Effects of the Nanofillers on Physical Properties of Acrylonitrile-Butadiene-Styrene Nanocomposites: Comparison of Graphene Nanoplatelets and Multiwall Carbon Nanotubes

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Materials Processing and Sample Preparations

2.3. Testing Techniques

2.3.1. Transmission Electron Microscopy (TEM)

2.3.2. Scanning Electron Microscopy (SEM)

2.3.3. Melt Flow Index

2.3.4. Quasi-Static Tensile Test

2.3.5. Creep Test

2.3.6. Electrical Resistivity and Resistive Heating

3. Results and Discussions

3.1. Morphology

3.2. Melt Flow Index

3.3. Quasi-Static Tensile Test

3.4. Creep Stability

3.5. Electrical Behaviour

3.5.1. Electrical Resistivity

3.5.2. Surface Temperature under Applied Voltage

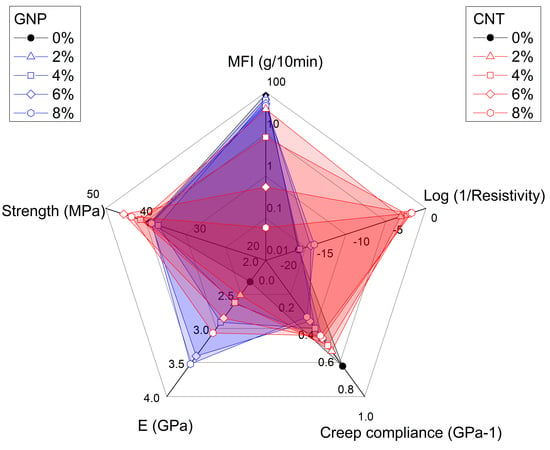

3.6. Comparative Effects of GNP and CNT

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Moniruzzaman, M.; Winey, K.I. Polymer nanocomposites containing carbon nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Li, B.; Zhong, W.H. Review on polymer/graphite nanoplatelet nanocomposites. J. Mater. Sci. 2011, 46, 5595–5614. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.-J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Cui, Y.; Kundalwal, S.I.; Kumar, S. Gas barrier performance of graphene/polymer nanocomposites. Carbon 2016, 98, 313–333. [Google Scholar] [CrossRef] [Green Version]

- Dorigato, A.; Moretti, V.; Dul, S.; Unterberger, S.H.; Pegoretti, A. Electrically conductive nanocomposites for fused deposition modelling. Synth. Met. 2017, 226, 7–14. [Google Scholar] [CrossRef] [Green Version]

- Dul, S.; Fambri, L.; Merlini, C.; Barra, G.M.O.; Bersani, M.; Vanzetti, L.; Pegoretti, A. Effect of graphene nanoplatelets structure on the properties of acrylonitrile–butadiene–styrene composites. Polym. Compos. 2017. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Filaments production and fused deposition modelling of abs/carbon nanotubes composites. Nanomaterials 2018, 8, 49. [Google Scholar]

- Schmitz, D.P.; Ecco, L.G.; Dul, S.; Pereira, E.C.L.; Soares, B.G.; Barra, G.M.O.; Pegoretti, A. Electromagnetic interference shielding effectiveness of ABS carbon-based composites manufactured via fused deposition modelling. Mater. Today Commun. 2018, 15, 70–80. [Google Scholar] [CrossRef] [Green Version]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef] [Green Version]

- Pandey, G.; Thostenson, E.T. Carbon nanotube-based multifunctional polymer nanocomposites. Polym. Rev. 2012, 52, 355–416. [Google Scholar] [CrossRef]

- Dermanaki Farahani, R.; Dubé, M. Printing polymer nanocomposites and composites in three dimensions. Adv. Eng. Mater. 2017, 20, 1700539. [Google Scholar] [CrossRef]

- Bianco, A.; Cheng, H.-M.; Enoki, T.; Gogotsi, Y.; Hurt, R.H.; Koratkar, N.; Kyotani, T.; Monthioux, M.; Park, C.R.; Tascon, J.M.D.; et al. All in the graphene family—A recommended nomenclature for two-dimensional carbon materials. Carbon 2013, 65, 1–6. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Abdul Kudus, M.H.; Md. Akil, H.; Mohd Thirmizir, M.Z. Comparative study of graphene nanoparticle and multiwall carbon nanotube filled epoxy nanocomposites based on mechanical, thermal and dielectric properties. Compos. Part B Eng. 2017, 119, 57–66. [Google Scholar] [CrossRef]

