The Study on the Lasing Modes Modulated by the Dislocation Distribution in the GaN-Based Microrod Cavities

Abstract

:1. Introduction

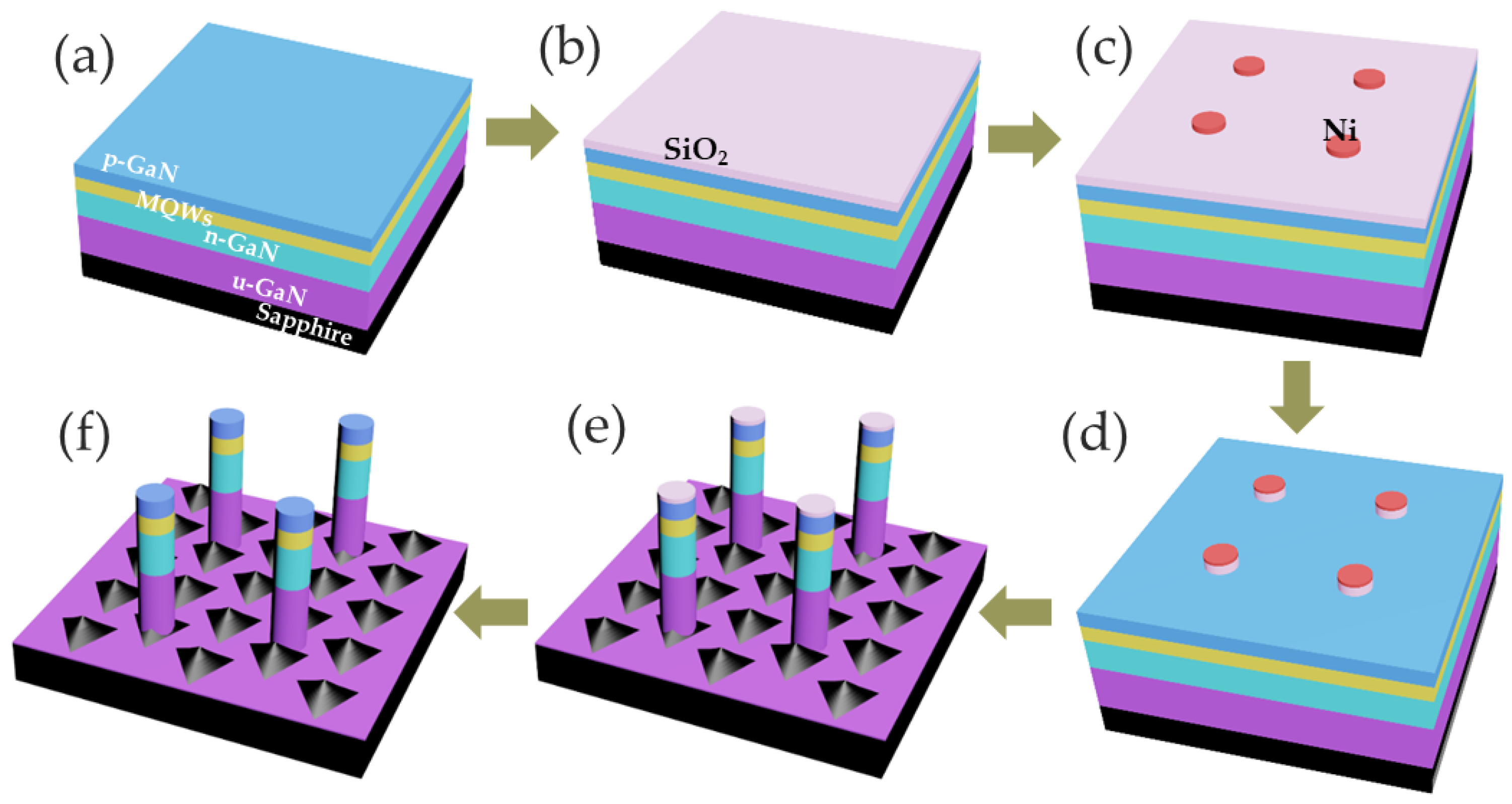

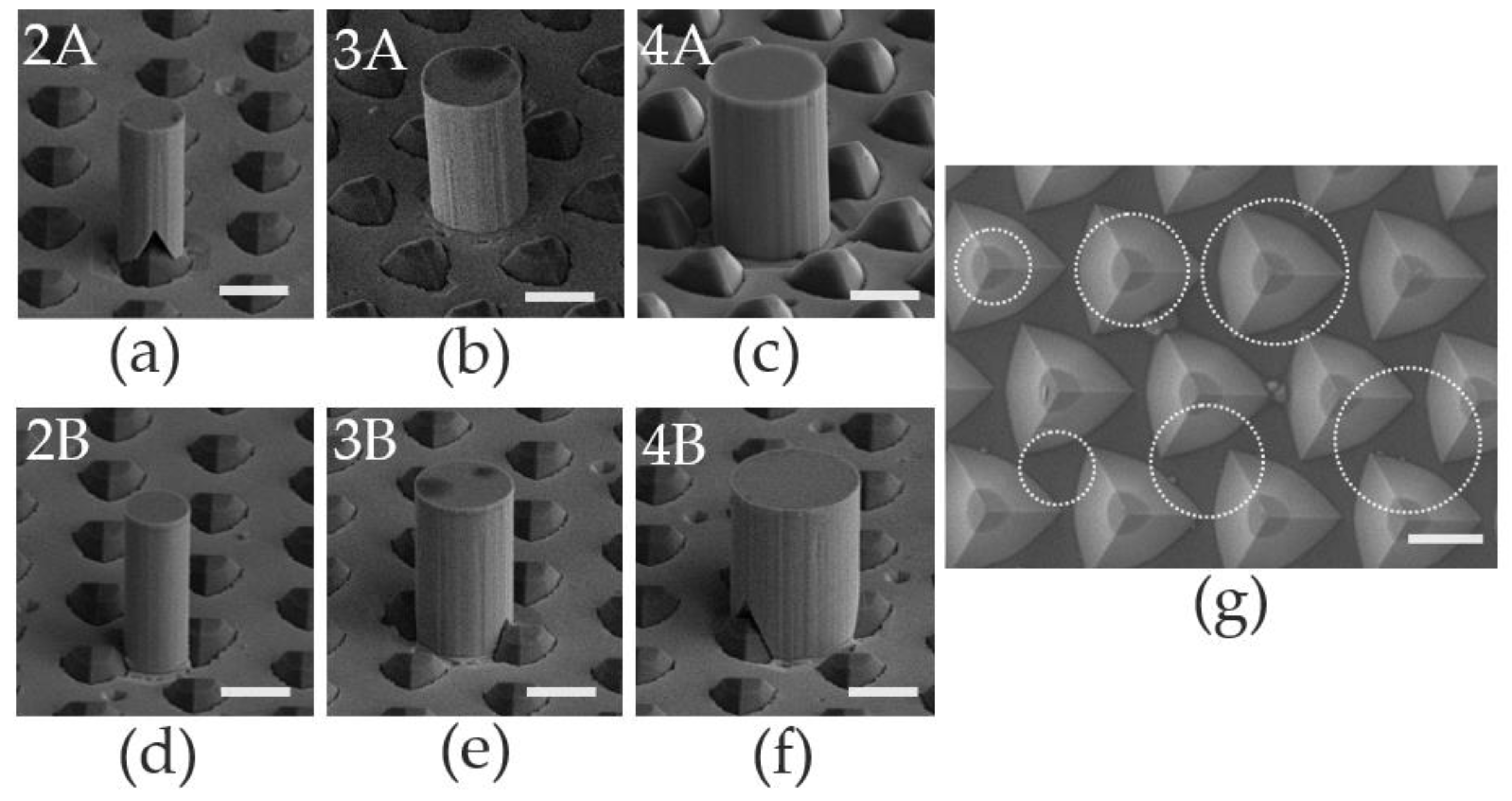

2. Materials and Methods

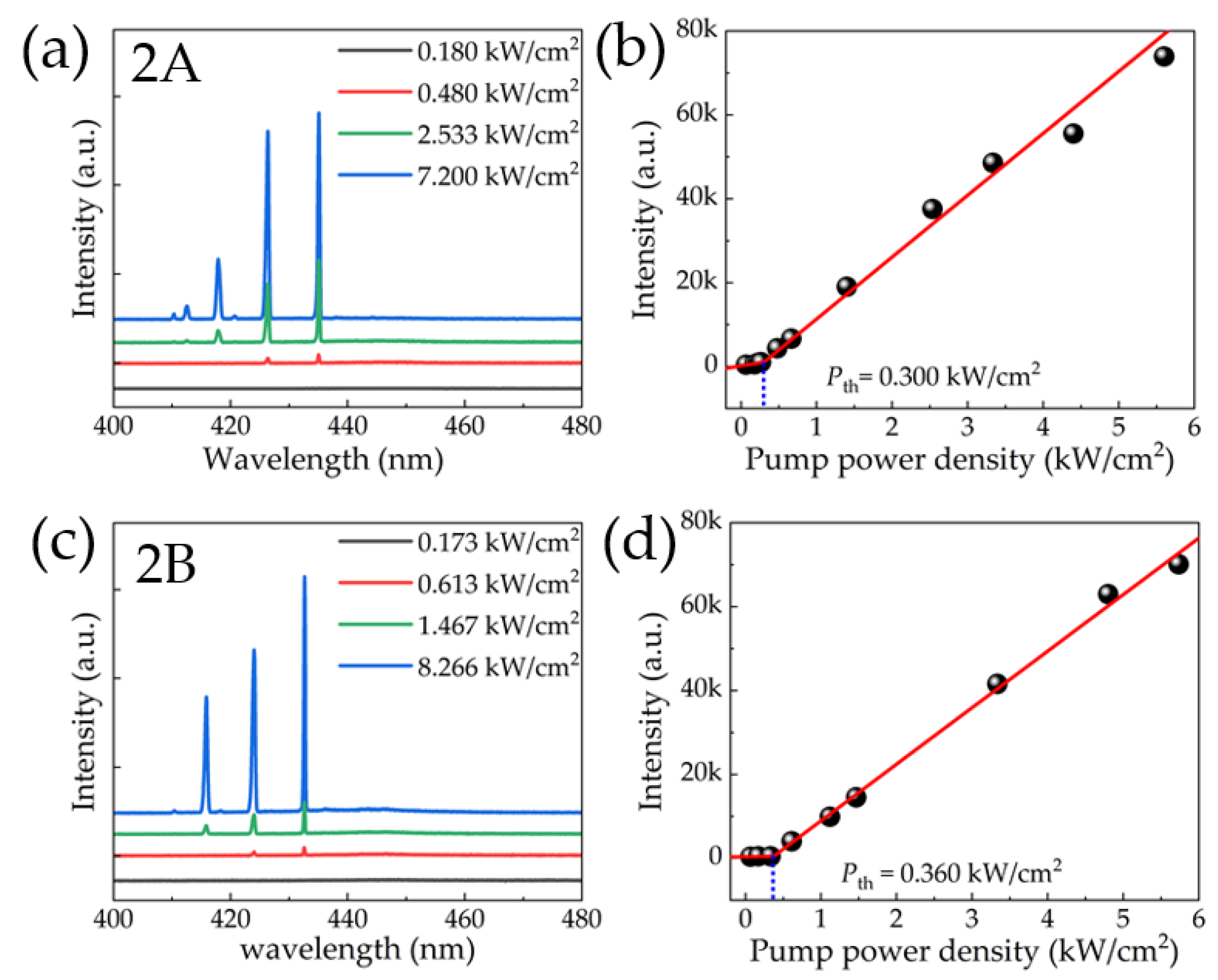

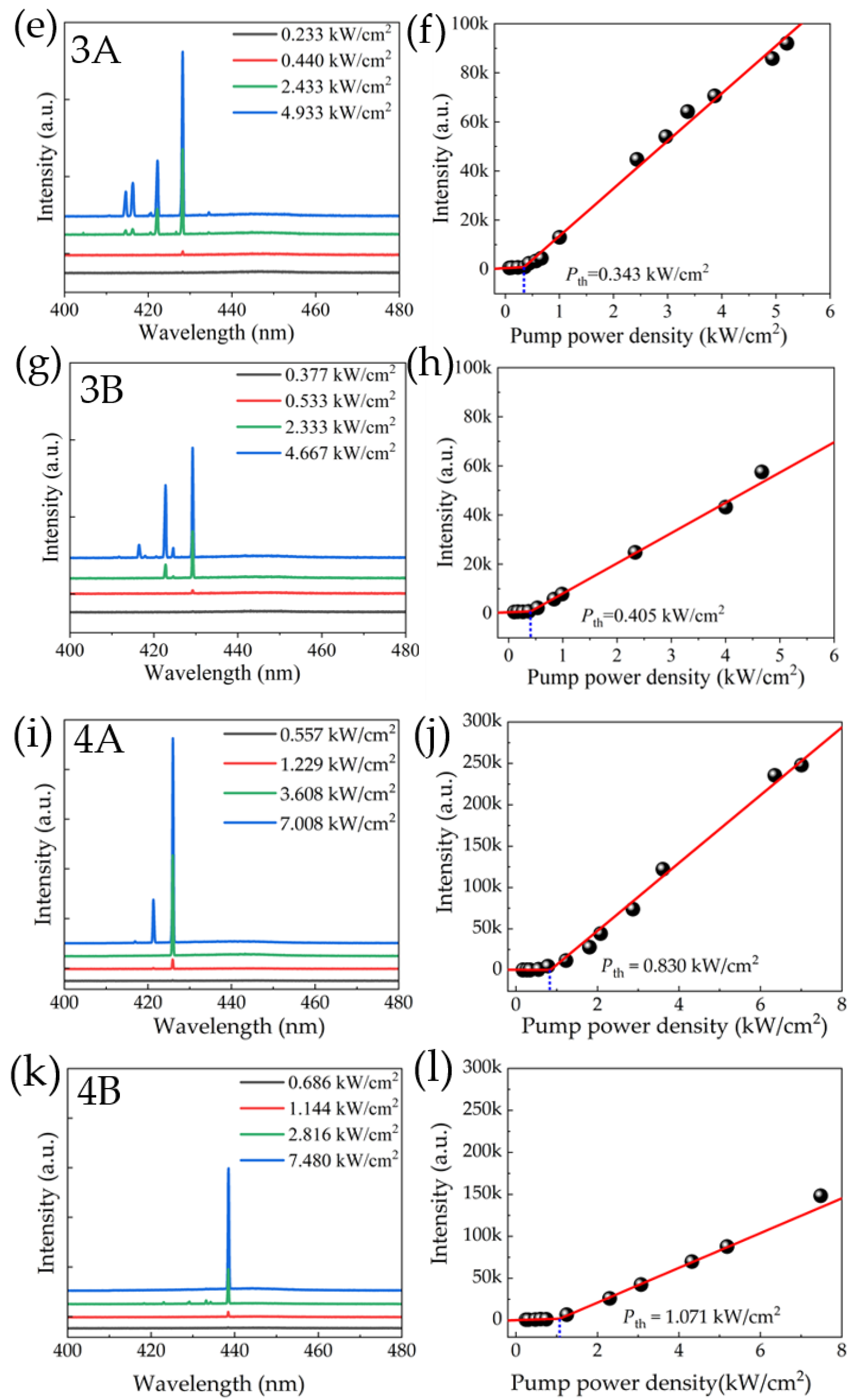

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ene, V.L.; Dinescu, D.; Zai, I.; Djourelov, N.; Vasile, B.S.; Serban, A.B.; Leca, V.; Andronescu, E. Study of Edge and Screw Dislocation Density in GaN/Al2O3 Heterostructure. Materials 2019, 12, 4205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kao, C.-C.; Su, Y.-K.; Lin, C.-L.; Chen, J.-J. The aspect ratio effects on the performances of GaN-based light-emitting diodes with nanopatterned sapphire substrates. Appl. Phys. Lett. 2010, 97, 023111. [Google Scholar] [CrossRef]

- Cheng, J.-H.; Wu, Y.S.; Liao, W.-C.; Lin, B.-W. Improved crystal quality and performance of GaN-based light-emitting diodes by decreasing the slanted angle of patterned sapphire. Appl. Phys. Lett. 2010, 96, 051109. [Google Scholar] [CrossRef]

- Wang, H.; Jin, G.; Tan, Q. Dislocation Evolution and Microstructural Properties on GaN Grown on Cone Patterned Sapphire Substrate. Russ. J. Phys. Chem. A 2018, 92, 1567–1571. [Google Scholar] [CrossRef]

