Design and Preparation of Flexible Graphene/Nonwoven Composites with Simultaneous Broadband Absorption and Stable Properties

Abstract

:1. Introduction

2. Experiments

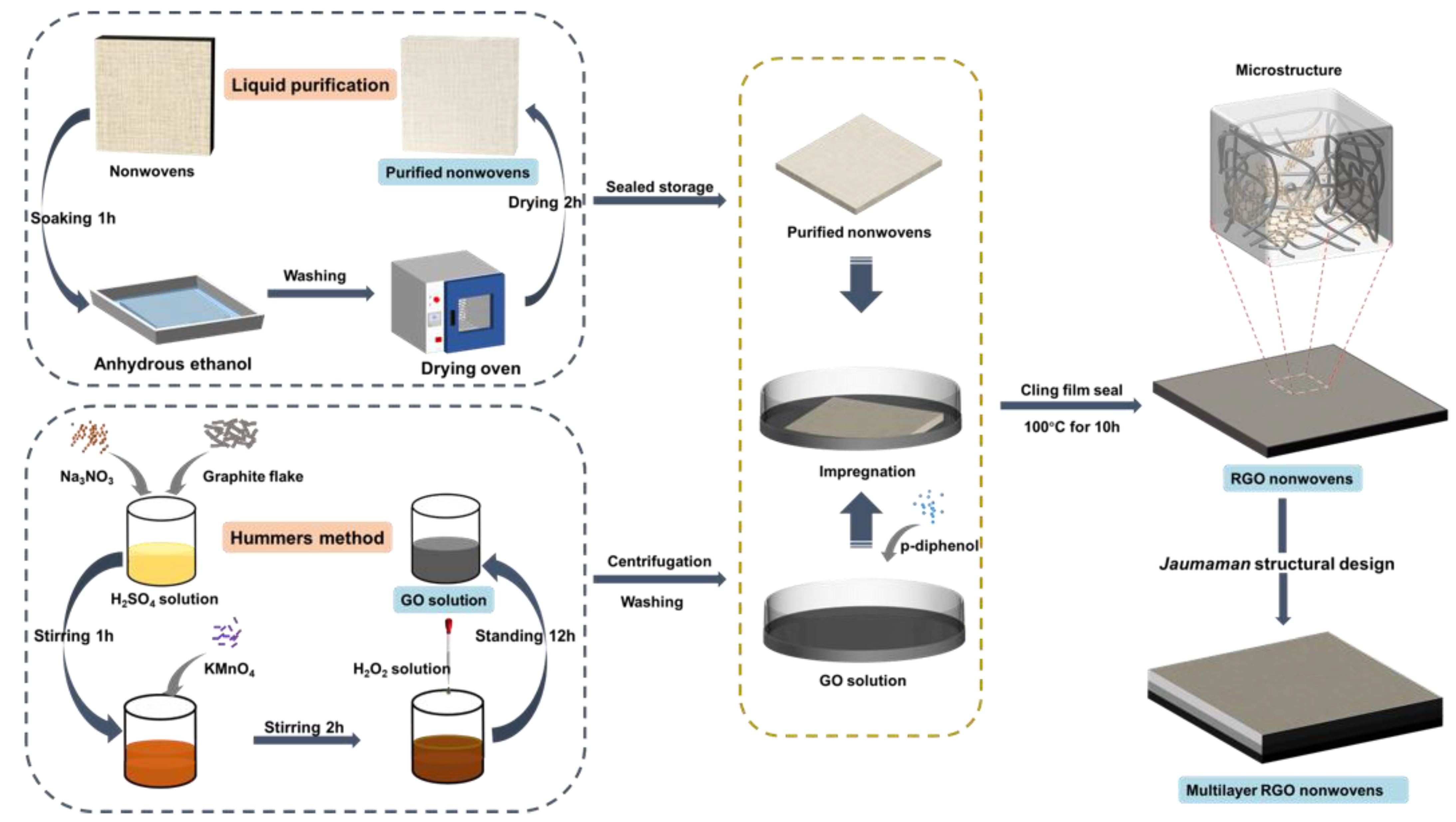

2.1. Preparation of RGO/NW Composites

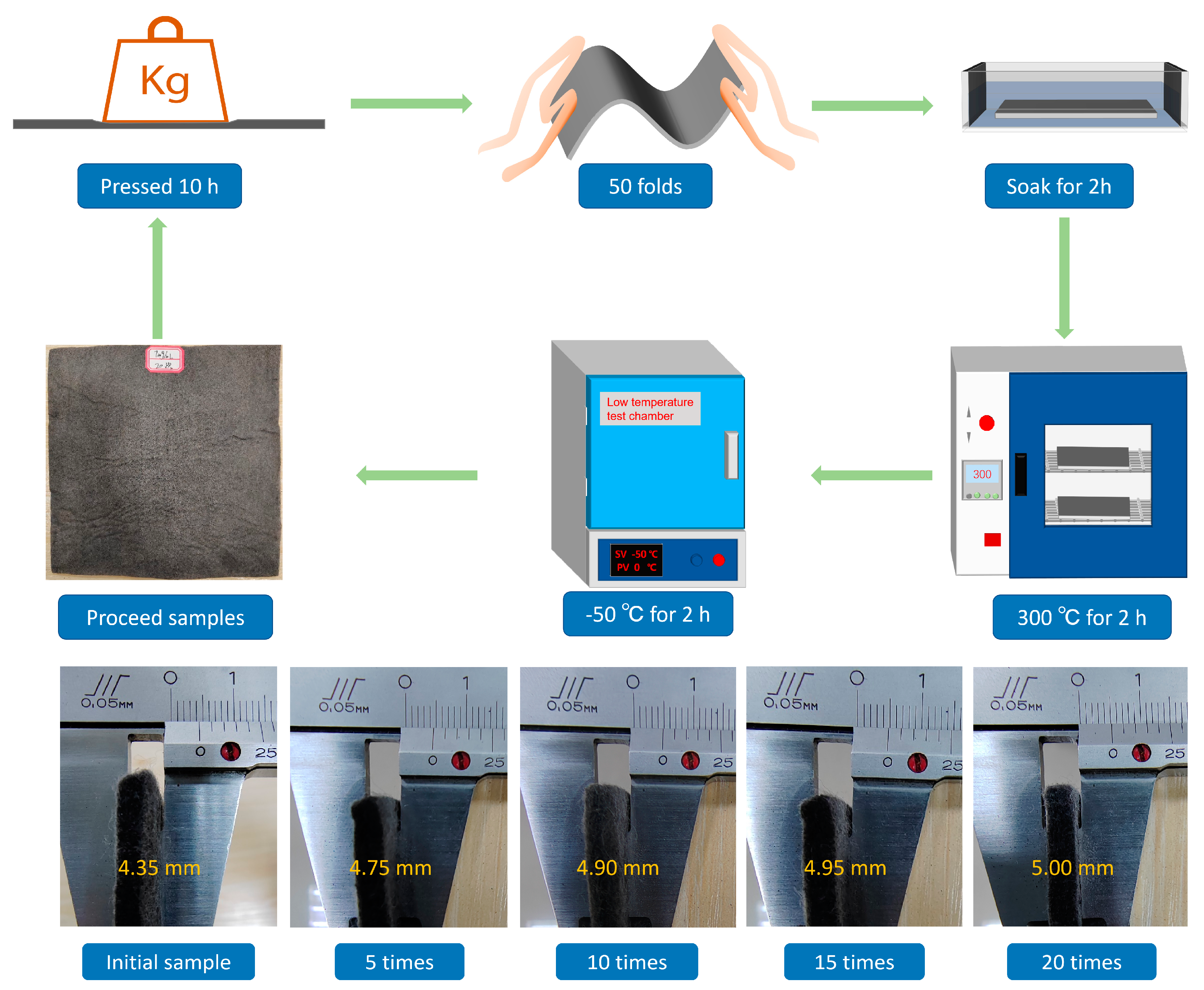

