Conductive Characteristics of Indium Tin Oxide Thin Film on Polymeric Substrate under Long-Term Static Deformation

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials and Specimen Preparation

2.2. Static Bending Test

2.3. Microstructural Analysis

3. Results and Discussion

3.1. Bending Effect on ITO Thin Film

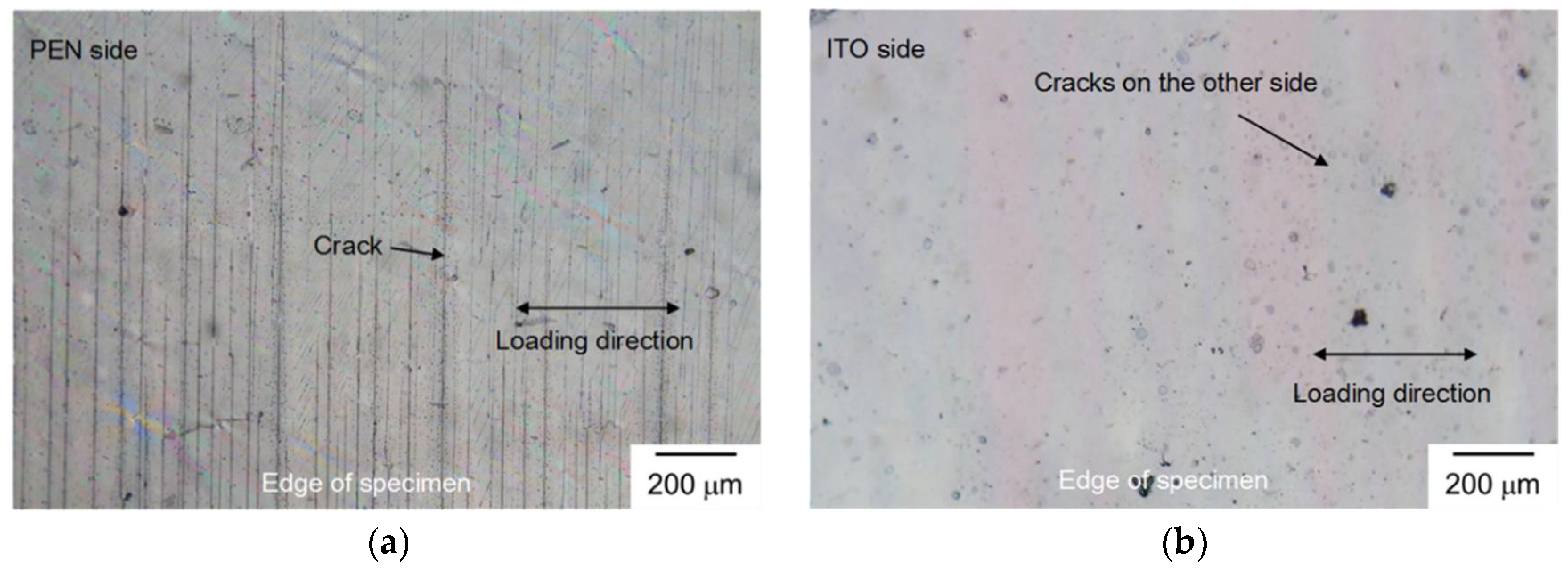

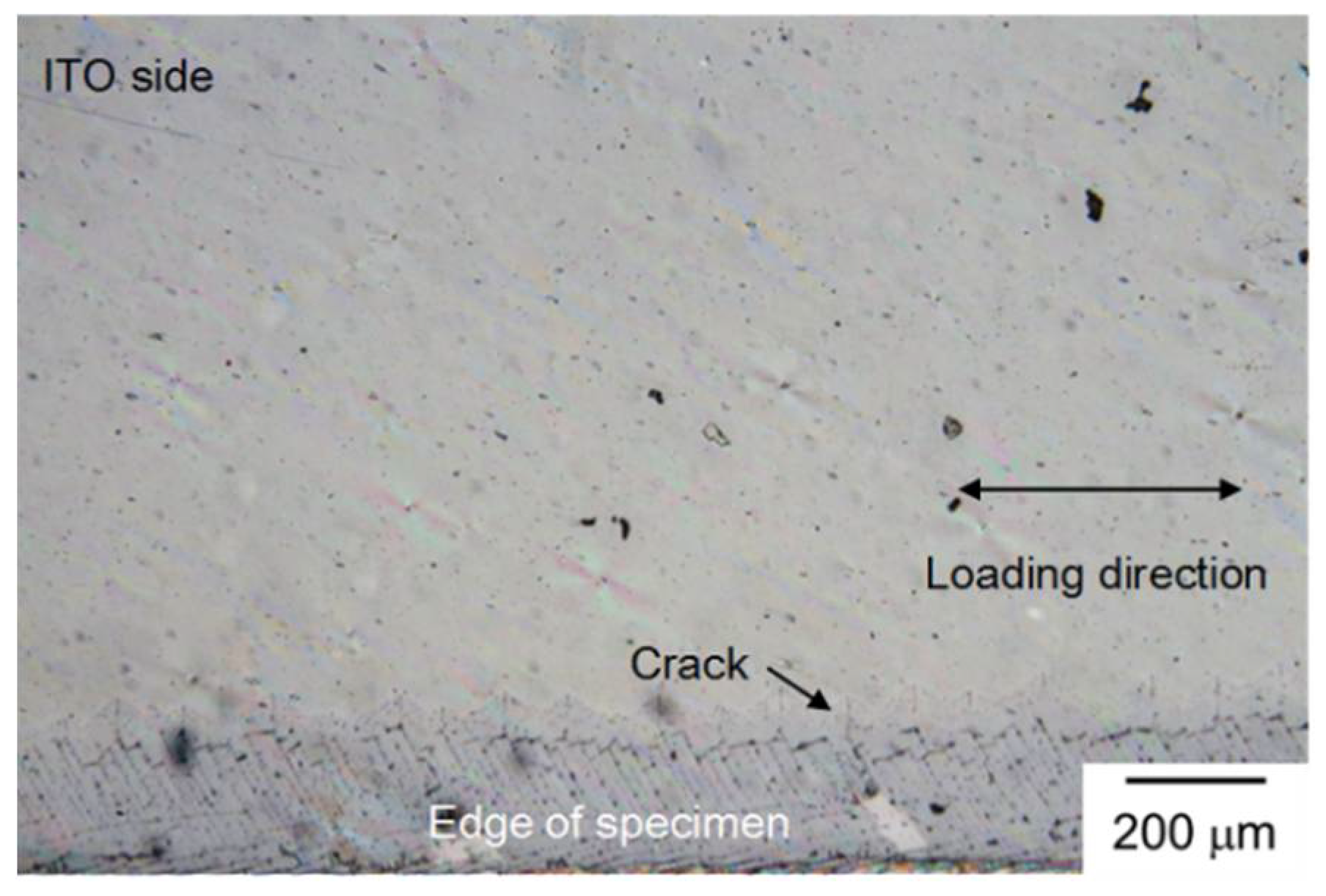

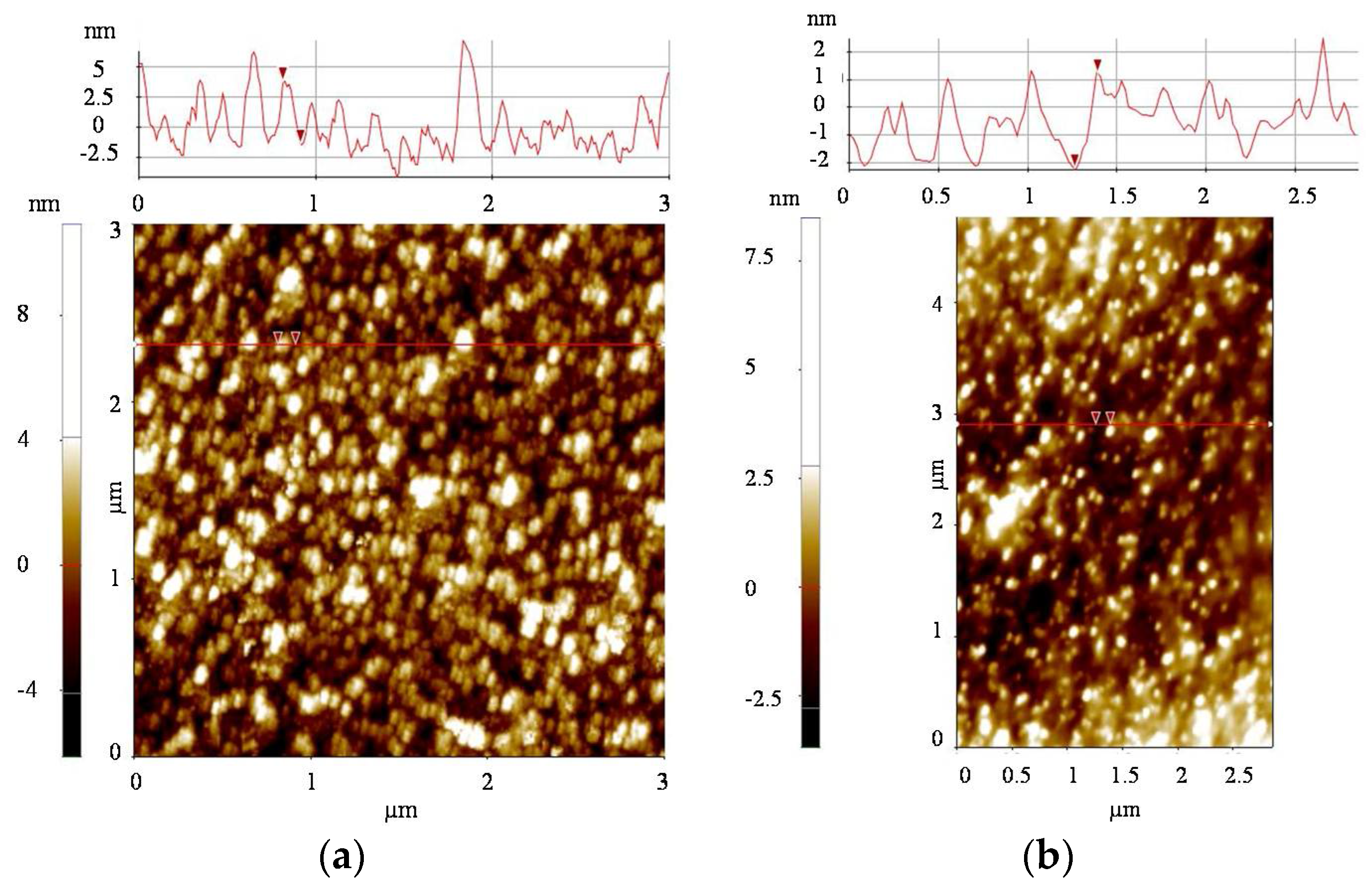

3.2. Failure Analysis

4. Conclusions

- (1)

- Tensile bending is much more detrimental than compressive bending to the electrical conductance of the given ITO/PEN and ITO/PET sheets under a long-term static flexural deformation.

- (2)