- Heying, B.; Wu, X.H.; Keller, S.; Li, Y.; Kapolnek, D.; Keller, B.P.; DenBaars, S.P.; Speck, J.S. Role of threading dislocation structure on the x-ray diffraction peak widths in epitaxial GaN films. Appl. Phys. Lett. 1996, 68, 643–645. [Google Scholar] [CrossRef]

- Wang, J.; You, H.; Guo, H.; Xue, J.; Yang, G.; Chen, D.; Liu, B.; Lu, H.; Zhang, R.; Zheng, Y. Do all screw dislocations cause leakage in GaN-based devices? Appl. Phys. Lett. 2020, 116, 062104. [Google Scholar] [CrossRef]

- Coldren, L.A.; Corzine, S.W.; Mashanovitch, M.L. Diode Lasers and Photonic Integrated Circuits; Wiley: New York, NY, USA, 2012. [Google Scholar]

- He, L.; Özdemir, Ş.K.; Yang, L. Whispering gallery microcavity lasers. Laser Photonics Rev. 2013, 7, 60–82. [Google Scholar] [CrossRef]

- Wang, X.; Liao, Q.; Kong, Q.; Zhang, Y.; Xu, Z.; Lu, X.; Fu, H. Whispering-gallery-mode microlaser based on self-assembled organic single-crystalline hexagonal microdisks. Angew. Chem. Int. Ed. Engl. 2014, 53, 5863. [Google Scholar] [CrossRef]

- Mi, Y.; Jin, B.; Zhao, L.; Chen, J.; Zhang, S.; Shi, J.; Zhong, Y.; Du, W.; Zhang, J.; Zhang, Q.; et al. High-Quality Hexagonal Nonlayered CdS Nanoplatelets for Low-Threshold Whispering-Gallery-Mode Lasing. Small 2019, 15, e1901364. [Google Scholar] [CrossRef]

- Selles, J.; Brimont, C.; Cassabois, G.; Valvin, P.; Guillet, T.; Roland, I.; Zeng, Y.; Checoury, X.; Boucaud, P.; Mexis, M.; et al. Deep-UV nitride-on-silicon microdisk lasers. Sci. Rep. 2016, 6, 21650. [Google Scholar] [CrossRef] [Green Version]

- Tamboli, A.C.; Haberer, E.D.; Sharma, R.; Lee, K.H.; Nakamura, S.; Hu, E.L. Room-temperature continuous-wave lasing in GaN/InGaN microdisks. Nat. Photonics 2006, 1, 61–64. [Google Scholar] [CrossRef]

- Rousseau, I.; Callsen, G.; Jacopin, G.; Carlin, J.-F.; Butté, R.; Grandjean, N. Optical absorption and oxygen passivation of surface states in III-nitride photonic devices. J. Appl. Phys. 2018, 123, 113103. [Google Scholar] [CrossRef] [Green Version]

- Tabataba-Vakili, F.; Brimont, C.; Alloing, B.; Damilano, B.; Doyennette, L.; Guillet, T.; El Kurdi, M.; Chenot, S.; Brändli, V.; Frayssinet, E.; et al. Analysis of low-threshold optically pumped III-nitride microdisk lasers. Appl. Phys. Lett. 2020, 117, 122103. [Google Scholar] [CrossRef]

- Li, J.; Chen, H.; Yu, G.; Lei, M.; Li, S.; Hu, X. Room-temperature exciton-polariton and photonic lasing in GaN/InGaN core-shell microrods. Physica. Scripta. 2023, 98, 074001. [Google Scholar] [CrossRef]

- Liu, M.-H.; Chen, P.; Xie, Z.-L.; Xiu, X.-Q.; Chen, D.-J.; Liu, B.; Han, P.; Shi, Y.; Zhang, R.; Zheng, Y.-D.; et al. High-efficiency photon–electron coupling resonant emission in GaN-based microdisks on Si. Chin. Phys. B 2020, 29, 084203. [Google Scholar] [CrossRef]

