Effect of Co Contents on Microstructure and Cavitation Erosion Resistance of NiTiAlCrCoxN Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Film Deposition

2.3. Film Characterization

3. Results and Discussion

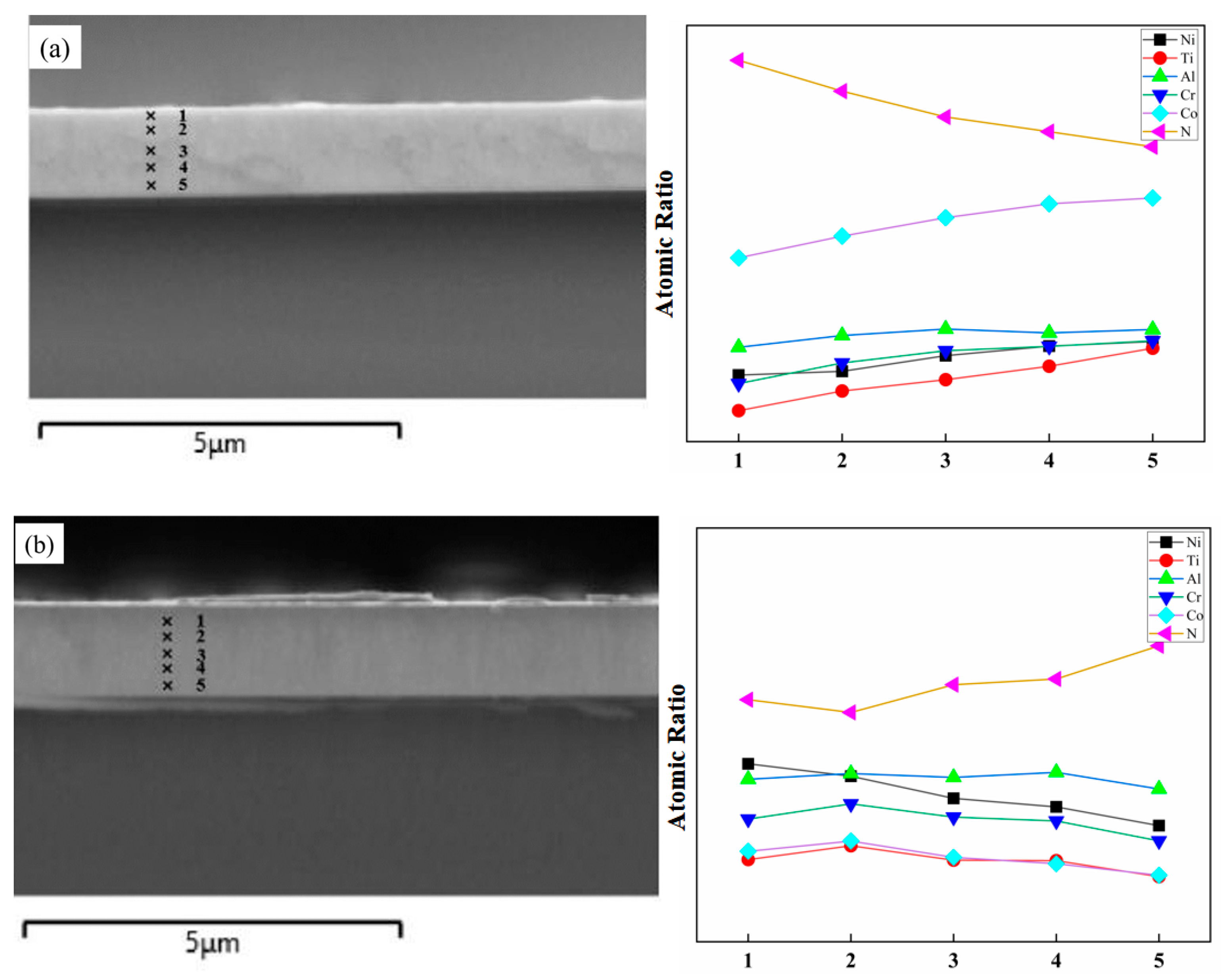

3.1. Film Structure

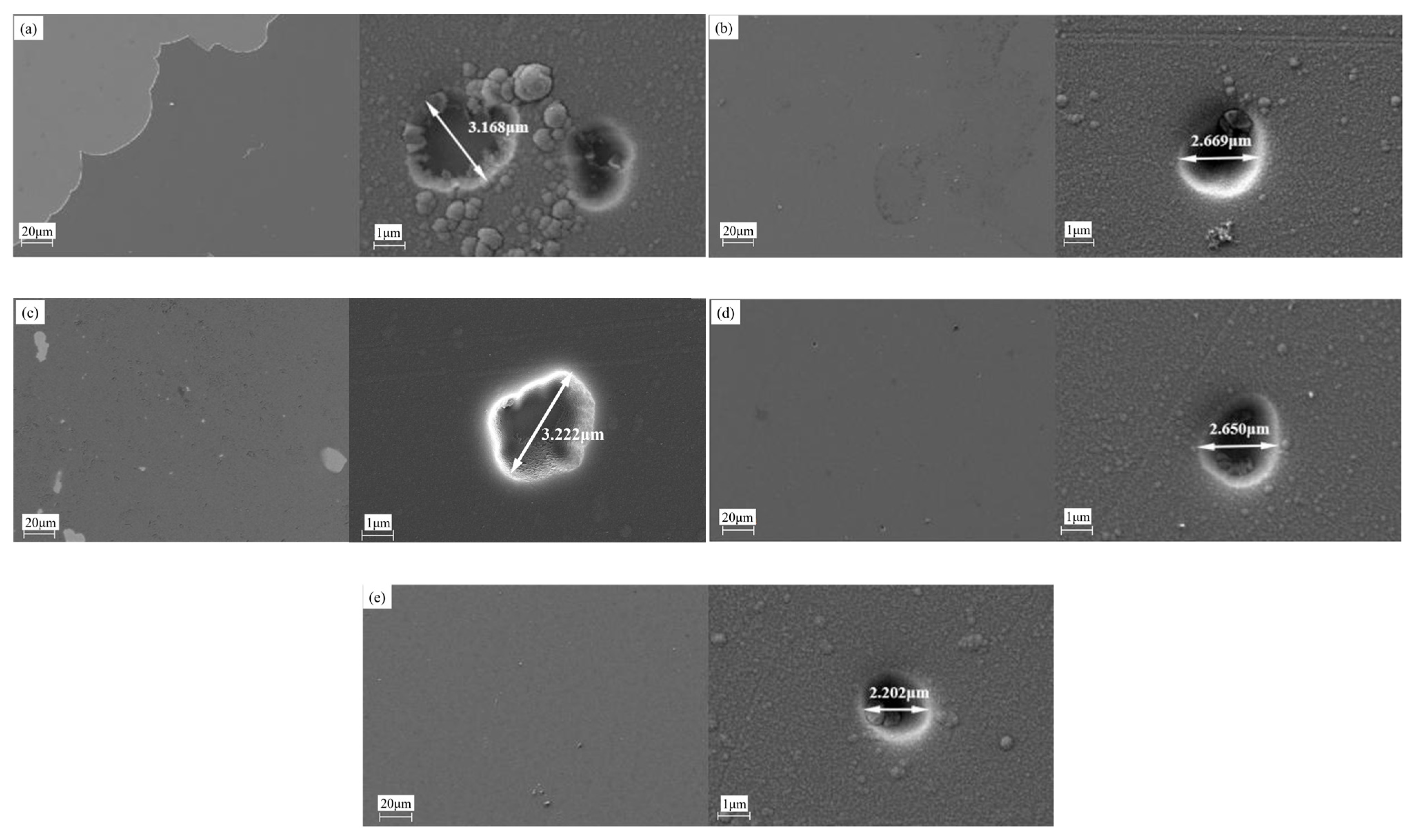

