Design and Fabrication of Moth-Eye Subwavelength Structure with a Waist on Silicon for Broadband and Wide-Angle Anti-Reflection Property

Abstract

:1. Introduction

2. Materials and Methods

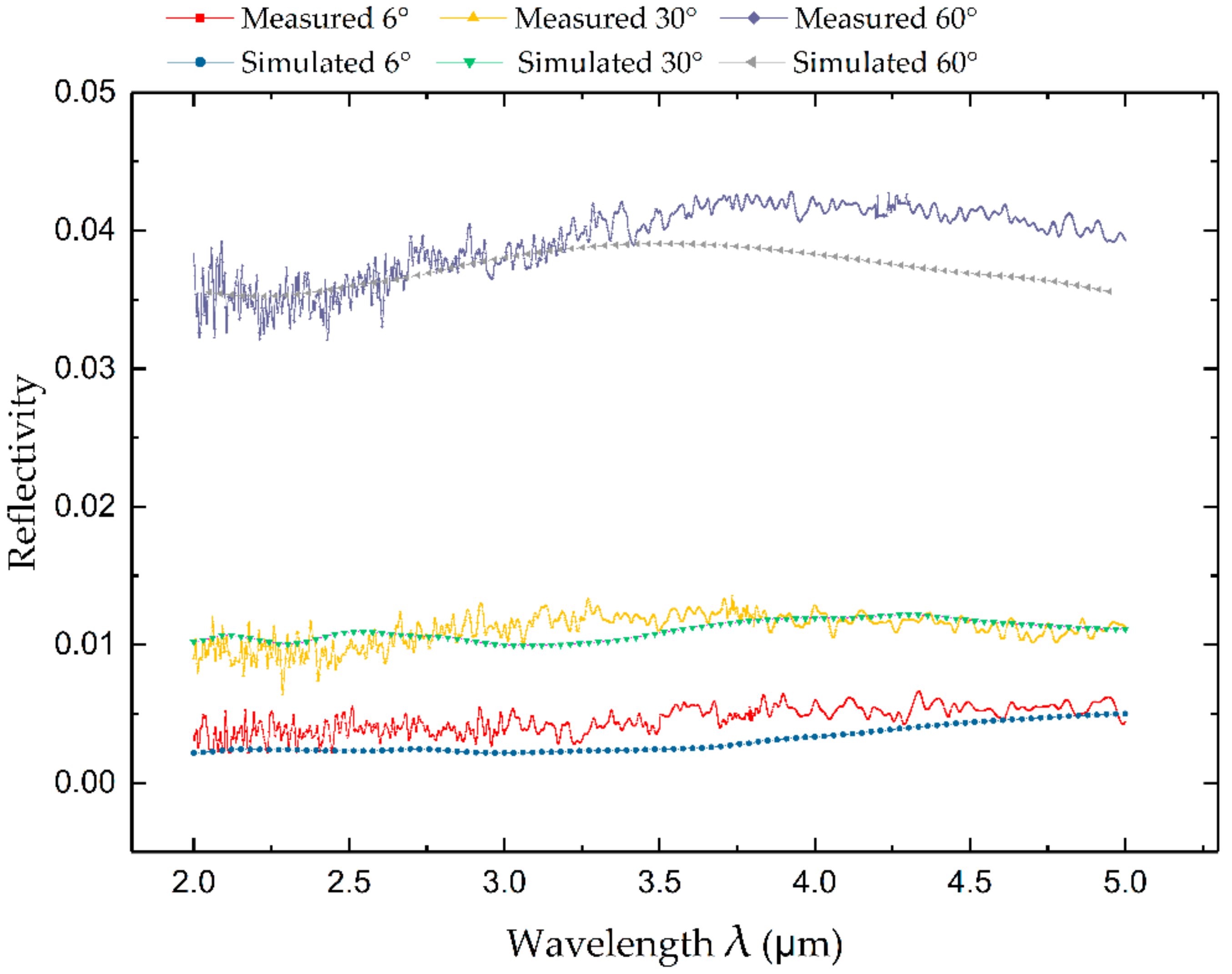

3. Results and Discussion

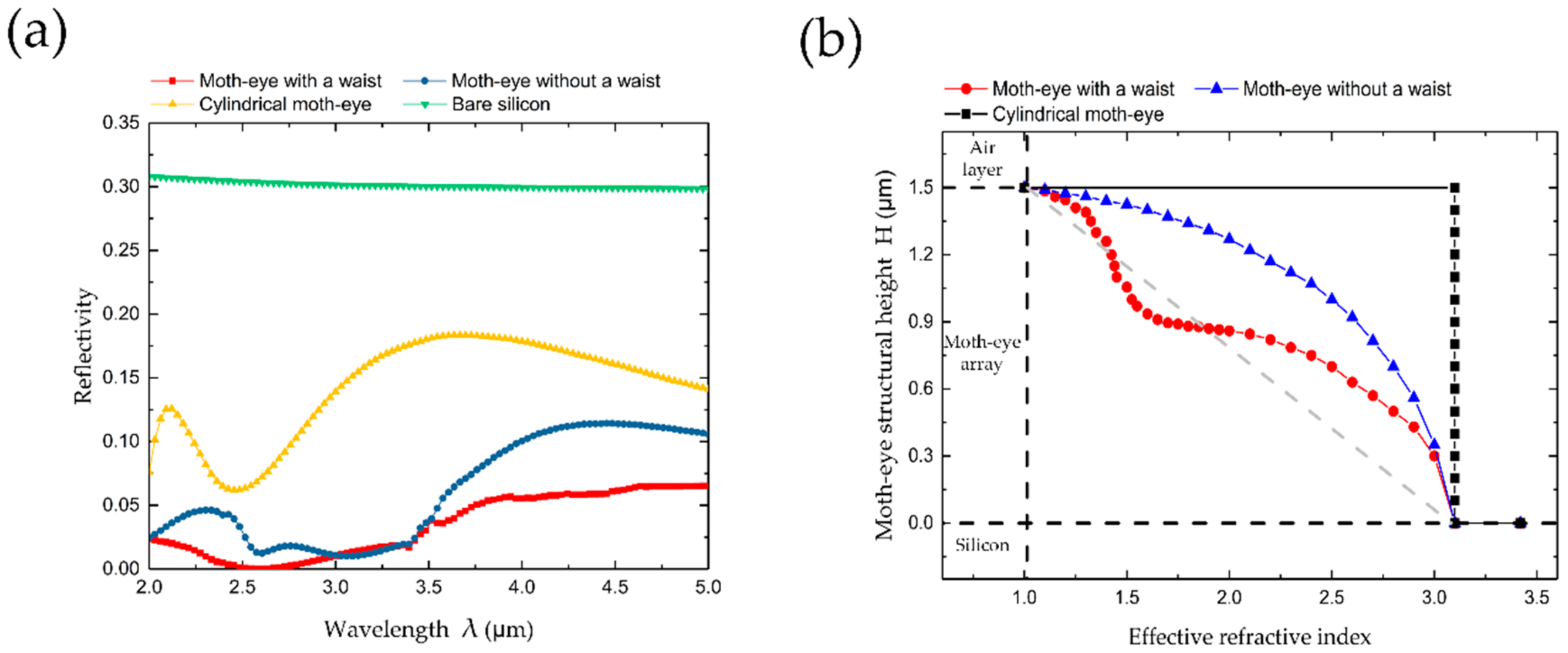

3.1. Basic Parameters of the Optimized Moth-eye Structure

3.2. Optimization of Waist Structure Parameters

