A Fault-Tolerant Control Method Based on Reconfiguration SPWM Signal for Cascaded Multilevel IGBT-Based Propulsion in Electric Ships

Abstract

:1. Introduction

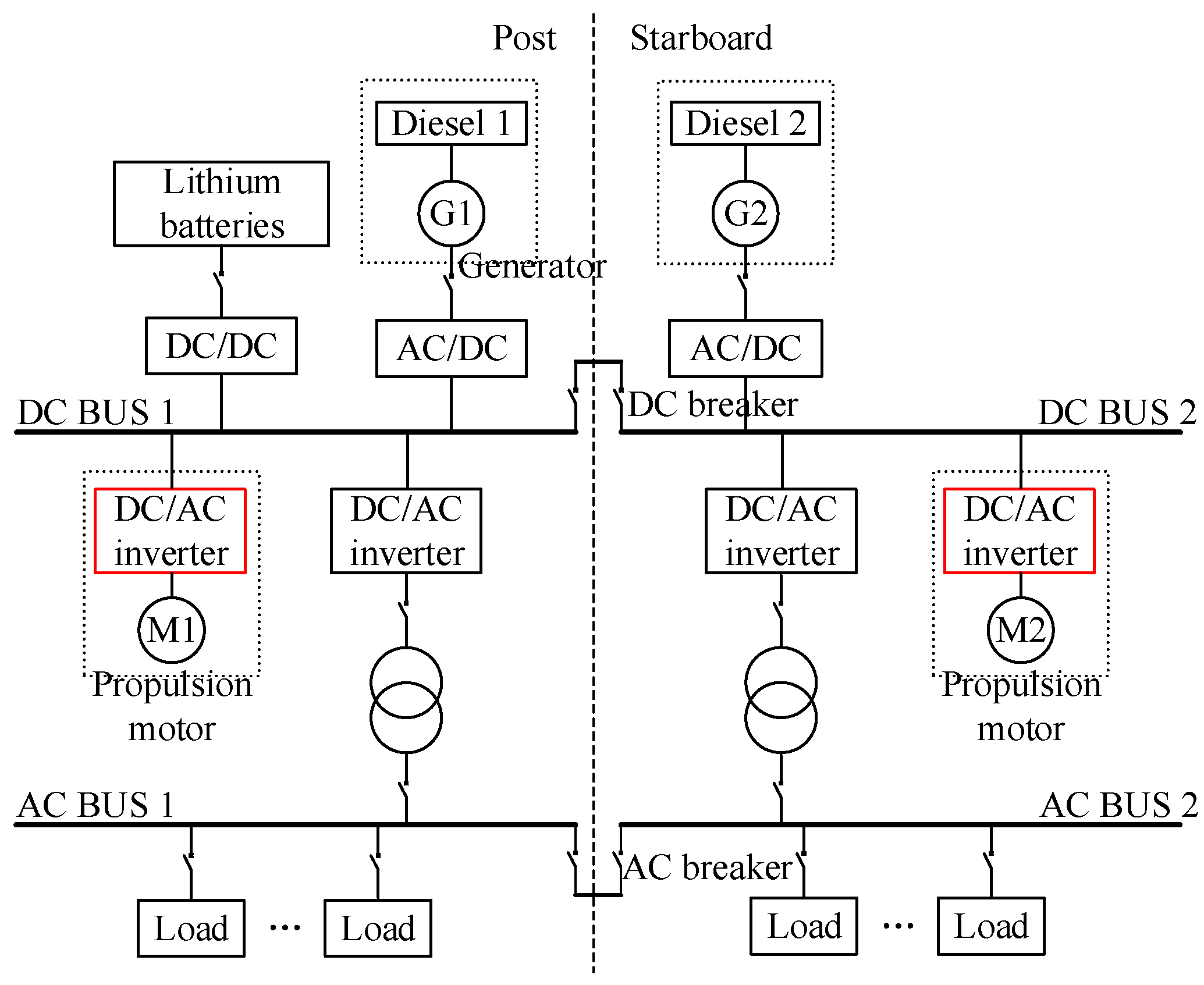

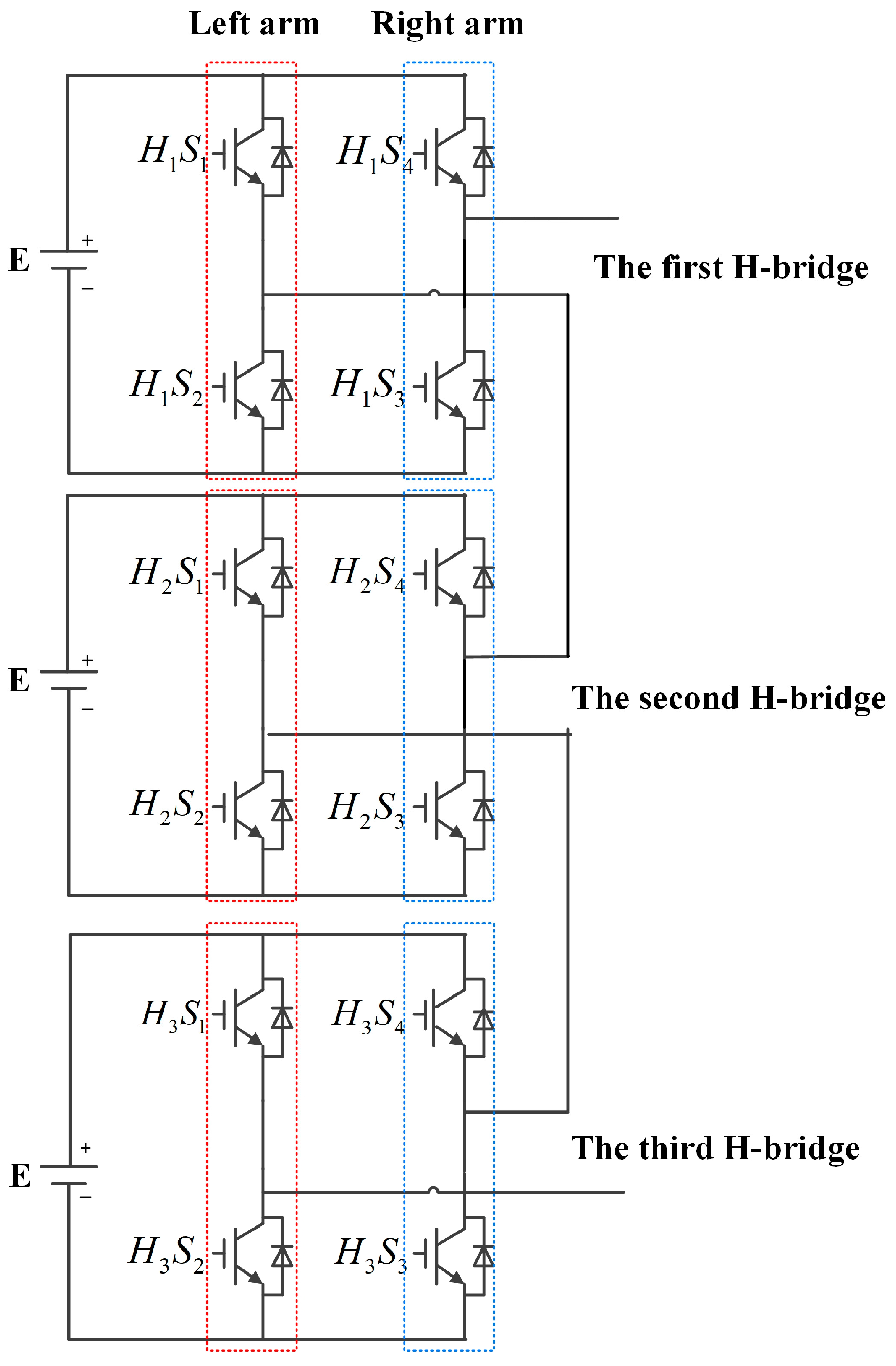

2. Problem Description

