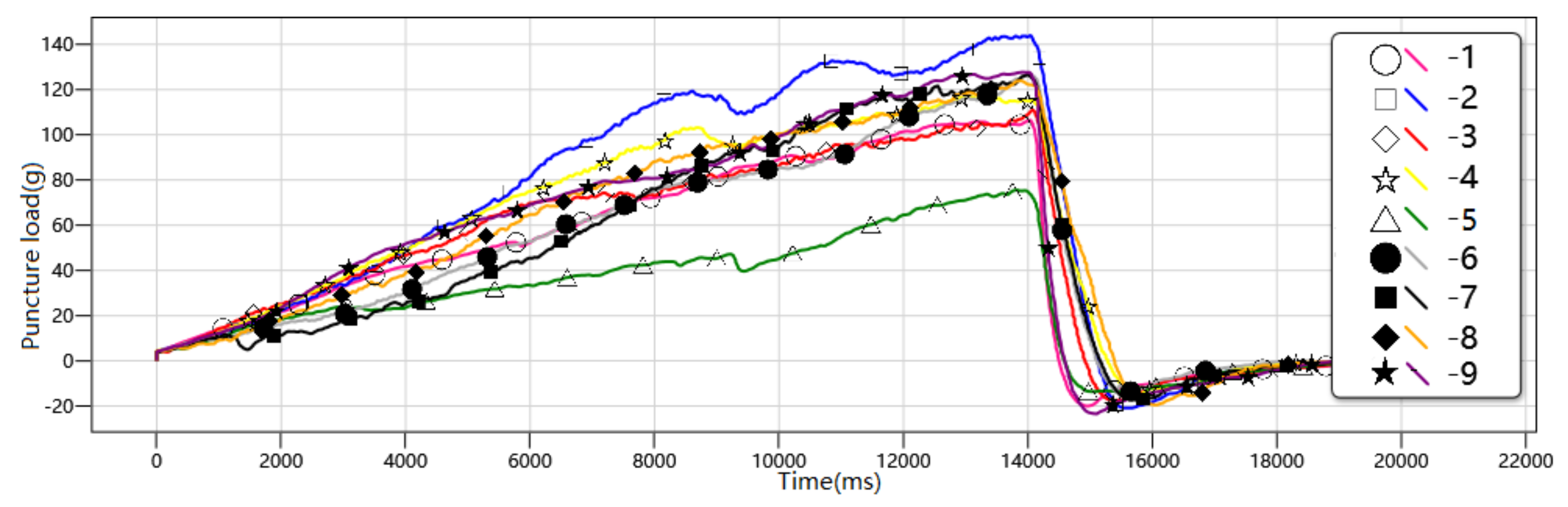

2.3. Test Methods for Mechanical Properties

2.4. BPNN Construction

- Mean square error (MSE):

- Mean absolute error (MAE):

- Mean absolute percentage error (MAPE):

- Coefficient of determination (R2):