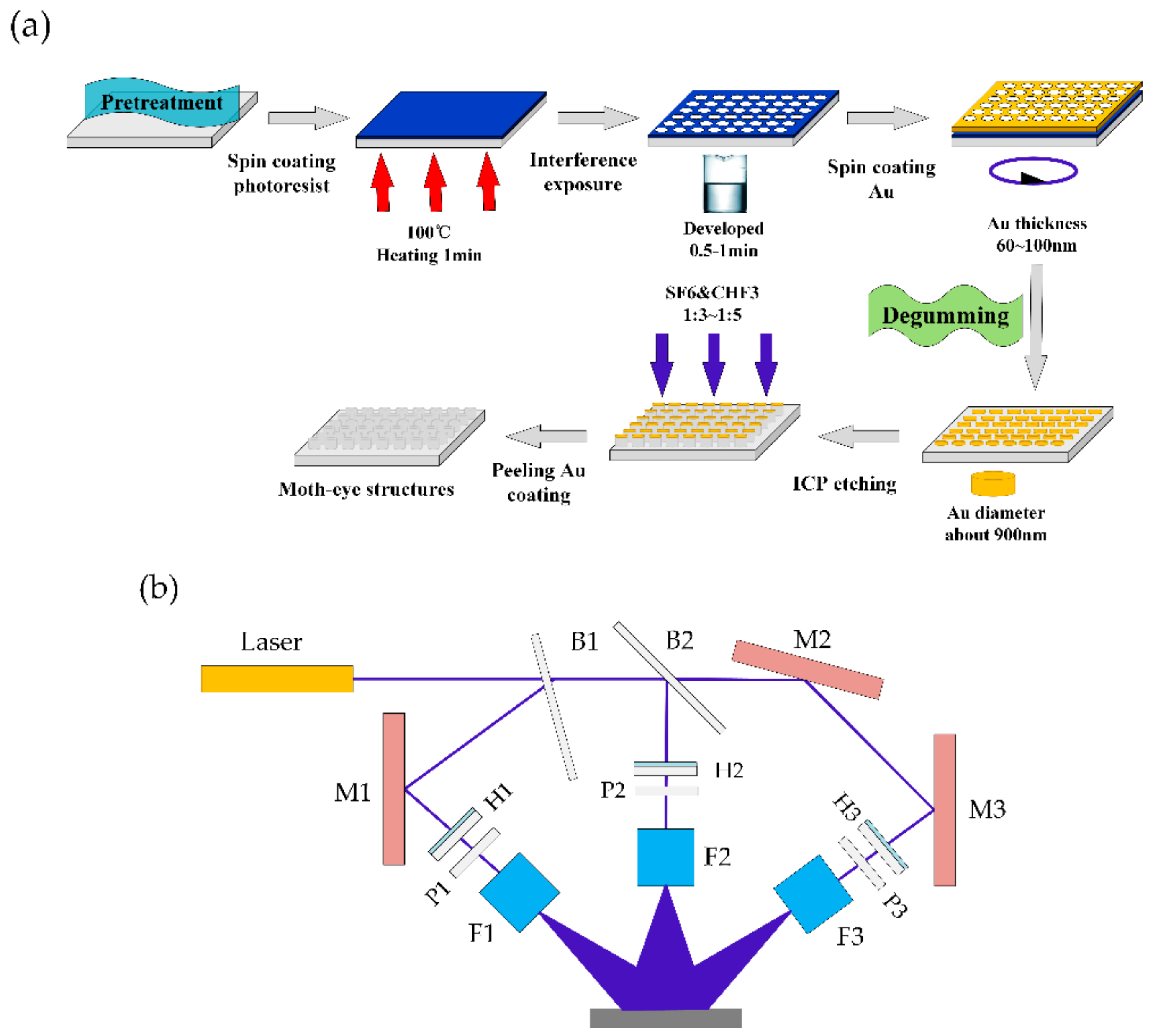

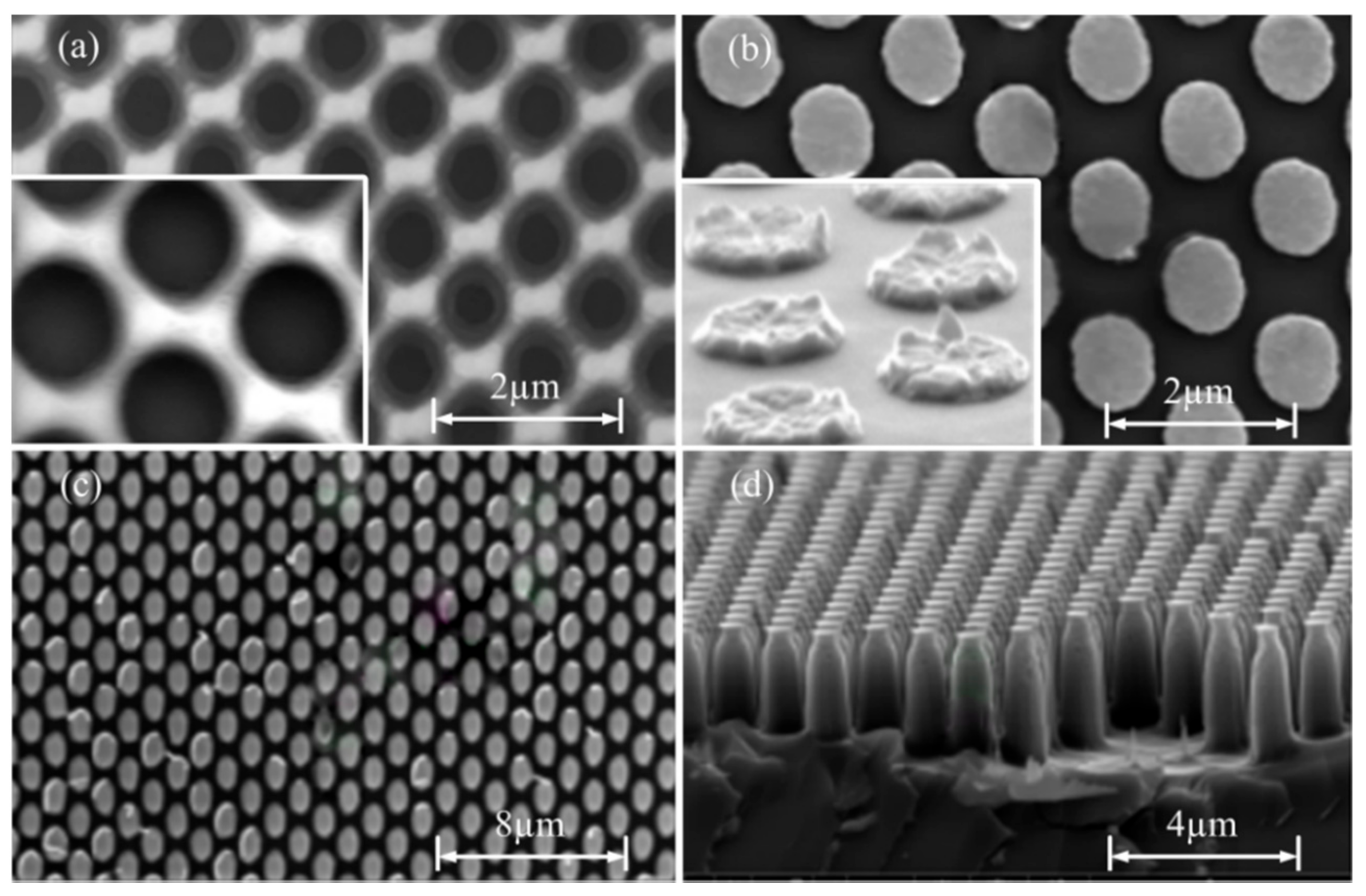

3.3. Fabrication Process and Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, J.; Zhu, J.; Gao, X. Bio-inspired high-performance antireflection and antifogging polymer films. Small 2014, 10, 2578–2582. [Google Scholar] [CrossRef] [PubMed]

- Raut, H.K.; Dinachali, S.S.; Loke, Y.C.; Ganesan, R.; Ansahantwi, K.K.; Góra, A. Multiscale ommatidial arrays with broadband and omnidirectional antireflection and antifogging properties by sacrificial layer mediated nanoimprinting. ACS Nano 2015, 9, 1305–1314. [Google Scholar] [CrossRef] [PubMed]

- Askar, K.; Phillips, B.M.; Jiang, B. Bioinspired self-cleaning antireflection coatings. Adv. Mater. 2015, 20, 65–95. [Google Scholar]

- Yang, Y.; Pillai, S.; Mehrvarz, H.; Green, M.A. Plasmonic degradation and the importance of over-coating metal nanoparticles for a plasmonic solar cell. Sol. Eng. Mat. Sol. Cell. 2014, 122, 208–216. [Google Scholar] [CrossRef]

- Bychanok, D.; Li, S.; Gorokhov, G.; Piasotski, K.; Meisak, D.; Kuzhir, P. Fully carbon metasurface: Absorbing coating in microwaves. J. Appl. Phys. 2017, 121, 2075–2084. [Google Scholar] [CrossRef]