2.1. Operation State

2.2. Fault-Tolerant State

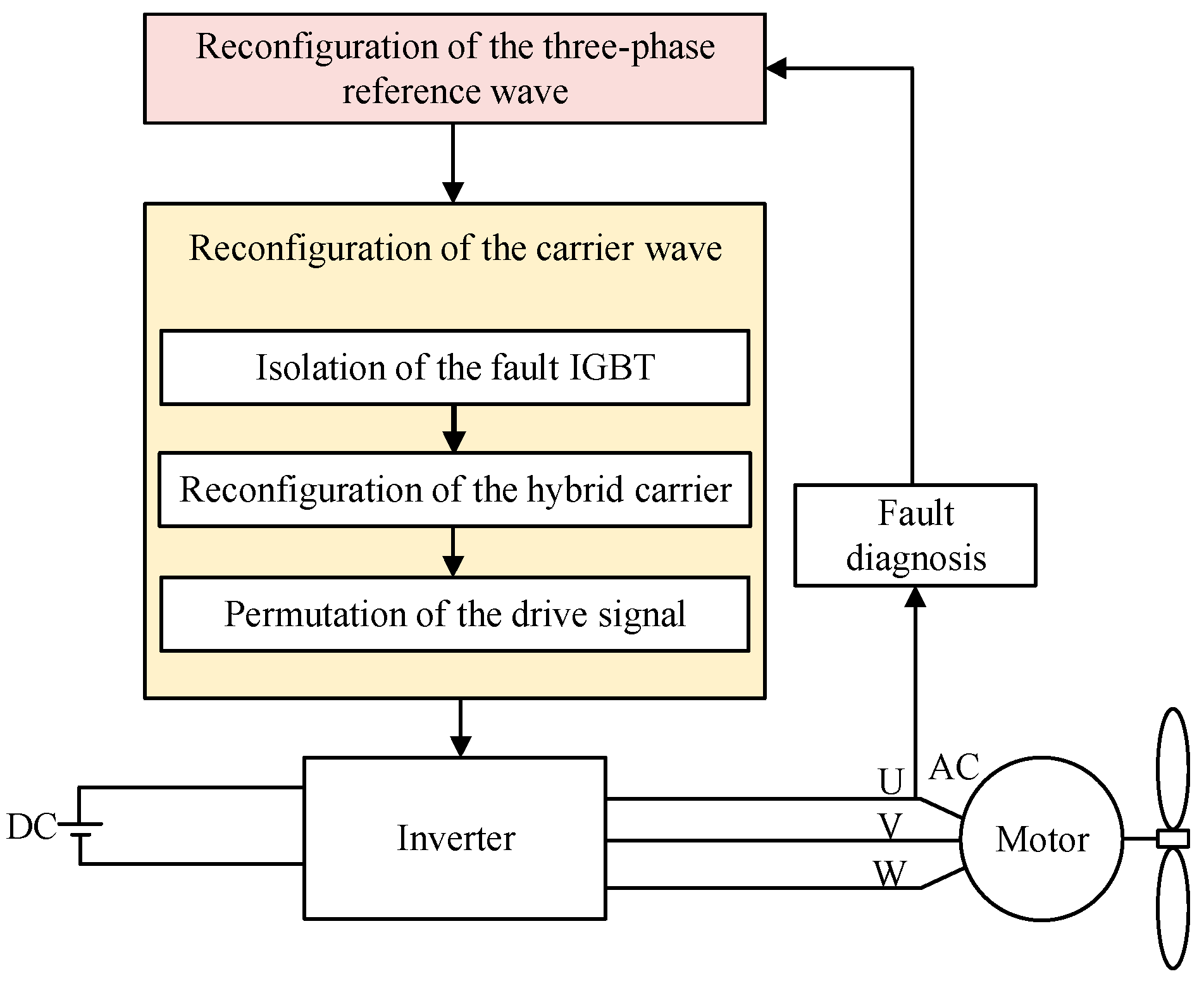

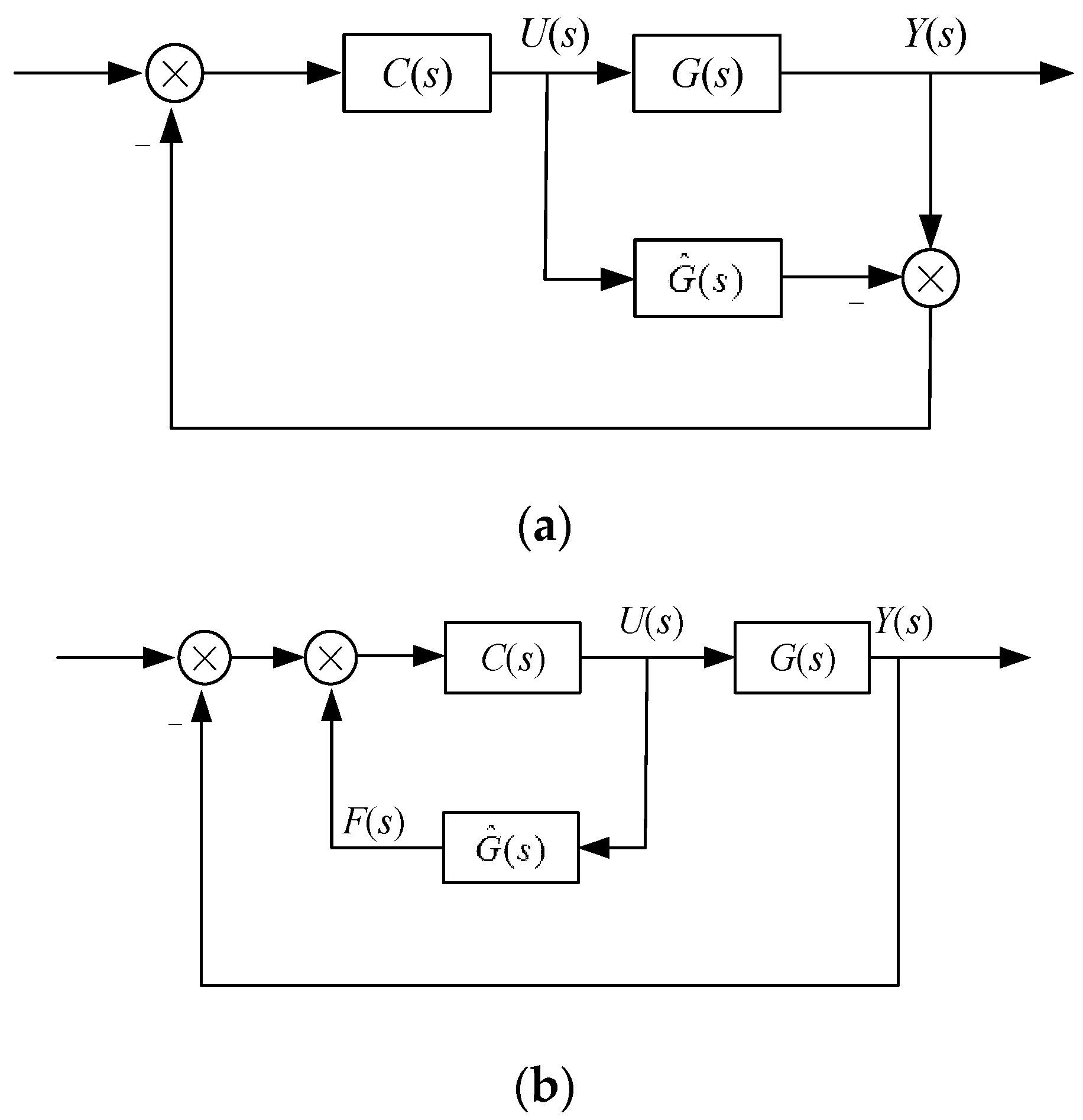

3. A Stratified Reconfiguration Carrier Disposition SPWM Fault-Tolerant Control Strategy

3.1. Reconfiguration of the Three-Phase Reference Wave

