Effect of Pore Structure on Soot Deposition in Diesel Particulate Filter

Abstract

:1. Introduction

2. Numerical Model

2.1. Soot Deposition Model

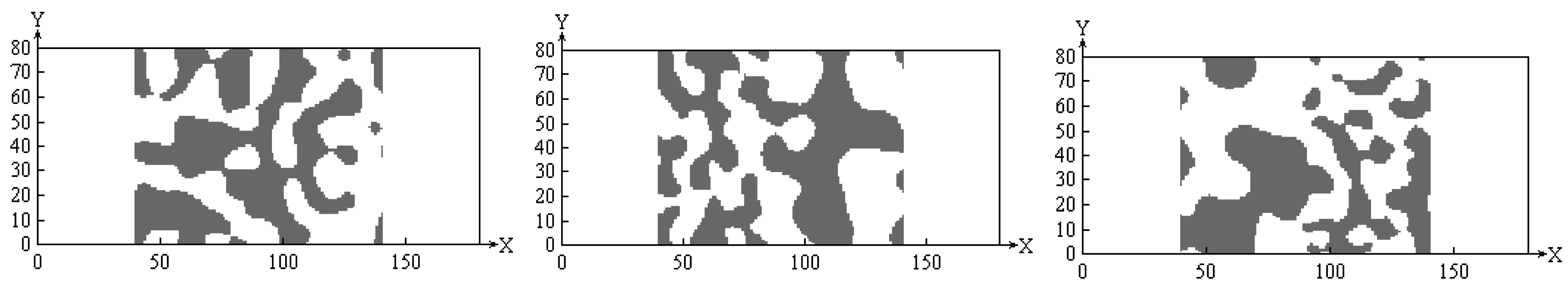

2.2. Porous Structure of DPF