3. Results and Discussion

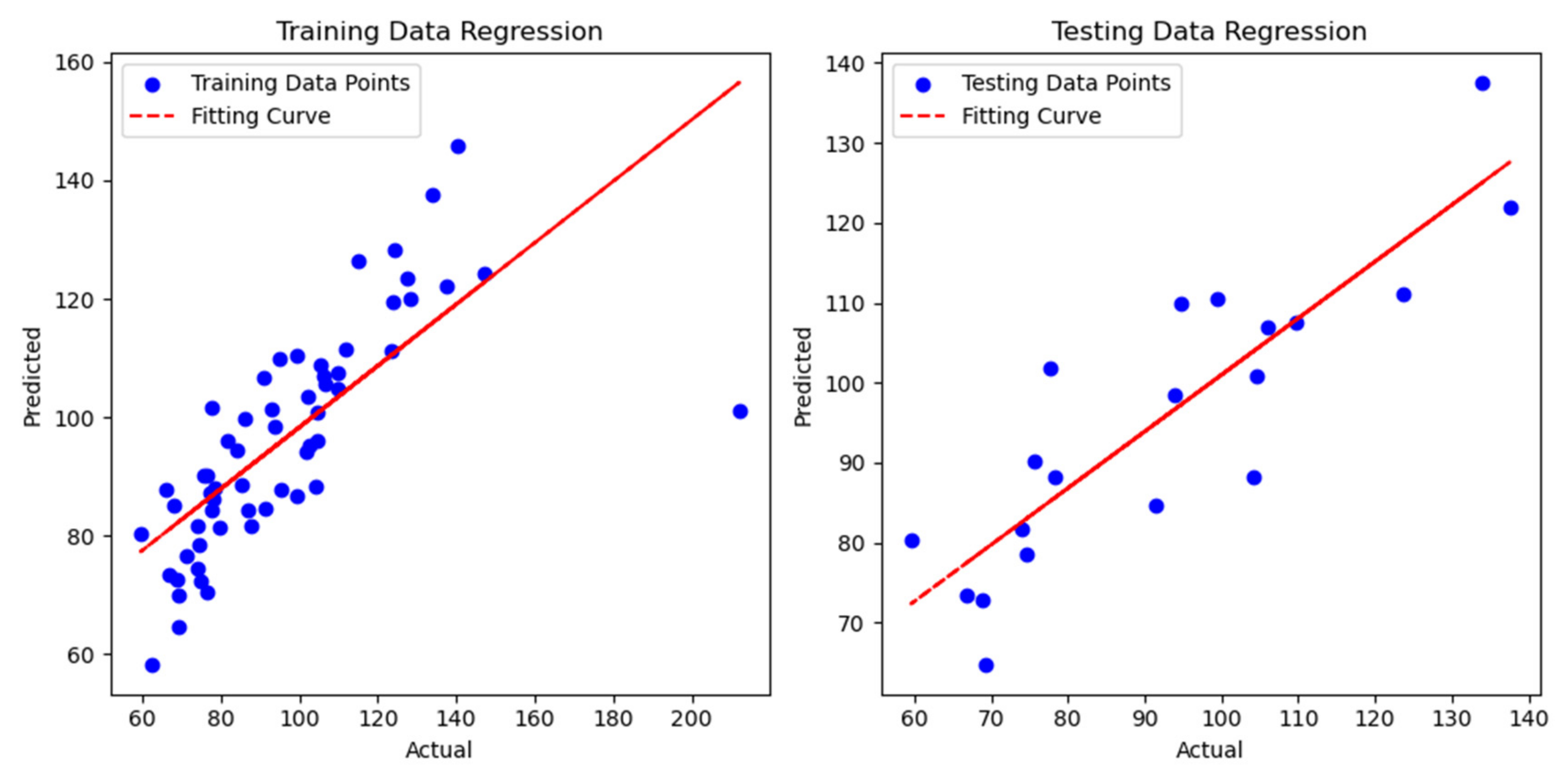

3.1. Neural Network Framework Results

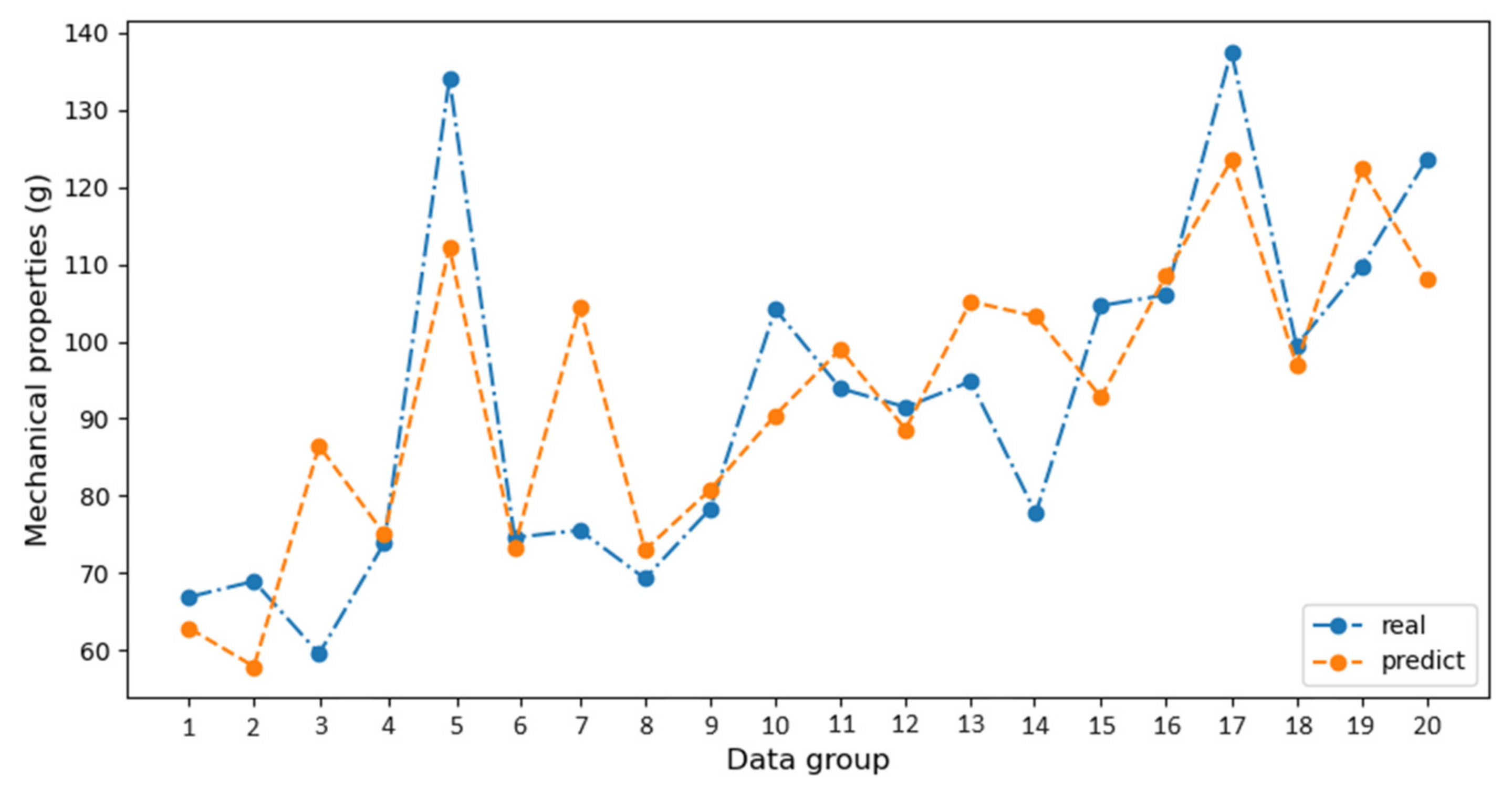

3.2. Prediction Verification Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rahul, K.; Raheman, H.; Paradkar, V. Design and development of a 5R 2DOF parallel robot arm for handling paper pot seedlings in a vegetable transplanter. Comput. Electron. Agric. 2013, 166, 105014. [Google Scholar] [CrossRef]

- Tian, Z.; Ma, W.; Yang, Q.; Yao, S.; Zhang, M.; Duan, F.; Xu, H. Research status and problem analysis of plug seedling transplanter in greenhouse. J. China Agric. Univ. 2022, 27, 22–38. [Google Scholar]

- Hu, J.; Han, L.; Wen, Y.; Yu, S.; Yang, Y. Mechanical properties of different vegetable seedlings associated with automatic transplanting. J. Agric. Mech. Res. 2018, 40, 132–136. [Google Scholar]

- Mohamed, S.; Liu, J. Effect of soil moisture content and end-effector speed on pick-up force and lump damage for seedling transplanting. AgriEngineering 2019, 1, 26. [Google Scholar] [CrossRef]

- Jiang, Z.; Hu, Y.; Jiang, H.; Tong, J. Design and force analysis of end-effector for plug seedling transplanter. PLoS ONE 2017, 12, e0180229. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Cao, W.; Tian, D.; Ouyang, Y.; Zhao, H. Optimization experiment of transplanting actuator parameters based on mechanical property of seedling pot. Trans. CSAE 2016, 32, 32–39. [Google Scholar]

- Ren, Z.; Wang, W.; Feng, J.; Yu, J. Experimental study on mechanical properties of plug seedlings. J. Chin. Agric. Mech. 2020, 41, 169–174. [Google Scholar]

- Zhang, N.; Kang, J.; Wang, X.; Peng, Q.; Zhang, C.; Wang, Y. Simulation and experiment on seeding performance of peanutroller type hill-drop planter based on EDEM. J. Chin. Agric. Mech. 2021, 42, 1–6. [Google Scholar]