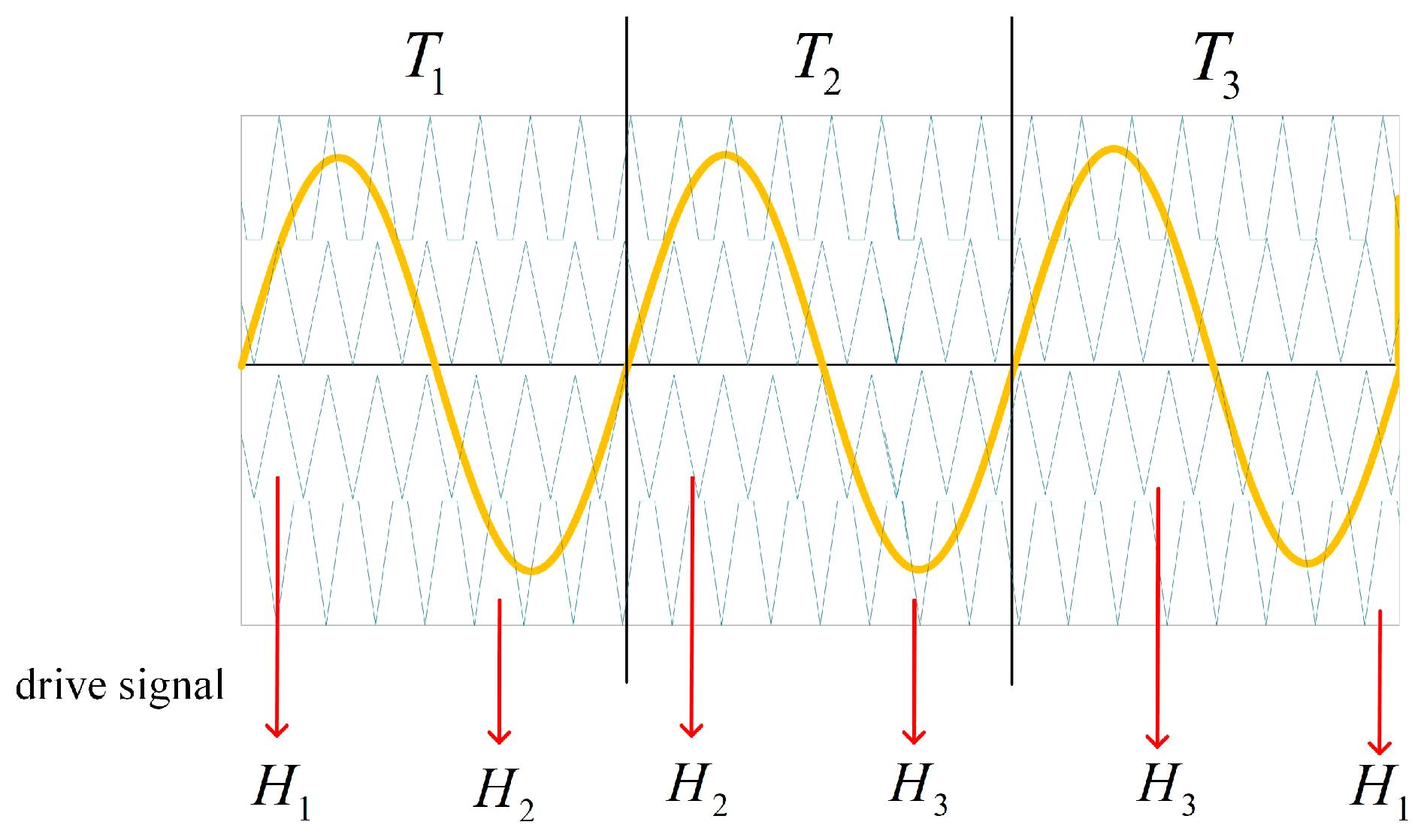

3.2. Reconfiguration of the Carrier Signal

3.2.1. Isolation of the Fault IGBT

3.2.2. Reconfiguration of the Hybrid Carrier

3.2.3. Redistribution of Drive Signal

4. Simulation Results and Analysis

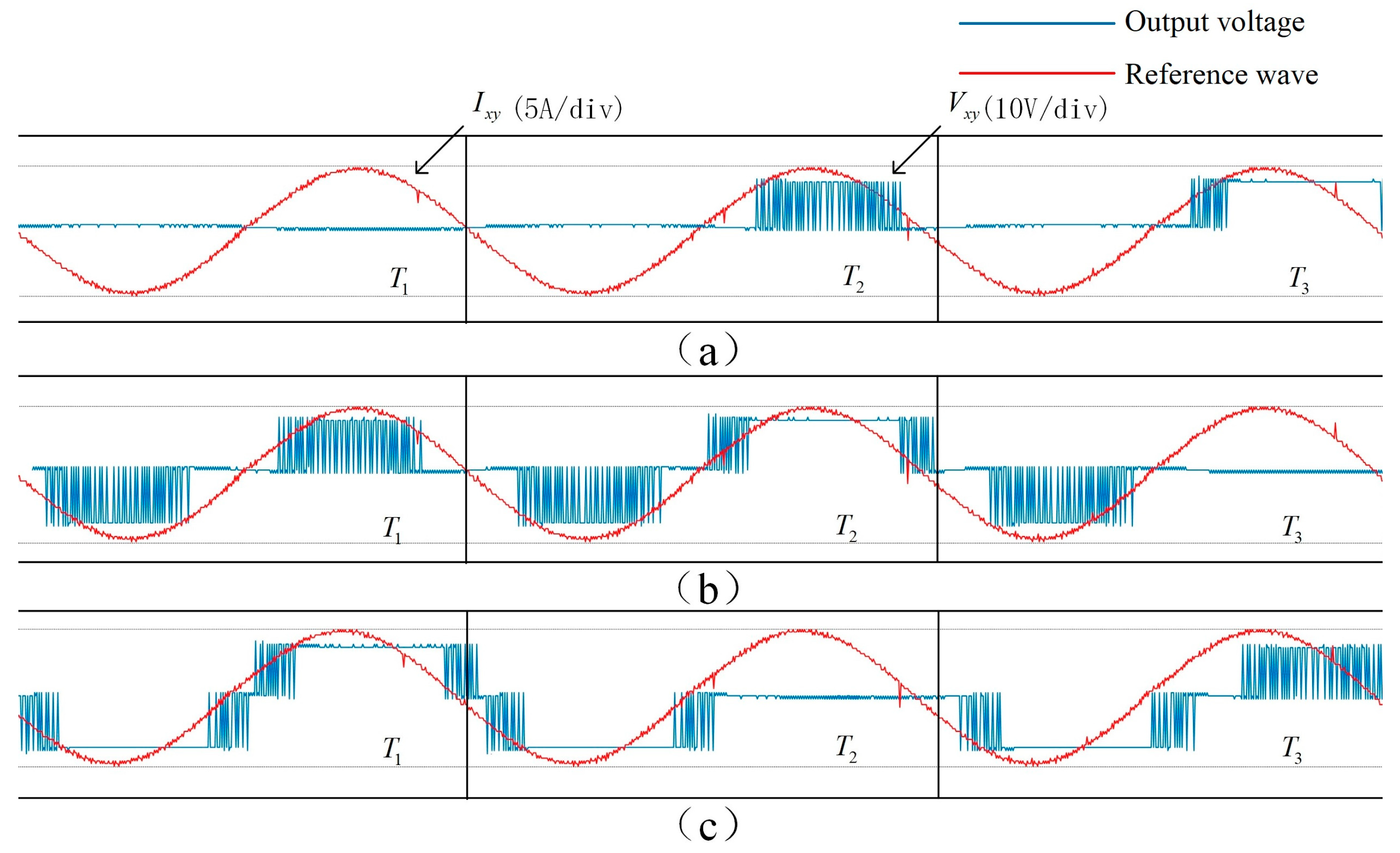