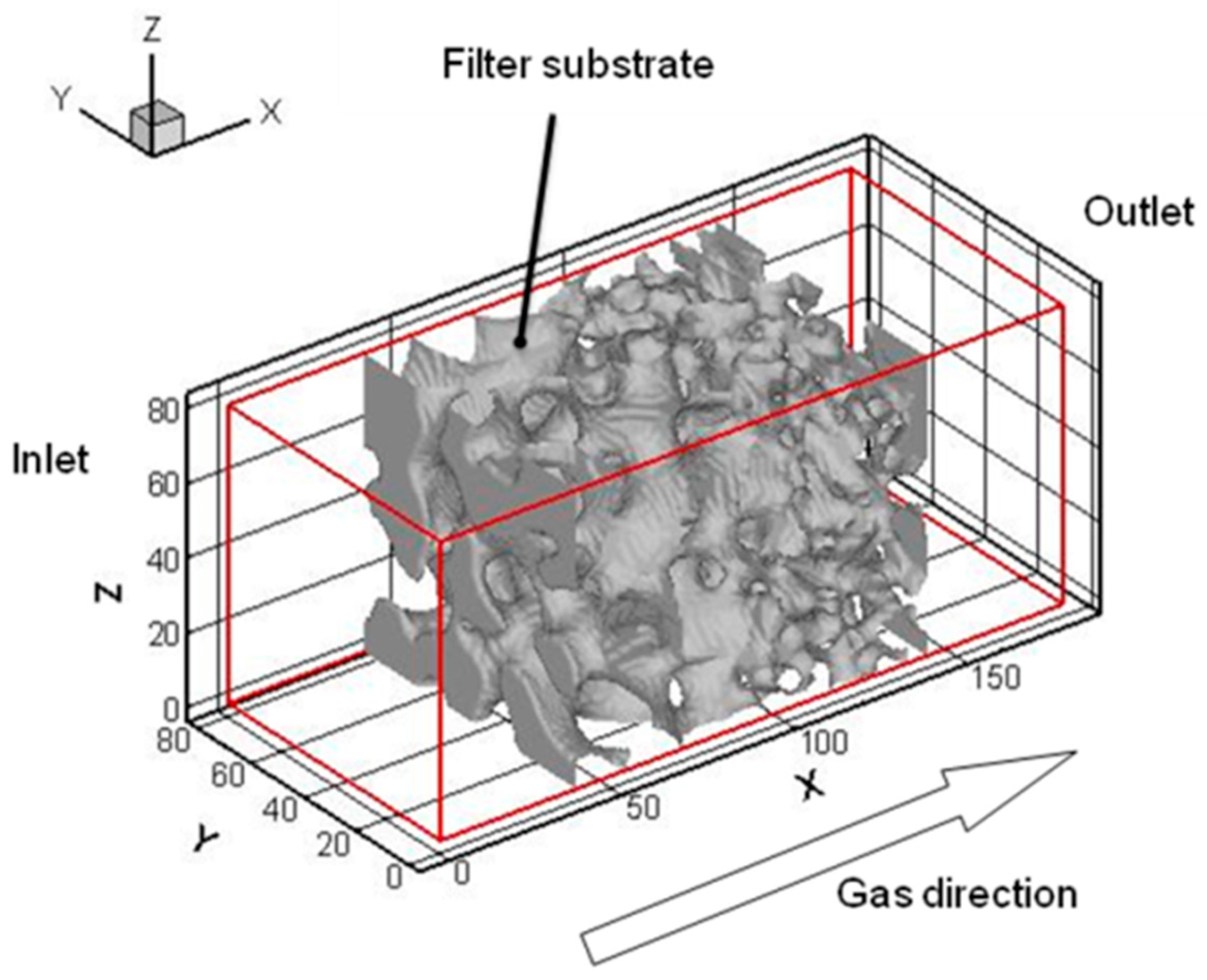

2.3. Numerical Domain

3. Results and Discussion

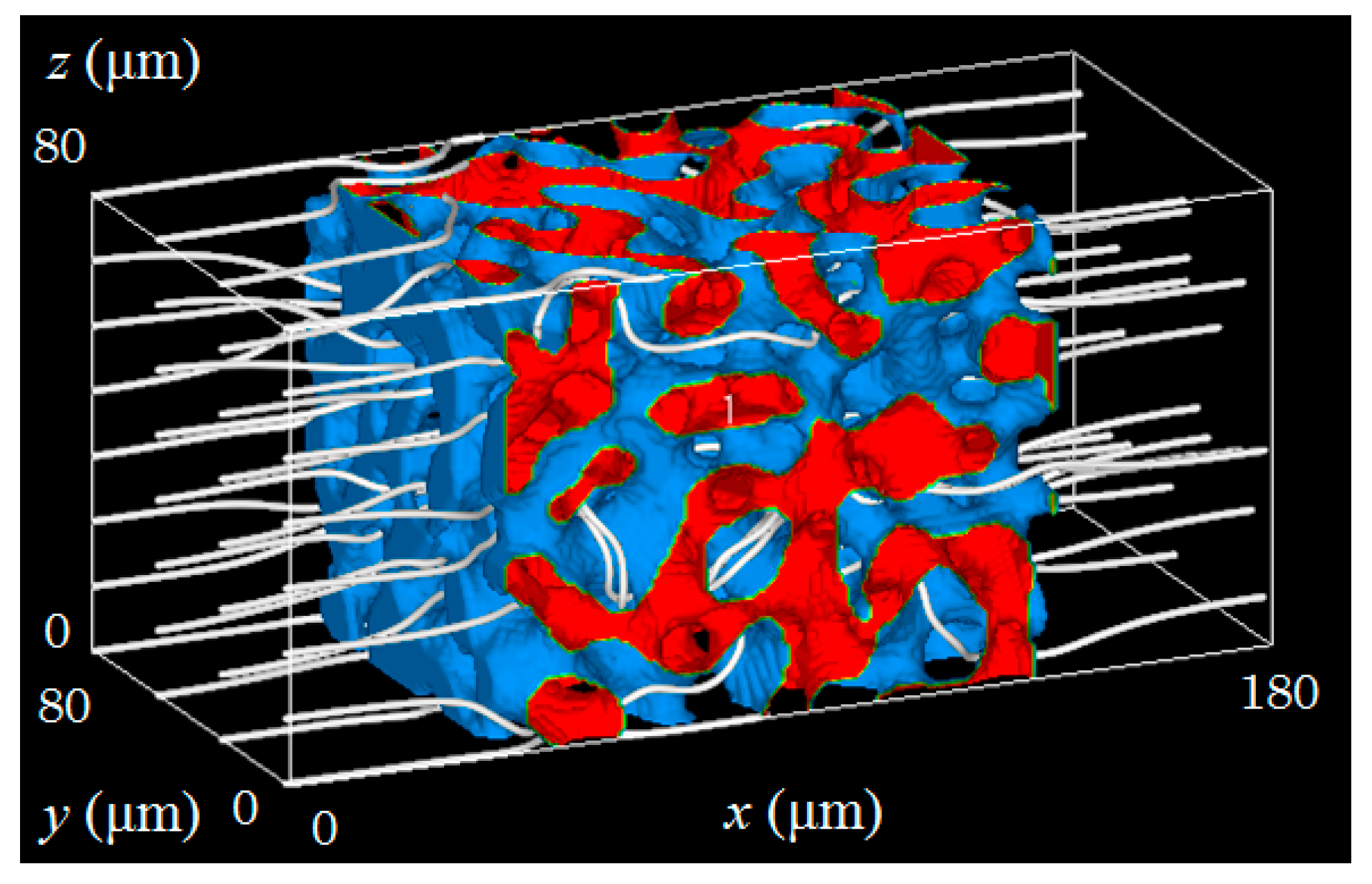

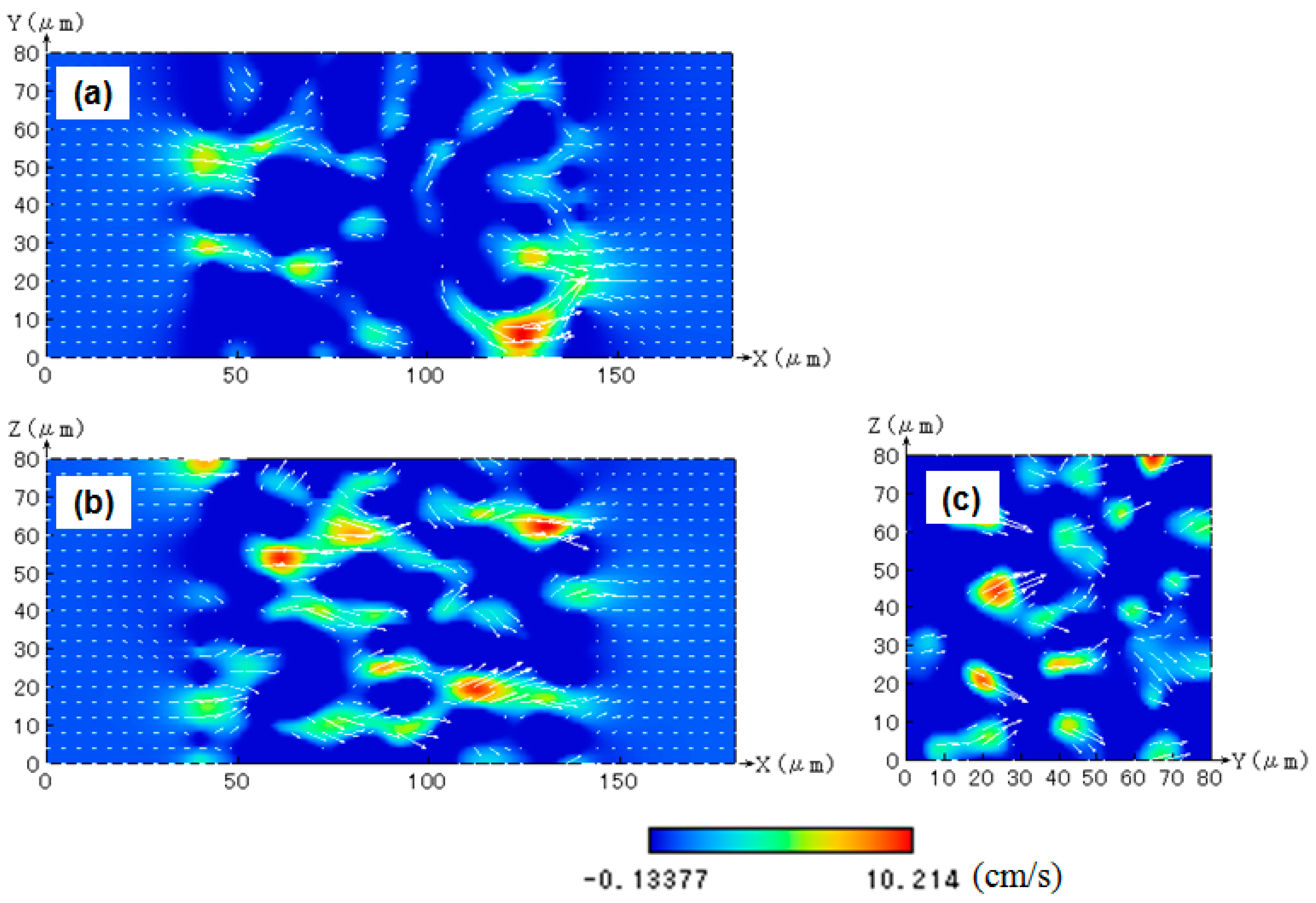