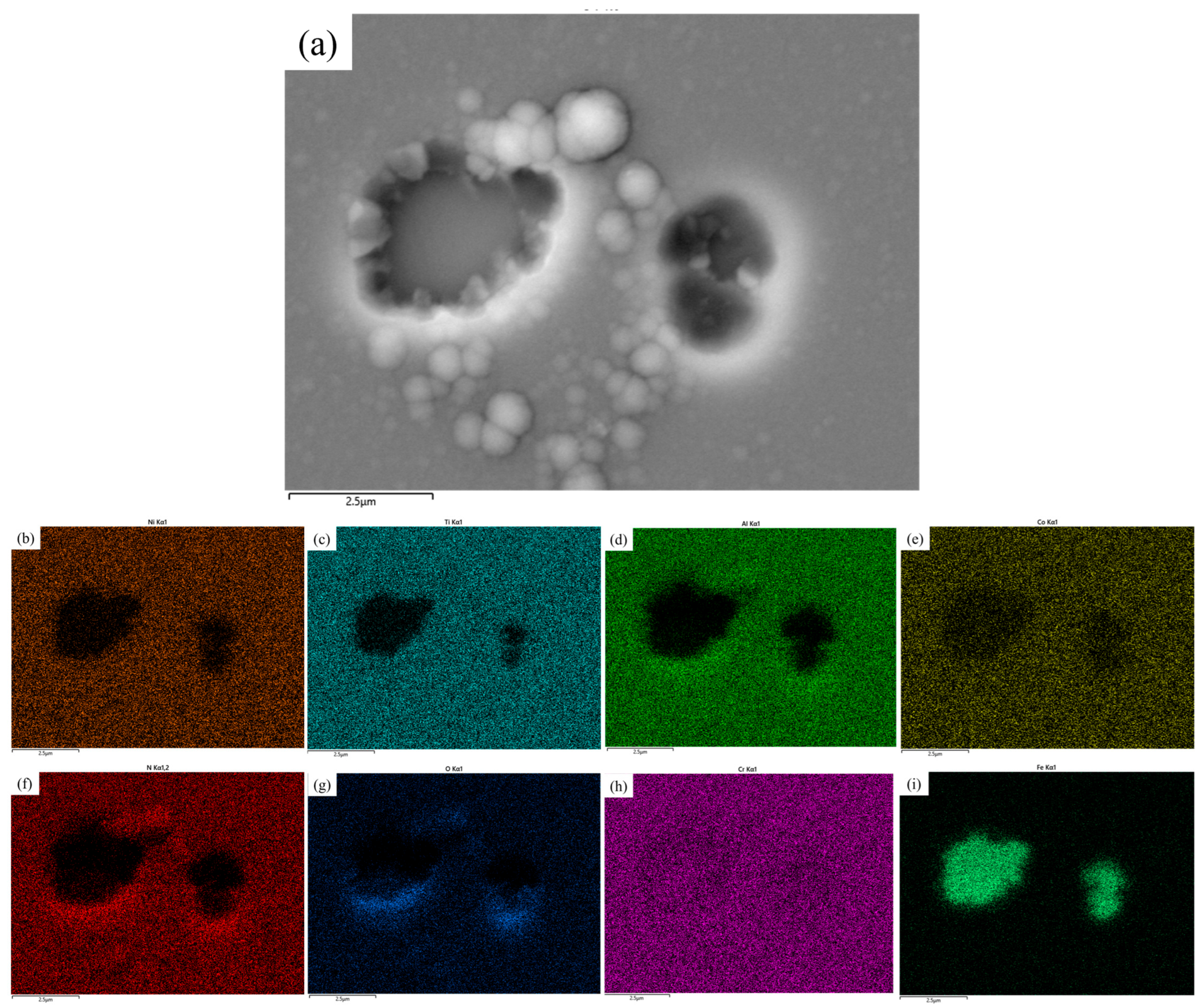

3.2. Morphology

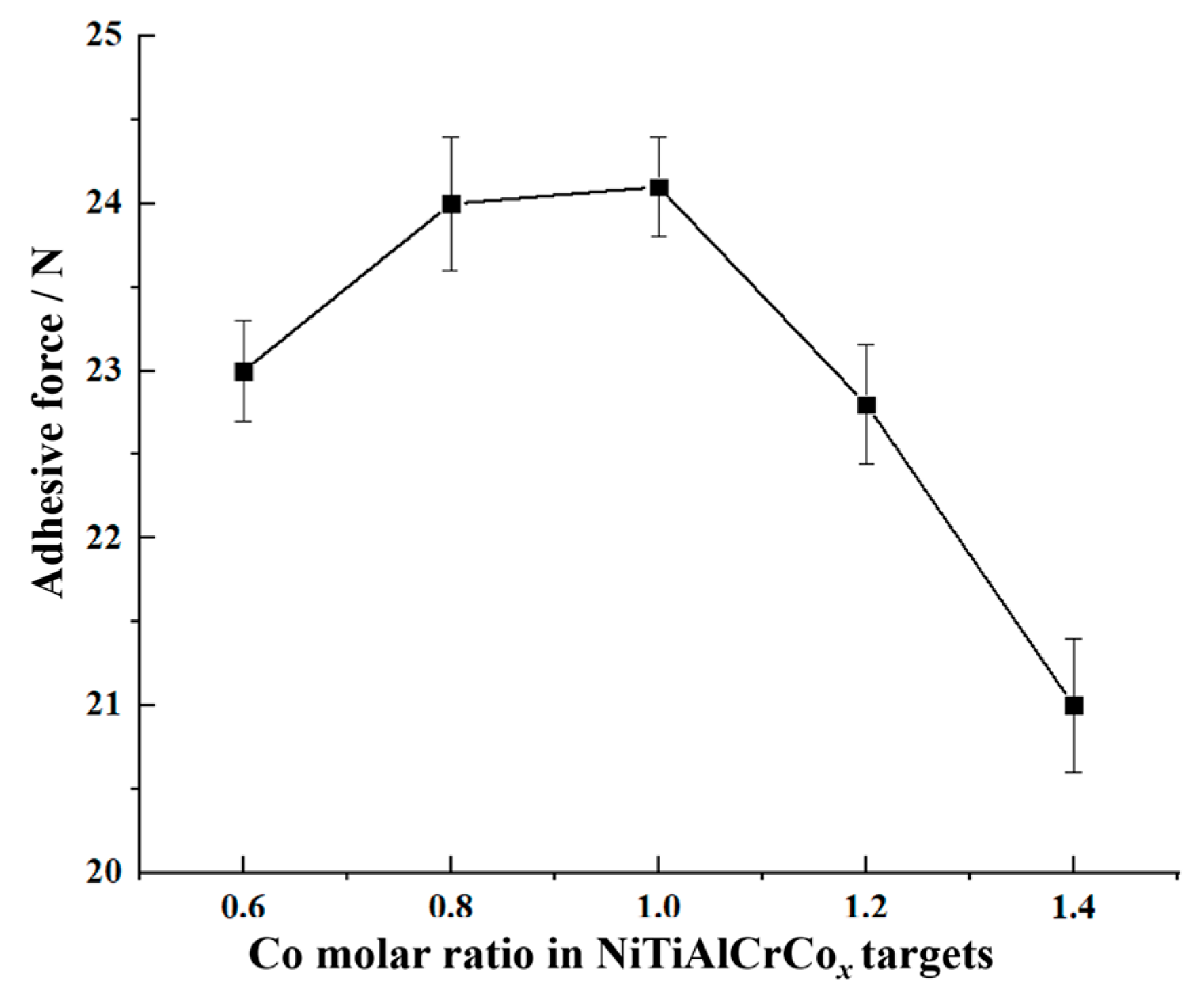

3.3. Mechanical Properties

3.4. Cavitation Erosion Resistance

4. Conclusions

- (1)

- The NiTiAlCrCoxN films with different Co contents have a simple face-centered cubic structure, and the preferred orientation appears on the (200) crystal plane. With the increase in Co contents, the interplanar spacing first increases and then decreases. The NiTiAlCrCoN film with equimolar ratios has the minimum interplanar spacing due to the lattice distortion effect and the slow diffusion effect.

- (2)

- With the increase in Co content, the nanohardness of the NiTiAlCrCoxN films decreases and the elastic modulus of the NiTiAlCrCoxN films increases, expect for the ones of the NiTiAlCrCo1.2N film. The NiTiAlCrCo1.4N film has the lowest nanohardness of 13.264 GPa, and the highest elastic modulus of 253.22 GPa.

