Large-Scale Moth-Eye-Structured Roll Mold Fabrication Using Sputtered Glassy Carbon Layer and Transferred Moth-Eye Film Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabricating a Moth-Eye-Structured Roll Mold Using Anodization

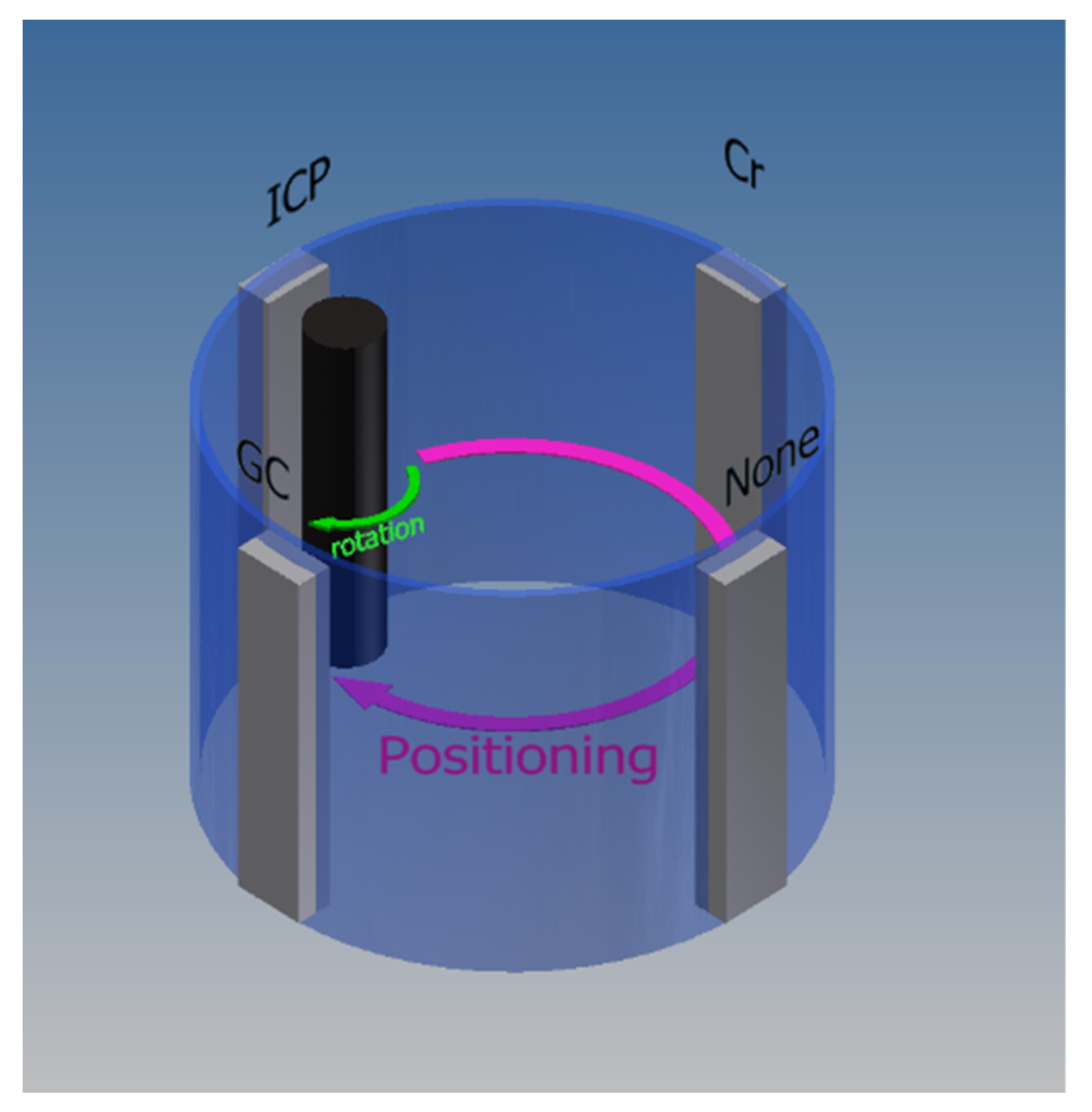