- Wang, M.; Liu, Q.; Ou, Y.; Zou, X. Numerical simulation and verification of seed-filling performance of single-bud billet sugarcane seed-metering device based on EDEM. Agriculture 2022, 12, 983. [Google Scholar] [CrossRef]

- Bai, H.; Li, X.; Zeng, F.; Su, Q.; Cui, J.; Wang, J.; Zhang, Y. Calibration and experiments of the simulation bonding parameters for plug seedling substrate block. INMATEH Agric. Eng. 2023, 69, 617–625. [Google Scholar] [CrossRef]

- Gao, G.; Wang, K.; Sun, X. Verification for EDEM simulation of process of jacking tray-seedling by steel needle in grafting machine and parameter optimization. Trans. CSAE 2017, 33, 29–35. [Google Scholar]

- Bai, H. Based on the collision damage test and prediction model of the cavity tray seedling of the hanging cup transplanter. Inn. Mong. Agric. Univ. 2023, 3, 16–65. [Google Scholar]

- Emmert-Streib, F.; Yang, Z.; Feng, H.; Tripathi, S.; Dehmer, M. An introductory review of deep learning for prediction models with big data. Front. Artif. Intell. 2020, 28, 4. [Google Scholar] [CrossRef] [PubMed]

- Jiang, M. Research on decision support system for prediction and control of apple tree diseases and insect pests. Shandong Agric. Univ. 2015, 14, 35–56. [Google Scholar]

- Arthit, A.; Supachai, P.; Kullapapruk, P. The role of pig size prediction in supply chain planning. Biosyst. Eng. 2012, 113, 298–307. [Google Scholar]

- Pareek, C.M.; Tewari, V.K.; Machavaram, R.; Brajesh, N. Optimizing the seed-cell filling performance of an inclined plate seed metering device using integrated ANN-PSO approach. Artif. Intell. Agric. 2021, 5, 1–12. [Google Scholar] [CrossRef]

- Kumar, S.P.; Tewari, V.K.; Chandel, A.K.; Mehta, C.R.; Pareek, C.M.; Chethan, C.R.; Nare, B. Modelling specific energy requirement for a power-operated vertical axis rotor type intra-row weeding tool using Artificial Neural Network. Appl. Sci 2023, 13, 10084. [Google Scholar] [CrossRef]

- Wang, M.; Wan, P.; Guo, J.; Xu, J.; Chai, Y.; Yue, M. Relationships among Leaf, Stem and Root Traits of the Dominant Shrubs from Four Vegetation Zones in Shaanxi Province, China. Isr. J. Ecol. Evol. 2017, 4, 25–32. [Google Scholar] [CrossRef]

- Tong, J.; Li, J.; Jiang, H. Machine vision techniques for the evaluation of seedling quality based on leaf area. Biosyst. Eng. 2013, 115, 369–379. [Google Scholar] [CrossRef]

- Tian, Z.; Ma, W.; Yang, Q.; Yao, S.; Guo, X.; Duan, F. Design and experiment of gripper for greenhouse plug seedling transplanting based on EDM. Agronomy 2022, 12, 1487. [Google Scholar] [CrossRef]

- Uzair, M.; Jamil, N. Effects of hidden layers on the efficiency of neural networks. In Proceedings of the IEEE 23rd International Multitopic Conference (INMIC), Bahawalpur, Pakistan, 5–7 November 2020; pp. 1–6. [Google Scholar]

- Karsoliya, S.; Abul Kalam Azad, M. Approximating number of hidden layer neurons in multiple hidden layer BPNN architecture. Int. J. Eng. Trends Technol. 2012, 3, 714–717. [Google Scholar]

- Guan, C.; Xu, T.; Cui, Z.; Yang, Y.; Chen, Y.; Gao, Q. Optimized parameters for compression molding of vegetable seedling substrate block for mechanical transplanting. Agric. Eng. J. 2020, 29, 1–12. [Google Scholar]

- Liu, W.; Tian, S.; Wang, Q. Key technologies of plug tray seedling transplanters in protected agriculture: A review. Agriculture 2023, 13, 1488. [Google Scholar] [CrossRef]

- Pohan, S.; Warsito, B.; Suryono, S. Back propagation artificial neural network for prediction plant seedling growth. J. Phys. Conf. Ser 2020, 1524, 012147. [Google Scholar] [CrossRef]

