Artificial Ageing of Photocatalytic Nanocomposites for the Protection of Natural Stones

Abstract

:1. Introduction

2. Materials and Methods

2.1. Stones

2.2. Protective Treatments

2.3. Ageing of Treatments

2.3.1. Solar Irradiation Ageing

2.3.2. Thermal Ageing

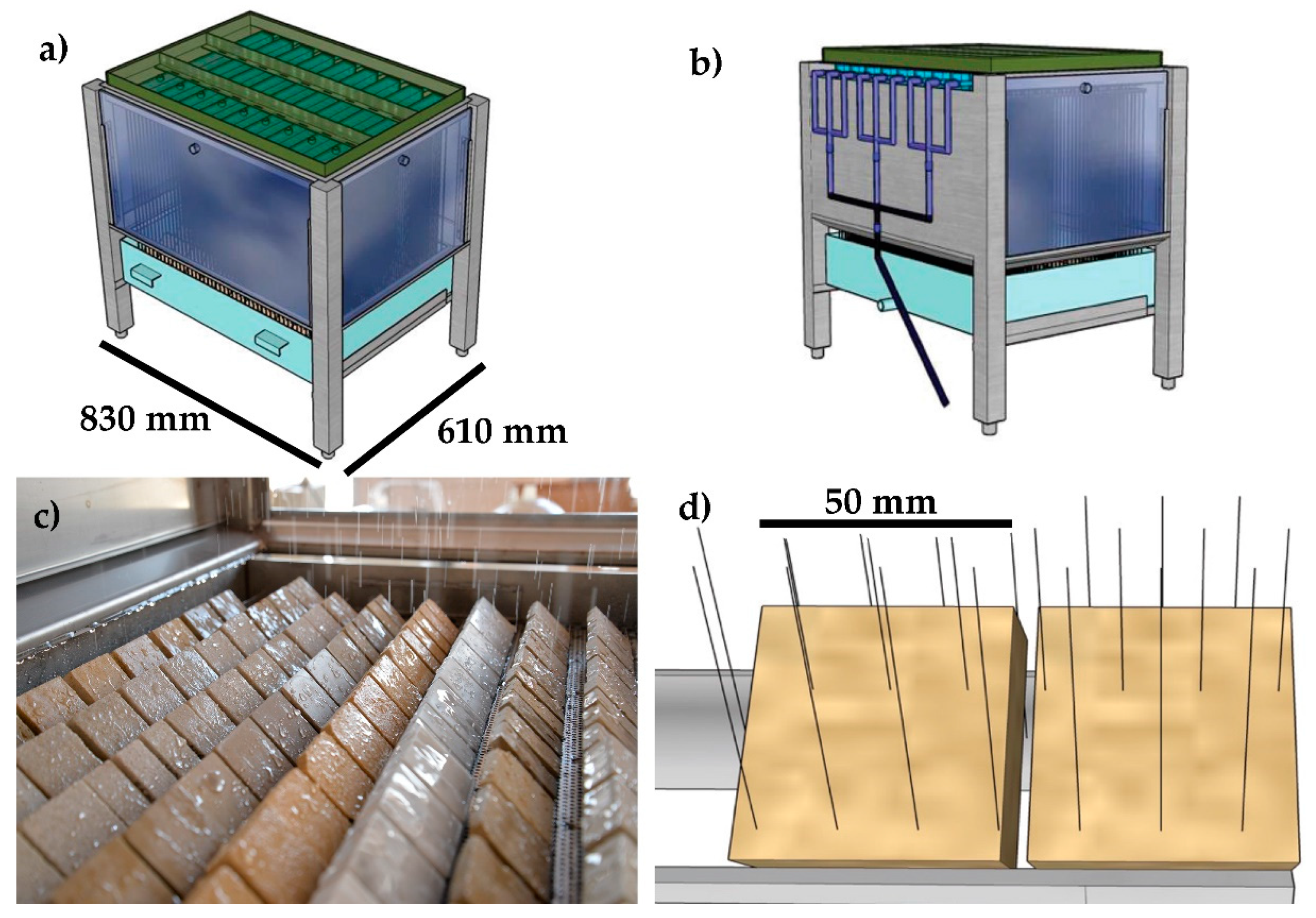

2.3.3. Rain Wash-Out Ageing

2.4. Testing of Specimens

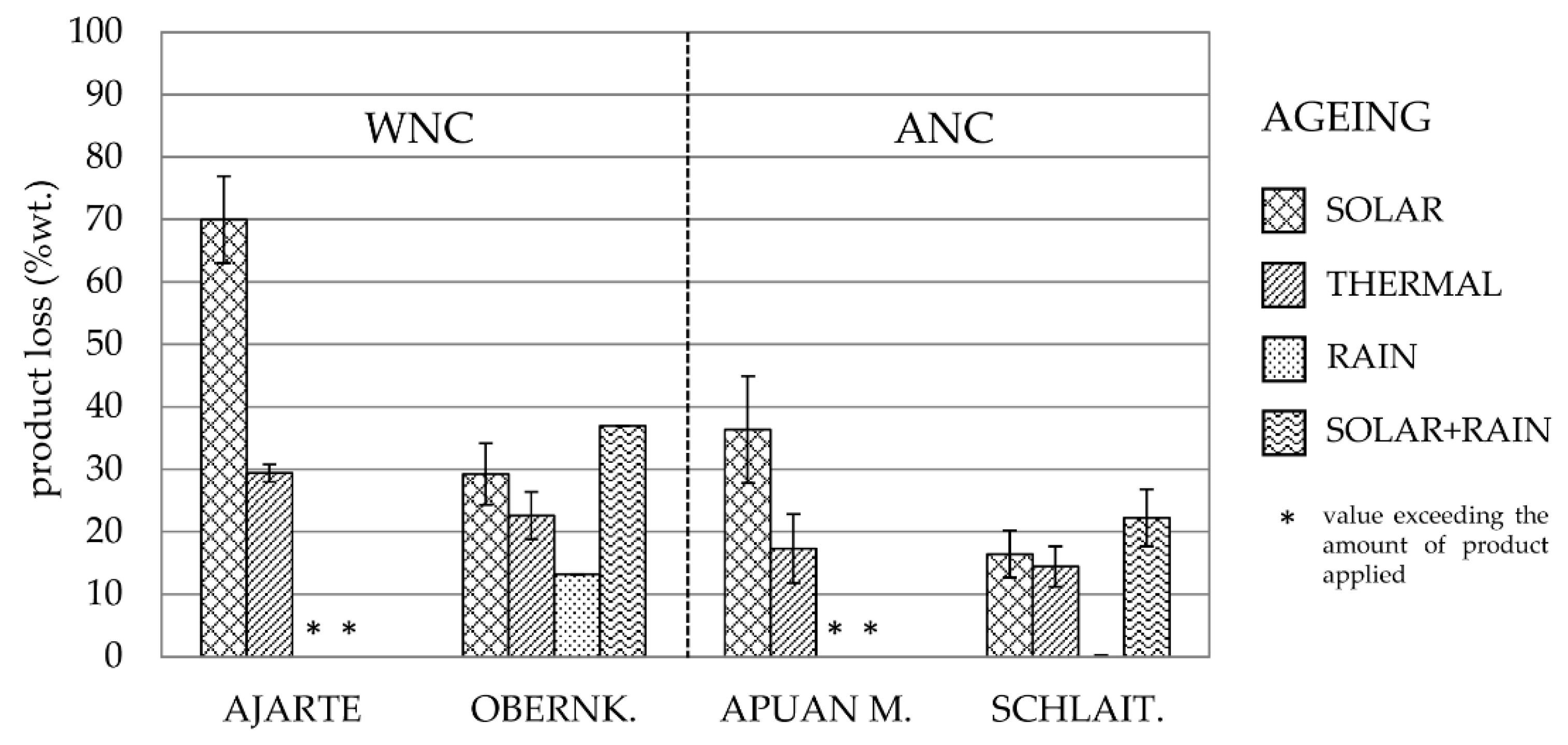

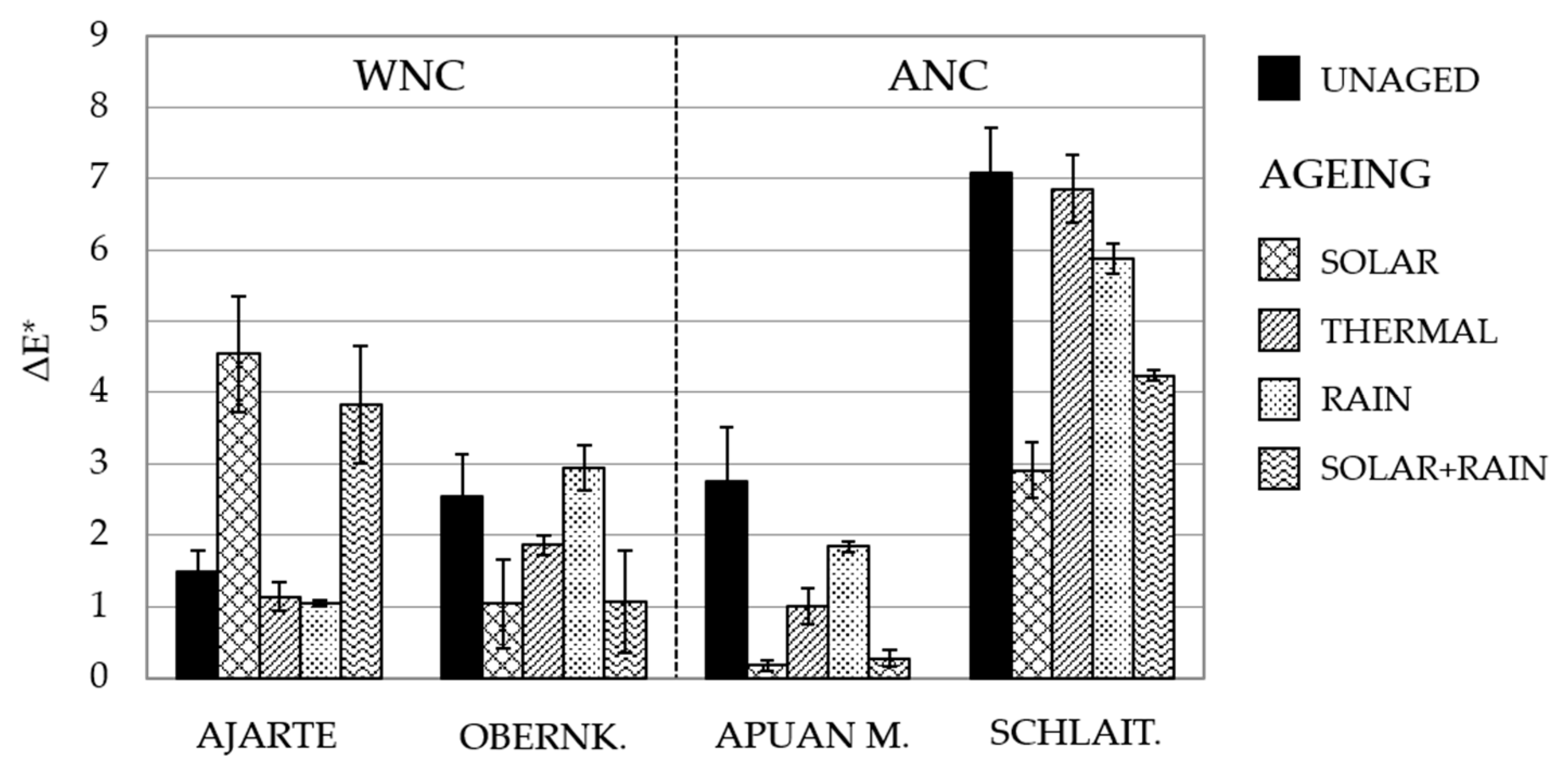

3. Results and Discussion

4. Conclusions

- The ageing procedures do not seriously compromise the protective efficacy of the treatments. Indeed, even though solar ageing expectably induces a certain photochemical degradation of the alkyl-silica matrices, this only involves the very stone surface, while the treatment that penetrated into the stone microstructure and settled on the inner pore surface retains its integrity, ensuring a rather stable protection of the pores towards water penetration. Moreover, both treatments retain a good aesthetic compatibility after ageing and do not end up compromising the stone vapour permeability.

- The alkyl-silica matrices are able to ensure a good mechanical stability of TiO2 nanoparticles on the stone surface, as it can be argued from the retention of photocatalytic activity upon rain wash-out. Furthermore, as the sequential application of solar and rain ageing seems to prove, this stability is retained even after the organic functional groups of the embedding alkyl-silica matrices have undergone photochemical degradation, which is probably due to the retention of the silica backbone molecular structure.