4.1. Simulation Results

4.1.1. Seven-Level Inverter

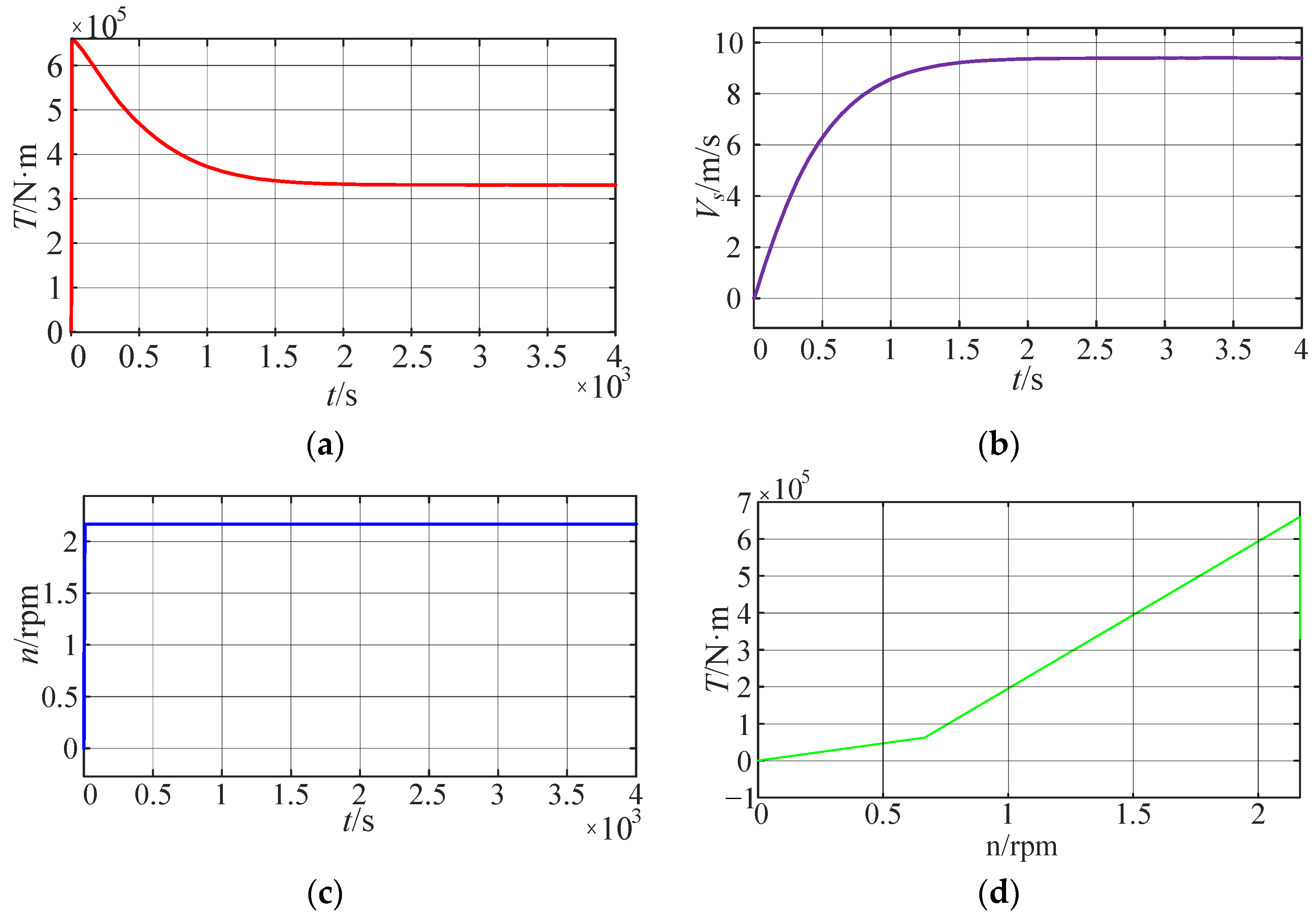

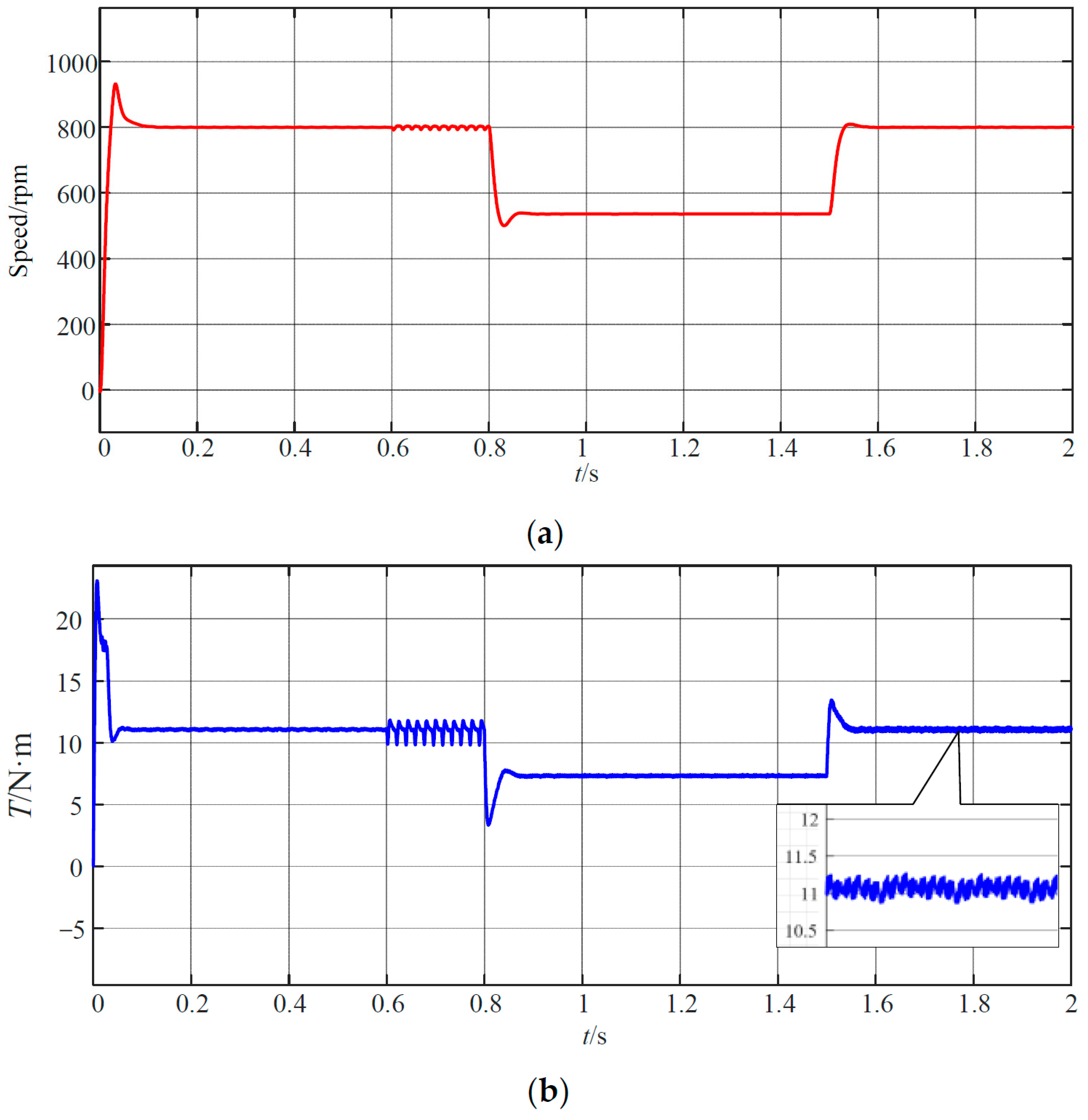

4.1.2. Motor Drive System

- (a)

- The parameters of Proportional Integral (PI) controller in the rotational speed loop

- (b)