2.2. RGO/NW Composite Stability Experiments

2.3. Preparation of Multilayer RGO/NW Composites

2.4. Characterization

3. Results and Discussion

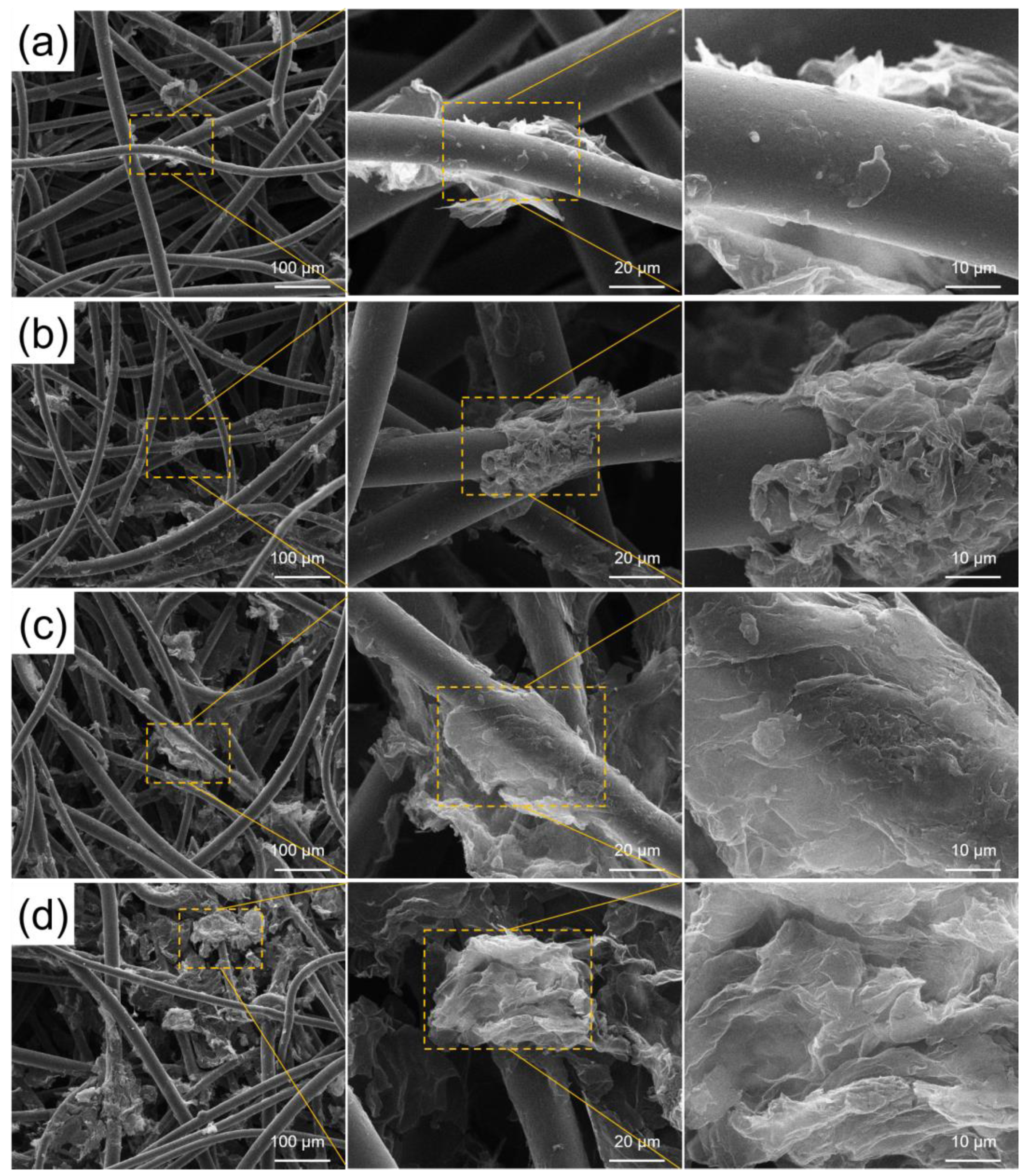

3.1. Morphological Analyses

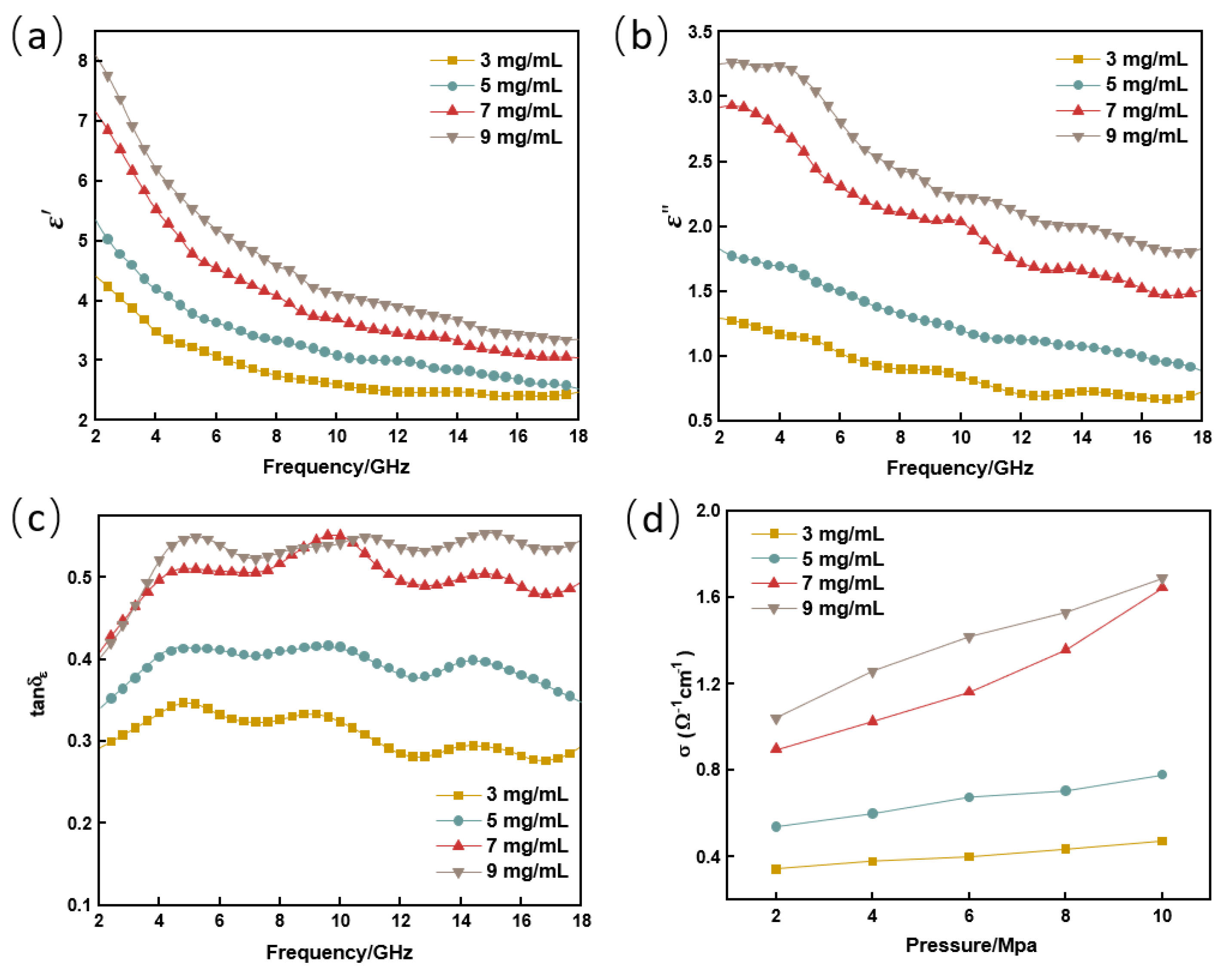

3.2. Dielectric Performance Analysis of RGO/NW Composites

3.3. Absorption Properties of RGO/NW Composites

3.3.1. Analysis of Absorption Performance of Single-Layer RGO/NW Composites

3.3.2. Structural and Electromagnetic Performance Stability of RGO/NW Composites

- The nonwoven fabric has good deformation recovery ability. Multiple foldings and pressings do not cause permanent deformation, thus ensuring a good spatial distribution of graphene inside the nonwoven fabric matrix.

- Graphene, as a carbon material, exhibits extremely stable physicochemical properties and does not react with oxygen or water in the air at 300 °C or −50 °C.