- The stone properties were shown to have a strong influence on the ageing behaviour of the treatments. Indeed, treatments tend to have a higher durability when applied to stones with higher porosity and higher surface roughness, because the former grants a deeper penetration and the latter contributes to protecting the treatments from the effects of photochemical degradation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Charola, A.E. Water-repellent treatments for building stones: A practical overview. APT Bull. J. Preserv. Technol. 1995, 26, 10–17. [Google Scholar] [CrossRef]

- Charola., A.E. Water repellents and other protective treatments: A critical review. In Proceedings of the Hydrophobe III—Third International Conference on Surface Technology with Water Repellent Agents, Hannover, Germany, 25–26 September 2001; Littmann, K., Charola, A.E., Eds.; Aedicatio Verlag: Freiburg, Germany, 2001; pp. 3–19. [Google Scholar]

- Manoudis, P.; Papadopoulou, S.; Karapanagiotis, I.; Tsakalof, A.; Zuburtikudis, I.; Panayiotou, C. Polymer-Silica nanoparticles composite films as protective coatings for stone-based monuments. J. Phys. IOP Conf. Ser. 2007, 61, 1361. [Google Scholar] [CrossRef]

- Manoudis, P.N.; Karapanagiotis, I. Modification of the wettability of polymer surfaces using nanoparticles. Prog. Org. Coat. 2014, 77, 331–338. [Google Scholar] [CrossRef]

- Facio, D.S.; Mosquera, M.J. Simple strategy for producing superhydrophobic coatings in situ on a building substrate. ACS Appl. Mater. Interfaces 2013, 5, 7517–7526. [Google Scholar] [CrossRef] [PubMed]

- Poulios, I.; Spathis, P.; Grigoriadou, A.; Delidou, K.; Tsoumparis, P. Protection of marbles against corrosion and microbial corrosion with TiO2 coatings. J. Environ. Sci. Health Part A 1999, 34, 1455–1471. [Google Scholar] [CrossRef]

- Quagliarini, E.; Bondioli, F.; Goffredo, G.B.; Cordoni, C.; Munafò, P. Self-cleaning and de-polluting stone surfaces: TiO2 nanoparticles for limestone. Constr. Build. Mat. 2012, 37, 51–57. [Google Scholar] [CrossRef]

- Munafò, P.; Goffredo, G.B.; Quagliarini, E. TiO2-based nanocoatings for preserving architectural stone surfaces: An overview. Constr. Build. Mat. 2015, 84, 201–218. [Google Scholar] [CrossRef]

- Hosseini, M.; Karapanagiotis, I. Advanced Materials for the Conservation of Stone, 1st ed.; Springer: New York, NY, USA, 2018. [Google Scholar]

- Kapridaki, C.; Maravelaki-Kalaitzaki, P. TiO2–SiO2–PDMS nano-composite hydrophobic coating with self-cleaning properties for marble protection. Prog. Org. Coat. 2013, 76, 400–410. [Google Scholar] [CrossRef]

- Aflori, M.; Simionescu, B.; Bordianu, I.E.; Sacarescu, L.; Varganici, C.D.; Doroftei, F.; Olaru, M. Silsesquioxane-based hybrid nanocomposites with methacrylate units containing titania and/or silver nanoparticles as antibacterial/antifungal coatings for monumental stones. Mat. Sci. Eng. B 2013, 178, 1339–1346. [Google Scholar] [CrossRef]

- Cappelletti, G.; Fermo, P.; Camiloni, M. Smart hybrid coatings for natural stones conservation. Prog. Org. Coat. 2015, 78, 511–516. [Google Scholar] [CrossRef]

- Colangiuli, D.; Calia, A.; Bianco, N. Novel multifunctional coatings with photocatalytic and hydrophobic properties for the preservation of the stone building heritage. Constr. Build. Mat. 2015, 93, 189–196. [Google Scholar] [CrossRef]

- Gherardi, F.; Goidanich, S.; Toniolo, L. Improvements in marble protection by means of innovative photocatalytic nanocomposites. Prog. Org. Coat. 2018, 121, 13–22. [Google Scholar] [CrossRef] [Green Version]