- The parameters of PI controller in the current loop

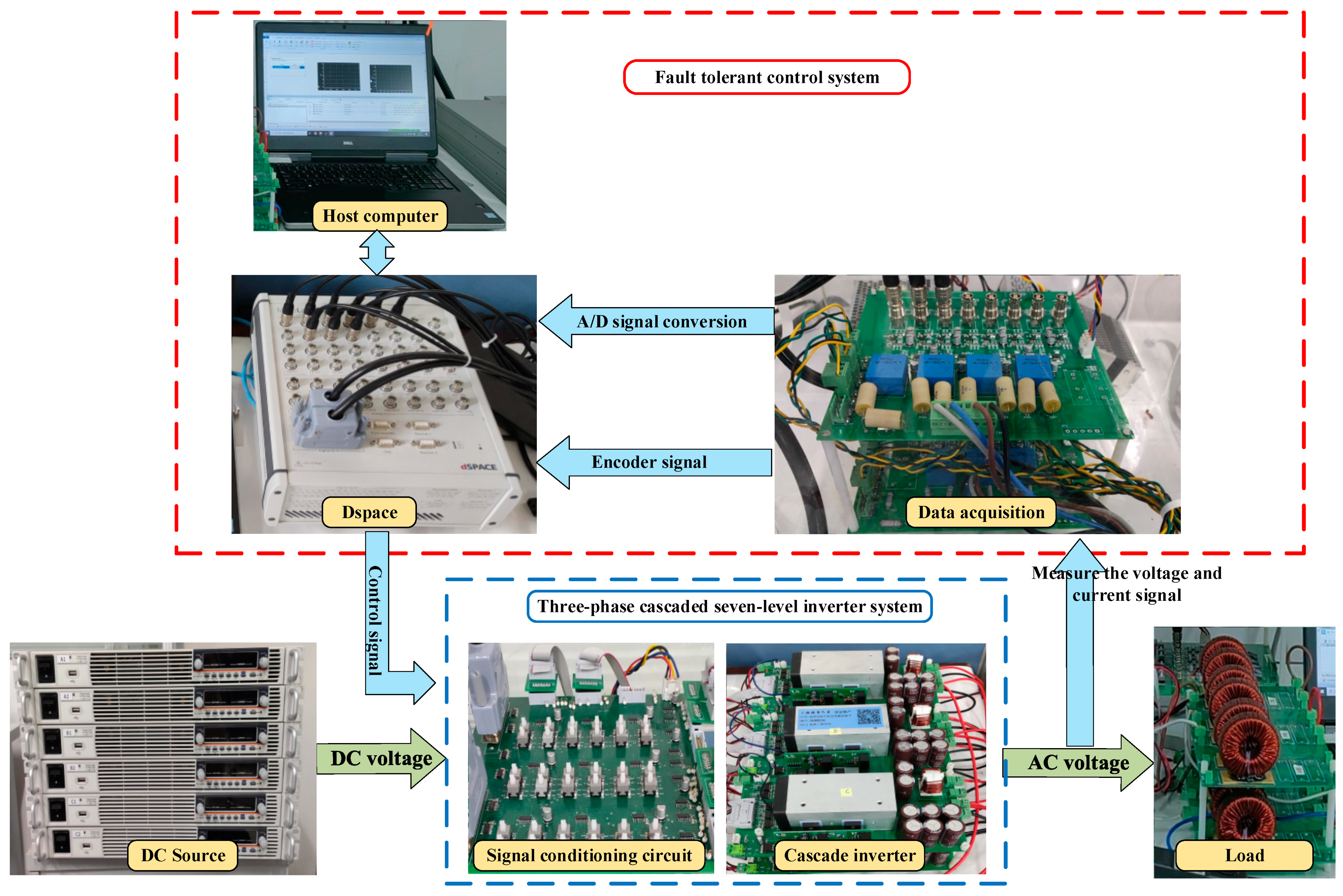

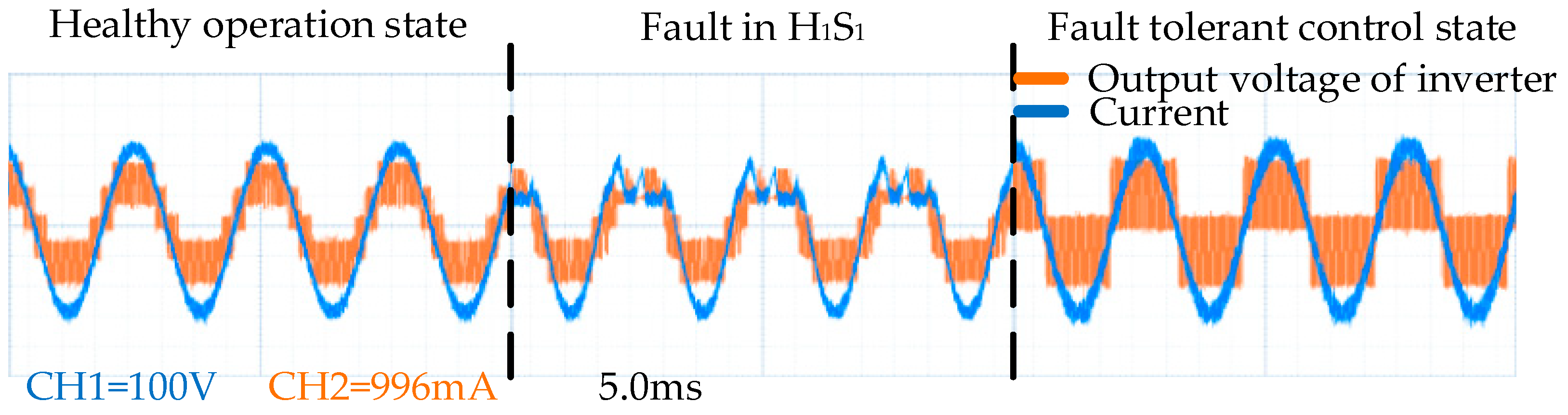

4.2. Experimental Results

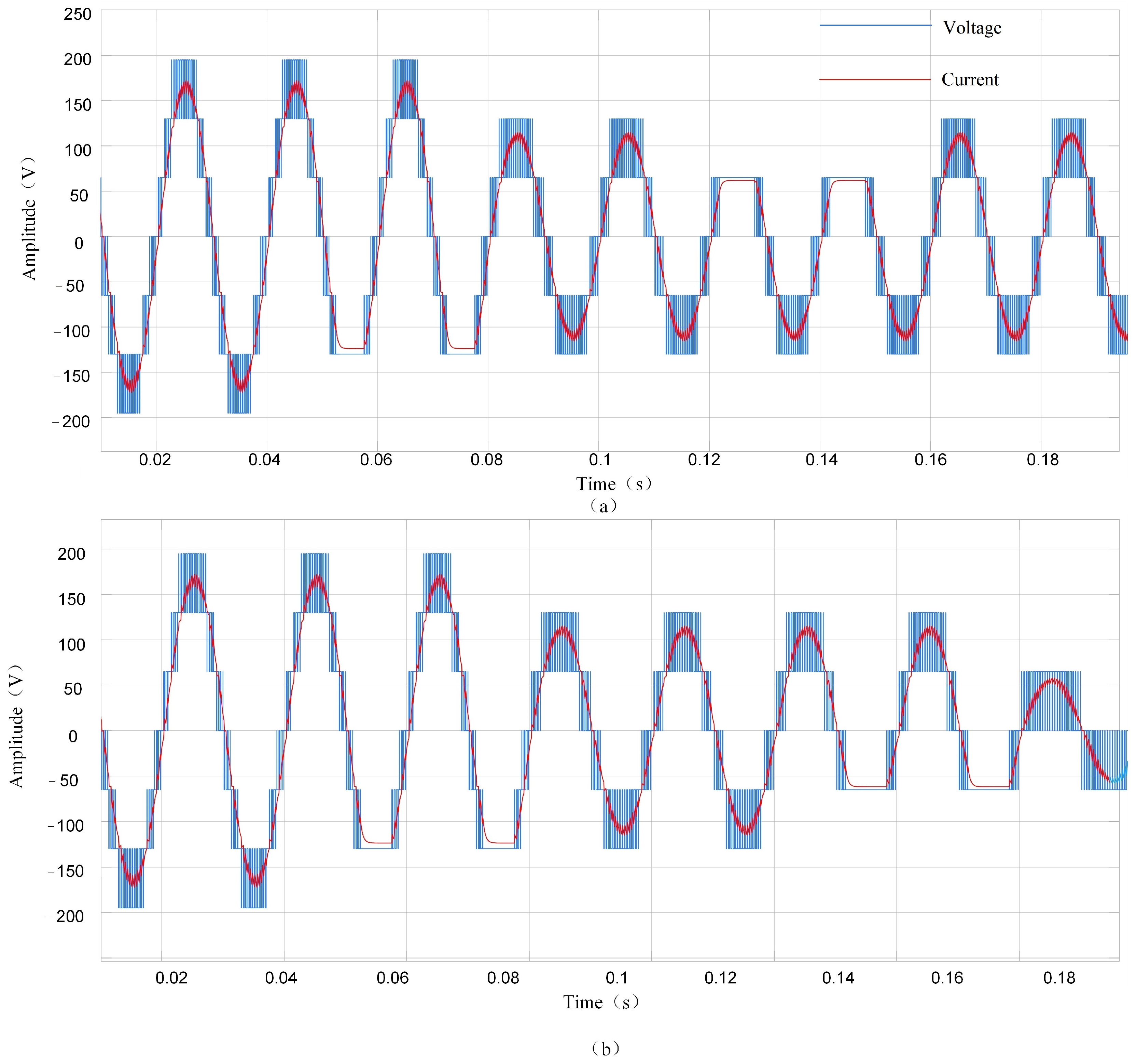