- Under tensile and compressive bending of a curvature radius of 30 mm or larger, electrical conductance of both ITO/PEN and ITO/PET sheets remain stable for up to 1000 h of static loading.

- (3)

- In 1000 h of tensile bending at a 20 mm curvature radius for the ITO/PEN sheet and at a 10 mm curvature radius for the ITO/PET sheet, the electrical conductance of ITO is degraded by 3–15% and 6–20%, respectively.

- (4)

- In 1000 h of tensile bending at a 10 mm curvature radius for the ITO/PEN sheet and at a 5 mm curvature radius for the ITO/PET sheet, the electrical conductance of ITO is significantly degraded by 800–900% and 60,000%, respectively.

- (5)

- The given ITO/PET sheet has a greater resistance to long-term mechanical bending than the ITO/PEN sheet in terms of change in electrical conductance. This is attributed to a smaller stress in the ITO layer because the ITO/PET sheet has a smaller stiffness and thickness in the substrate than the ITO/PEN sheet.

Author Contributions

Funding

Conflicts of Interest

References

- Greiner, M.T.; Lu, Z.-H. Thin-film metal oxides in organic semiconductor devices: Their electronic structures, work functions and interfaces. NPG Asia Mater. 2013. [Google Scholar] [CrossRef]

- Indium Tin Oxide (ITO) (In2O3):(SnO2), Indium Corporation. Available online: http://www.indium.com/inorganic-compounds/indium-compounds/indium-tin-oxide/ (accessed on 31 May 2018).