- Ko, D.H.; Tumbleston, J.R.; Gadisa, A.; Aryal, M.; Liu, Y.; Lopez, R. Light-trapping nano-structures in organic photovoltaic cells. J. Mater. Chem. 2011, 21, 16293–16303. [Google Scholar] [CrossRef]

- Voroshilov, P.M.; Simovski, C.R.; Belov, P.A.; Shalin, A.S. Enhancement of photovoltaic absorption in thin-film silicon solar cells by all-dielectric light-trapping and antireflective coatings. In Proceedings of the 2015 9th International Congress on Advanced Electromagnetic Materials in Microwaves and Optics (METAMATERIALS), Oxford, UK, 7–12 September 2015; pp. 517–519. [Google Scholar]

- Loh, J.; Kherani, N. Design of nano-porous multilayer antireflective coatings. Coatings 2017, 7, 134. [Google Scholar] [CrossRef]

- Cao, W.; Myers, J.D.; Zheng, Y.; Hammond, W.T.; Wrzesniewski, E.; Xue, J. Enhancing light harvesting in organic solar cells with pyramidal rear reflectors. Appl. Phys. Lett. 2011, 99, 135. [Google Scholar] [CrossRef]

- Glass, R.; Möller, M.; Spatz, J.P. Block copolymer micelle nanolithography. Nanotechnology 2003, 14, 1153–1160. [Google Scholar] [CrossRef]

- Ono, Y.; Kimura, Y.; Ohta, Y.; Nishida, N. Antireflection effect in ultrahigh spatial-frequency holographic relief gratings. Appl. Opt. 1987, 26, 1142–1146. [Google Scholar] [CrossRef] [PubMed]

- Bruynooghe, S.; Schulze, M.; Helgert, M.; Challier, M.; Tonova, D.; Sundermann, M. Broadband and wide-angle hybrid antireflection coatings prepared by combining interference multilayers with subwavelength structures. J. Nanophotonics 2016, 10, 033002. [Google Scholar] [CrossRef]

- Min, W.L.; Jiang, B.; Jiang, P. Bioinspired self-cleaning antireflection coatings. Adv. Mater. 2008, 20, 3914–3918. [Google Scholar] [CrossRef]

- Grilli, S.; Ferraro, P.; De Natale, P.; Tiribilli, B. Surface nanoscale periodic structures in congruent lithium niobate by domain reversal patterning and differential etching. Appl. Phys. Lett. 2005, 87, 233106. [Google Scholar] [CrossRef]

- Rianna, C.; Calabuig, A.; Ventre, M.; Cavalli, S.; Pagliarulo, V.; Grilli, S.; Ferraro, P.; Netti, P.A. Reversible holographic patterns on azopolymers for guiding cell adhesion and orientation. ACS Appl. Mater. Interfaces 2015, 7, 16984–16991. [Google Scholar] [CrossRef] [PubMed]

- De Nicola, S.; Ferraro, P.; Finizio, A.; Grilli, S.; Coppola, G.; Iodice, M.; De Natale, P.; Chiarini, M. Surface topography of microstructures in lithium niobate by digital holographic microscopy. Meas. Sci. Technol. 2004, 15, 961. [Google Scholar] [CrossRef]

- Schade, M.; Fuhrmann, B.; Bohley, C.; Schlenker, S.; Sardana, N.; Schilling, J. Regular arrays of Al nanoparticles for plasmonic applications. J. Appl. Phys. 2014, 115, 205–213. [Google Scholar] [CrossRef]

- Cao, Y.; Ge, Z.; Jiang, X.; Xu, J.; Xu, L.; Li, W. Light harvesting and enhanced performance of Si quantum dot/Si nanowire heterojunction solar cells. Part. Part. Syst. Charact. 2016, 33, 38–43. [Google Scholar] [CrossRef]

- Ha, D.; Chen, G.; Leite, M.S.; Munday, J.N. Demonstration of resonance coupling in scalable dielectric micro-resonator coatings for photovoltaics. ACS Appl. Mater. Interfaces 2016, 8, 24536. [Google Scholar] [CrossRef] [PubMed]