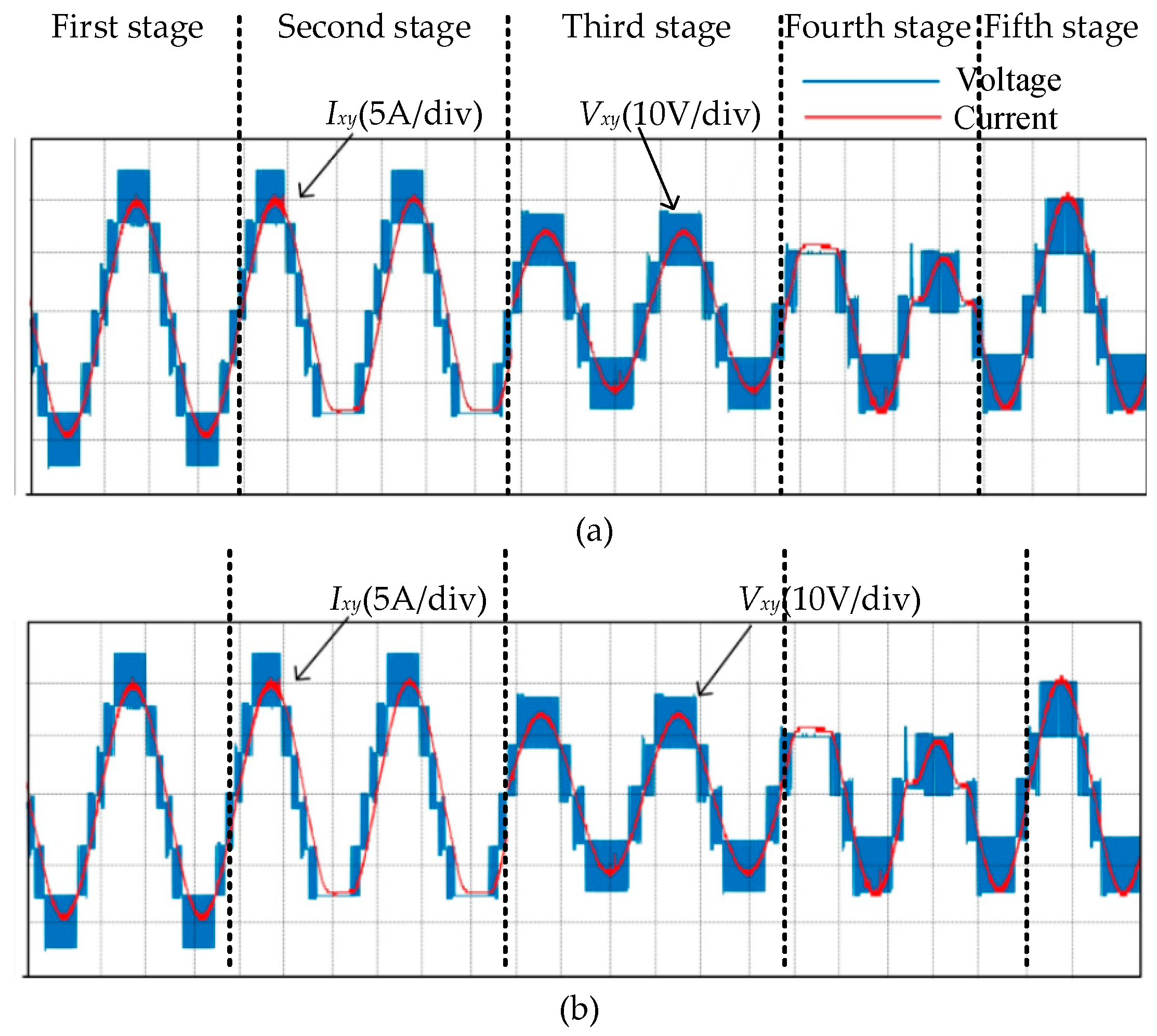

- (1)

- In the first stage, the inverter is in a normal working state. The output voltage of the inverter is a symmetrical seven-level voltage waveform, with the output current being a sine wave.