- Cao, W.; Li, J.; Chen, H.; Xue, J. Transparent electrodes for organic optoelectronic devices: A review. J. Photonics Energy 2014, 4, 040990. [Google Scholar] [CrossRef]

- Canhola, P.; Martins, N.; Raniero, L.; Pereira, S.; Fortunato, E.; Ferreira, I.; Martins, R. Role of annealing environment on the performances of large area ITO films produced by rf magnetron sputtering. Thin Solid Films 2005, 487, 271–276. [Google Scholar] [CrossRef]

- Gonçalves, G.; Grasso, V.; Barquinha, P.; Pereira, L.; Elamurugu, E.; Brignone, M.; Martins, R.; Lambertini, V.; Fortunato, E. Role of room temperature sputtered high conductive and high transparent indium zinc oxide film contacts on the performance of orange, green, and blue organic light emitting diodes. Plasma Process. Polym. 2011, 8, 340–345. [Google Scholar] [CrossRef]

- Alam, M.J.; Cameron, D.C. Optical and electrical properties of transparent conductive ITO thin films deposited by sol–gel process. Thin Solid Films 2000, 377, 455–459. [Google Scholar] [CrossRef]

- Ding, X.; Yan, J.; Li, T.; Zhang, L. Transparent conductive ITO/Cu/ITO films prepared on flexible substrates at room temperature. Appl. Surf. Sci. 2012, 258, 3082–3085. [Google Scholar] [CrossRef]

- Yu, S.; Yang, W.; Li, L.; Zhang, W. Improved chemical stability of ITO transparent anodes with a SnO2 buffer layer for organic solar cells. Sol. Energy Mater. Sol. Cells 2016, 144, 652–656. [Google Scholar] [CrossRef]

- Gil, Y.; Kim, H. Hybrid ITO transparent conductive electrodes embedded with Pt nanoclusters for enhanced output efficiency of GaN-based light-emitting diodes. Thin Solid Films 2016, 603, 307–312. [Google Scholar] [CrossRef]

- Tan, N.-N.; Hung, D.-T.; Anh, V.-T.; Kang, B.-C.; Kim, H.-C. Improved patterning of ITO coated with gold masking layer on glass substrate using nanosecond fiber laser and etching. Appl. Surf. Sci. 2015, 336, 163–169. [Google Scholar] [CrossRef]

- Park, S.-H.; Lee, S.-J.; Lee, J.-H.; Kal, J.; Hahn, J.; Kim, H.-K. Large area roll-to-roll sputtering of transparent ITO/Ag/ITO cathodes for flexible inverted organic solar cell modules. Org. Electron. 2016, 30, 112–121. [Google Scholar] [CrossRef]

- Lim, C.-Y.; Park, J.-K.; Kim, Y.-H.; Han, J.-I. Mechanical and electrical stability indium-tin-oxide coated polymer substrates under continuous bending stress condition. J. Int. Counc. Electr. Eng. 2012, 2, 237–241. [Google Scholar] [CrossRef]

- Peccell Product Information, Peccell Technologies, Inc. Available online: http://www.peccell.com/products/PECF/ (accessed on 31 May 2018).

- Ibeh, C.C. Thermoplastic Materials: Properties, Manufacturing Methods, and Applications; CRC Press: Cleveland, OH, USA, 2011. [Google Scholar]

- Kirubanandham, A.; Basu, S. On Characterization of Mechanical Deformation in Flexible Electronic Structures; Agilent Technologies, Inc.: Santa Clara, CA, USA, 2012. [Google Scholar]

- Li, T.-C.; Lin, J.-F. Fatigue life study of ITO/PET specimens in cyclic bending tests. J. Mater. Sci. Mater. Electron. 2014, 26, 250–261. [Google Scholar] [CrossRef]

- Li, T.-C.; Han, C.-F.; Chen, K.-T.; Lin, J.-F. Fatigue life study of ITO/PET specimens in terms of electrical resistance and stress/strain via cyclic bending tests. J. Display Technol. 2013, 9, 577–585. [Google Scholar] [CrossRef]