- The carbon atoms in graphene are connected by strong covalent bonds. When subjected to external mechanical forces, the carbon atoms are bent, but remain in a strict order, ensuring structural stability.

- Graphene is the material with the largest specific surface area found so far, and due to its light and flexible web-like structure, it is entangled between the fibers inside the nonwoven fabric and does not easily loosen from the nonwoven fabric matrix.

- Unlike graphene oxide prepared by the Hummers’ method, the chemically reduced graphene is not soluble in water, so it does not dissolve and disperse during immersion.

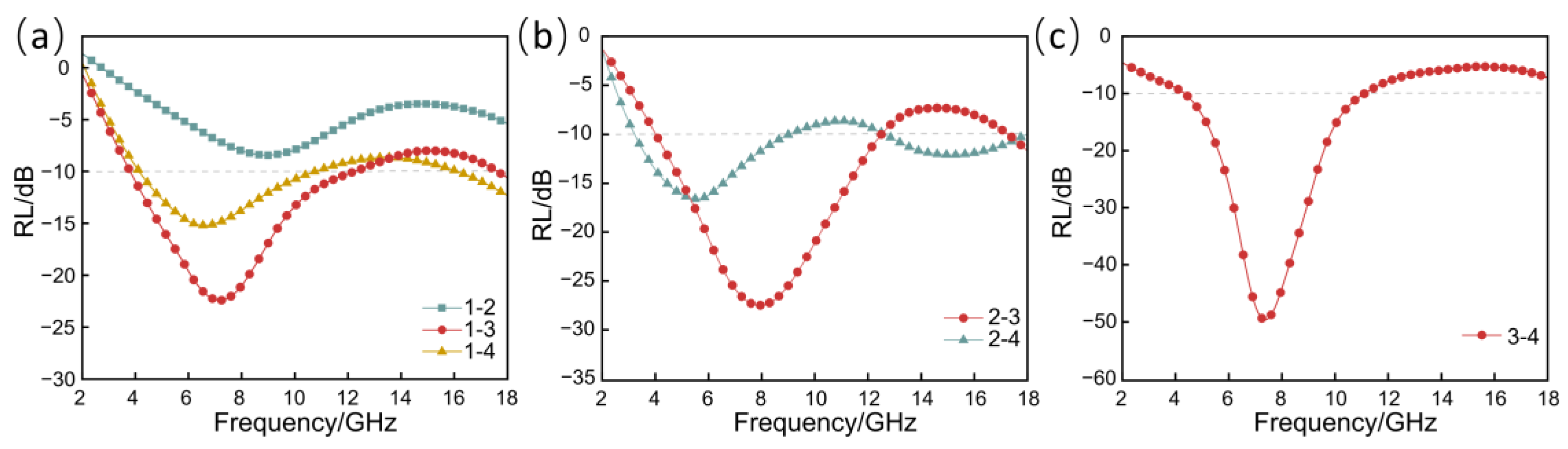

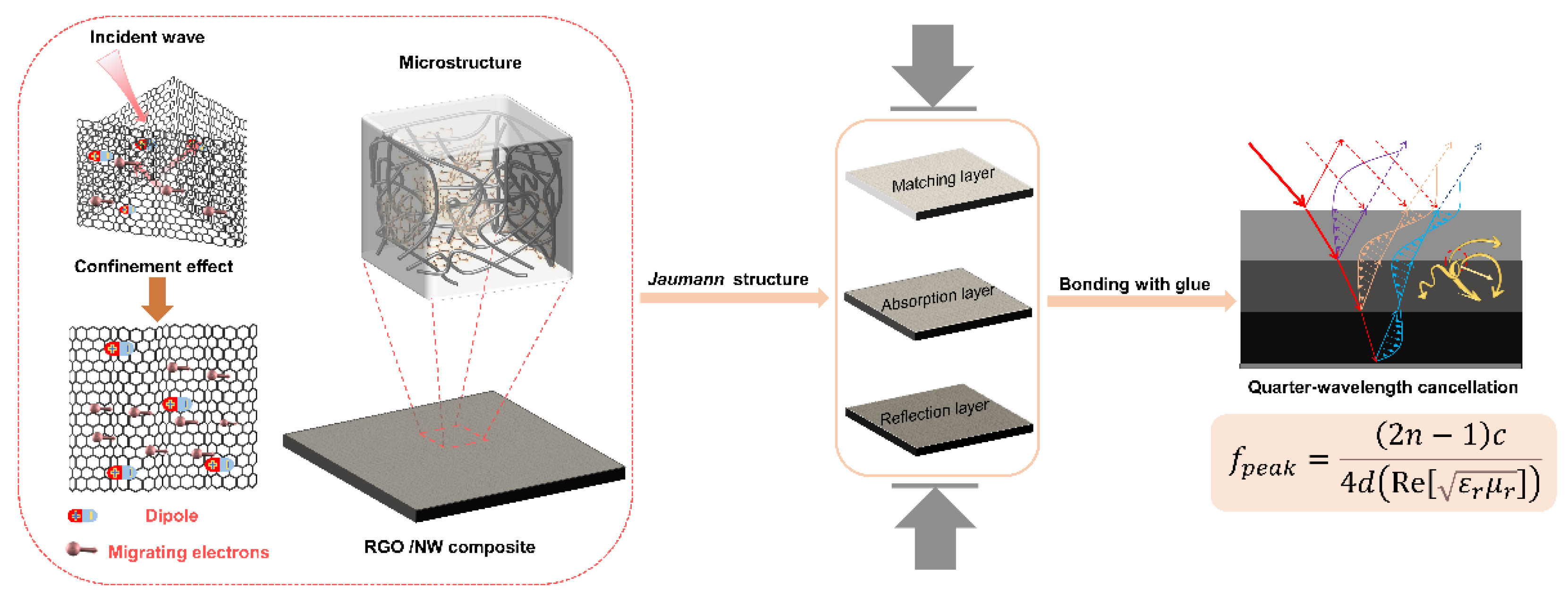

3.3.3. Analysis of Absorption Performance of Multilayer HC Composite

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, P.; Zhang, Y.; Yan, J.; Huang, Y.; Xia, L.; Guang, Z. Synthesis of lightweight N-doped graphene foams with open reticular structure for high-efficiency electromagnetic wave absorption. Chem. Eng. J. 2019, 368, 285–298. [Google Scholar] [CrossRef]