- (2)

- In the second stage, due to the IGBT (H3S4) on the H3 reverse conduction circuit having an open-circuit fault, there is a level reduction in the output voltage on the negative half axis. As a result, the total harmonic distortion of the output voltage increases and the output current is distorted.

- (3)

- In the third stage, a fault-tolerant control method is adopted based on the reconstructed SPWM signal. Although the amplitude of the output voltage is reduced and the voltage level is reduced compared to the normal state, the inverter can output a symmetrical five-level voltage waveform. This means the total harmonic distortion of the output voltage is reduced during faults, and the output current is restored to a sinusoidal waveform.

- (4)

- In the fourth stage, the IGBT (H2S4) on the H2 reverse conduction circuit has an open-circuit fault. As a consequence, the output voltage of the five levels loses one voltage level on the negative half axis, and the total harmonic distortion increases further.

- (5)

- In the fifth stage, the inverter can output a symmetrical three-level voltage by the proposed fault-tolerant control strategy, and the output current is restored to a sine wave.

4.3. Comparison with Other Methods

- (a)

- The DC power supply is replaced by the actual ship’s DC bus;

- (b)

- Wind disturbance factors should be considered, such as mean wind pressure, variable wind pressure, the ship’s absolute heading angle, absolute wind angle, drift angle, etc.;

- (c)

- Wave interference factors should be considered, such as irregular wave drift force and moment, wave and ship encounter angle, drift force coefficient, wave force interference coefficient, etc.;

- (d)

- The electromagnetic interference generated by the inverters needs to be dealt with.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, D.; Wang, X.; Wang, T.; Wang, Y.; Xu, X. Optimal Thrust Allocation Strategy of Electric Propulsion Ship Based on Improved Non-Dominated Sorting Genetic Algorithm II. IEEE Access 2019, 7, 135247–135255. [Google Scholar] [CrossRef]

- He, Y.; Fan, A.; Wang, Z.; Liu, Y.; Mao, W. Two-phase energy efficiency optimisation for ships using parallel hybrid electric propulsion system. Ocean. Eng. 2019, 238, 1–30. [Google Scholar] [CrossRef]

- Gan, S.H.; Shi, W.F.; Xu, X.Y. Proposed Z-Source Electrical Propulsion System of a Fuel Cell/Supercapacitor-Powered Ship. J. Mar. Sci. Eng. 2023, 11, 1543. [Google Scholar] [CrossRef]

- Apsley, J.M.; Gonzalez-Villasenor, A.; Barnes, M.; Smith, A.C.; Williamson, S.; Schuddebeurs, J.D.; Norman, P.J.; Booth, C.D.; Burt, G.M.; McDonald, J.R. Propulsion Drive Models for Full Electric Marine Propulsion Systems. IEEE Trans. Ind. Appl. 2009, 45, 676–684. [Google Scholar] [CrossRef]

- Kim, M.-G.; Choi, J.-L.; Song, T.-H.; Kim, Y.-S.; Lee, S.-G. A control power module for a hybrid inverter systems to drive electric propulsion ships. J. Adv. Mar. Eng. Technol. 2018, 42, 75–81. [Google Scholar] [CrossRef]

- Kanellos, F.D.; Tsekouras, G.J.; Prousalidis, J. Onboard DC grid employing smart grid technology: Challenges, state of the art and future prospects. IET Electr. Syst. Transp. 2015, 5, 1–11. [Google Scholar] [CrossRef]

- Che, Y.B.; Xue, S.Y.; Wang, D.M. An AC Voltage Sensor-less Control Strategy for Ocean Ship Photovoltaic Grid-connected Inverter with LCL Filter. J. Coast. Res. 2018, 83, 109–115. [Google Scholar] [CrossRef]

- Yao, N.; Zhang, Z.; Zhang, Z.Y. Application of Photovoltaic Off-Grid Inverter in Marine Engineering. J. Coast. Res. 2020, 110, 193–196. [Google Scholar] [CrossRef]

- Rodr´ıguez, J.; Bernet, S.; Wu, B.; Pontt, J.O.; Kouro, S. Multilevel voltage-source-converter topologies for industrial medium-voltage drives. IEEE Trans. Ind. Electron. 2007, 54, 2930–2944. [Google Scholar] [CrossRef]

- Rodríguez, J.; Bernet, S.; Steimer, P.K.; Lizama, I.E. A survey on neutral-point-clamped inverters. IEEE Trans. Ind. Electron. 2010, 57, 2219–2230. [Google Scholar] [CrossRef]

- Mathew, J.; Rajeevan, P.P.; Mathew, K.; Azeez, N.A.; Gopakumar, K. A multilevel inverter scheme with dodecagonal voltage space vectors based on flying capacitor topology for induction motor drives. IEEE Trans. Power Electron. 2013, 28, 516–525. [Google Scholar] [CrossRef]

- Peng, H.; Hagiwara, M.; Akagi, H. Modeling and analysis of swithing-ripple voltage on the DC link between a diode rectifier and a modular multilevel cascaded inverter. IEEE Trans. Power Electron. 2013, 28, 75–84. [Google Scholar] [CrossRef]

- Menaka, S.; Muralidharan, S. Novel Symmetric and Asymmetric Multilevel Inverter Topologies with Minimum Number of Switches for High Voltage of Electric Ship Propulsion System. Indian. J. Geo-Mar. Sci. 2017, 46, 1920–1930. [Google Scholar]

- Kumar, A.; Bhatia, R.S.; Nijhawan, P. Performance investigation of an innovative H-bridge derived multilevel inverter topology for marine applications. Indian J. Geo-Mar. Sci. 2020, 49, 441–449. [Google Scholar]

- Jeon, H.-M.; Hur, J.-J.; Yoon, K.-K. Control Method for Performance Improvement of BLDC Motor used for Propulsion of Electric Propulsion Ship. J. Korean Soc. Mar. Environ. Saf. 2019, 25, 802–808. [Google Scholar] [CrossRef]

- Muralidharan, S.; Gnanavadivel, J.; Muhaidheen, M.Y.S.; Menaka, S. Harmonic Elimination in Multilevel Inverter Using TLBO Algorithm for Marine Propulsion System. Mar. Technol. Soc. J. 2021, 55, 117–126. [Google Scholar] [CrossRef]

- Townsend, C.D.; Summers, T.J.; Watson, A.J.; Betz, R.E.; Clare, J.C. A Simplified Space Vector Pulse Width Modulation Implementation in Modular Multilevel Converters for Electric Ship Propulsion Systems. IEEE Trans. Transp. Electr. 2019, 5, 335–342. [Google Scholar]

- Chen, Y.; Li, Z.Y.; Zhao, S.S.; Wei, X.G.; Kang, Y. Design and Implementation of a Modular Multilevel Converter with Hierarchical Redundancy Ability for Electric Ship MVDC System. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 189–202. [Google Scholar] [CrossRef]

- Wang, B.; Cai, J.; Du, X.; Zhou, L. Review of power semiconductor device reliability for power converters. CPSS. Trans. Power. Electron. Appl. 2017, 2, 101–117. [Google Scholar] [CrossRef]

- Yaghoubi, M.; Moghani, J.S.; Noroozi, N.; Zolghadri, M.R. IGBT open-circuit fault diagnosis in a quasi-Z-source inverter. IEEE Trans. Ind. Electron. 2019, 66, 2847–2856. [Google Scholar] [CrossRef]

- Yan, G.; Hu, Y.; Shi, Q. A Convolutional Neural Network-Based Method of Inverter Fault Diagnosis in a Ship’s DC Electrical System. Pol. Marit. Res. 2022, 29, 105–114. [Google Scholar] [CrossRef]