- Leterrier, Y.; Médico, L.; Demarco, F.; Månson, J.A.E.; Betz, U.; Escolà, M.F.; Kharrazi Olsson, M.; Atamny, F. Mechanical integrity of transparent conductive oxide films for flexible polymer-based displays. Thin Solid Films 2004, 460, 156–166. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Shi, W.-Q.; Chen, Z.-Z. Effect of deflection on the mechanical and optoelectronic properties of indium tin oxide films deposited on polyethylene terephthalate substrates by pulse magnetron sputtering. Thin Solid Films 2009, 517, 1701–1705. [Google Scholar] [CrossRef]

- Hamasha, M.M.; Alzoubi, K.; Lu, S.; Desu, S.B. Durability study on sputtered indium tin oxide thin film on poly ethylene terephthalate substrate. Thin Solid Films 2011, 519, 6033–6038. [Google Scholar] [CrossRef]

- Lee, C.-C. Modeling and validation of mechanical stress in indium tin oxide layer integrated in highly flexible stacked thin films. Thin Solid Films 2013, 544, 443–447. [Google Scholar] [CrossRef]

- Jung, S.; Lim, K.; Kang, J.-W.; Kim, J.-K.; Oh, S.-I.; Eun, K.; Kim, D.-G.; Choa, S.-H. Electromechanical properties of indium–tin–oxide/poly(3,4-ethylenedioxythiophene): Poly(styrenesulfonate) hybrid electrodes for flexible transparent electrodes. Thin Solid Films 2014, 550, 435–443. [Google Scholar] [CrossRef]

- Machinaga, H.; Ueda, E.; Mizuike, A.; Takeda, Y.; Shimokita, K.; Miyazaki, T. Effects of annealing temperature on mechanical durability of indium-tin oxide film on polyethylene terephthalate substrate. Thin Solid Films 2014, 559, 36–39. [Google Scholar] [CrossRef]

- Kim, E.-H.; Yang, C.-W.; Park, J.-W. Improving the delamination resistance of indium tin oxide (ITO) coatings on polymeric substrates by O2 plasma surface treatment. Curr. Appl. Phys. 2010, 10, 510S–514S. [Google Scholar] [CrossRef]

- Hauger, T.C.; Zeberoff, A.; Worfolk, B.J.; Elias, A.L.; Harris, K.D. Real-time resistance, transmission and figure-of-merit analysis for transparent conductors under stretching-mode strain. Sol. Energy Mater. Sol. Cells 2014, 124, 247–255. [Google Scholar] [CrossRef]

- Saleh, M.N.; Lubineau, G. Understanding the mechanisms that change the conductivity of damaged ITO-coated polymeric films: A micro-mechanical investigation. Sol. Energy Mater. Sol. Cells 2014, 130, 199–207. [Google Scholar] [CrossRef]

- Van der Sluis, O.; Abdallah, A.A.; Bouten, P.C.P.; Timmermans, P.H.M.; den Toonder, J.M.J.; de With, G. Effect of a hard coat layer on buckle delamination of thin ITO layers on a compliant elasto-plastic substrate: An experimental–numerical approach. Eng. Fract. Mech. 2011, 78, 877–889. [Google Scholar] [CrossRef]

- Neerinck, D.G.; Vink, T.J. Depth profiling of thin ITO films by grazing incidence X-ray diffraction. Thin Solid Films 1996, 278, 12–17. [Google Scholar] [CrossRef]

- Chang, R.-C.; Tsai, F.-T.; Tu, C.-H. A direct method to measure the fracture toughness of indium tin oxide thin films on flexible polymer substrates. Thin Solid Films 2013, 540, 118–124. [Google Scholar] [CrossRef]

- Yang, C.-W.; Park, J.-W. The cohesive crack and buckle delamination resistances of indium tin oxide (ITO) films on polymeric substrates with ductile metal interlayers. Surf. Coat. Technol. 2010, 204, 2761–2766. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Hwang, W.-J.; Eun, K.-T.; Choa, S.-H. Mechanical reliability of transparent conducting IZTO film electrodes for flexible panel displays. Appl. Surf. Sci. 2011, 257, 8134–8138. [Google Scholar] [CrossRef]