- Liu, P.B.; Gao, S.; Wang, Y.; Huang, Y.; Wang, Y.; Luo, J.H. Core–Shell CoNi@ Graphitic Carbon Decorated on B,N-Codoped Hollow Carbon Polyhedrons toward Lightweight and High-Efficiency Microwave Attenuation. ACS Appl. Mater. Interfaces 2019, 11, 25624–25635. [Google Scholar] [CrossRef]

- Yan, Z.; Yao, W.; Hu, L.; Liu, D.; Wang, C.; Lee, C.-S. Progress in the preparation and application of three-dimensional graphene-based porous nanocomposites. Nanoscale 2015, 7, 5563–5577. [Google Scholar] [CrossRef] [PubMed]

- Agra, K.; Bohn, F.; Mori, T.J.A.; Callegari, G.L.; Dorneles, L.S.; Correa, M.A. Handling magnetic anisotropy and magnetoimpedance effect in flexible multilayers under external stress. J. Magn. Magn. Mater. 2016, 420, 81–87. [Google Scholar] [CrossRef]

- Aguilar, C.M.M.; Svalov, A.V.; Kharlamova, A.A.; Shalygina, E.E.; Larranaga, A.; Orue, I.; Kurlyandskaya, G.V. Magnetic and Microwave Properties of FeNi Thin Films of Different Thicknesses Deposited onto Cyclo Olefin Copolymer Flexible Substrates. IEEE Trans. Magn. 2022, 58, 2200105. [Google Scholar] [CrossRef]

- Cao, X.; Yin, Z.; Zhang, H. Three-dimensional graphene materials: Preparation, structures and application in supercapacitors. Energy Environ. Sci. 2014, 7, 1850–1865. [Google Scholar] [CrossRef]

