The Efficiencies, Environmental Impacts and Economics of Energy Consumption for Groundwater-Based Irrigation in Oklahoma

Abstract

:1. Introduction

2. Materials and Methods

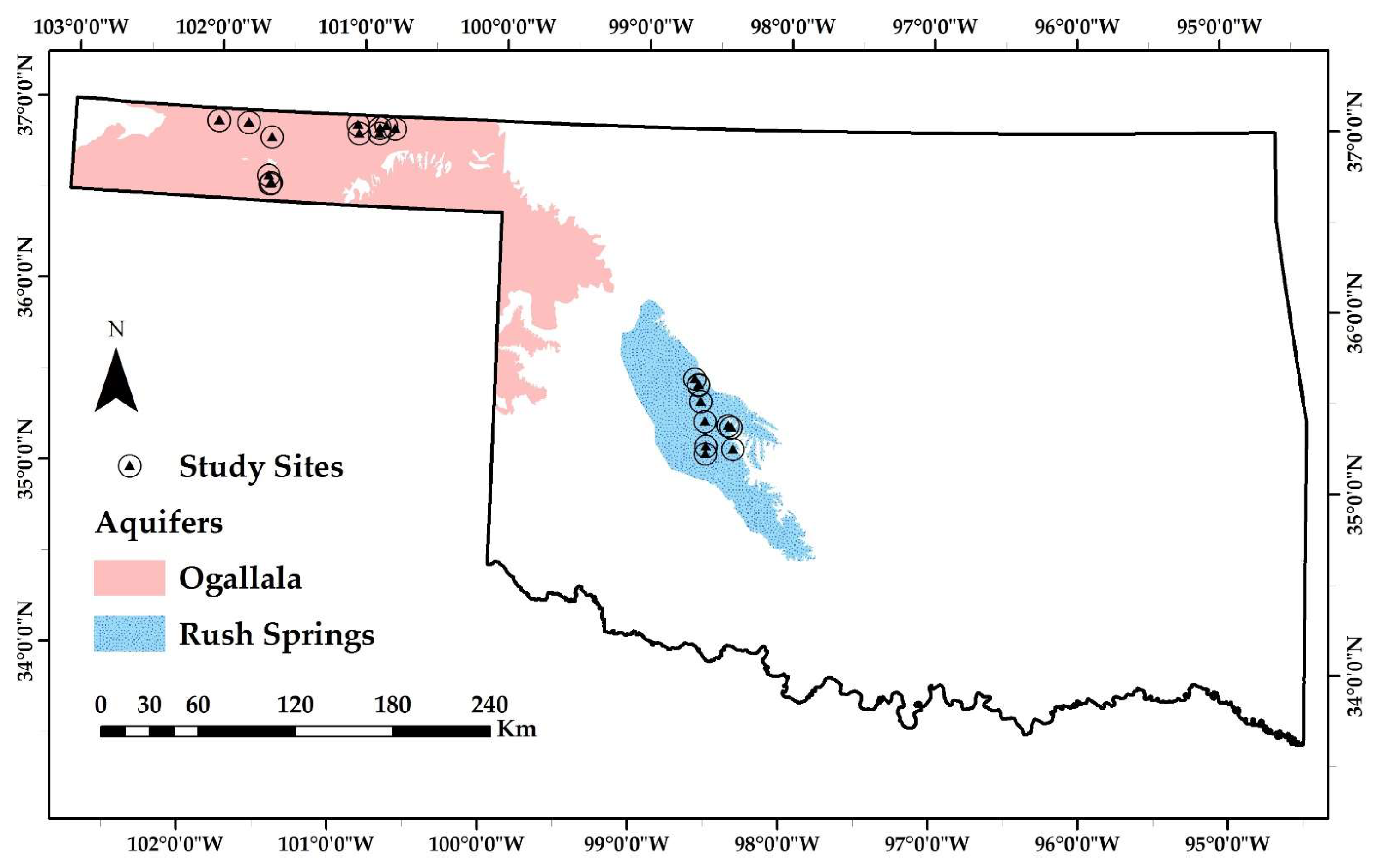

2.1. Study Area

2.2. Energy Audits

2.2.1. Electric Motors

2.2.2. Natural Gas Engines

2.3. Life Cycle Assessment

2.4. Long-Term Trends

2.5. Economic Analysis

3. Results and Discussion

3.1. Energy Audits

3.2. Life Cycle Assessment

3.3. Long-Term Trends

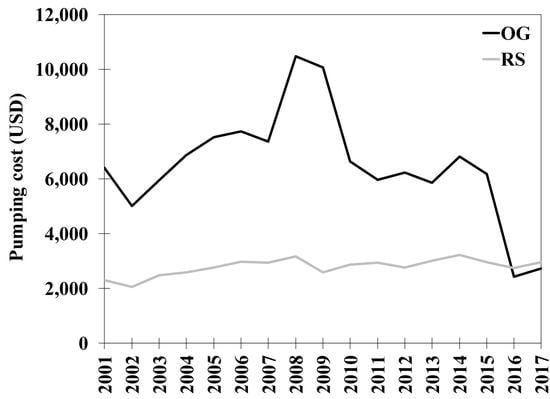

3.4. Economic Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Khan, M.A.; Khan, M.Z.; Zaman, K.; Naz, L. Global estimates of energy consumption and greenhouse gas emissions. Renew. Sustain. Energy Rev. 2014, 29, 336–344. [Google Scholar] [CrossRef]

- Pradeleix, L.; Roux, P.; Bouarfa, S.; Jaouani, B.; Lili-Chabaane, Z.; Bellon-Maurel, V. Environmental impacts of contrasted groundwater pumping systems assessed by life cycle assessment methodology: Contribution to the water-energy nexus study. Irrig. Drain. 2015, 64, 124–138. [Google Scholar] [CrossRef]

- Wang, J.; Rothausen, S.G.; Conway, D.; Zhang, L.; Xiong, W.; Holman, I.P.; Li, Y. China’s water–energy nexus: Greenhouse-gas emissions from groundwater use for agriculture. Environ. Res. Lett. 2012, 7, 014035. [Google Scholar] [CrossRef]

- Karimi, P.; Qureshi, A.S.; Bahramloo, R.; Molden, D. Reducing carbon emissions through improved irrigation and groundwater management: A case study from Iran. Agric. Water Manag. 2012, 108, 52–60. [Google Scholar] [CrossRef]

- Shah, T. Climate change and groundwater: India’s opportunities for mitigation and adaptation. Environ. Res. Lett. 2009, 4, 035005. [Google Scholar] [CrossRef] [Green Version]

- Follett, R.F. Soil management concepts and carbon sequestration in cropland soils. Soil Tillage Res. 2001, 61, 77–92. [Google Scholar] [CrossRef]