- Abdallah, A.A.; Bouten, P.C.P.; den Toonder, J.M.J.; de With, G. Buckle initiation and delamination of patterned ITO layers on a polymer substrate. Surf. Coat. Technol. 2011, 205, 3103–3111. [Google Scholar] [CrossRef]

- Boehme, M.; Charton, C. Properties of ITO on PET film in dependence on the coating conditions and thermal processing. Surf. Coat. Technol. 2005, 200, 932–935. [Google Scholar] [CrossRef]

- Can, M.; Havare, A.K.; Aydın, H.; Yagmurcukardes, N.; Demic, S.; Icli, S.; Okur, S. Electrical properties of SAM-modified ITO surface using aromatic small molecules with double bond carboxylic acid groups for OLED applications. Appl. Surf. Sci. 2014, 314, 1082–1086. [Google Scholar] [CrossRef] [Green Version]

- Han, D.; Lee, S.; Kim, H.; Jeong, S.; Yoo, S. Cathodic multilayer transparent electrodes for ITO-free inverted organic solar cells. Org. Electron. 2013, 14, 1477–1482. [Google Scholar] [CrossRef]

- Kim, D.-H.; Park, M.-R.; Lee, H.-J.; Lee, G.-H. Thickness dependence of electrical properties of ITO film deposited on a plastic substrate by RF magnetron sputtering. Appl. Surf. Sci. 2006, 253, 409–411. [Google Scholar] [CrossRef]

- Kim, E.-H.; Kim, G.; Lee, G.-H.; Park, J.-W. Nucleation and growth of crystalline indium tin oxide (ITO) coatings on polyethylene terephthalate (PET). Surf. Coat. Technol. 2010, 205, 1–8. [Google Scholar] [CrossRef]

- Lim, K.; Jung, S.; Kim, J.-K.; Kang, J.-W.; Kim, J.-H.; Choa, S.-H.; Kim, D.-G. Flexible PEDOT: PSS/ITO hybrid transparent conducting electrode for organic photovoltaics. Sol. Energy Mater. Sol. Cells 2013, 115, 71–78. [Google Scholar] [CrossRef]

- Minami, T. Present status of transparent conducting oxide thin-film development for indium-tin-oxide (ITO) substitutes. Thin Solid Films 2008, 516, 5822–5828. [Google Scholar] [CrossRef]

- Leppänen, K.; Augustine, B.; Saarela, J.; Myllylä, R.; Fabritius, T. Breaking mechanism of indium tin oxide and its effect on organic photovoltaic cells. Sol. Energy Mater. Sol. Cells 2013, 117, 512–518. [Google Scholar] [CrossRef]

- Tran, D.-P.; Lu, H.-I.; Lin, C.-K. Effects of cyclic deformation on conductive characteristics of indium tin oxide thin film on polyethylene terephthalate substrate. Surf. Coat. Technol. 2015, 283, 298–310. [Google Scholar] [CrossRef]

- Alkhazaili, A.; Hamasha, M.M.; Choi, G.; Lu, S.; Westgate, R. Reliability of thin films: Experimental study on mechanical and thermal behavior of indium tin oxide and poly(3,4-ethylenedioxythiophene). Microelectron. Reliab. 2015, 55, 538–546. [Google Scholar] [CrossRef]

- Peng, C.-Y.; Hamasha, M.M.; VanHart, D.; Lu, S.; Westgate, C.R. Electrical and optical degradation studies on AZO thin films under cyclic bending conditions. IEEE Trans. Device Mater. Reliab. 2013, 13, 236–244. [Google Scholar] [CrossRef]

- Hamasha, M.M.; Alzoubi, K.; Switzer, J.C.; Lu, S.; Poliks, M.D.; Westgate, C.R. Reliability of sputtered aluminum thin film on flexible substrate under high cyclic bending fatigue conditions. IEEE Trans. Compon. Packag. Technol. 2012, 2, 2007–2016. [Google Scholar] [CrossRef]

- Peng, C.-Y.; Dhakal, T.P.; Garner, S.M.; Cimo, P.; Lu, S.; Westgate, C.R. Strained growth of aluminum-doped zinc oxide on flexible glass substrate and degradation studies under cyclic bending conditions. IEEE Trans. Device Mater. 2014, 14, 121–126. [Google Scholar] [CrossRef]