2.2. Fabricating a Moth-Eye-Structured Roll Mold Using a GC Thin Film

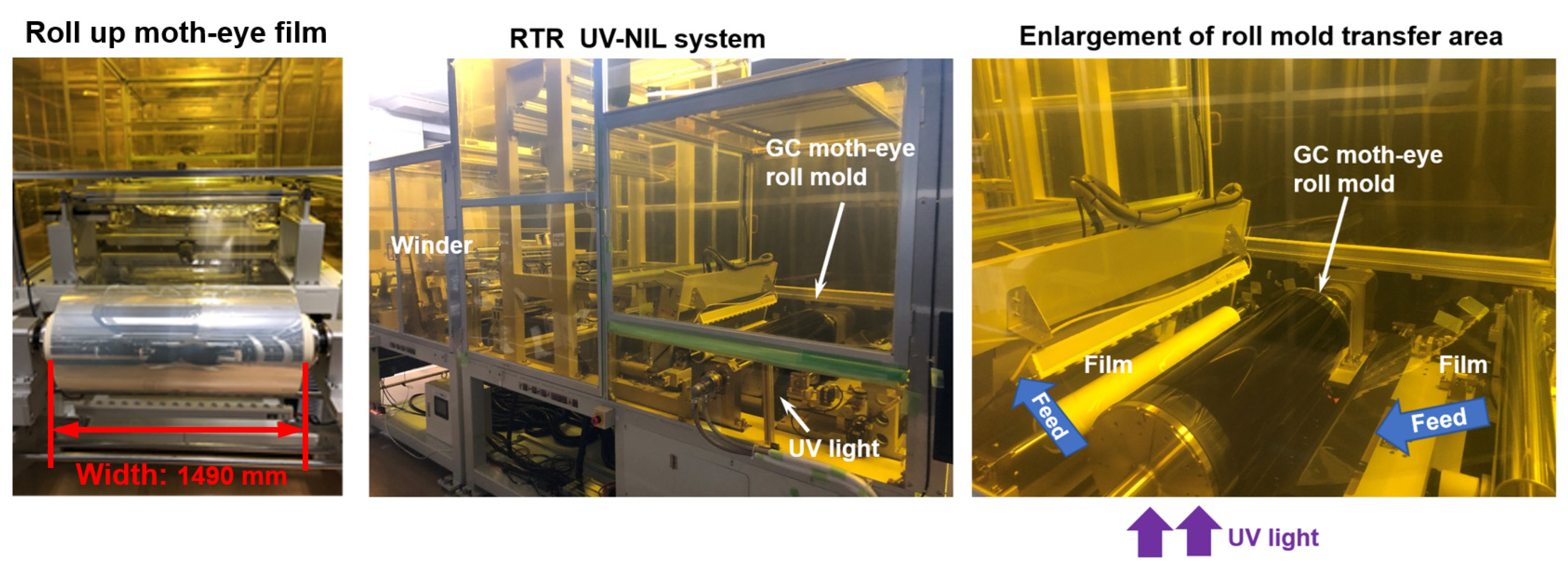

2.3. Moth-Eye-Structured Film Transfer Method Using RTR UV-NIL

2.4. Roll Mold and Transfer Pattern Evaluation

3. Results

