Fabrication of Hydrophobic ZnO/PMHS Coatings on Bamboo Surfaces: The Synergistic Effect of ZnO and PMHS on Anti-Mildew Properties

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

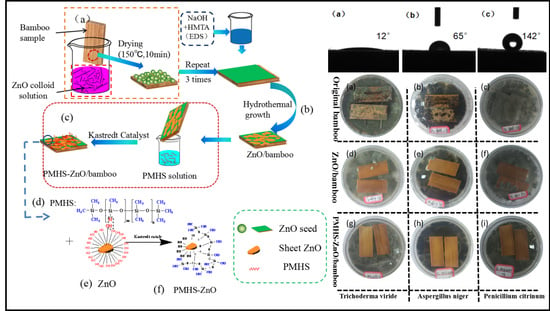

2.2. Preparation of ZnO-Coated Bamboo Timber

2.3. Surface Modification of ZnO/Bamboo

2.4. Characterization

2.5. Test of Anti-Mildew Properties

3. Results and Discussion

3.1. Morphology of ZnO Coatings on Bamboo Surface

3.2. Chemical Structure of the Bamboo Surface

3.3. Hydrophobicity of Modified Bamboo Surfaces

3.4. Schematic Representation of Surface Modification

3.5. Anti-Mildew Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Scurlock, J.M.O.; Dayton, D.C.; Hames, B. Bamboo: An overlooked biomass resource? Biomass Bioenergy 2000, 19, 229–244. [Google Scholar] [CrossRef]

- Ma, W.S.A.; Wang, M.J.J.; Chou, F.S. Evaluating the mechanical injury problem in the wood-bamboo furniture manufacturing industry. Int. J. Ind. Ergon. 1991, 7, 347–355. [Google Scholar] [CrossRef]

- Dang, M.N.; Grillet, A.C.; Diep, T.M.H.; Do, T.V.V.; Chi, N.H.T.; Woloszyn, M. Hygric and thermal insulation properties of building materials based on bamboo fibers. In Proceedings of the 4th Congrès International de Géotechnique-Ouvrages-Structures, Ho Chi Minh City, Vietnam, 26–27 October 2017; pp. 508–522. [Google Scholar]

- Chung, K.F.; Yu, W.K. Mechanical properties of structural bamboo for bamboo scaffoldings. Eng. Struct. 2002, 24, 429–442. [Google Scholar] [CrossRef]

- Wang, Y.; Ge, W.; Tian, G.; Zheng, L.; Xiao, Q.F.; Zhou, X.; Han, X.; Gao, X. Structures of bamboo fiber for textiles. Text. Res. J. 2010, 80, 334–343. [Google Scholar] [CrossRef]

- Sun, F.; Bao, B.; Ma, L.; Chen, A.; Duan, X. Mould-resistance of bamboo treated with the compound of chitosan-copper complex and organic fungicides. J. Wood Sci. 2012, 58, 51–56. [Google Scholar] [CrossRef]

- Yu, H.; Du, C.; Liu, H.; Wei, J.; Zhou, Z. Advance in anti-mildew research of bamboo. J. Bamboo Res. 2016, 35, 46–51. (In Chinese) [Google Scholar]

- Liu, Y.D. Bamboo timber mildew and anti-mold technology. Adv. Eng. Forum 2012, 4, 139–144. [Google Scholar] [CrossRef]

- Kang, F.; Cheng, Y.; Huang, Q.; Wei, Y.; Zhang, R.; Yang, F. Advances in application of microwave technology to pest quarantine. Plant Prot. 2009, 35, 36–39. (In Chinese) [Google Scholar]

- Cheng, D.; Jiang, S.; Zhang, Q. Mould resistance of moso bamboo treated by two step heat treatment with different aqueous solutions. Eur. J. Wood Wood Prod. 2013, 71, 143–145. [Google Scholar] [CrossRef]

- Ullah, M.A. Biotreatment of Pentachlorophenol Using Wood Rotting Fungi. Ph.D. Thesis, The University of Westminster, London, UK, 2000. [Google Scholar]

- Bolin, C.A.; Smith, S. Life cycle assessment of ACQ-treated lumber with comparison to wood plastic composite decking. J. Clean. Prod. 2011, 19, 620–629. [Google Scholar] [CrossRef]

- Janin, A.; Coudert, L.; Blais, J.F.; Mercier, G.; Cooper, P.; Gastonguay, L.; Morris, P. Design and performance of a pilot-scale equipment for CCA-treated wood remediation. Sep. Purif. Technol. 2012, 85, 90–95. [Google Scholar] [CrossRef]