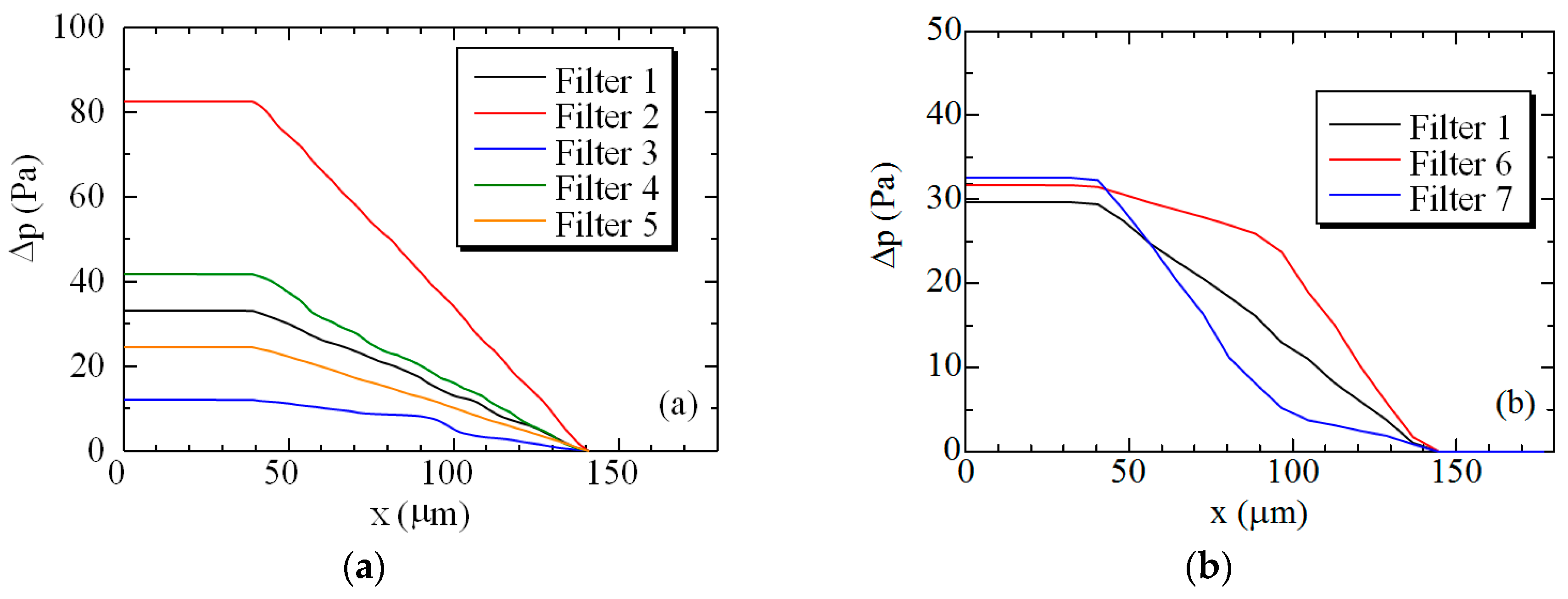

3.1. Flow Field and Pressure Drop without Soot Deposition

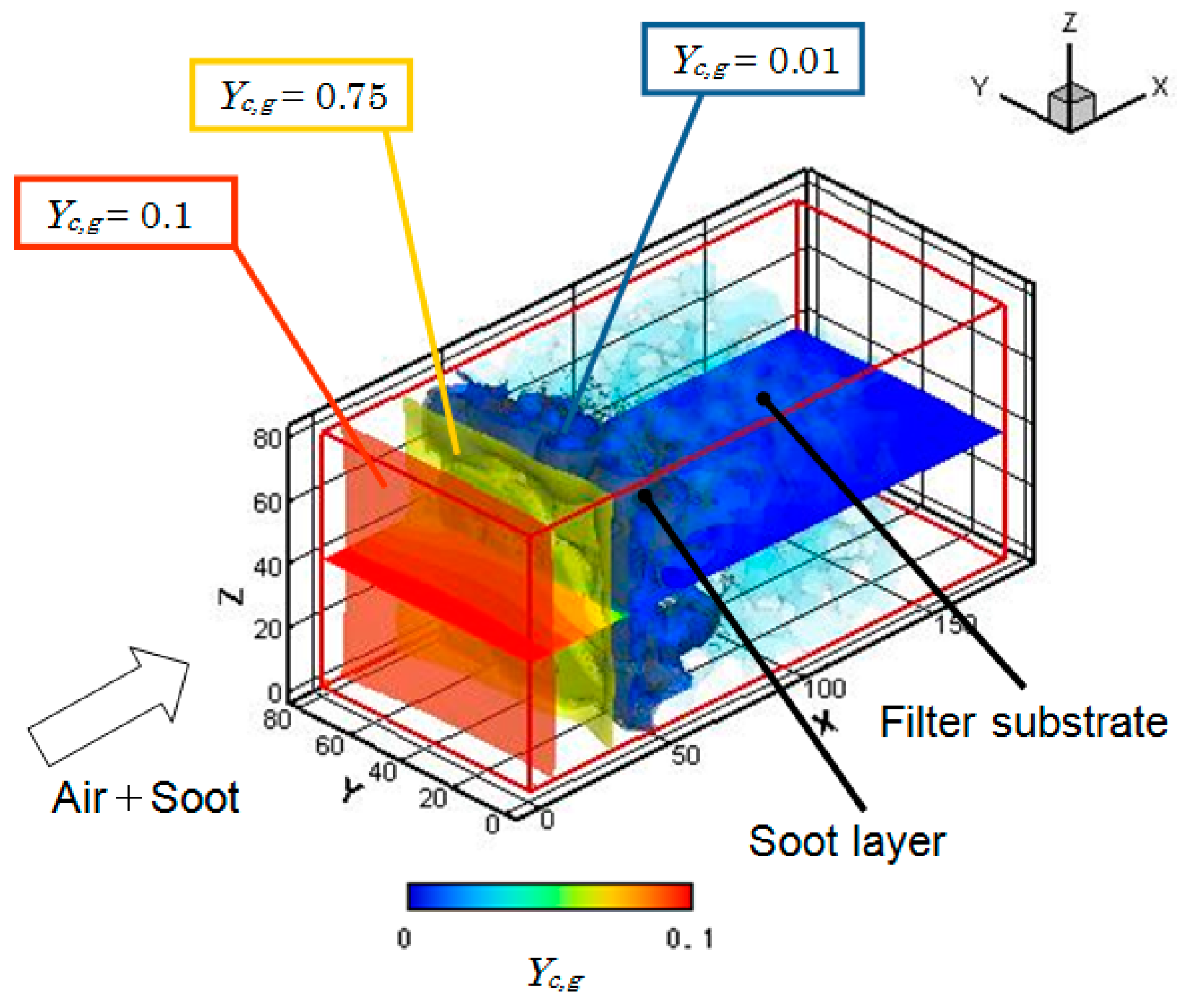

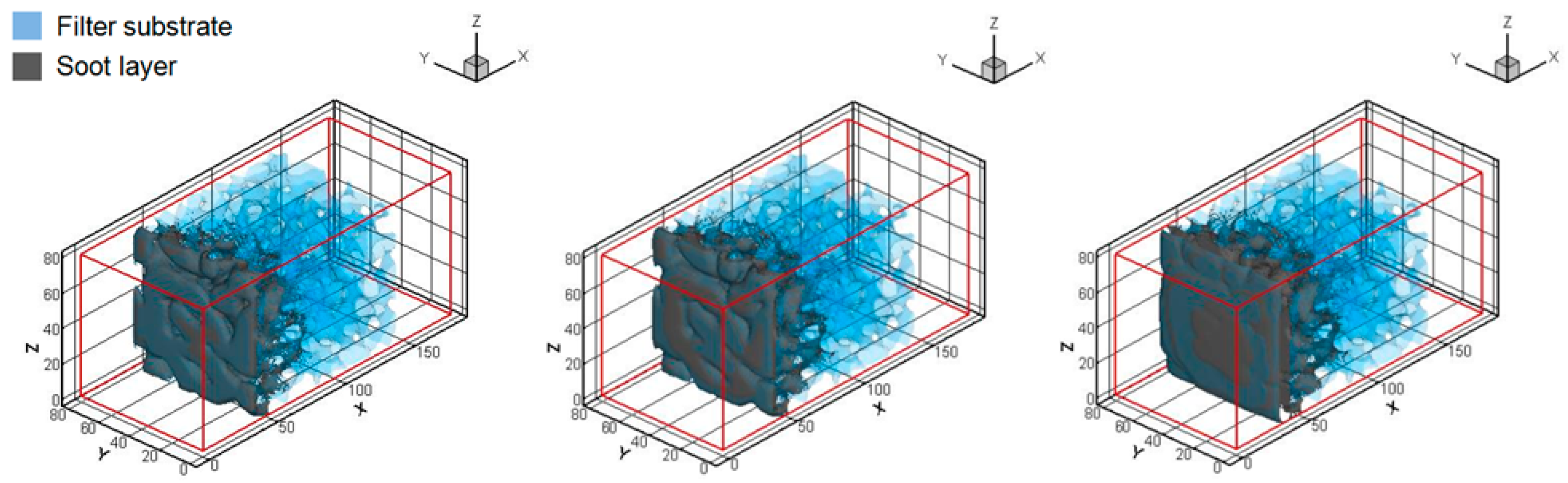

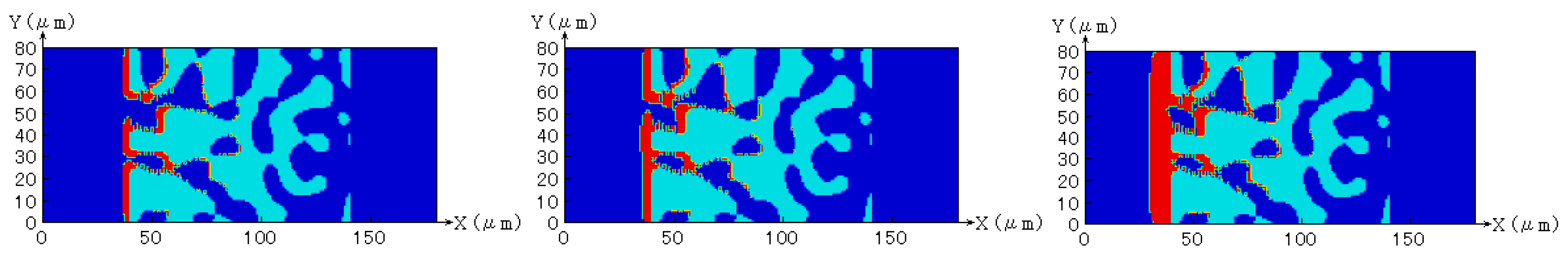