- (3)

- The NiTiAlCrCoxN films have no peeling, cracks and plastic deformation, and there are few cavitation pits on the surface of the films, except for the NiTiAlCrCo0.6N film. The NiTiAlCrCox1.4N film exhibits the minimum mass loss of cavitation erosion. There are two reasons for the improvement in the cavitation erosion resistance. Firstly, the addition of the Co element enhances the solid solution strengthening effect. Secondly, the NiTiAlCrCox1.4N film with the biggest elastic modulus has better elasticity to reduce the micro jet impact, which improves the cavitation erosion resistance of the film.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Hao, E.; An, Y.; Chen, J.; Zhou, H. Effects of microstructure and mechanical properties on cavitation erosion resistance of NiCrWMoCuCBFe coatings. Appl. Surf. Sci. 2021, 547, 149125. [Google Scholar] [CrossRef]

- Wei, Z.; Wu, Y.; Hong, J.; Cheng, J.; Qiao, L.; Cheng, J.; Zhu, S. Ultrasonic cavitation erosion behaviors of high-velocity oxygen-fuel (HVOF) sprayed AlCoCrFeNi high-entropy alloy coating in different solutions. Surf. Coat. Technol. 2021, 409, 126899. [Google Scholar] [CrossRef]

- Guan, Y.; Cui, X.; Chen, D.; Su, W.; Zhao, Y.; Li, J.; Li, X.; Feng, L.; Jin, G. Microstructure and properties analysis of FeCoNiAlCu dual-phase high-entropy alloy coating by laser cladding. Surf. Coat. Technol. 2023, 467, 129695. [Google Scholar] [CrossRef]

- Luo, D.; Zhou, Q.; Huang, Z.; Li, Y.; Liu, Y.; Li, Q.; He, Y.; Wang, H. Tribological Behavior of High Entropy Alloy Coatings: A Review. Coatings 2022, 12, 1428. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, Y.; Zhang, M.; Mao, C.; Tong, Y.; Zhang, J.; Li, K.; Wang, K. On the enhanced wear resistance of laser-clad CoCrCuFeNiTixhigh-entropy alloy coatings at elevated temperature. Tribol. Int. 2022, 174, 107767. [Google Scholar] [CrossRef]

- Xu, J.; Peng, S.; Li, Z.; Jiang, S.; Xie, Z.H.; Munroe, P.; Lu, H. Remarkable cavitation erosion–corrosion resistance of CoCrFeNiTiMo high-entropy alloy coatings. Corros. Sci. 2021, 190, 109663. [Google Scholar] [CrossRef]

- Rong, Z.; Wang, C.; Wang, Y.; Dong, M.; You, Y.; Wang, J.; Liu, H.; Liu, J.; Wang, Y.; Zhu, Z. Microstructure and properties of FeCoNiCrx (x = Mn, Al) high-entropy alloy coatings. J. Alloy. Compd. 2022, 921, 166061. [Google Scholar] [CrossRef]

- Liu, Y.; Xiang, D.; Wang, K.; Yu, T. Corrosion of Laser Cladding High-Entropy Alloy Coatings: A Review. Coatings 2022, 12, 1669. [Google Scholar] [CrossRef]

- Wu, X.; Lv, Y. Study on the Corrosion Resistance of Laser Clad Al0.7FeCoCrNiCux High-Entropy Alloy Coating in Marine Environment. Coatings 2022, 12, 1855. [Google Scholar] [CrossRef]

- Lan, L.W.; Wang, X.J.; Guo, R.P.; Yang, H.J.; Qiao, J.W. Effect of environments and normal loads on tribological properties of nitrided Ni45(FeCoCr)40(AlTi)15 high-entropy alloys. J. Mate. Sci. Technol. 2020, 42, 85–96. [Google Scholar] [CrossRef]

- Straumal, B.; Rabkin, E.; Lopez, G.A.; Korneva, A.; Kuzmin, A.; Gornakova, A.; Straumal, A.; Baretzky, B. Grain boundary wetting phenomena in high entropy alloys containing nitrides, carbides, borides, silicides, and hydrogen: A review. Crystals 2021, 11, 1540. [Google Scholar] [CrossRef]

- Pogrebnjaka, A.D.; Yakushchenkoa, I.V.; Abadiasb, G.; Chartier, P.; Bondar, O.V.; Beresnev, V.M.; Takeda, Y.; Sobol’, O.V.; Oyoshi, K.; Andreyev, A.A.; et al. The effect of the deposition parameters of nitrides of high entropy alloys (TiZrHfVNb)N on their structure, composition, mechanical and tribological properties. J. Super. Mater. 2013, 35, 356–368. [Google Scholar] [CrossRef]

- Lu, K.; Zhu, J.; Ge, W.; Hui, X. Progress on New Preparation Methods, Microstructures, and Protective Properties of High-Entropy Alloy Coatings. Coatings 2022, 12, 1472. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, S.; Dong, C. Research process and challenge of high entropy ceramic metarials. J. Mater. Eng. 2024, 52, 83–100. [Google Scholar]