- Hong, J.-Y.; Wie, J.J.; Xu, Y.; Park, H.S. Chemical modification of graphene aerogels for electrochemical capacitor applications. Phys. Chem. Chem. Phys. 2015, 17, 30946–30962. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Huang, Y.; Zhang, T.; Chang, H.; Xiao, P.; Chen, H.; Huang, Z.; Chen, Y. Broadband and Tunable High-Performance Microwave Absorption of an Ultralight and Highly Compressible Graphene Foam. Adv. Mater. 2015, 27, 2049–2053. [Google Scholar] [CrossRef]

- Shen, B.; Li, Y.; Yi, D.; Zhai, W.; Wei, X.; Zheng, W. Microcellular graphene foam for improved broadband electromagnetic interference shielding. Carbon 2016, 102, 154–160. [Google Scholar] [CrossRef]

- Fang, S.; Huang, D.; Lv, R.; Bai, Y.; Huang, Z.-H.; Gu, J.; Kang, F. Three-dimensional reduced graphene oxide powder for efficient microwave absorption in the S-band (2–4 GHz). RSC Adv. 2017, 7, 25773–25779. [Google Scholar] [CrossRef] [Green Version]

- Fernández, E.; Svalov, A.V.; García-Arribas, A.; Feuchtwanger, J.; Barandiaran, J.M.; Kurlyandskaya, G.V. High Performance Magnetoimpedance in FeNi/Ti Nanostructured Multilayers with Opened Magnetic Flux. J. Nanosci. Nanotechnol. 2012, 12, 7496–7500. [Google Scholar] [CrossRef] [PubMed]

- Grimes, C.A. Sputter deposition of magnetic thin films onto plastic: The effect of undercoat and spacer layer composition on the magnetic properties of multilayer permalloy thin films. IEEE Trans. Magn. 1995, 31, 4109–4111. [Google Scholar] [CrossRef]

- Kurlyandskaya, G.V.; Safronov, A.P.; Bhagat, S.M.; Lofland, S.E.; Beketov, I.V.; Prieto, L.M. Tailoring functional properties of Ni nanoparticles-acrylic copolymer composites with different concentrations of magnetic filler. J. Appl. Phys. 2015, 117, 123917. [Google Scholar] [CrossRef]

- Li, B.; Kavaldzhiev, M.N.; Kosel, J. Flexible magnetoimpedance sensor. J. Magn. Magn. Mater. 2015, 378, 499–505. [Google Scholar] [CrossRef]

- Jiang, X.; Huang, D.; Zhang, Y.; Shi, Y.; Wang, Z. Electromagnetic absorbing properties of Jaumann absorber. Hang Kong Cai Liao Xue Bao 2021, 41, 133. [Google Scholar] [CrossRef]

- Li, X.; Yang, Q.; Zhou, G.; Zhu, X.; Ren, G.; Zhang, W.; Yang, M.; Gao, Z. Preparation and properties of a Jaumann type microwave absorbing ceramic with carbon felt film. Ceram. Int. 2021, 47, 1381–1388. [Google Scholar] [CrossRef]

- Al Faruque, M.A.; Syduzzaman, M.; Sarkar, J.; Bilisik, K.; Naebe, M. A review on the production methods and applications of graphene-based materials. Nanomaterials 2021, 11, 2414. [Google Scholar] [CrossRef]

- Li, J.S.; Xie, Y.; Lu, W.B.; Chou, T.W. Flexible electromagnetic wave absorbing composite based on 3D rGO-CNT-Fe3O4 ternary films. Carbon 2018, 129, 76–84. [Google Scholar] [CrossRef]

- Lu, S.; Xia, L.; Xu, J.M.; Ding, C.H.; Li, T.; Yang, H.; Zhong, B.; Zhang, T.; Huang, L.N.; Xiong, L.; et al. Permittivity-Regulating Strategy Enabling Superior Electromagnetic Wave Absorption of Lithium Aluminum Silicate/rGO Nanocomposites. ACS Appl. Mater. Interfaces 2019, 11, 18626–18636. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.L.; Ruan, K.P.; Shi, X.T.; Qiu, H.; Pan, Y.; Yan, Y.; Gu, J.W. Ti3C2Tx/rGO porous composite films with superior electromagnetic interference shielding performances. Carbon 2021, 175, 271–280. [Google Scholar] [CrossRef]