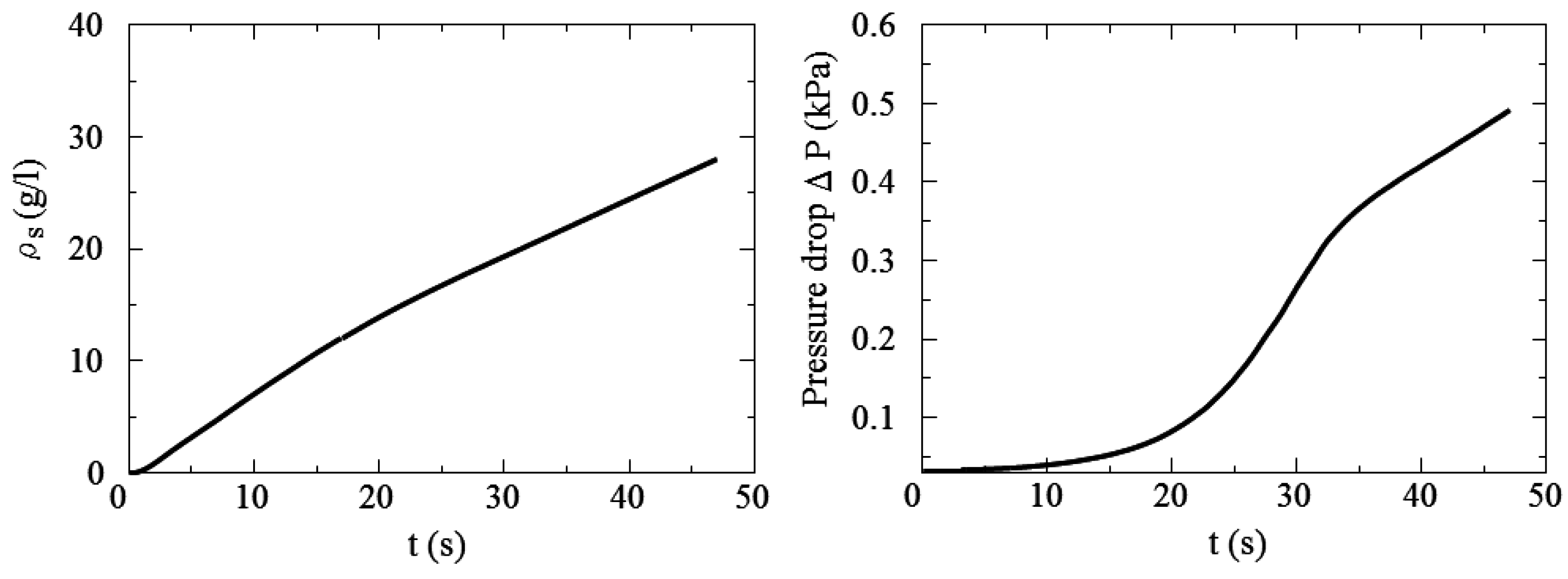

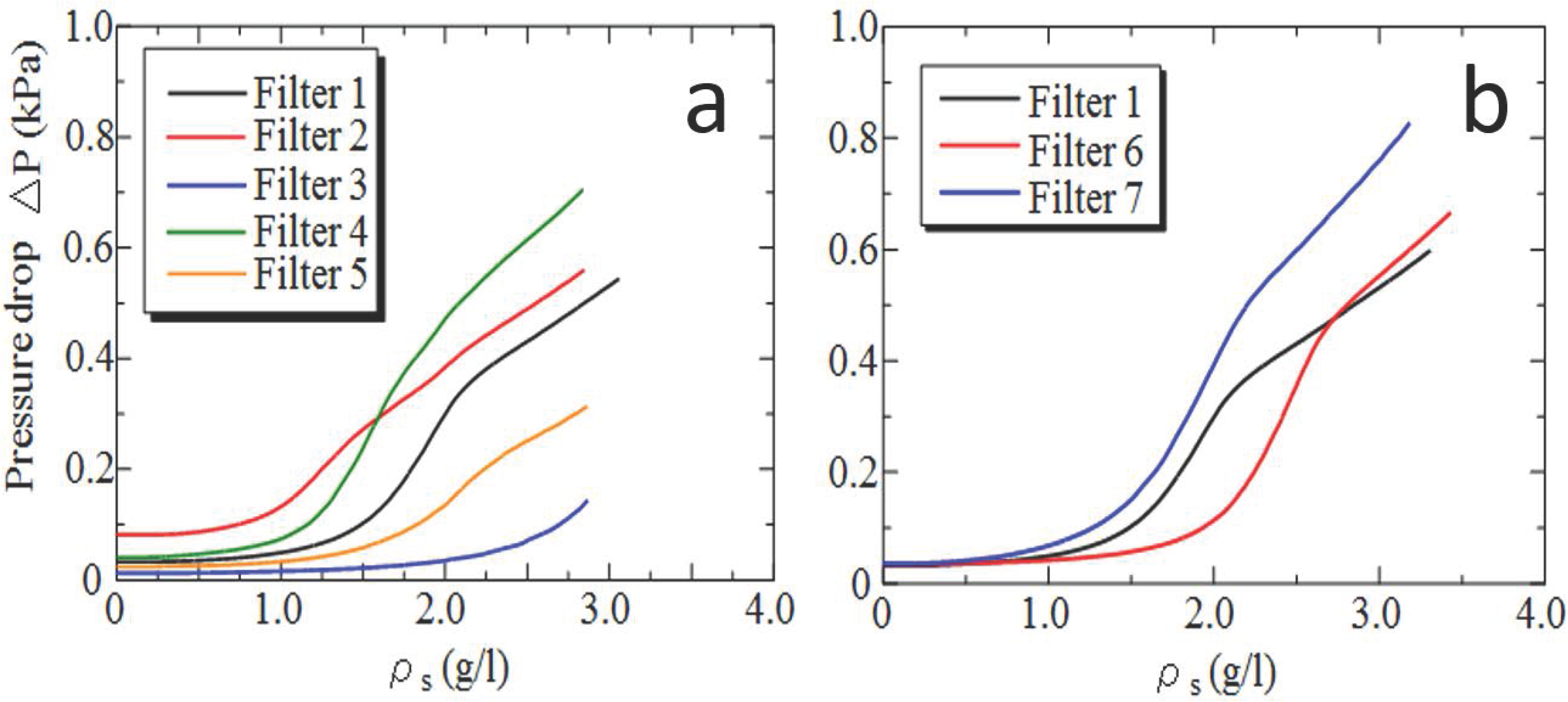

3.2. Soot Deposition for Filtration

4. Conclusions

- (1)

- Even in cold flow, a complex flow pattern is observed, with a number of flow paths. If the porous structure is uniform, the linear pressure drops along the flow direction is observed across the filter wall. As the porosity is lower, or pore size is smaller, the initial pressure drop increases. In the case of non-uniform filters, the gradient of the pressure drop changes, but simply, the initial pressure drop is almost the same if the averaged porosity and pore size are the same.