- Thorhallsson, A.I.; Fanicchia, F.; Davison, E.; Paul, S.; Davidsdottir, S.; Olafsson, D.I. Erosion and Corrosion Resistance Performance of Laser Metal Deposited High-Entropy Alloy Coatings at Hellisheidi Geothermal Site. Materials 2021, 14, 3071. [Google Scholar] [CrossRef]

- Bao, Y.; Guo, L.; Zhong, C.; Song, Q.; Yang, K.; Jiang, Y.; Wang, Z. Effects of WC on the cavitation erosion resistance of FeCoCrNiB0.2 high entropy alloy coating prepared by laser cladding. Mater. Today Commun. 2021, 26, 102154. [Google Scholar] [CrossRef]

- Wu, C.L.; Zhang, S.; Zhang, C.H.; Zhang, H.; Dong, S.Y. Phase evolution and cavitation erosion-corrosion behavior of FeCoCrAlNiTix high entropy alloy coatings on 304 stainless steel by laser surface alloying. J. Alloy. Compd. 2017, 698, 761–770. [Google Scholar] [CrossRef]

- Baufeld, B. Effect of deposition parameters on mechanical properties of shaped metal deposition parts. Proc. Inst. Mech. Eng. B-J. Eng. 2012, 226, 126–136. [Google Scholar] [CrossRef]

- Dai, C.D.; Fu, Y.; Guo, J.X.; Du, C.W. Effects of substrate temperature and deposition time on the morphology and corrosion resistance of FeCoCrNiMo0.3 high-entropy alloy coating fabricated by magnetron sputtering. Int. J. Miner. Metall. Mater. 2020, 27, 1388–1397. [Google Scholar] [CrossRef]

- Beresnev, V.M.; Nyemchenko, U.S.; Srebniuk, P.O.; Lytovchenko, S.V.; Sobol, O.V. Study of influence physical and technological parameters of deposition on the structure, physical and mechanical properties of vacuum arc coatings (Mo + Ti6%Si)N. In Proceedings of the 2016 International Conference on Nanomaterials: Application & Properties (NAP), Lviv, Ukraine, 14–19 September 2016. [Google Scholar]

- Chen, L.; Li, W.; Liu, P.; Zhang, K.; Ma, F.; Chen, X.; Zhou, H.; Liu, X. Microstructure and mechanical properties of (AlCrTiZrV)Nxhigh-entropy alloy nitride films by reactive magnetron sputtering. Vacuum 2020, 181, 109706. [Google Scholar] [CrossRef]

- Xu, Y.; Li, G.; Xia, Y. Synthesis and characterization of super-hard AlCrTiVZr high-entropy alloy nitride films deposited by HiPIMS. Appl. Surf. Sci. 2020, 523, 146529. [Google Scholar] [CrossRef]

- Yan, H.; Liu, Y.; Mi, Z.; Si, L.; Dou, A.; Liu, F. Effect of nitrogen-argon flow ratio on cavitation resistance of NiTiAlCrN coating. J. Func. Mater. 2023, 54, 1007–1011. [Google Scholar]

- Novikov, V.; Stepanov, N.; Zherebtsov, S.; Salishchev, G. Structure and properties of high-Entropy nitride coatings. Metals 2022, 12, 847. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, A.; Wang, G.; Zhang, J.; Liu, W. Investigation on the microstructure, wear and corrosion resistance of FeCoNiCrMoxhigh-entropy alloy coatings deposited on 40Cr by laser cladding. J. Mater. Sci. 2022, 57, 18615–18639. [Google Scholar] [CrossRef]

- Xiao, J.; Li, T.; Wu, Y.; Chen, J.; Zhang, C. Microstructure and tribological properties of plasma-sprayed CoCrFeNi-based high-entropy alloy coatings under dry and oil-lubricated sliding conditions. J. Therm. Spray. Technol. 2021, 30, 926–936. [Google Scholar] [CrossRef]

- Sun, S.; Liu, H.; Hao, J.; Yang, H. Microstructural evolution and corrosion behavior of CoCrFeNiAlxMn(1−x) dual-phase high-entropy alloy coatings prepared by laser cladding. J. Alloy. Compd. 2021, 886, 161251. [Google Scholar] [CrossRef]