- Peper, M.; Ertl, M.; Gerhard, I. Long-term exposure to wood-preserving chemicals containing pentachlorophenol and lindane is related to neurobehavioral performance in women. Am. J. Ind. Med. 1999, 35, 632–641. [Google Scholar] [CrossRef]

- Zheng, R.-Z.; Zhang, Q.-H.; He, Y.-X.; Zhang, Q.; Yang, L.-S.; Zhang, Z.-H.; Zhang, X.-J.; Hu, J.-T.; Huang, F. Historical long-term exposure to pentachlorophenol causing risk of cancer-a community study. Asian Pac. J. Cancer Prev. 2013, 14, 811–816. [Google Scholar] [CrossRef] [PubMed]

- Mercer, T.G.; Frostick, L.E. Evaluating the potential for environmental pollution from chromated copper arsenate (CCA)-treated wood waste: A new mass balance approach. J. Hazard. Mater. 2014, 276, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Laohhasurayotin, K.; Pookboonmee, S. Multifunctional properties of Ag/TiO2/bamboo charcoal composites: Preparation and examination through several characterization methods. Appl. Surf. Sci. 2013, 282, 236–244. [Google Scholar] [CrossRef]

- Ren, D.; Li, J.; Xu, J.; Wu, Z.; Bao, Y.; Li, N.; Chen, Y. Efficient antifungal and flame-retardant properties of ZnO-TiO2-layered double-nanostructures coated on bamboo substrate. Coatings 2018, 8, 341. [Google Scholar] [CrossRef]

- Sun, F.B.; Yu, Y.; Jiang, Z.H.; Ren, H.Q.; Wang, G.; Liu, X.E. Nano TiO2 modification of bamboo and its antibacterial and mildew resistance performance. Spectrosc. Spectr. Anal. 2010, 30, 1056–1060. (In Chinese) [Google Scholar]

- Teli, M.D.; Sheikh, J. Modified bamboo rayon-copper nanoparticle composites as antibacterial textiles. Int. J. Biol. Macromol. 2013, 61, 302–307. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Li, J.; Zhuang, X.; Pan, X.; Yu, H.; Sun, F.; Song, J.; Jin, C.; Jiang, Y. Improved mould resistance and antibacterial activity of bamboo coated with ZnO/graphene. R. Soc. Open Sci. 2018, 5, 180173. [Google Scholar] [CrossRef] [PubMed]

- Devi, R.R.; Gogoi, K.; Konwar, B.K.; Maji, T.K. Synergistic effect of nano TiO2 and nanoclay on mechanical, flame retardancy, UV stability, and antibacterial properties of wood polymer composites. Polym. Bull. 2013, 70, 1397–1413. [Google Scholar] [CrossRef]

- Xie, G.; Zhou, Y.; Cao, Y.; Li, L. Anti-mildew properties of copper cured heat-treated wood. Bioresources 2018, 13, 5643–5655. [Google Scholar]

- Li, J.; Wu, Z.; Bao, Y.; Chen, Y.; Huang, C.; Li, N.; He, S.; Chen, Z. Wet chemical synthesis of ZnO nanocoating on the surface of bamboo timber with improved mould-resistance. J. Saudi Chem. Soc. 2016, 21, 920–928. [Google Scholar] [CrossRef]

- Khan, M.F.; Hameedullah, M.; Ansari, A.H.; Ahmad, E.; Lohani, M.B.; Khan, R.H.; Alam, M.M.; Khan, W.; Husain, F.M.; Ahmad, I. Flower-shapedZnO nanoparticles synthesized by a novel approach at near-room temperatures with antibacterial and antifungal properties. Int. J. Nanomed. 2014, 9, 853–864. [Google Scholar] [CrossRef] [PubMed]

- Godbole, V.S.; Lakkad, S.C. Effect of water absorption on the mechanical properties of bamboo. J. Mater. Sci. Lett. 1986, 5, 303–304. [Google Scholar] [CrossRef]

- Wang, C.; Piao, C.; Lucas, C. Synthesis and characterization of superhydrophobic wood surfaces. J. Appl. Polym. Sci. 2011, 119, 1667–1672. [Google Scholar] [CrossRef]

- Wang, F.; Li, S.; Wang, L. Fabrication of artificial super-hydrophobic lotus-leaf-like bamboo surfaces through soft lithography. Colloids Surf. A Physicochem. Eng. Asp. 2017, 513, 389–395. [Google Scholar] [CrossRef]

- Jin, C.; Li, J.; Han, S.; Wang, J.; Sun, Q. A durable, superhydrophobic, superoleophobic and corrosion-resistant coating with rose-like ZnO nanoflowers on a bamboo surface. Appl. Surf. Sci. 2014, 320, 322–327. [Google Scholar] [CrossRef]