- Patle, G.T.; Singh, D.K.; Sarangi, A.; Khanna, M. Managing CO2 emission from groundwater pumping for irrigating major crops in trans indo-gangetic plains of India. Clim. Chang. 2016, 136, 265–279. [Google Scholar] [CrossRef]

- Luc, J.P.; Tarhouni, J.; Calvez, R.; Messaoud, L.; Sablayrolles, C. Performance indicators of irrigation pumping stations: Application to drill holes of minor irrigated areas in the Kairouan plains (Tunisia) and impact of malfunction on the price of water. Irrig. Drain. 2006, 55, 85–98. [Google Scholar] [CrossRef]

- Mora, M.; Vera, J.; Rocamora, C.; Abadia, R. Energy efficiency and maintenance costs of pumping systems for groundwater extraction. Water Resour. Manag. 2013, 27, 4395–4408. [Google Scholar] [CrossRef]

- Qiu, G.Y.; Zhang, X.; Yu, X.; Zou, Z. The increasing effects in energy and GHG emission caused by groundwater level declines in North China’s main food production plain. Agric. Water Manag. 2018, 203, 138–150. [Google Scholar] [CrossRef]

- Taghvaeian, S. Irrigated Agriculture in Oklahoma. Oklahoma Cooperative Extension, Publication BAE-1530. 2014. Available online: http://pods.dasnr.okstate.edu/docushare/dsweb/Get/Document-9561/BAE-1530web.pdf (accessed on 10 October 2018).

- Oklahoma Water Resources Board. Oklahoma Groundwater Report. Beneficial Use Monitoring Program. 2017. Available online: https://www.owrb.ok.gov/quality/monitoring/bump/pdf_bump/Reports/GMAPReport.pdf (accessed on 10 October 2018).

- Brar, D.; Kranz, W.L.; Lo, T.H.; Irmak, S.; Martin, D.L. Energy conservation using variable-frequency drives for centerpivot irrigation: Standard systems. Trans. ASABE 2017, 60, 95–106. [Google Scholar]

- Masasi, B.; Frazier, R.S.; Taghvaeian, S. Review and Operational Guidelines for Portable Ultrasonic Flowmeters. Oklahoma Cooperative Extension, Publication BAE-1535. 2017. Available online: http://pods.dasnr.okstate.edu/docushare/dsweb/Get/Document-10723/BAE-1535web.pdf (accessed on 10 October 2018).