- Yang, S.-Y.; Lin, W.-N.; Huang, Y.-L.; Tien, H.-W.; Wang, J.-Y.; Ma, C.-C.M.; Li, S.-M.; Wang, Y.-S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Kostagiannakopoulou, C.; Tsilimigkra, X.; Sotiriadis, G.; Kostopoulos, V. Synergy effect of carbon nano-fillers on the fracture toughness of structural composites. Compos. Part B Eng. 2017, 129, 18–25. [Google Scholar] [CrossRef]

- Wang, P.-N.; Hsieh, T.-H.; Chiang, C.-L.; Shen, M.-Y. Synergetic effects of mechanical properties on graphene nanoplatelet and multiwalled carbon nanotube hybrids reinforced epoxy/carbon fiber composites. J. Nanomater. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Li, J.; Wong, P.-S.; Kim, J.-K. Hybrid nanocomposites containing carbon nanotubes and graphite nanoplatelets. Mater. Sci. Eng. A 2008, 483–484, 660–663. [Google Scholar] [CrossRef]

- Chatterjee, S.; Nüesch, F.A.; Chu, B.T.T. Comparing carbon nanotubes and graphene nanoplatelets as reinforcements in polyamide 12 composites. Nanotechnology 2011, 22, 275714. [Google Scholar] [CrossRef] [PubMed]

- Kuester, S.; Demarquette, N.R.; Ferreira, J.C.; Soares, B.G.; Barra, G.M.O. Hybrid nanocomposites of thermoplastic elastomer and carbon nanoadditives for electromagnetic shielding. Eur. Polym. J. 2017, 88, 328–339. [Google Scholar] [CrossRef]

- Waheed, Q.; Khan, A.N.; Jan, R. Investigating the reinforcement effect of few layer graphene and multi-walled carbon nanotubes in acrylonitrile-butadiene-styrene. Polymer 2016, 97, 496–503. [Google Scholar] [CrossRef]

- Crawford, R. Plastics Engineering, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 1998. [Google Scholar]

- Campo, E.A. Industrial polymers. In Industrial Polymers; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2007; pp. I–XIII. [Google Scholar]

- Blyler, L.L. The influence of additives on the flow behavior of abs. Polym. Eng. Sci. 1974, 14, 806–809. [Google Scholar] [CrossRef]

- Dul, S.; Mahmood, H.; Fambri, L.; Pegoretti, A. Graphene-ABS nanocomposites for fused deposition modelling. In Proceedings of the 17th European Conference on Composite Materials (ECCM 2017), Munich, Germany, 26–30 June 2016. [Google Scholar]

- Dul, S.; Fambri, L.; Pegoretti, A. Fused deposition modelling with ABS–graphene nanocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 85, 181–191. [Google Scholar] [CrossRef]

- Versalis, s.P. A Sinkral® f 322—ABS Product Data. Available online: https://www.Materialdatacenter.Com/ms/en/sinkral/versalis+s%252ep%252ea/sinkral%c2%ae+f+332/c6da6726/1895 (accessed on 5 July 2018).

- Xg Sciences (2017) xgnp® Graphene Nanoplatelets Grade m Product Data. Available online: https://xgsciences.Com/materials/graphene-nano-platelets (accessed on 5 July 2018).

- Nanocyl®nc7000tm (2016) Multiwall Carbon Nanotubes Product Data. Available online: http://www.Nanocyl.Com/wp-content/uploads/2016/07/dm-ti-02-tds-nc7000-v08.Pdfxg (accessed on 5 July 2018).

- Fambri, L.; Bragagna, S.; Migliaresi, C. Biodegradable fibers of poly-l, dl-lactide 70/30 produced by melt spinning. Macromol. Symp. 2006, 234, 20–25. [Google Scholar] [CrossRef]

- MacDermott, C.P.; Shenoy, A.V. Selecting Thermoplastics for Engineering Applications; Marcel Dekker: New York, NY, USA, 1997. [Google Scholar]

- Pandey, A.K.; Kumar, R.; Kachhavah, V.S.; Kar, K.K. Mechanical and thermal behaviours of graphite flake-reinforced acrylonitrile-butadiene-styrene composites and their correlation with entanglement density, adhesion, reinforcement and c factor. RSC Adv. 2016, 6, 50559–50571. [Google Scholar] [CrossRef]