- Lazzeri, A.; Coltelli, M.B.; Castelvetro, V.; Bianchi, S.; Chiantore, O.; Lezzerini, M.; Toniolo, L. European Project “NANO-CATHEDRAL: Nanomaterials for conservation of European architectural heritage developed by research on characteristic lithotypes”. In Proceedings of the 13th International Congress on the Deterioration and Conservation of Stone, Paisley, UK, 6–10 September 2016; University of the West of Scotland: Paisley, UK, 2016; Volume 2, pp. 847–854. [Google Scholar]

- Gherardi, F.; Gulotta, D.; Goidanich, S.; Colombo, A.; Toniolo, L. On-site monitoring of the performance of innovative treatments for marble conservation in architectural heritage. Herit. Sci. 2017, 5, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Melo, M.J.; Bracci, S.; Camaiti, M.; Chiantore, O.; Piacenti, F. Photodegradation of acrylic resins used in the conservation of stone. Polym. Degrad. Stab. 1999, 66, 23–30. [Google Scholar] [CrossRef]

- Chiantore, O.; Lazzari, M. Photo-oxidative stability of paraloid acrylic protective polymers. Polymer 2001, 42, 17–27. [Google Scholar] [CrossRef]

- Poli, T.; Toniolo, L.; Sansonetti, A. Durability of protective polymers: The effect of UV and thermal ageing. Macromol. Symp. 2006, 238, 78–83. [Google Scholar] [CrossRef]

- Tesser, E.; Antonelli, F.; Sperni, L.; Ganzerla, R.; Maravelaki, N.-P. Study of the stability of siloxane stone strengthening agents. Polym. Degrad. Stab. 2014, 110, 232–240. [Google Scholar] [CrossRef]

- Favaro, M.; Mendichi, R.; Ossola, F.; Simon, S.; Tomasin, P.; Vigato, P.A. Evaluation of polymers for conservation treatments of outdoor exposed stone monuments. Part II: Photo-oxidative and salt-induced weathering of acrylic-silicone mixtures. Polym. Degrad. Stab. 2007, 92, 335–351. [Google Scholar] [CrossRef]

- Khallaf, M.K.; El-Midany, A.A.; El-Mofty, S.E. Influence of acrylic coatings on the interfacial, physical, and mechanical properties of stone-based monuments. Prog. Org. Coat. 2011, 72, 592–598. [Google Scholar] [CrossRef]

- Franzoni, E.; Fregni, A.; Gabrielli, R.; Graziani, G.; Sassoni, E. Compatibility of photocatalytic TiO2-based finishing for renders in architectural restoration: A preliminary study. Build. Environ. 2014, 80, 125–135. [Google Scholar] [CrossRef]

- Munafò, P.; Quagliarini, E.; Goffredo, G.B.; Bondioli, F.; Licciulli, A. Durability of nano-engineered TiO2 self-cleaning treatments on limestone. Constr. Build. Mat. 2014, 65, 218–231. [Google Scholar] [CrossRef]

- Aldoasri, M.A.; Darwish, S.S.; Adam, M.A.; Elmarzugi, N.A.; Ahmed, S.M. Protecting of marble stone facades of historic buildings using multifunctional TiO2 nanocoatings. Sustainability 2017, 9, 2002. [Google Scholar] [CrossRef]

- Maury-Ramirez, A.; Demeestere, K.; De Belie, N. Photocatalytic activity of titanium dioxide nanoparticle coatings applied on autoclaved aerated concrete: Effect of weathering on coating physical characteristics and gaseous toluene removal. J. Hazard. Mat. 2012, 211–212, 218–225. [Google Scholar] [CrossRef] [PubMed]

- Graziani, L.; Quagliarini, E.; Bondioli, F.; D’Orazio, M. Durability of self-cleaning TiO2 coatings on fired clay brick façades: Effects of UV exposure and wet & dry cycles. Build. Environ. 2014, 71, 193–203. [Google Scholar]

- Guo, M.-Z.; Maury-Ramirez, A.; Poon, C.S. Self-cleaning ability of titanium dioxide clear paint coated architectural mortar and its potential in field application. J. Clean. Prod. 2016, 112, 3583–3588. [Google Scholar] [CrossRef]

- Carmona-Quiroga, P.M.; Martínez-Ramírez, S.; Viles, H.A. Efficiency and durability of a self-cleaning coating on concrete and stones under both natural and artificial ageing trials. Appl. Surf. Sci. 2018, 433, 312–320. [Google Scholar] [CrossRef]