- Frazier, R.S.; Taghvaeian, S.; Handa, D. Measuring Depth to Groundwater in Irrigation Wells. Oklahoma Cooperative Extension, Publication BAE-1538. 2017. Available online: http://pods.dasnr.okstate.edu/docushare/dsweb/Get/Document-10865/BAE-1538web.pdf (accessed on 10 October 2018).

- Ross, E.A.; Hardy, L.A. National Engineering Handbook; Irrigation Guide; USDA: Beltsville, MD, USA, 1997.

- Hanson, B. Improving pumping plant efficiency does not always save energy. Calif. Agric. 2002, 56, 123–127. [Google Scholar] [CrossRef] [Green Version]

- U.S. Environmental Protection Agency. Greenhouse Gas Inventory Guidance; United States Environmental Protection Agency: Washington, DC, USA, 2016. [Google Scholar]

- Rothausen, S.G.; Conway, D. Greenhouse-gas emissions from energy use in the water sector. Nat. Clim. Chang. 2011, 1, 210–219. [Google Scholar] [CrossRef]

- Shahdany, S.M.H.; Firoozfar, A.; Maestre, J.M.; Mallakpour, I.; Taghvaeian, S.; Karimi, P. Operational performance improvements in irrigation canals to overcome groundwater overexploitation. Agric. Water Manag. 2018, 204, 234–246. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. Available online: https://www.eia.gov/ (accessed on 10 October 2018).

- Barefoot, A.D. Investigation of Factors Affecting Energy for Irrigation Pumping; Oklahoma Water Resources Research Institute: Stillwater, OK, USA, 1980. [Google Scholar]

- Fipps, G.; Neal, B. Texas Irrigation Pumping Plant Efficiency Testing Program; Texas A & M University System: College Station, TX, USA, 1995. [Google Scholar]

- New, L.; Schneider, A.D. Irrigation Pumping Plant Efficiencies, High Plains and Trans-Pecos Areas of Texas; Texas Agricultural Experiment Station, Texas A & M University System: College Station, TX, USA, 1988. [Google Scholar]

- DeBoer, D.W.; Lundstrom, D.R.; Wright, J.A. Efficiency analysis of electric irrigation pumping plants in the upper Midwest, USA. Energy Agric. 1983, 2, 51–59. [Google Scholar] [CrossRef]

- Hardin, D.C.; Lacewell, R.D. Implication of improved irrigation pumping efficiency for farmer profit and energy use. J. Agric. Appl. Econ. 1979, 11, 89–94. [Google Scholar] [CrossRef]

- U.S. Department of Agriculture 2013 Farm and Ranch Irrigation Survey. Available online: https://www.nass.usda.gov/Publications/AgCensus/2012/Online_Resources/Farm_and_Ranch_Irrigation_Survey/ (accessed on 10 October 2018).

| Parameter | RS | OG |

|---|---|---|

| Static groundwater depth (m) | 24.4 | 79.7 |

| Dynamic groundwater depth (m) | 30.7 | 89.1 |

| Total dynamic head (m) | 67.8 | 105.9 |

| Discharge (l s−1) | 36.2 | 36.0 |

| Overall pumping efficiency (%) | 43.3 | 13.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Handa, D.; Frazier, R.S.; Taghvaeian, S.; Warren, J.G. The Efficiencies, Environmental Impacts and Economics of Energy Consumption for Groundwater-Based Irrigation in Oklahoma. Agriculture 2019, 9, 27. https://doi.org/10.3390/agriculture9020027

Handa D, Frazier RS, Taghvaeian S, Warren JG. The Efficiencies, Environmental Impacts and Economics of Energy Consumption for Groundwater-Based Irrigation in Oklahoma. Agriculture. 2019; 9(2):27. https://doi.org/10.3390/agriculture9020027

Chicago/Turabian StyleHanda, Divya, Robert S. Frazier, Saleh Taghvaeian, and Jason G. Warren. 2019. "The Efficiencies, Environmental Impacts and Economics of Energy Consumption for Groundwater-Based Irrigation in Oklahoma" Agriculture 9, no. 2: 27. https://doi.org/10.3390/agriculture9020027