- Hamasha, M.M.; Dhakal, T.P.; Vasekar, P.; Alzoubi, K.; Lu, S.; Vanhart, D.; Westgate, C.R. Reliability of sputter deposited aluminum-doped zinc oxide under harsh environmental conditions. Sol. Energy 2013, 89, 54–61. [Google Scholar] [CrossRef]

- Hamasha, M.M.; Alzoubi, K.; Lu, S. Behavior of sputtered indium–tin–oxide thin film on poly-ethylene terephthalate substrate under stretching. J. Display Technol. 2011, 7, 426–433. [Google Scholar] [CrossRef]

- Kim, J.-H.; Park, J.-W. Improving the flexibility of large-area transparent conductive oxide electrodes on polymer substrates for flexible organic light emitting diodes by introducing surface roughness. Org. Electron. 2013, 14, 3444–3452. [Google Scholar] [CrossRef]

- Park, J.-M.; Gu, G.-Y.; Wang, Z.-J.; Kwon, D.-J.; Devries, K.L. Interfacial durability and electrical properties of CNT or ITO/PVDF nanocomposites for self-sensor and micro actuator applications. Appl. Surf. Sci. 2013, 287, 75–83. [Google Scholar] [CrossRef]

- Tseng, S.-F.; Hsiao, W.-T.; Huang, K.-C.; Chiang, D.; Chen, M.-F.; Chou, C.-P. Laser scribing of indium tin oxide (ITO) thin films deposited on various substrates for touch panels. Appl. Surf. Sci. 2010, 257, 1487–1494. [Google Scholar] [CrossRef]

- Yu, Z.; Li, Y.; Xia, F.; Zhao, Z.; Xue, W. Properties of indium tin oxide films deposited on unheated polymer substrates by ion beam assisted deposition. Thin Solid Films 2009, 517, 5395–5398. [Google Scholar] [CrossRef]

- Product Specification of WT155hh, Win-Optical Technology Co., Ltd. Available online: http://www.win-optical.com.tw/products_cf.html (accessed on 31 May 2018).

- Busfield, J.; Thomas, A.; Yamaguchi, K. Electrical and mechanical behavior of filled rubber. III. Dynamic loading and the rate of recovery. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 1649–1661. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Busfield, J.; Thomas, A. Electrical and mechanical behavior of filled elastomers. I. The effect of strain. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 2079–2089. [Google Scholar] [CrossRef]

- Shimamura, H.; Nakamura, T. Mechanical properties degradation of polyimide films irradiated by atomic oxygen. Polym. Degrad. Stab. 2009, 94, 1389–1396. [Google Scholar] [CrossRef]

- Crawford, G. Flexible Flat Panel Displays; Wiley: New York, NY, USA, 2005. [Google Scholar]

- Kim, N.; Graham, S. Development of highly flexible and ultra-low permeation rate thin-film barrier structure for organic electronics. Thin Solid Films 2013, 547, 57–62. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, D.-P.; Lu, H.-I.; Lin, C.-K. Conductive Characteristics of Indium Tin Oxide Thin Film on Polymeric Substrate under Long-Term Static Deformation. Coatings 2018, 8, 212. https://doi.org/10.3390/coatings8060212

Tran D-P, Lu H-I, Lin C-K. Conductive Characteristics of Indium Tin Oxide Thin Film on Polymeric Substrate under Long-Term Static Deformation. Coatings. 2018; 8(6):212. https://doi.org/10.3390/coatings8060212

Chicago/Turabian StyleTran, Dinh-Phuc, Hung-I Lu, and Chih-Kuang Lin. 2018. "Conductive Characteristics of Indium Tin Oxide Thin Film on Polymeric Substrate under Long-Term Static Deformation" Coatings 8, no. 6: 212. https://doi.org/10.3390/coatings8060212

APA StyleTran, D.-P., Lu, H.-I., & Lin, C.-K. (2018). Conductive Characteristics of Indium Tin Oxide Thin Film on Polymeric Substrate under Long-Term Static Deformation. Coatings, 8(6), 212. https://doi.org/10.3390/coatings8060212