- Liang, J.; Huang, Y.; Zhang, L.; Wang, Y.; Ma, Y.; Guo, T.; Chen, Y. Molecular-level dispersion of graphene into poly(vinyl alcohol) and effective reinforcement of their nanocomposites. Adv. Funct. Mater. 2009, 19, 2297–2302. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. The halpin-tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar]

- Kalaitzidou, K.; Fukushima, H.; Miyagawa, H.; Drzal, L.T. Flexural and tensile moduli of polypropylene nanocomposites and comparison of experimental data to halpin-tsai and tandon-weng models. Polym. Eng. Sci. 2007, 47, 1796–1803. [Google Scholar] [CrossRef]

- Duguay, A.; Nader, J.; Kiziltas, A.; Gardner, D.; Dagher, H. Exfoliated graphite nanoplatelet-filled impact modified polypropylene nanocomposites: Influence of particle diameter, filler loading, and coupling agent on the mechanical properties. Appl. Nanosci. 2014, 4, 279–291. [Google Scholar] [CrossRef]

- King, J.A.; Klimek, D.R.; Miskioglu, I.; Odegard, G.M. Mechanical properties of graphene nanoplatelet/epoxy composites. J. Compos. Mater. 2015, 49, 659–668. [Google Scholar] [CrossRef]

- Halpin, J.C.; Tsai, T.W. Effects of environmental factors on composite materials. Air Force Mater. Lab. Tech. Rep. 1969, AFML-TR-67, 423. [Google Scholar]

- Halpin, J.C. Stiffness and expansion estimates for oriented short fiber composites. J. Compos. Mater. 1969, 3, 732–734. [Google Scholar] [CrossRef]

- Van Es, M.A. Polymer-Clay Nanocomposites: The Importance of Particle Dimensions. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2001. [Google Scholar]

- Chong, H.M.; Hinder, S.J.; Taylor, A.C. Graphene nanoplatelet-modified epoxy: Effect of aspect ratio and surface functionality on mechanical properties and toughening mechanisms. J. Mater. Sci. 2016, 51, 8764–8790. [Google Scholar] [CrossRef]

- Fornes, T.D.; Paul, D.R. Modeling properties of nylon 6/clay nanocomposites using composite theories. Polymer 2003, 44, 4993–5013. [Google Scholar] [CrossRef]

- Karevan, M.; Pucha, R.V.; Bhuiyan, M.A.; Kalaitzidou, K. Effect of interphase modulus and nanofiller agglomeration on the tensile modulus of graphite nanoplatelets and carbon nanotube reinforced polypropylene nanocomposites. Carbon Lett. 2010, 11, 325–331. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Pegoretti, A. Hybridization of short glass fiber polypropylene composites with nanosilica and graphite nanoplatelets. J. Reinf. Plast. Compos. 2014, 33, 1682–1695. [Google Scholar] [CrossRef]

- Pegoretti, A. Creep and fatigue behavior of polymer nanocomposites. In Nano- and Micro-mechanics of Polymer Blends and Composites; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2009; pp. 301–339. [Google Scholar]

- Findley, W.N. 26-Year creep and recovery of poly(vinyl chloride) and polyethylene. Polym. Eng. Sci. 1987, 27, 582–585. [Google Scholar] [CrossRef]

- Williams, G.; Watts, D.C. Non-symmetrical dielectric relaxation behaviour arising from a simple empirical decay function. Trans. Faraday Soc. 1970, 66, 80–85. [Google Scholar] [CrossRef]

- Li, W.; Dichiara, A.; Bai, J. Carbon nanotube–graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos. Sci. Technol. 2013, 74, 221–227. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef] [Green Version]

- Al-Saleh, M.H.; Al-Anid, H.K.; Hussain, Y.A. CNT/ABS nanocomposites by solution processing: Proper dispersion and selective localization for low percolation threshold. Compos. Part A Appl. Sci. Manuf. 2013, 46, 53–59. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. A simple model for electrical conductivity of polymer carbon nanotubes nanocomposites assuming the filler properties, interphase dimension, network level, interfacial tension and tunneling distance. Compos. Sci. Technol. 2018, 155, 252–260. [Google Scholar] [CrossRef]