- (2)

- When the flow path inside the filter is plugged with soot, the filter backpressure increases. Gradually, pores at the filter surface are clogged with soot, forming a soot deposition layer on the filter wall surface (called a soot cake). Once, the soot cake is formed, all the soot is trapped by this soot layer. Then, a transition between depth filtration and surface filtration is observed. By comparing the pressure drop of seven filters, Filter 5 with high porosity could be appropriate, because the pressure rise during the depth filtration is suppressed.

Author Contributions

Conflicts of Interest

Abbreviations

Notation

| c | advection speed in LB coordinate |

| D | pore size |

| e | unit vector for advection speed in LB coordinate |

| f | external force |

| Fi | external force term |

| fp,α | distribution function of pressure |

| fs,α | distribution function of soot in gas phase |

| IT | time step |

| p | pressure |

| PD | soot deposition probability |

| t | time |

| u | velocity vector of (u, v, w) |

| Uin | inlet velocity |

| x | direction normal to the filter |

| y | direction perpendicular to x |

| z | direction perpendicular to x |

| Yc | mass fraction of soot |

| ɛ | porosity |

| κ | permeability |

| ν | kinematic viscosity |

| ρ | density |

| τ | relaxation time |

Subscripts

| 0 | reference condition |

| 1 | value of upstream region |

| 2 | value of downstream region |

| C | properties of soot in gas phase |

| in | value at inlet |

| out | value at outlet |

| s | properties of soot per total filter volume |

| α | number of advection speed in LB coordinate |

References

- Clerc, J.C. Catalytic Diesel Exhaust After-Treatment. Appl. Catal. B-Environ. 1996, 10, 99–115. [Google Scholar] [CrossRef]

- Johnson, T.V. Diesel emissions in review. SAE Int. J. Engines 2011, 4, 143–157. [Google Scholar] [CrossRef]

- Kittelson, D.B. Engines and nanoparticles: A review. J. Aerosol Sci. 1998, 29, 575–588. [Google Scholar] [CrossRef]

- Stratakis, G.A.; Psarianos, D.L.; Stamatelos, A.M. Experimental investigation of the pressure drop in porous ceramic diesel particulate filters. Proc. Inst. Mech. Eng. D-J. Automob. Eng. 2002, 216, 773–784. [Google Scholar] [CrossRef]

- Wirojsakunchai, E.; Schroeder, E.; Kolodziej, C.; Foster, D.E.; Schmidt, N.; Root, T.; Kawai, T.; Suga, T.; Nevius, T.; Kusaka, T. Detailed diesel exhaust particulate characterization and real-time DPF filtration efficiency measurements during PM filling process. SAE Tech. Pap. 2007, 2007, 1–14. [Google Scholar]

- Tsuneyoshi, K.; Takagi, O.; Yamamoto, K. Effects of washcoat on initial PM filtration efficiency and pressure drop in SiC DPF. SAE Tech. Pap. 2011, 2011, 1–10. [Google Scholar]

- Yamamoto, K.; Takada, N.; Misawa, M. Combustion simulation with lattice Boltzmann method in a three-dimensional porous structure. Proc. Comb. Inst. 2005, 30, 1509–1515. [Google Scholar] [CrossRef]

- Yamamoto, K.; Ohori, S. Simulation on flow and soot deposition in diesel particulate filter. Int. J. Eng. Res. 2013, 14, 333–340. [Google Scholar] [CrossRef]

- Yamamoto, K.; Satake, S.; Yamashita, H.; Takada, N.; Misawa, M. Fluid simulation and X-ray CT images for soot deposition in a diesel filter. Eur. Phys. J. 2009, 171, 205–212. [Google Scholar] [CrossRef]

- Yamamoto, K.; Nakamura, M.; Yane, H.; Yamashita, H. Simulation on catalytic reaction in diesel particulate filter. Catal. Today 2010, 153, 118–124. [Google Scholar] [CrossRef]

- Yamamoto, K.; Yamauchi, K.; Takada, N.; Misawa, M.; Furutani, H.; Shinozaki, O. Lattice Boltzmann simulation on continuously regenerating diesel filter. Philos. Trans. A 2011, 369, 2584–2591. [Google Scholar] [CrossRef] [PubMed]

- Atanasov, A.; Uekermann, B.; Pachajoa Mejía, C.A.; Bungartz, H.J.; Neumann, P. Steady-state Anderson accelerated coupling of lattice Boltzmann and Navier–Stokes solvers. Computation 2016, 4, 38–56. [Google Scholar] [CrossRef]

- Chen, S.; Doolen, G.D. Lattice Boltzmann method for fluid flows. Annu. Rev. Fluid Mech. 1998, 30, 329–364. [Google Scholar] [CrossRef]

- Succi, S.; Foti, E.; Higuera, F. Three-dimensional flows in complex geometries with the lattice Boltzmann method. Europhys. Lett. 1989, 10, 433–438. [Google Scholar] [CrossRef]

- Cancelliere, A.; Chang, C.; Foti, E.; Rothman, D.H.; Succi, S. The permeability of a random medium: Comparison of simulation with theory. Phys. Fluids A 1990, 2, 2085–2088. [Google Scholar] [CrossRef]