- Krishnan, P.; Zhang, M.-H.; Yu, L.; Feng, H. Photocatalytic degradation of particulate pollutants and self-cleaning performance of TiO2-containing silicate coating and mortar. Constr. Build. Mat. 2013, 44, 309–316. [Google Scholar] [CrossRef]

- Goffredo, G.B.; Terlizzi, V.; Munafò, P. Multifunctional TiO2-based hybrid coatings on limestone: Initial performances and durability over time. J. Build. Eng. 2017, 14, 134–149. [Google Scholar] [CrossRef]

- Calia, A.; Lettieri, M.; Masieri, M. Durability assessment of nanostructured TiO2 coatings applied on limestones to enhance building surface with self-cleaning ability. Build. Environ. 2016, 110, 1–10. [Google Scholar] [CrossRef]

- Quagliarini, E.; Graziani, L.; Diso, D.; Licciulli, A.; D’Orazio, M. Is nano-TiO2 alone an effective strategy for the maintenance of stones in Cultural Heritage? J. Cult. Herit. 2018, 30, 81–91. [Google Scholar] [CrossRef]

- Pinho, L.; Mosquera, M.J. Titania-silica nanocomposite photocatalysts with application in stone self-cleaning. J. Phys. Chem. C 2011, 115, 22851–22862. [Google Scholar] [CrossRef]

- Gherardi, F.; Goidanich, S.; Dal Santo, V.; Toniolo, L. Layered Nano-TiO2 Based Treatments for the Maintenance of Natural Stones in Historical Architecture. Angew. Chem. Int. Ed. 2018, 57, 7360–7363. [Google Scholar] [CrossRef] [Green Version]

- Scalarone, D.; Lazzari, M.; Chiantore, O. Acrylic protective coatings modified with titanium dioxide nanoparticles: Comparative study of stability under irradiation. Polym. Degrad. Stab. 2012, 97, 2136–2142. [Google Scholar] [CrossRef]

- Roveri, M.; Gherardi, F.; Toniolo, L. Stone/coating interaction and durability of Si-based photocatalytic nanocomposites applied to porous lithotypes. Materials 2018, 11, 2289. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gherardi, F.; Roveri, M.; Goidanich, S.; Toniolo, L. Photocatalytic Nanocomposites for the Protection of European Architectural Heritage. Materials 2018, 11, 65. [Google Scholar] [CrossRef] [Green Version]

- Roveri, M.; Goidanich, S.; Dotelli, G.; Toniolo, L. Semi-empirical models to describe the absorption of liquid water in natural stones employed in built heritage before and after the application of water repellent treatments. Constr. Build. Mat. 2020, 241, 117918. [Google Scholar] [CrossRef]

- Lezzerini, M.; Marroni, M.; Raneri, S.; Tamayo, S.; Narbona, B.; Fernández, B.; Weber, J.; Ghaffari, E.; Ban, M.; Rohatsch, A. D1.5—Mapping of Stones and Their Decay: Part I—Natural Stone Test Methods; Nano-Cathedral Project Grant Agreement No. 646178—Confidential Deliverable; Nano-Cathedral: Brussels, Belgium, 2017; pp. 8–16. [Google Scholar]

- Piccoli, B.; Orsini, S. Luce e UV, 1st ed.; Reggiani Editore: Sovico, Italy, 1998. [Google Scholar]

- Kift, R.; Webb, A.R.; Page, J.; Rimmer, J.; Janjai, S. A web-based tool for UV irradiance data: Predictions for European and Southeast Asian sites. Photochem. Photobiol. 2006, 82, 579–586. [Google Scholar] [CrossRef]

- Jacovides, C.P.; Tymvios, F.S.; Asimakopoulos, D.N.; Kaltsounides, N.A.; Theoharatos, G.A.; Tsitouri, M. Solar global UVB (280-315 nm) and UVA (315-380 nm) radiant fluxes and their relationships with broadband global radiant flux at an eastern Mediterranean site. Agricult. For. Meteorol. 2009, 149, 1188–1200. [Google Scholar] [CrossRef]

- Weatherbase. Available online: www.weatherbase.com (accessed on 26 March 2018).