- Zhou, M.M.M.; Kimbeng, C.A.; Tew, T.L.; Gravois, K.A.; Pontif, M.J. Artificial neural network models as a decision support tool for selection in sugarcane: A case study using seedling populations. Crop Sci. 2011, 51, 21–31. [Google Scholar] [CrossRef]

- Hara, P.; Piekutowska, M.; Niedbała, G. Prediction of Pea (Pisum sativum L.) seeds yield using artificial neural networks. Agriculture 2023, 13, 661. [Google Scholar] [CrossRef]

- Han, L.; Mao, H.; Hu, J.; Miao, X.; Tian, K.; Yang, X. Experiment on mechanical property of seedling pot for automatic transplanter. Trans. Chin. Soc. Agric. Eng. 2013, 29, 24–29. [Google Scholar]

| No. | Number of Hidden Layers | Hidden Layer 1 | Hidden Layer 2 | Hidden Layer 3 | MAE | MSE | MAPE (%) | R2 |

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 5 | 5 | 0 | 11.289 | 191.325 | 12.350% | 0.607 |

| 2 | 2 | 6 | 6 | 0 | 12.023 | 231.834 | 13.924% | 0.524 |

| 3 | 2 | 7 | 7 | 0 | 11.761 | 231.280 | 13.727% | 0.525 |

| 4 | 2 | 8 | 8 | 0 | 13.637 | 268.522 | 15.624% | 0.448 |

| 5 | 2 | 9 | 9 | 0 | 13.550 | 257.552 | 15.164% | 0.471 |

| 6 | 2 | 10 | 10 | 0 | 12.867 | 228.178 | 14.509% | 0.531 |

| 7 | 2 | 11 | 11 | 0 | 12.189 | 224.697 | 13.687% | 0.539 |

| 8 | 2 | 12 | 12 | 0 | 9.327 | 143.817 | 11.132% | 0.705 |

| 9 | 2 | 13 | 13 | 0 | 11.710 | 218.793 | 13.588% | 0.551 |

| 10 | 2 | 14 | 14 | 0 | 9.527 | 157.982 | 10.935% | 0.676 |

| 11 | 2 | 15 | 15 | 0 | 7.669 | 88.842 | 9.076% | 0.867 |

| 12 | 3 | 5 | 5 | 2 | 12.155 | 239.242 | 13.654% | 0.509 |

| 13 | 3 | 6 | 6 | 3 | 11.876 | 206.582 | 13.571% | 0.576 |

| 14 | 3 | 7 | 7 | 3 | 13.495 | 283.368 | 15.416% | 0.418 |

| 15 | 3 | 8 | 8 | 4 | 13.942 | 289.851 | 15.917% | 0.405 |

| 16 | 3 | 9 | 9 | 4 | 13.497 | 258.325 | 15.250% | 0.471 |

| 17 | 3 | 10 | 10 | 5 | 9.117 | 138.587 | 10.582% | 0.715 |

| 18 | 3 | 11 | 11 | 5 | 11.715 | 191.551 | 13.375% | 0.607 |

| 19 | 3 | 12 | 12 | 6 | 12.847 | 233.136 | 14.804% | 0.521 |

| 20 | 3 | 13 | 13 | 6 | 12.998 | 252.724 | 14.989% | 0.481 |

| 21 | 3 | 14 | 14 | 7 | 12.572 | 229.730 | 14.844% | 0.528 |

| 22 | 3 | 15 | 15 | 7 | 9.191 | 141.258 | 10.884% | 0.710 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Z.; Gao, A.; Ma, W.; Jiang, H.; Cao, D.; Wang, W.; Qian, J.; Xu, L. Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks. Agriculture 2024, 14, 651. https://doi.org/10.3390/agriculture14050651

Tian Z, Gao A, Ma W, Jiang H, Cao D, Wang W, Qian J, Xu L. Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks. Agriculture. 2024; 14(5):651. https://doi.org/10.3390/agriculture14050651

Chicago/Turabian StyleTian, Zhiwei, Ang Gao, Wei Ma, Huanyu Jiang, Dongping Cao, Weizi Wang, Jianping Qian, and Lijia Xu. 2024. "Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks" Agriculture 14, no. 5: 651. https://doi.org/10.3390/agriculture14050651