- Mokariantabari, P.; Senthamaraikannan, R.; Glynn, C.; Collins, T.W.; Cummins, C.; Nugent, D.; O'Dwyer, C.; Morris, M. Large block copolymer self-assembly for fabrication of subwavelength nanostructures for applications in optics. Nano Lett. 2017, 17, 2973–2978. [Google Scholar] [CrossRef] [PubMed]

- Merola, F.; Grilli, S.; Coppola, S.; Vespini, V.; De Nicola, S.; Maddalena, P.; Carfagna, C.; Ferraro, P. Reversible fragmentation and self-assembling of nematic liquid crystal droplets on functionalized pyroelectric substrates. Adv. Funct. Mater. 2012, 22, 3267–3272. [Google Scholar] [CrossRef]

- Grilli, S.; Coppola, S.; Vespini, V.; Merola, F.; Finizio, A.; Ferraro, P. 3D lithography by rapid curing of the liquid instabilities at nanoscale. Proc. Natl. Acad. Sci. 2011, 108, 15106–15111. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, G.; Chen, J.; Wang, L.; Wang, D.; Yang, J.; Li, Y. Titanium oxide/silicon moth-eye structures with antireflection, p-n heterojunctions and superhydrophilicity. ACS J. Surf. 2016, 32, 41. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Yi, P.; Peng, L.; Ni, J. Optimization and continuous fabrication of moth-eye nanostructure array on flexible polyethylene terephthalate substrate towards broadband antireflection. Appl. Opt. 2017, 56, 2901. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Shields, P.; Liu, C.W.; Allsopp, D.W.E. Broadband moth-eye antireflection coatings fabricated by low-cost nanoimprinting. Appl. Phys. Lett. 2009, 94, 263118. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Yang, B. Antireflective surfaces based on biomimetic nanopillared arrays. Nano Today 2010, 5, 117–127. [Google Scholar] [CrossRef]

- Wu, F.; Shi, G.; Xu, H.; Liu, L.; Wang, Y.; Qi, D. Fabrication of antireflective compound eyes by imprinting. ACS Appl. Mater. Interfaces 2013, 5, 12799–12803. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.C.; Shao, J.D.; Wang, Y.J.; Fan, Z.X. Theoretical study of graded-index coatings prepared by glancing angle deposition. Acta Phys. Sin. 2005, 54, 3069–3074. [Google Scholar]

- Shen, Z.C.; Shen, J.; Liu, S.J.; Kong, W.J.; Shao, J.D.; Fan, Z.X. Discussion on the stratified merit of graded index coatings. Acta Phys. Sin. 2007, 56, 1325–1328. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, H.; Ouyang, M.; Chen, B.; Zhu, Q.; Wu, J.; Lou, N.; Dong, L.; Wang, Z.; Fu, Y. Design and Fabrication of Moth-Eye Subwavelength Structure with a Waist on Silicon for Broadband and Wide-Angle Anti-Reflection Property. Coatings 2018, 8, 360. https://doi.org/10.3390/coatings8100360

Lin H, Ouyang M, Chen B, Zhu Q, Wu J, Lou N, Dong L, Wang Z, Fu Y. Design and Fabrication of Moth-Eye Subwavelength Structure with a Waist on Silicon for Broadband and Wide-Angle Anti-Reflection Property. Coatings. 2018; 8(10):360. https://doi.org/10.3390/coatings8100360

Chicago/Turabian StyleLin, He, Mingzhao Ouyang, Bingxu Chen, Qifan Zhu, Jinshuang Wu, Nan Lou, Litong Dong, Zuobin Wang, and Yuegang Fu. 2018. "Design and Fabrication of Moth-Eye Subwavelength Structure with a Waist on Silicon for Broadband and Wide-Angle Anti-Reflection Property" Coatings 8, no. 10: 360. https://doi.org/10.3390/coatings8100360

APA StyleLin, H., Ouyang, M., Chen, B., Zhu, Q., Wu, J., Lou, N., Dong, L., Wang, Z., & Fu, Y. (2018). Design and Fabrication of Moth-Eye Subwavelength Structure with a Waist on Silicon for Broadband and Wide-Angle Anti-Reflection Property. Coatings, 8(10), 360. https://doi.org/10.3390/coatings8100360