- Zhuang, Z.; Guo, X.; Zhang, G.; Liu, B.; Zhang, R.; Zhi, T.; Tao, T.; Ge, H.; Ren, F.; Xie, Z.; et al. Large-scale fabrication and luminescence properties of GaN nanostructures by a soft UV-curing nanoimprint lithography. Nanotechnology 2013, 24, 405303. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, Z.; Guo, X.; Liu, B.; Hu, F.; Dai, J.; Zhang, Y.; Li, Y.; Tao, T.; Zhi, T.; Xie, Z.; et al. Great enhancement in the excitonic recombination and light extraction of highly ordered InGaN/GaN elliptic nanorod arrays on a wafer scale. Nanotechnology 2016, 27, 015301. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Chen, P.; Zhou, J.; Xu, R.; Mao, X.; Xie, Z.; Xiu, X.; Chen, D.; Liu, B.; Han, P.; et al. Realization of regular resonance mode in GaN-based polygonal microdisks on Si. J. Appl. Phys. 2020, 127, 113102. [Google Scholar] [CrossRef]

- Yuan, G.; Zhang, C.; Xiong, K.; Han, J. InGaN/GaN microdisks enabled by nanoporous GaN cladding. Opt. Lett. 2018, 43, 5567–5570. [Google Scholar] [CrossRef]

- Wang, H.; Jin, G.; Tan, Q. Characteristic enhancement of InGaN-based light emitting diodes grown on pattern sapphire substrates. IOP Conf. Ser. Mater. Sci. Eng. 2020, 758, 012087. [Google Scholar] [CrossRef]

- Wang, M.-T.; Liao, K.-Y.; Li, Y.-L. Growth Mechanism and Strain Variation of GaN Material Grown on Patterned Sapphire Substrates with Various Pattern Designs. IEEE Photonics Technol. Lett. 2011, 23, 962–964. [Google Scholar] [CrossRef]

- Li, H.; Cheng, H.Y.; Chen, W.L.; Huang, Y.H.; Li, C.K.; Chang, C.Y.; Wu, Y.R.; Lu, T.C.; Chang, Y.M. Three dimensional characterization of GaN-based light emitting diode grown on patterned sapphire substrate by confocal Raman and photoluminescence spectromicroscopy. Sci. Rep. 2017, 7, 45519. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsueh, H.-H.; Ou, S.-L.; Peng, Y.-C.; Cheng, C.-Y.; Wuu, D.-S.; Horng, R.-H. Effect of Top-Region Area of Flat-Top Pyramid Patterned Sapphire Substrate on the Optoelectronic Performance of GaN-Based Light-Emitting Diodes. J. Nanomater. 2016, 2016, 2701028. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.H.; Ruh, H.; Noh, Y.K.; Kim, M.D.; Oh, J.E. Microstructural properties and dislocation evolution on a GaN grown on patterned sapphire substrate: A transmission electron microscopy study. J. Appl. Phys. 2010, 107, 063501. [Google Scholar] [CrossRef]

- Shin, H.-Y.; Kwon, S.K.; Chang, Y.I.; Cho, M.J. Reducing dislocation density in GaN films using a cone-shaped patterned sapphire substrate. J. Cryst. Growth 2009, 311, 4167–4170. [Google Scholar] [CrossRef]