- Ben, Q.; Zhang, Y.; Sun, L.; Wang, L.; Wang, Y.; Zhan, X. Wear and corrosion resistance of FeCoCrxNiAl high-entropy alloy coatings fabricated by laser cladding on Q345 welded joint. Metals 2022, 12, 1428. [Google Scholar] [CrossRef]

- Yu, W.; Li, W.; Liu, P.; Zhang, K.; Ma, F.; Chen, X.; Feng, R.; Liaw, P.K. Silicon-content-dependent microstructures and mechanical behavior of (AlCrTiZrMo)-Six-N high-entropy alloy nitride films. Mater. Design. 2021, 203, 109553. [Google Scholar] [CrossRef]

- Szala, M.; Chocyk, D.; Skic, A.; Kamiński, M.; Macek, W.; Turek, M. Effect of nitrogen ion implantation on the cavitation erosion resistance and Cobalt-based solid solution phase transformations of HIPed Stellite 6. Materials 2021, 14, 2324. [Google Scholar] [CrossRef] [PubMed]

- Szala, M.; Walczak, M.; Pasierbiewicz, K.; Kamiński, M. Cavitation erosion and sliding wear mechanisms of AlTiN and TiAlN flims deposited on stainless steel substrate. Coatings 2019, 9, 340. [Google Scholar] [CrossRef]

| Elements | Fe | Cr | Ni | Mn | Si | C | S | P |

|---|---|---|---|---|---|---|---|---|

| Contents/wt.% | 67~71 | 17~19 | 8~11 | ≤2.0 | ≤1.0 | ≤0.08 | ≤0.03 | ≤0.035 |

| Co Content | Diffraction Angle 2θ/(°) | Interplanar Spacing d/nm | FWHM B/rad |

|---|---|---|---|

| NiTiAlCrCo0.6N | 43.399 | 2.0833 | 0.119 |

| NiTiAlCrCo0.8N | 43.342 | 2.0859 | 0.152 |

| NiTiAlCrCoN | 43.381 | 2.0842 | 0.193 |

| NiTiAlCrCo1.2N | 43.340 | 2.0860 | 0.122 |

| NiTiAlCrCo1.4N | 43.338 | 2.0861 | 0.115 |

| Ni | Ti | Al | Cr | Co | N | |

|---|---|---|---|---|---|---|

| NiTiAlCrCo0.6N | 14.85 | 10.92 | 11.56 | 14.59 | 9.4 | 38.68 |

| NiTiAlCrCo0.8N | 13.86 | 10.7 | 11.36 | 13.82 | 10.72 | 39.54 |

| NiTiAlCrCoN | 12.15 | 10.64 | 12.16 | 13.29 | 11.88 | 39.88 |

| NiTiAlCrCo1.2N | 11.52 | 9.6 | 10.86 | 11.37 | 17.89 | 38.76 |

| NiTiAlCrCo1.4N | 10.35 | 8.21 | 9.05 | 10.74 | 22.53 | 39.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Cheng, F.; Si, L.; Yang, Y.; Dou, Z.; Liu, F. Effect of Co Contents on Microstructure and Cavitation Erosion Resistance of NiTiAlCrCoxN Films. Coatings 2024, 14, 603. https://doi.org/10.3390/coatings14050603

Yan H, Cheng F, Si L, Yang Y, Dou Z, Liu F. Effect of Co Contents on Microstructure and Cavitation Erosion Resistance of NiTiAlCrCoxN Films. Coatings. 2024; 14(5):603. https://doi.org/10.3390/coatings14050603

Chicago/Turabian StyleYan, Hongjuan, Fangying Cheng, Lina Si, Ye Yang, Zhaoliang Dou, and Fengbin Liu. 2024. "Effect of Co Contents on Microstructure and Cavitation Erosion Resistance of NiTiAlCrCoxN Films" Coatings 14, no. 5: 603. https://doi.org/10.3390/coatings14050603

APA StyleYan, H., Cheng, F., Si, L., Yang, Y., Dou, Z., & Liu, F. (2024). Effect of Co Contents on Microstructure and Cavitation Erosion Resistance of NiTiAlCrCoxN Films. Coatings, 14(5), 603. https://doi.org/10.3390/coatings14050603