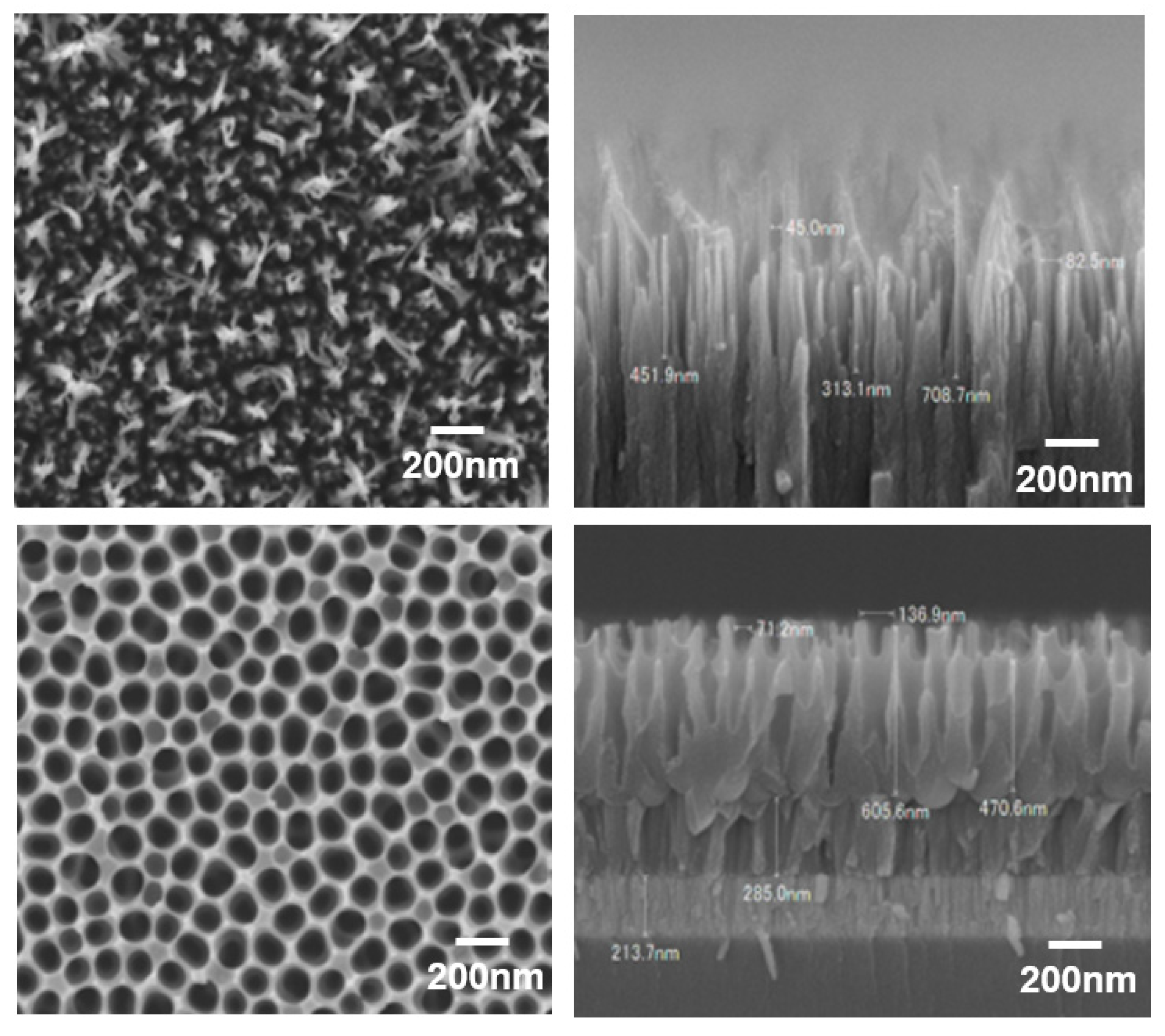

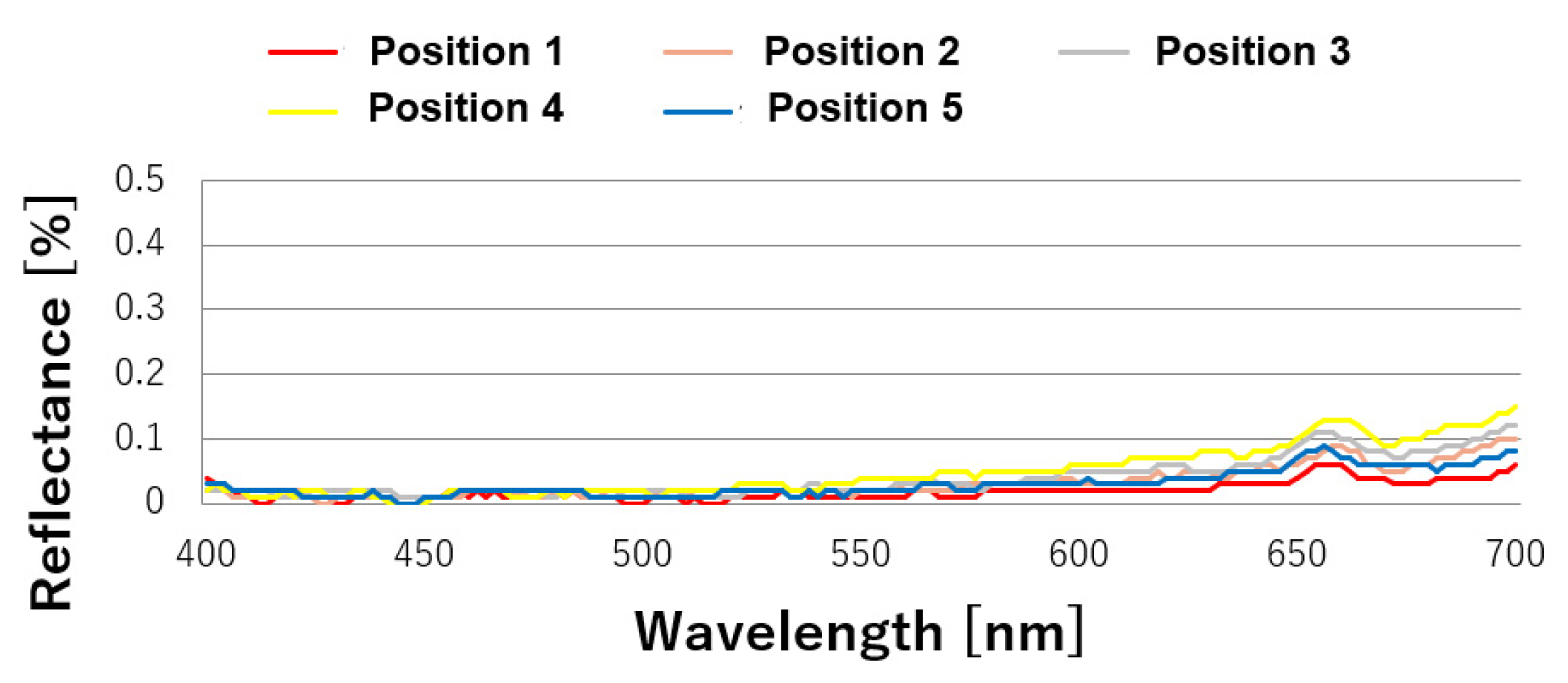

3.1. Roll Mold Shape and Reflectance Characteristics

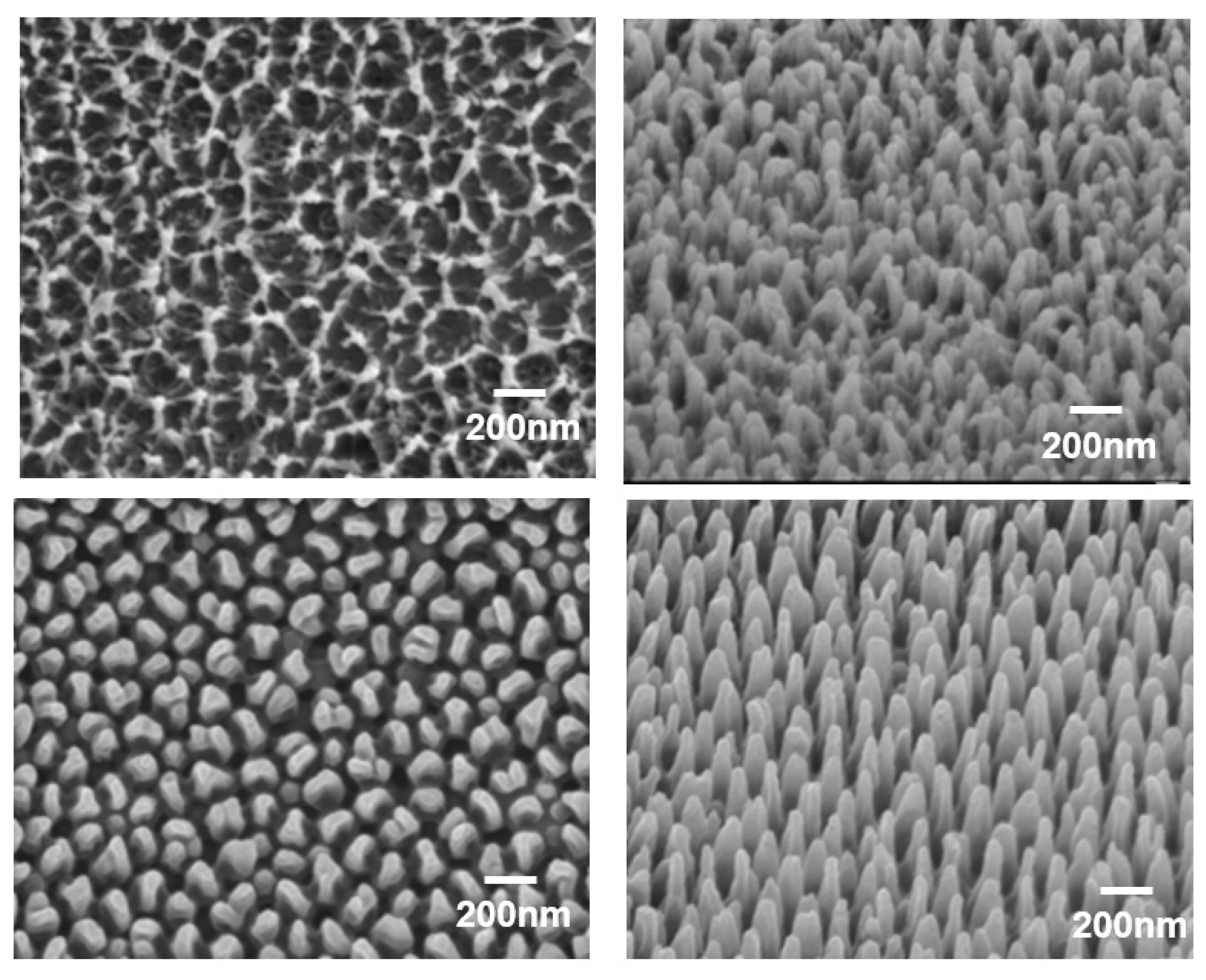

3.2. Moth-Eye-Structured Film Shape and Optical Properties

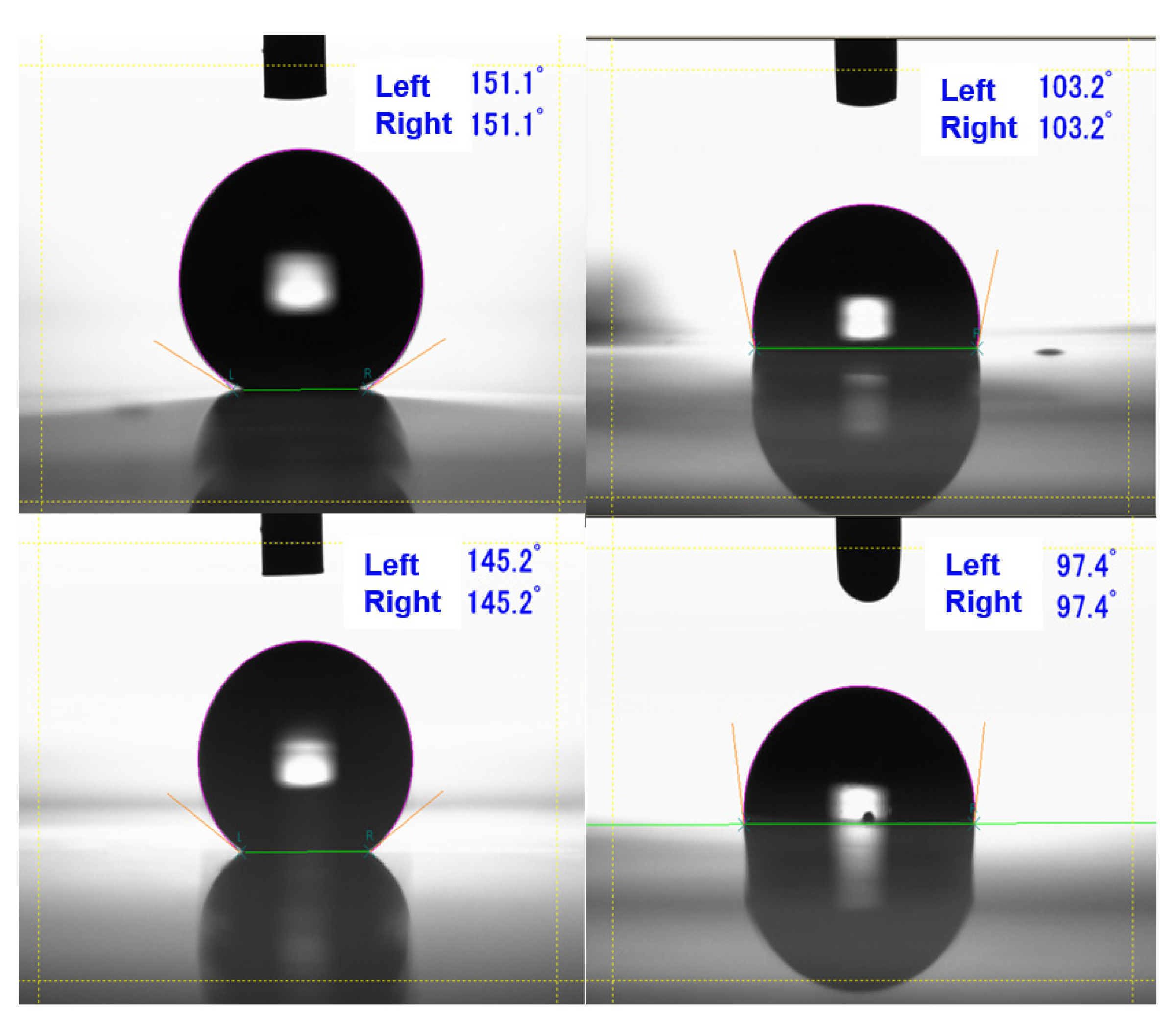