- Fadeeva, E.; Truong, V.K.; Stiesch, M.; Chichkov, B.N.; Crawford, R.J.; Wang, J.; Ivanova, E.P. Bacterial retention on superhydrophobic titanium surfaces fabricated by femtosecond laser ablation. Langmuir 2011, 27, 3012–3019. [Google Scholar] [CrossRef] [PubMed]

- Tang, P.; Zhang, W.; Wang, Y.; Zhang, B.; Wang, H.; Lin, C.; Zhang, L. Effect of superhydrophobic surface of titanium onstaphylococcus aureusadhesion. J. Nanomater. 2011, 20, 3385. [Google Scholar] [CrossRef]

- Shen, Y.; Wu, Y.; Shen, Z.; Chen, H. Fabrication of self-healing superhydrophobic surfaces from water-soluble polymer suspensions free of inorganic particles through polymer thermal reconstruction. Coatings 2018, 8, 144. [Google Scholar] [CrossRef]

- Lin, W.; Huang, Y.; Li, J.; Liu, Z.; Yang, W.; Li, R.; Chen, H.; Zhang, X. Preparation of highly hydrophobic and anti-fouling wood using poly (methylhydrogen) siloxane. Cellulose 2018, 25, 7341–7353. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Yu, J.W.; Lin, W.S.; Yang, W.B.; Li, R.; Chen, H.X.; Zhang, X.X. Facile method for the hydrophobic modification of filter paper for applications in water-oil separation. Surf. Coat. Technol. 2018, 352, 313–319. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Lin, H.; Hu, X.Y.; Chen, C.X.; Xie, X.Z.; Yang, W.B.; Zhang, X.X.; Chen, H.X. Refractive-tunable and hydrophobic antireflective coatings by PMHS-modification assisted sol-gel method. Mater. Lett. 2017, 186, 123–126. [Google Scholar] [CrossRef]

- Jin, C.; Li, J.; Han, S.; Wang, J.; Yao, Q.; Sun, Q. Silver mirror reaction as an approach to construct a durable, robust superhydrophobic surface of bamboo timber with high conductivity. J. Alloy Compd. 2015, 635, 300–306. [Google Scholar] [CrossRef]

- GB/T 18261-2013 Test Method for Anti-Mildew Agents in Controlling Wood Mould and Stain Fungi; Standardization Administration of China: Beijing, China, 2013; (In Chinese).

- Meng, F.D.; Yu, Y.L.; Zhang, Y.M.; Yu, W.J.; Gao, J.M. Surface chemical composition analysis of heat-treated bamboo. Appl. Surf. Sci. 2016, 371, 383–390. [Google Scholar] [CrossRef]

- Vinogradov, I.; Lunk, A. Film deposition in the dielectric barrier discharge at atmospheric pressure in He/O2/HMDSO and He/N2O/HMDSO mixtures. Plasma Proc. Polym. 2010, 6, 514–518. [Google Scholar] [CrossRef]

- Jie, C.; Zhang, J.H.; Li, M.A.; Lu, H.D. Study of crystallinity performance of pretreated bamboo fibers based on X-ray diffraction and NMR. Spectrosc. Spectr. Anal. 2017, 37, 256–261. (In Chinese) [Google Scholar]

| Grading | Description |

|---|---|

| 0 | No hypha or mold |

| 1 | The surface infection area of the sample is less than ¼ |

| 2 | The surface infection area of the sample is between ¼ and ½ |

| 3 | The surface infection area of the sample is between ½ and ¾ |

| 4 | The surface infection area of the sample is greater than ¾ |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Ma, Y.; Lin, H.; Zheng, Q.; Zhang, X.; Yang, W.; Li, R. Fabrication of Hydrophobic ZnO/PMHS Coatings on Bamboo Surfaces: The Synergistic Effect of ZnO and PMHS on Anti-Mildew Properties. Coatings 2019, 9, 15. https://doi.org/10.3390/coatings9010015

Chen J, Ma Y, Lin H, Zheng Q, Zhang X, Yang W, Li R. Fabrication of Hydrophobic ZnO/PMHS Coatings on Bamboo Surfaces: The Synergistic Effect of ZnO and PMHS on Anti-Mildew Properties. Coatings. 2019; 9(1):15. https://doi.org/10.3390/coatings9010015

Chicago/Turabian StyleChen, Jingbing, Yunyun Ma, Huiping Lin, Qingzhu Zheng, Xinxiang Zhang, Wenbin Yang, and Ran Li. 2019. "Fabrication of Hydrophobic ZnO/PMHS Coatings on Bamboo Surfaces: The Synergistic Effect of ZnO and PMHS on Anti-Mildew Properties" Coatings 9, no. 1: 15. https://doi.org/10.3390/coatings9010015