- Yuan, H.; Li, Y.; Qian, Z.; Ren, L.; Ren, L. A Piezoresistive Sensor with High Sensitivity and Flexibility Based on Porous Sponge. Nanomaterials 2022, 12, 3833. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Cheng, Y.; Liu, W.; Yang, L.; Zhang, B.; Wang, L.P.; Ji, G.; Xu, Z.J. Biomass-Derived Porous Carbon-Based Nanostructures for Microwave Absorption. Nanomicro. Lett. 2019, 11, 24. [Google Scholar] [CrossRef]

- Orasugh, J.T.; Ray, S.S. Graphene-Based Electrospun Fibrous Materials with Enhanced EMI Shielding: Recent Developments and Future Perspectives. ACS Omega 2022, 7, 33699–33718. [Google Scholar] [CrossRef]

- Cao, M.S.; Han, C.; Wang, X.X.; Zhang, M.; Zhang, Y.; Shu, J.C.; Yang, H.J.; Fang, X.Y.; Yuan, J. Graphene nanohybrids: Excellent electromagnetic properties for the absorbing and shielding of electromagnetic waves. J. Mater. Chem. C 2018, 6, 4586–4602. [Google Scholar] [CrossRef]

- Luo, C.J.; Jiao, T.; Gu, J.W.; Tang, Y.S.; Kong, J. Graphene shield by SiBCN ceramic: A promising high-temperature electromagnetic wave-absorbing material with oxidation resistance. ACS Appl. Mater. Interfaces 2018, 10, 39307–39318. [Google Scholar] [CrossRef]

- Liu, J.; Cao, M.S.; Luo, Q.; Shi, H.L.; Wang, W.Z.; Yuan, J. Electromagnetic property and tunable microwave absorption of 3D nets from nickel chains at elevated temperature. ACS Appl. Mater. Interfaces 2016, 8, 22615–22622. [Google Scholar] [CrossRef] [PubMed]

- Watts, C.M.; Liu, X.; Padilla, W.J. Metamaterial electromagnetic wave absorbers. Adv. Mater. 2012, 24, OP98–OP120. [Google Scholar] [CrossRef]

- Cao, M.S.; Cai, Y.Z.; He, P.; Shu, J.C.; Cao, W.Q.; Yuan, J. 2D MXenes: Electromagnetic property for microwave absorption and electromagnetic interference shielding. Chem. Eng. J. 2019, 359, 1265–1302. [Google Scholar] [CrossRef]

| Sample Code | Type | Thickness | Stacking Order (High to Low) |

|---|---|---|---|

| #1-2 | Double-layer | 10 mm | 1, 2 |

| #1-3 | 10 mm | 1, 3 | |

| #1-4 | 10 mm | 1, 4 | |

| #2-3 | 10 mm | 2, 3 | |

| #2-4 | 10 mm | 2, 4 | |

| #3-4 | 10 mm | 3, 4 | |

| #1-2-3 | Three-layer | 15 mm | 1, 2, 3 |

| #1-2-4 | 15 mm | 1, 2, 4 | |

| #1-3-4 | 15 mm | 1, 3, 4 | |

| #2-3-4 | 15 mm | 2, 3, 4 | |

| #1-2-3-4 | Four-layer | 20 mm | 1, 2, 3, 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, S.; Song, Y.; Hou, G.; Li, H.; Yang, N.; Liu, Z. Design and Preparation of Flexible Graphene/Nonwoven Composites with Simultaneous Broadband Absorption and Stable Properties. Nanomaterials 2023, 13, 634. https://doi.org/10.3390/nano13040634

Bi S, Song Y, Hou G, Li H, Yang N, Liu Z. Design and Preparation of Flexible Graphene/Nonwoven Composites with Simultaneous Broadband Absorption and Stable Properties. Nanomaterials. 2023; 13(4):634. https://doi.org/10.3390/nano13040634

Chicago/Turabian StyleBi, Song, Yongzhi Song, Genliang Hou, Hao Li, Nengjun Yang, and Zhaohui Liu. 2023. "Design and Preparation of Flexible Graphene/Nonwoven Composites with Simultaneous Broadband Absorption and Stable Properties" Nanomaterials 13, no. 4: 634. https://doi.org/10.3390/nano13040634