3.3. Reflectance, Contact Angle, Haze, and Producibility Comparison of Moth-Eye-Structured Films

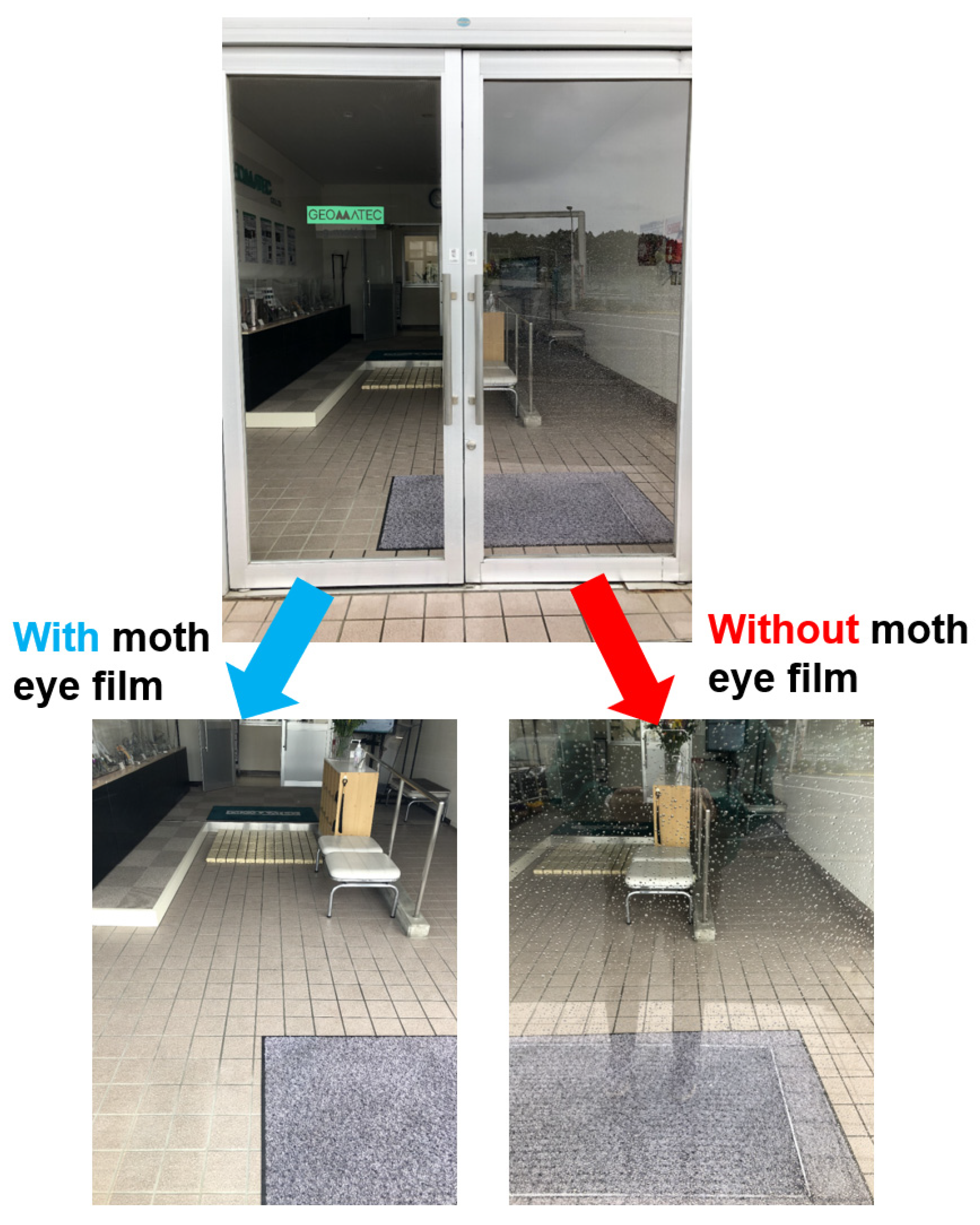

3.4. Example of GC Moth-Eye Film Use

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Decher, G.; Hong, J.D.; Schmitt, J. Buildup of ultrathin multilayer films by a self-assembly process III. Consecutively alternating adsorption of anionic and cationic polyelectrolytes on charged surfaces. Thin Solid Film. 1992, 210–211, 831–835. [Google Scholar] [CrossRef]