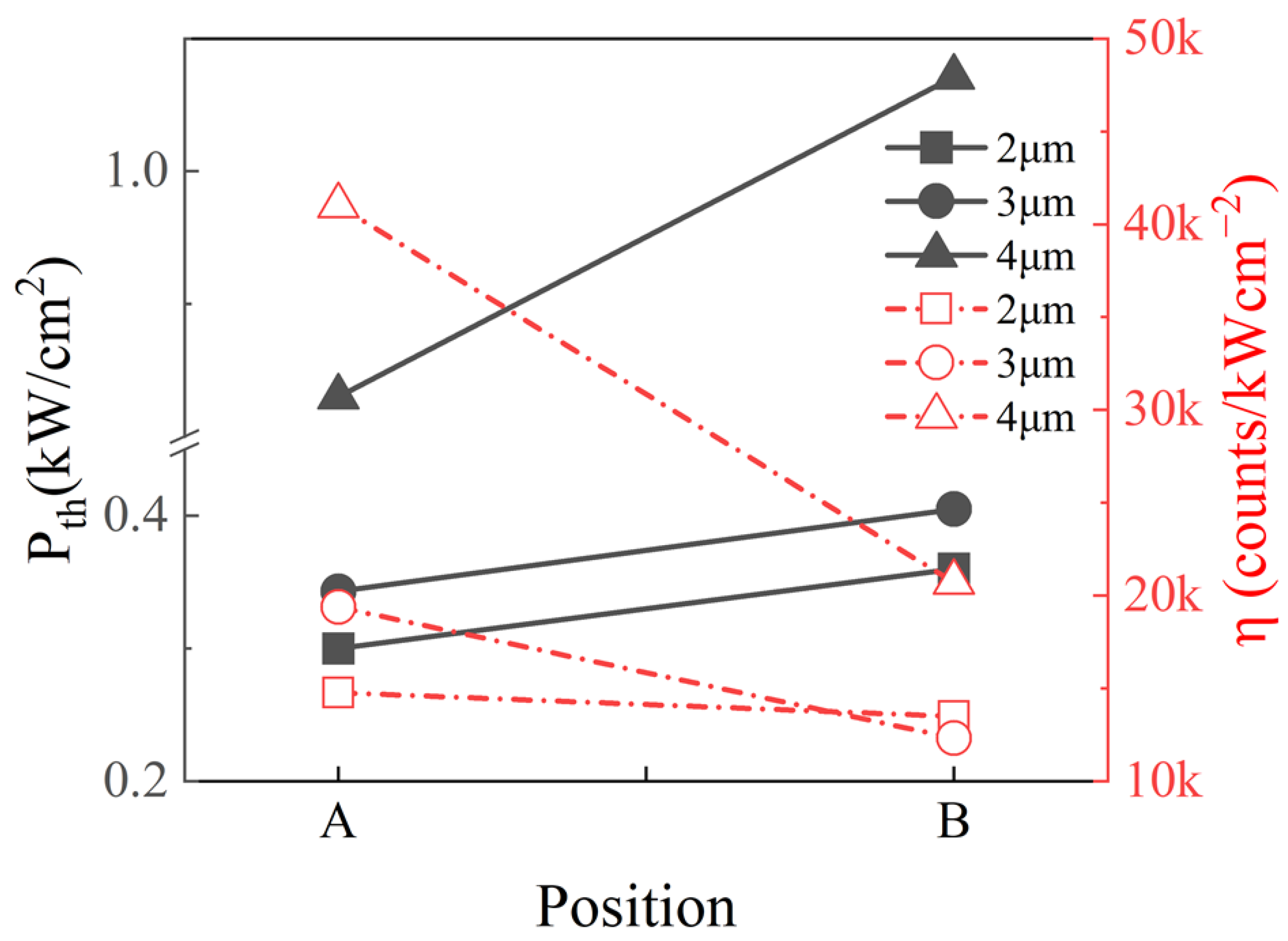

| 2A | 2B | 3A | 3B | 4A | 4B | |

|---|---|---|---|---|---|---|

| Pth (KW/cm2) | 0.300 | 0.360 | 0.343 | 0.405 | 0.830 | 1.071 |

| Wavelength (nm) | 435.08 | 432.65 | 428.24 | 429.31 | 425.98 | 438.51 |

| FWHM (nm) | 0.36 | 0.29 | 0.33 | 0.29 | 0.28 | 0.31 |

| Q | 1208 | 1502 | 1313 | 1470 | 1521 | 1414 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Chen, P.; Zhang, X.; Yan, Z.; Xu, T.; Xie, Z.; Xiu, X.; Chen, D.; Zhao, H.; Shi, Y.; et al. The Study on the Lasing Modes Modulated by the Dislocation Distribution in the GaN-Based Microrod Cavities. Nanomaterials 2023, 13, 2228. https://doi.org/10.3390/nano13152228

Li Y, Chen P, Zhang X, Yan Z, Xu T, Xie Z, Xiu X, Chen D, Zhao H, Shi Y, et al. The Study on the Lasing Modes Modulated by the Dislocation Distribution in the GaN-Based Microrod Cavities. Nanomaterials. 2023; 13(15):2228. https://doi.org/10.3390/nano13152228

Chicago/Turabian StyleLi, Yuyin, Peng Chen, Xianfei Zhang, Ziwen Yan, Tong Xu, Zili Xie, Xiangqian Xiu, Dunjun Chen, Hong Zhao, Yi Shi, and et al. 2023. "The Study on the Lasing Modes Modulated by the Dislocation Distribution in the GaN-Based Microrod Cavities" Nanomaterials 13, no. 15: 2228. https://doi.org/10.3390/nano13152228