- Inamuro, T.; Yoshino, M.; Ogino, F. Lattice Boltzmann simulation of flows in a three-dimensional porous structure. Int. J. Numer. Methods Fluids 1999, 29, 737–748. [Google Scholar] [CrossRef]

- Bernsdorf, J.; Brenner, G.; Durst, F. Numerical analysis of the pressure drop in porous media flow with lattice Boltzmann (BGK) automata. Comput. Phys. Commun. 2000, 129, 247–255. [Google Scholar] [CrossRef]

- Yoshino, M.; Inamuro, T. Lattice Boltzmann simulations for flow and heat/mass transfer problems in a three-dimensional porous structure. Int. J. Numer. Methods Fluids 2003, 43, 183–198. [Google Scholar] [CrossRef]

- Abdallaoui, M.E.; Hasnaoui, M.; Amahmid, A. Numerical simulation of natural convection between a decentered triangular heating cylinder and a square outer cylinder filled with a pure fluid or a nanofluid using the lattice Boltzmann method. Powder Technol. 2015, 277, 193–205. [Google Scholar] [CrossRef]

- Yamamoto, K.; Satake, S.; Yamashita, H.; Takada, N.; Misawa, M. Lattice Boltzmann simulation on porous structure and soot accumulation. Math. Comput. Simul. 2006, 72, 257–263. [Google Scholar] [CrossRef]

- Yamamoto, K.; Takada, N. LB simulation on soot combustion in porous media. Phys. A 2006, 362, 111–117. [Google Scholar] [CrossRef]

- Yamamoto, K.; Satake, S.; Yamashita, H. Microstructure and particle-laden flow in diesel particulate filter. Int. J. Ther. Sci. 2009, 48, 303–307. [Google Scholar] [CrossRef]

- Qian, Y.H.; D’Humières, D.; Lallemand, P. Lattice BGK models for Navier-Stokes equation. Europys. Lett. 1992, 17, 479–484. [Google Scholar] [CrossRef]

- Muntean, G.G.; Reactor, D.; Herling, D.; Lessor, D.; Khaleel, M. Lattice-Boltzmann diesel particulate filter sub-grid modelling – a progress report. SAE Tech. Pap. 2003, 2003, 1–8. [Google Scholar]

- Hayashi, H. Lattice Boltzmann method and its application to flow analysis in porous media. R D Rev. Toyota CRDL 2003, 38, 17–25. [Google Scholar]

- Dillon, H.; Stewart, M.; Maupin, G.; Gallant, T.; Li, C.; Mao, F.; Pyzik, A.; Ramanathan, R. Optimizing the advanced ceramic material for diesel particulate filter applications. SAE Tech. Pap. 2007, 2007, 1–8. [Google Scholar]

- Konstandopoulos, A.G.; Skaperdas, E. Microstructural properties of soot deposits in diesel particulate traps. SAE Tech. Pap. 2002, 2002, 1–11. [Google Scholar]

- Hinds, W.C. Aerosol Technology, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1999; pp. 233–259. [Google Scholar]

- Yamamoto, K.; Yamauchi, K. Numerical simulation of continuously regenerating diesel particulate filter. Proc. Combus. Inst. 2013, 34, 3083–3090. [Google Scholar] [CrossRef]

- Yamamoto, K.; He, X.; Doolen, G.D. Simulation of combustion field with lattice Boltzmann method. J. Stat. Phys. 2002, 107, 367–383. [Google Scholar] [CrossRef]

- Zou, Q.; He, X. On pressure and velocity boundary conditions for the lattice Boltzmann BGK model. Phys. Fluids 1997, 9, 1591–1598. [Google Scholar] [CrossRef]

| Filter No. | Porosity, ɛ (−) | Upstream Pore Size D1 (μm) | Downstream Pore Size, D2 (μm) | Average Pore Size, D (μm) | Initial Pressure Drop, p0 (Pa) |

|---|---|---|---|---|---|

| 1 | 0.49 | 18 | 18 | 18 | 33.1 |

| 2 | 0.49 | 11 | 11 | 11 | 82.4 |

| 3 | 0.49 | 31 | 31 | 31 | 12.2 |

| 4 | 0.42 | 18 | 18 | 18 | 41.7 |

| 5 | 0.61 | 18 | 18 | 18 | 24.6 |

| 6 | 0.49 | 28 | 15 | 19 | 34.5 |

| 7 | 0.49 | 15 | 28 | 20 | 36.5 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamamoto, K.; Sakai, T. Effect of Pore Structure on Soot Deposition in Diesel Particulate Filter. Computation 2016, 4, 46. https://doi.org/10.3390/computation4040046

Yamamoto K, Sakai T. Effect of Pore Structure on Soot Deposition in Diesel Particulate Filter. Computation. 2016; 4(4):46. https://doi.org/10.3390/computation4040046

Chicago/Turabian StyleYamamoto, Kazuhiro, and Tatsuya Sakai. 2016. "Effect of Pore Structure on Soot Deposition in Diesel Particulate Filter" Computation 4, no. 4: 46. https://doi.org/10.3390/computation4040046

APA StyleYamamoto, K., & Sakai, T. (2016). Effect of Pore Structure on Soot Deposition in Diesel Particulate Filter. Computation, 4(4), 46. https://doi.org/10.3390/computation4040046