- Hiller, J.A.; Mendelsohn, J.D.; Rubner, M.F. Reversibly erasable nanoporous anti-reflection coatings from polyelectrolyte multilayers. Nat. Mater. 2002, 1, 59–63. [Google Scholar] [CrossRef] [PubMed]

- Cai, H.; Wang, M.; Wu, Z.; Wang, X.; Liu, J. Design of multilayer planar film structures for near-perfect absorption in the visible to near-infrared. Opt. Express 2022, 30, 35219–35231. [Google Scholar] [CrossRef]

- Clapham, P.B.; Hutley, M.C. Reduction of lens reflection by the ‘Moth Eye’ principle. Nature 1973, 244, 281–282. [Google Scholar] [CrossRef]

- Kanamori, Y.; Kikuta, H.; Hane, K. Broadband antireflection gratings for glass substrates fabricated by fast atom beam etching. Jpn. J. Appl. Phys. 2000, 39, L735–L737. [Google Scholar] [CrossRef]

- Kanamori, Y.; Kobayashi, K.; Yugami, H.; Hane, K. Subwavelength Antireflection Gratings for GaSb in Visible and Near-Infrared Wavelengths. Jpn. J. Appl. Phys. 2003, 42, 4020–4023. [Google Scholar] [CrossRef]

- Yanagishita, T.; Yasui, K.; Kondo, T.; Kawamoto, Y.; Nishio, K.; Masuda, H. Antireflection polymer surface using anodic porous alumina molds with tapered holes. Chem. Lett. 2007, 36, 530–531. [Google Scholar] [CrossRef]

- Yanagishita, T.; Kondo, T.; Nishio, K.; Masuda, H. Optimization of antireflection structures of polymer based on nanoimprinting using anodic porous alumina. J. Vac. Sci. Technol. B 2008, 26, 1856–1859. [Google Scholar] [CrossRef]

- Yanagishita, T.; Nishio, K.; Masuda, H. Antireflection polymer hole array structures by imprinting using metal molds from anodic porous alumina. Appl. Phys. Exp. 2008, 1, 067004. [Google Scholar] [CrossRef]

- Yanagishita, T.; Nishio, K.; Masuda, H. Anti-Reflection Structures on Lenses by Nanoimprinting Using Ordered Anodic Porous Alumina. Appl. Phys. Exp. 2009, 2, 2. [Google Scholar] [CrossRef]

- Taniguchi, J.; Nemoto, Y.; Sugiyama, Y. Fabrication of non-reflective structure on glassy carbon surface using oxygen ion beam irradiation. J. Nanosci. Nanotechnol. 2009, 9, 445–449. [Google Scholar] [CrossRef]

- Taniguchi, J.; Kamiya, Y.; Ohsaki, T.; Sakai, N. Technique for transfer of high-density, high-aspect-ratio nanoscale patterns in UV nanoimprint lithography and measurement of the release force. Microelectron. Eng. 2010, 87, 859–863. [Google Scholar] [CrossRef]

- Takahashi, J.; Taniguchi, J.; Kamiya, Y. Assessment of release properties in UV nanoimprint lithography using high-aspect-ratio nanoscale molds. J. Vac. Sci. Technol. B 2010, 28, C6M23–C6M27. [Google Scholar] [CrossRef]

- Taniguchi, J.; Kamiya, Y.; Unno, N. Fabrication of Anti-reflection Structure using Photo-curable Polymer. J. Photopolym. Sci. Technol. 2011, 24, 105–110. [Google Scholar] [CrossRef]

- Taguchi, T.; Hayashi, H.; Fujii, A.; Tsuda, K.; Yamada, N.; Minoura, K.; Isurugi, A.; Ihara, I.; Itoh, Y. 80.3: Distinguished Paper: Ultra-Low-Reflective 60-in. LCD with Uniform Moth-Eye Surface for Digital Signage. SID Int. Symp. Dig. Tech. Pap. 2010, 41, 1196–1199. [Google Scholar] [CrossRef]

- Yano, T.; Sugawara, H.; Taniguchi, J. Moth-eye structured mold using sputtered glassy carbon layer for large-scale applications. Micro Nano Eng. 2020, 9, 100077. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Nanoimprint lithography. J. Vac. Sci. Technol. B 1996, 14, 4129–4133. [Google Scholar] [CrossRef]

- Krauss, P.R.; Chou, S.Y. Nano-compact disks with 400 Gbit/in2 storage density fabricated using nanoimprint lithography and read with proximal probe. Appl. Phys. Lett. 1997, 71, 3174–3176. [Google Scholar] [CrossRef]

- Sun, X.Y.; Zhuang, L.; Zhang, W.; Chou, S.Y. Multilayer resist methods for nanoimprint lithography on nonflat surfaces. J. Vac. Sci. Technol. B 1998, 16, 3922–3925. [Google Scholar] [CrossRef]