- EN 15801:2009. Conservation of Cultural Property—Test Methods—Determination of Water Absorption by Capillarity; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- EN15802:2009. Conservation of Cultural Property—Test Methods—Determination of Static Contact Angle; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- EN 15803:2010. Conservation of Cultural Property—Test Methods—Determination of Water Vapour Permeability (δp); European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- EN 15886:2000. Conservation of Cultural Property—Test Methods—Colour Measurements of Surfaces; European Committee for Standardization: Brussels, Belgium, 2000. [Google Scholar]

- García, O.; Malaga, K. Definition of the procedure to determine the suitability and durability of an anti-graffiti product for application on cultural heritage porous materials. J. Cult. Herit. 2012, 13, 77–82. [Google Scholar] [CrossRef]

- De Buergo Ballester, M.A.; Gonzalez, R.F. Basic methodology for the assessment and selection of water-repellent treatments applied on carbonatic materials. Prog. Org. Coat. 2001, 43, 258–266. [Google Scholar] [CrossRef]

| Property | Ajarte | Obernkirchen | Apuan Marble | Schlaitdorf |

|---|---|---|---|---|

| Open porosity | 23.5 ± 0.4 | 24.1 ± 0.1 | 0.7 a | 16 ± 1 |

| Median pore diameter | 1.96 ± 0.04 | 11.1 ± 0.6 | 1.3 a | 8 ± 4 |

| Product | Ajarte | Obernk. | Apuan m. | Schlait. |

|---|---|---|---|---|

| WNC | 9 ± 4 | 9 ± 2 | – | – |

| ANC | – | – | 0.51 ± 0.07 | 16 ± 5 |

| Ageing | WNC | ANC | ||||||

|---|---|---|---|---|---|---|---|---|

| Ajarte | Obernk. | Apuan m. | Schlait. | |||||

| Mean | σ | Mean | σ | Mean | σ | Mean | σ | |

| Unaged | 122 | 7 | 136 | 3 | 140 | 10 | 137 | 3 |

| Solar | <10 | – | <10 | – | 58 | 5 | 110 | 0 |

| Thermal | 122 | 8 | 138 | 2 | 130 | 4 | 134 | 4 |

| Rain | 126 | 2 | 128 | 4 | 122 | 7 | 130 | 3 |

| Solar+Rain | <10 | – | <10 | – | 45 | 2 | 106 | 5 |

| Product | Stone | Ageing | δt (/10−11) | δt/δnt | ||

|---|---|---|---|---|---|---|

| Mean | σ | Mean | σ | |||

| WNC | Ajarte | Unaged | 1.65 | 0.32 | 0.68 | 0.08 |

| Solar | 1.03 | 0.11 | 0.47 | 0.02 | ||

| Thermal | 1.04 | 0.00 | 0.43 | 0.02 | ||

| Rain | 1.25 | 0.26 | 0.45 | 0.04 | ||

| Obernk. | Unaged | 1.09 | 0.09 | 0.77 | 0.21 | |

| Solar | 0.72 | 0.05 | 0.42 | 0.07 | ||

| Thermal | 0.69 | 0.02 | 0.46 | 0.00 | ||

| Rain | 0.77 | 0.03 | 0.66 | 0.01 | ||

| ANC | Apuan m. | Unaged | 0.10 | 0.03 | 0.90 | 0.08 |

| Solar | 0.12 | – | 1.00 | – | ||

| Thermal | 0.14 | – | 0.93 | – | ||

| Rain | 0.01 | 0.00 | 0.19 | 0.04 | ||

| Schlait. | Unaged | 0.88 | 0.17 | 0.99 | 0.20 | |

| Solar | 0.58 | 0.18 | 0.58 | 0.11 | ||

| Thermal | 0.64 | 0.04 | 0.69 | 0.05 | ||

| Rain | 0.57 | 0.05 | 0.73 | 0.07 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roveri, M.; Goidanich, S.; Toniolo, L. Artificial Ageing of Photocatalytic Nanocomposites for the Protection of Natural Stones. Coatings 2020, 10, 729. https://doi.org/10.3390/coatings10080729

Roveri M, Goidanich S, Toniolo L. Artificial Ageing of Photocatalytic Nanocomposites for the Protection of Natural Stones. Coatings. 2020; 10(8):729. https://doi.org/10.3390/coatings10080729

Chicago/Turabian StyleRoveri, Marco, Sara Goidanich, and Lucia Toniolo. 2020. "Artificial Ageing of Photocatalytic Nanocomposites for the Protection of Natural Stones" Coatings 10, no. 8: 729. https://doi.org/10.3390/coatings10080729