| Samples | MFI (g/10 min) | Log(C0) | Eact1 (kJ/mol) | ||

|---|---|---|---|---|---|

| 220 °C | 250 °C | 280 °C | |||

| ABS | 23.6 ± 1.3 | 89.7 ± 2.5 | 232 ± 19 | 10.6 ± 0.6 | 86.6 ± 5.5 |

| GNP-2 | 18.9 ± 1.0 | 72.5 ± 1.8 | 203 ± 6 | 10.8 ± 0.3 | 89.9 ± 3.9 |

| GNP-4 | 14.7 ± 1.0 | 63.9 ± 0.7 | 172 ± 5 | 11.0 ± 0.7 | 93.1 ± 7.3 |

| GNP-6 | 13.7 ± 0.7 | 52.7 ± 4.3 | 163 ± 4 | 11.1 ± 0.2 | 93.7 ± 1.6 |

| GNP-8 | 10.7 ± 0.5 | 47.1 ± 1.0 | 149 ± 14 | 11.6 ± 0.4 | 99.6 ± 3.9 |

| GNP-12 | 8.3 ± 0.2 | nt 2 | nt 2 | nt 2 | nt 2 |

| GNP-16 | 6.3 ± 0.2 | nt 2 | nt 2 | nt 2 | nt 3 |

| GNP-20 | 5.2 ± 0.4 | nt 2 | nt 2 | nt 2 | nt 3 |

| GNP-30 | 1.9 ± 0.1 | nt 2 | nt 2 | nt 2 | nt 2 |

| CNT-2 | 9.5 ± 0.6 | 39.3 ± 3.2 | 107 ± 12 | 10.7 ± 0.6 | 91.7 ± 6.3 |

| CNT-4 | 1.4 ± 0.1 | 8.4 ± 1.3 | 23.3 ± 5.8 | 11.6 ± 1.4 | 107.6 ± 13.6 |

| CNT-6 | 0.08 ± 0.01 | 0.55 ± 0.04 | 1.87 ± 0.19 | 11.4 ± 1.0 | 117.2 ± 10.3 |

| CNT-8 | 0.03 ± 0.01 | 0.06 ± 0.01 | 0.28 ± 0.02 | 11.4 | 126.8 3 |

| Samples | E (MPa) | σy (MPa) | σb (MPa) | εb (%) | TEB(MJ·mm−3) | Enorm1 |

|---|---|---|---|---|---|---|

| ABS | 2315 ± 100 | 41.7 ± 0.4 | 33.6 ± 0.4 | 35.9 ± 6.1 | 11.785 ± 2.007 | nd 2 |

| GNP-2 | 2631 ± 133 | 41.5 ± 1.2 | 39.9 ± 2.3 | 4.1 ± 0.2 | 1.057 ± 0.078 | 6.8 |

| GNP-4 | 2911 ± 109 | 40.2 ± 1.5 | 39.3 ± 1.2 | 3.7 ± 0.2 | 0.929 ± 0.096 | 6.4 |

| GNP-6 | 3406 ± 86 | - | 41.5 ± 0.8 | 3.1 ± 0.1 | 0.788 ± 0.086 | 7.9 |

| GNP-8 | 3523 ± 209 | - | 41.4 ± 1.0 | 3.1 ± 0.3 | 0.780 ± 0.132 | 6.5 |

| GNP-12 | 4450 ± 224 | - | 42.4 ± 1.7 | 2.5 ± 0.3 | 0.645 ± 0.115 | 7.7 |

| GNP-16 | 5072 ± 270 | - | 41.6 ± 1.1 | 2.0 ± 0.1 | 0.491 ± 0.032 | 7.4 |

| GNP-20 | 5725 ± 308 | - | 42.9 ± 1.6 | 1.9 ± 0.1 | 0.468 ± 0.041 | 7.4 |

| GNP-30 | 7362 ± 569 | - | 44.3 ± 1.9 | 1.3 ± 0.1 | 0.340 ± 0.034 | 7.3 |

| CNT-2 | 2513 ± 101 | 43.3 ± 0.4 | 34.1 ± 1.5 | 7.5 ± 2.4 | 2.313 ± 0.832 | 4.3 |

| CNT-4 | 2622 ± 29 | 43.5 ± 1.0 | 40.3 ± 1.8 | 4.5 ± 0.6 | 1.253 ± 0.263 | 3.3 |

| CNT-6 | 2849 ± 70 | - | 46.6 ± 0.5 | 3.9 ± 0.2 | 1.112 ± 0.110 | 3.8 |

| CNT-8 | 3068 ±156 | - | 45.1 ± 2.3 | 3.2 ± 0.3 | 0.805 ± 0.117 | 4.1 |

| Samples | Del (GPa−1) | Dve,3600s (GPa−1) | Dtot,3600s (GPa−1) | De (GPa−1) | k (GPa−1 s−n) | n | R2 |