- Xie, J.; Shi, W.; Shi, Y. Research on Fault Diagnosis of Six-Phase Propulsion Motor Drive Inverter for Marine Electric Propulsion System Based on Res-BiLSTM. Machines 2022, 10, 736. [Google Scholar] [CrossRef]

- Jin, G.; Wang, T.; Amirat, Y.; Zhou, Z.; Xie, T. A Layering Linear Discriminant Analysis-Based Fault Diagnosis Method for Grid-Connected Inverter. J. Mar. Sci. Eng. 2022, 10, 939. [Google Scholar] [CrossRef]

- Park, J. Multi-Phase Fault Tolerant PMSM Drive System; Texas A&M University: College Station, TX, USA, 2015. [Google Scholar]

- Chikondra, B.; Muduli, U.; Behera, R. An Improved Open-Phase Fault-Tolerant DTC Technique for Five-Phase Induction Motor Drive Based on Virtual Vectors Assessment. IEEE Trans. Ind. Electron. 2021, 68, 4598–4609. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, T.; Chen, G.; Amirat, Y. A Serial Fault-Tolerant Topology Based on Sustainable Reconfiguration for Grid-Connected Inverter. J. Mar. Sci. Eng. 2023, 11, 751. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, Y.; Gou, B. A Data-Driven Method for IGBT Open-Circuit Fault Diagnosis Based on Hybrid Ensemble Learning and Sliding-Window Classification. IEEE Trans. Industr. Inform. 2019, 16, 5223–5233. [Google Scholar] [CrossRef]

- Song, W.; Huang, A.Q. Fault-tolerant design and control strategy for cascaded H-bridge multilevel converter-based STATCOM. IEEE Trans. Ind. Electron. 2010, 57, 2700–2708. [Google Scholar] [CrossRef]

- Yazdani, A.; Sepahvand, H.; MCrow, L.; Ferdowsi, M. Fault detection and mitigation in multilevel converter STATCOMs. IEEE Trans. Ind. Electron. 2011, 58, 1307–1315. [Google Scholar] [CrossRef]

- Aleenejad, M.; Iman-Eini, H.; Farhangi, S. Modified space vector modulation for fault-tolerant operation of multilevel cascaded H-bridge inverters. IET Power Electron. 2013, 6, 742–751. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, T.; Benbouzid, M. A fault-tolerant reconfiguration system based on pilot switch for grid-connected inverters. Microelectron. Reliab. 2022, 131, 114511. [Google Scholar] [CrossRef]

- Haji-Esmaeili, M.; Naseri, M.; Khoun-Jahan, H.; Abapour, M. Fault-tolerant structure for cascaded H-bridge multilevel inverter 538 and reliability evaluation. IET Power Electron. 2017, 10, 59–70. [Google Scholar] [CrossRef]

- Jahan, H.K.; Panahandeh, F.; Abapour, M.; Tohidi, S. Reconfigurable Multilevel Inverter with Fault-Tolerant Ability. IEEE Trans. Power Electron. 2018, 33, 7880–7893. [Google Scholar] [CrossRef]

- Mhiesan, H.; McCann, R.; Farnell, C.; Mantooth, A. Novel Circuit and Method for Fault Reconfiguration in Cascaded H-Bridge Multilevel Inverters. In Proceedings of the 2019 IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–22 March 2019; pp. 1800–1804. [Google Scholar]

- Maddugari, S.K.; Borghate, V.B.; Sabyasachi, S.; Karasani, R.R. A Linear-Generator-Based Wave Power Plant Model Using Reliable Multilevel Inverter. IEEE Trans. Ind. Appl. 2019, 55, 2964–2972. [Google Scholar] [CrossRef]

- Jalhotra, M.; Sahu, L.K.; Gautam, S.P.; Gupta, S. Reliability and energy sharing analysis of a fault-tolerant multilevel inverter topology. IET Power Electron. 2019, 12, 759–768. [Google Scholar] [CrossRef]

- Geng, C.; Wang, T.; Tang, T.; Benbouzid, M.; Qin, H. Fault-tolerant control strategy of the cascaded five-level inverter based on divided voltage modulation algorithm. In Proceedings of the 2016 IEEE IPEMC ECCE Asia, Hefei, China, 22–26 May 2016. [Google Scholar]

- Zhang, J.H.; Liu, Z.; Wang, T.; Benbouzid, M.E.H.; Wang, Y. An Arm Isolation and Reconfiguration Fault Tolerant Control Method Based on Data-driven Methodology for Cascaded Seven-level Inverter. In Proceedings of the 2018 IEEE 7th Data Driven Control and Learning Systems Conference (DDCLS), Enshi, China, 25–27 May 2018; pp. 939–943. [Google Scholar]

- Chen, J.J.; Chin, K.P. Minimum copper loss flux-weakening control of surface mounted permanent magnet synchronous motors. IEEE Trans. Power Electron. 2003, 18, 929–936. [Google Scholar] [CrossRef]

- Wang, T.Z.; Zhang, J.H.; Wang, H.; Wang, Y. A Multi-Mode Fault-Tolerant Control Strategy for Cascaded H-Bridge Multilevel Inverters. IET Power Electron. 2020, 13, 3119–3126. [Google Scholar] [CrossRef]

| Components | Value |

|---|---|

| Internal resistance | Ron = 1 × 10−3 Ω |

| Snubber resistance | Rs = 1 × 105 Ω |

| Snubber capacitance | Cs = inf |

| Parameters | Number of Pole Pairs | Stator Inductance | Stator Resistance | Flux Linkage | Moment of Inertia | Damping Coefficient | |

|---|---|---|---|---|---|---|---|

| R | J | B | |||||

| Value | 4 | 8.5 (mH) | 8.5 (mH) | 2.875 (Ω) | 0.175 (Wb) | 0.003 (kg·m2) | 0.008 (N·m·s) |

| Parameter Type | Value |

|---|---|

| Speed loop parameters | Kpw = 0.35, Kiw = 0.85 |

| D-axis current loop parameters | Kpd = 0.0085, Kid = 2.875 |

| Q-axis current loop parameters | Kpq = 8.5, Kiq = 2.875 |

| Components | Value |

|---|---|

| DC source voltage | Vdc = 56 V |

| Resistive load | R = 21 Ω |

| Inductive load | L = 12 mH |

| Reference frequency | 50 Hz |

| Switching frequency | 3 kHz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Zhang, Z.; Zhang, Z.; Wang, T.; Han, J.; Amirat, Y. A Fault-Tolerant Control Method Based on Reconfiguration SPWM Signal for Cascaded Multilevel IGBT-Based Propulsion in Electric Ships. J. Mar. Sci. Eng. 2024, 12, 500. https://doi.org/10.3390/jmse12030500

Zhang F, Zhang Z, Zhang Z, Wang T, Han J, Amirat Y. A Fault-Tolerant Control Method Based on Reconfiguration SPWM Signal for Cascaded Multilevel IGBT-Based Propulsion in Electric Ships. Journal of Marine Science and Engineering. 2024; 12(3):500. https://doi.org/10.3390/jmse12030500

Chicago/Turabian StyleZhang, Fan, Zhiwei Zhang, Zhonglin Zhang, Tianzhen Wang, Jingang Han, and Yassine Amirat. 2024. "A Fault-Tolerant Control Method Based on Reconfiguration SPWM Signal for Cascaded Multilevel IGBT-Based Propulsion in Electric Ships" Journal of Marine Science and Engineering 12, no. 3: 500. https://doi.org/10.3390/jmse12030500