- Haisma, J.; Verheijen, M.; VandenHeuvel, K.; VandenBerg, J. Mold-assisted nanolithography: A process for reliable pattern replication. J. Vac. Sci. Technol. B 1996, 14, 4124–4128. [Google Scholar] [CrossRef]

- Choi, B.J.; Sreenivasan, S.V.; Johnson, S.; Colburn, M.; Wilson, C.G. Design of orientation stages for step and flash imprint lithography. Precis. Eng. 2001, 25, 192–199. [Google Scholar] [CrossRef]

- Bergmair, I.; Mühlberger, M.; Gusenbauer, M.; Schöftner, R.; Hingerl, K. Equalising stamp and substrate deformations in solid parallel-plate UV-based nanoimprint lithography. Microelectron. Eng. 2008, 85, 822–824. [Google Scholar] [CrossRef]

- Bergmair, I.; Mühlberger, M.; Hingerl, K.; Pshenay-Severin, E.; Pertsch, T.; Kley, E.B.; Schmidt, H.; Schöftner, R. 3D materials made of gold using Nanoimprint Lithography. Microelectron. Eng. 2010, 87, 1008–1010. [Google Scholar] [CrossRef]

- Schift, H.; Spreu, C.; Schleunitz, A.; Lee, J. Shape control of polymer reflow structures fabricated by nanoimprint lithography. Microelectron. Eng. 2011, 88, 87–92. [Google Scholar] [CrossRef]

- Teng, L.; Plötner, M.; Türke, A.; Adolphi, B.; Finn, A.; Kirchner, R.; Fischer, W.J. Nanoimprint assisted inkjet printing to fabricate sub-micron channel organic field effect transistors. Microelectron. Eng. 2013, 110, 292–297. [Google Scholar] [CrossRef]

- Pianigiani, M.; Kirchner, R.; Sovernigo, E.; Pozzato, A.; Tormen, M.; Schift, H. Effect of nanoimprint on the elastic modulus of PMMA: Comparison between standard and ultrafast thermal NIL. Microelectron. Eng. 2016, 155, 85–91. [Google Scholar] [CrossRef]

- Ma, X.; Deng, D.; Cui, D. Double nanoimprint lithography: A technology for effectively reducing feature size. J. Vac. Sci. Technol. B 2017, 35, 06G304. [Google Scholar] [CrossRef]

- Eto, H.; Hiwasa, S.; Taniguchi, J. Tough and antifouling antireflection structures made by partial-filling ultraviolet nanoimprint lithography. Microelectron. Eng. 2018, 197, 33–38. [Google Scholar] [CrossRef]

- Bastiaens, A.J.; Xie, S.; Luttge, R. Investigating the interplay of lateral and height dimensions influencing neuronal processes on nanogrooves. J. Vac. Sci. Technol. B 2018, 36, 06J801. [Google Scholar] [CrossRef]

- Mayer, A.; Ai, W.; Rond, J.; Staabs, J.; Steinberg, C.; Papenheim, M.; Scheer, H.C.; Tormen, M.; Cian, A.; Zajadacz, J.; et al. Electrically-assisted nanoimprint of block copolymers. J. Vac. Sci. Technol. B 2019, 37, 011601. [Google Scholar] [CrossRef]

- Nakamura, M.; Kurihara, K.; Hokari, R.; Hiwasa, S.; Taniguchi, J. Anti-fouling and optical characterization of micro-lens array with antireflection structure by UV-NIL. Jpn. J. Appl. Phys. 2020, 59, SIIJ06. [Google Scholar] [CrossRef]

- Luo, M.; Hu, X. Direct imprinting of TiO2 patterns on highly curved substrates. J. Vac. Sci. Technol. B 2020, 38, 062604. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, M.; Zhang, X.; Zheng, X.; Xue, S.; Wang, Q. Effects of cavity shapes and rounded corners of mold on polymer filling process in nanoimprint lithography. J. Vac. Sci. Technol. B 2020, 38, 062802. [Google Scholar] [CrossRef]

- Ban, Y.H.; Bonnecaze, R.T. Minimizing filling time for ultraviolet nanoimprint lithography with templates with multiple structures. J. Vac. Sci. Technol. B 2021, 39, 012601. [Google Scholar] [CrossRef]

- Xie, S.; Erjawetz, J.; Schuster, C.; Schift, H. Hybrid structures by direct write lithography—Tuning the contrast and surface topography of grayscale photoresist with nanoimprint. J. Vac. Sci. Technol. B 2021, 39, 052603. [Google Scholar] [CrossRef]

- Nakamura, F.; Suzuki, K.; Noriki, A.; Amano, T. Micromirror fabrication for co-packaged optics using 3D nanoimprint technology. J. Vac. Sci. Technol. B 2022, 40, 063203. [Google Scholar] [CrossRef]

- Tan, H.; Gilbertson, A.; Chou, S.Y. Roller nanoimprint lithography. J. Vac. Sci. Technol. B 1998, 16, 3926–3928. [Google Scholar] [CrossRef]

- Ahn, S.H.; Kim, J.S.; Guo, L.J. Bilayer metal wire-grid polarizer fabricated by roll-to-roll nanoimprint lithography on flexible plastic substrate. J. Vac. Sci. Technol. B 2007, 25, 2388–2391. [Google Scholar] [CrossRef]