|---|---|---|---|---|---|---|---|

| ABS | 0.572 | 0.205 | 0.777 | 0.553 | 0.0164 | 0.324 | 0.998 |

| GNP-2 | 0.451 | 0.122 | 0.573 | 0.448 | 0.0030 | 0.464 | 0.987 |

| GNP-4 | 0.415 | 0.084 | 0.499 | 0.414 | 0.0018 | 0.487 | 0.982 |

| GNP-6 | 0.382 | 0.065 | 0.447 | 0.377 | 0.0077 | 0.277 | 0.991 |

| GNP-8 | 0.328 | 0.088 | 0.416 | 0.329 | 0.0011 | 0.536 | 0.997 |

| GNP-12 | 0.214 | 0.077 | 0.290 | 0.230 | 0.0009 | 0.517 | 0.991 |

| GNP-30 | 0.138 | 0.039 | 0.177 | 0.139 | 0.0002 | 0.656 | 0.983 |

| CNT-2 | 0.515 | 0.205 | 0.777 | 0.502 | 0.0084 | 0.373 | 0.992 |

| CNT-4 | 0.478 | 0.152 | 0.667 | 0.466 | 0.0101 | 0.346 | 0.994 |

| CNT-6 | 0.436 | 0.149 | 0.627 | 0.435 | 0.0033 | 0.462 | 0.995 |

| CNT-8 | 0.413 | 0.135 | 0.572 | 0.408 | 0.0038 | 0.455 | 0.991 |

| Samples | Del (GPa−1) | Dve,3600s (GPa−1) | Dtot,3600s (GPa−1) | De (GPa−1) | k (GPa−1 s−n) | n | R2 |

|---|---|---|---|---|---|---|---|

| T= 50 °C | |||||||

| ABS | 0.604 | 0.380 | 0.984 | 0.5545 | 0.0164 | 0.3538 | 0.982 |

| GNP-6 | 0.494 | 0.349 | 0.843 | 0.4519 | 0.0232 | 0.3553 | 0.984 |

| CNT-6 | 0.521 | 0.334 | 0.855 | 0.4711 | 0.0268 | 0.3367 | 0.979 |

| T= 70 °C | |||||||

| ABS | 0.617 | 0.957 | 1.574 | 0.5416 | 0.0342 | 0.4243 | 0.990 |

| GNP-6 | 0.442 | 0.836 | 1.278 | 0.3436 | 0.0522 | 0.3620 | 0.986 |

| CNT-6 | 0.534 | 0.997 | 1.532 | 0.4298 | 0.0531 | 0.3788 | 0.989 |

| T= 90 °C | |||||||

| ABS | 0.687 | 5.747 | 6.435 | 0.4931 | 0.0569 | 0.5744 | 0.994 |

| GNP-6 | 0.516 | 3.726 | 4.242 | 0.3745 | 0.0507 | 0.5363 | 0.994 |

| CNT-6 | 0.561 | 3.920 | 4.482 | 0.3149 | 0.0894 | 0.4774 | 0.990 |

| Samples | Eact (kJ/mol) |

|---|---|

| ABS | 15.1 ± 3.4 |

| GNP-6 | 22.8 ± 1.9 |

| CNT-6 | 21.2 ± 3.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dul, S.; Pegoretti, A.; Fambri, L. Effects of the Nanofillers on Physical Properties of Acrylonitrile-Butadiene-Styrene Nanocomposites: Comparison of Graphene Nanoplatelets and Multiwall Carbon Nanotubes. Nanomaterials 2018, 8, 674. https://doi.org/10.3390/nano8090674

Dul S, Pegoretti A, Fambri L. Effects of the Nanofillers on Physical Properties of Acrylonitrile-Butadiene-Styrene Nanocomposites: Comparison of Graphene Nanoplatelets and Multiwall Carbon Nanotubes. Nanomaterials. 2018; 8(9):674. https://doi.org/10.3390/nano8090674

Chicago/Turabian StyleDul, Sithiprumnea, Alessandro Pegoretti, and Luca Fambri. 2018. "Effects of the Nanofillers on Physical Properties of Acrylonitrile-Butadiene-Styrene Nanocomposites: Comparison of Graphene Nanoplatelets and Multiwall Carbon Nanotubes" Nanomaterials 8, no. 9: 674. https://doi.org/10.3390/nano8090674