- Makela, T.; Haatainen, T.; Majander, P.; Ahopelto, J. Continuous roll to roll nanoimprinting of inherently conducting polyaniline. Microelectron. Eng. 2007, 84, 877–879. [Google Scholar] [CrossRef]

- Ahn, S.H.; Guo, L.J. High-speed roll-to-roll nanoimprint lithography on flexible plastic substrates. Adv. Mater. 2008, 20, 2044. [Google Scholar] [CrossRef]

- Makela, T.; Haatainen, T.; Majander, P.; Ahopelto, J.; Lambertini, V. Continuous double-sided roll-to-roll imprinting of polymer film. Jpn. J. Appl. Phys. 2008, 47, 5142–5144. [Google Scholar] [CrossRef]

- Ahn, S.H.; Guo, L.J. Large-Area Roll-to-Roll and Roll-to-Plate Nanoimprint Lithography: A Step toward High-Throughput Application of Continuous Nanoimprinting. ACS Nano 2009, 3, 2304–2310. [Google Scholar] [CrossRef] [PubMed]

- Taniguchi, J.; Aratani, M. Fabrication of a seamless roll mold by direct writing with an electron beam on a rotating cylindrical substrate. J. Vac. Sci. Technol. B 2009, 27, 2841–2845. [Google Scholar] [CrossRef]

- Taniguchi, J.; Unno, N.; Maruyama, H. Large-diameter roll mold fabrication method using a small-diameter quartz roll mold and UV nanoimprint lithography. J. Vac. Sci. Technol. B 2011, 29, 6. [Google Scholar] [CrossRef]

- Moro, M.; Taniguchi, J.; Hiwasa, S. Fabrication of antireflection structure film by roll-to-roll ultraviolet nanoimprint lithography. J. Vac. Sci. Technol. B 2014, 32, 6. [Google Scholar] [CrossRef]

- Takahashi, K.; Nagato, K.; Hamaguchi, T.; Nakao, M. High-speed replication of light-extraction structure with thermal roller nanoimprinting. Microelectron. Eng. 2015, 141, 285–288. [Google Scholar] [CrossRef]

- Faria-Briceno, J.J.; Zhu, R.; Sasidharan, V.; Neumann, A.; Singhal, S.; Sreenivasan, S.V.; Brueck, S.R.J. Optical angular scatterometry: In-line metrology approach for roll-to-roll and nanoimprint fabrication. J. Vac. Sci. Technol. B 2019, 37, 052904. [Google Scholar] [CrossRef]

- Howell, I.R.; Einck, V.J.; Nees, D.; Stadlober, B.; Watkins, J.J. Solvent-free, transparent, high-refractive index ZrO2 nanoparticle composite resin for scalable roll to roll UV-nanoimprint lithography. Opt. Las. Technol. 2021, 141, 107101. [Google Scholar] [CrossRef]

- Ghaznavi, Z.; Butcher, N.; Djurdjanovic, D.; Sreenivasan, S.V. Roll-to-roll reactive ion etching of large-area nanostructure arrays in Si: Process development, characterization, and optimization. J. Vac. Sci. Technol. B 2023, 41, 022802. [Google Scholar] [CrossRef]

| Reflectance Properties | Contact Angle [°] | Haze | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 450 nm | 550 nm | 700 nm | Y | x | y | L* | a* | b* | Water | n-Hexadecane | [%] | ||

| [%] | [%] | [%] | |||||||||||

| GC moth-eye film | Average | 0.085 | 0.16 | 0.26 | 0.17 | 0.37 | 0.35 | −2.31 | 1.13 | 2.79 | 150 | 103 | 0.32 |

| SD | 0.02 | 0.033 | 0.026 | 0.032 | 0.012 | 0.009 | 0.89 | 0.25 | 0.57 | 0.66 | 0.53 | 0.05 | |

| Al moth-eye film | Average | 0.17 | 0.22 | 0.24 | 0.22 | 0.31 | 0.32 | −0.87 | −0.28 | 0.049 | 145 | 97 | 0.352 |

| SD | 0.07 | 0.033 | 0.025 | 0.029 | 0.03 | 0.038 | 0.64 | 0.79 | 2.63 | 0.29 | 0.91 | 0.016 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kato, K.; Sugawara, H.; Taniguchi, J. Large-Scale Moth-Eye-Structured Roll Mold Fabrication Using Sputtered Glassy Carbon Layer and Transferred Moth-Eye Film Characterization. Nanomaterials 2023, 13, 1591. https://doi.org/10.3390/nano13101591

Kato K, Sugawara H, Taniguchi J. Large-Scale Moth-Eye-Structured Roll Mold Fabrication Using Sputtered Glassy Carbon Layer and Transferred Moth-Eye Film Characterization. Nanomaterials. 2023; 13(10):1591. https://doi.org/10.3390/nano13101591

Chicago/Turabian StyleKato, Kazuhiro, Hiroyuki Sugawara, and Jun Taniguchi. 2023. "Large-Scale Moth-Eye-Structured Roll Mold Fabrication Using Sputtered Glassy Carbon Layer and Transferred Moth-Eye Film Characterization" Nanomaterials 13, no. 10: 1591. https://doi.org/10.3390/nano13101591