Plasma Pre-treatments to Improve the Weather Resistance of Polyurethane Coatings on Black Spruce Wood

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design and Statstical Analysis of Data

2.2. Effects of Plasma Treatment on Penetration of Coatings into Black Spruce Wood

2.3. Effects of Plasma Treatment on Adhesion of Coatings to Black Spruce Wood

2.4. Effects of Plasma Treatment on Weather Resistance of Coatings on Black Spruce Wood

2.5. Effects of Plasma Treatment on the Microstructure and Surface Wettability of Black Spruce Wood

3. Results

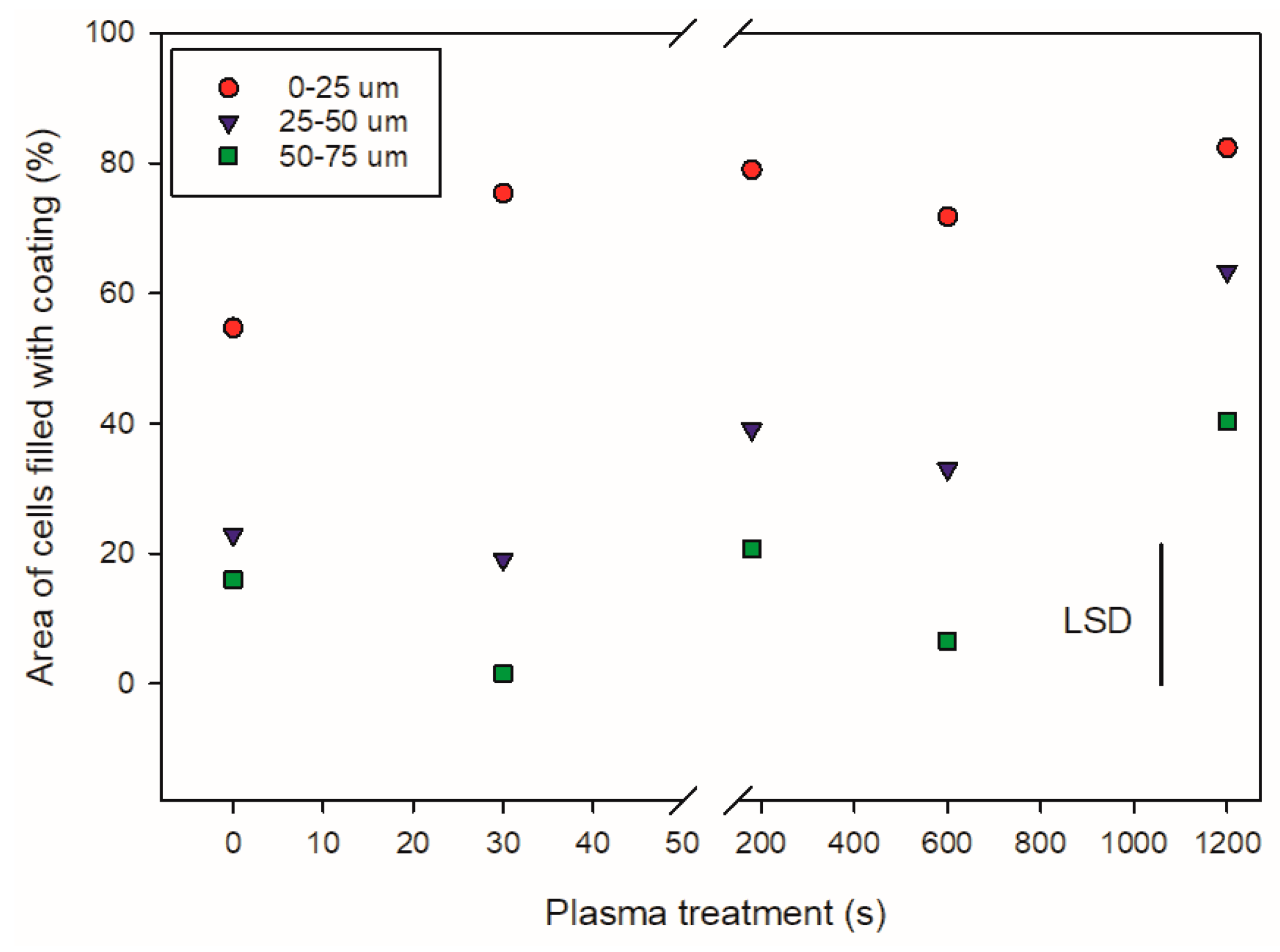

3.1. Coating Penetration

3.2. Coating Adhesion

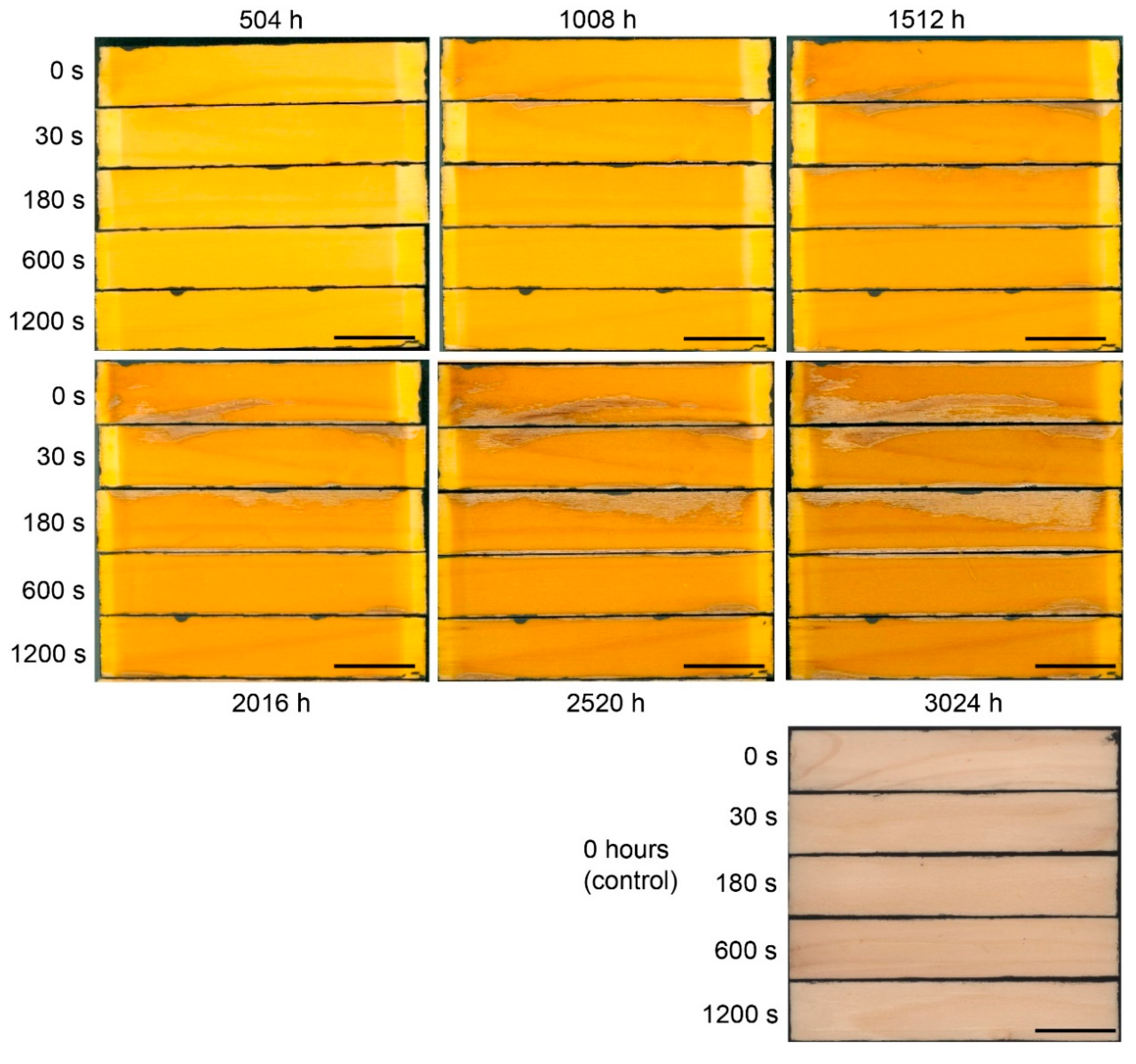

3.3. Performance of Coatings Exposed to Artificial Accelerated Weathering

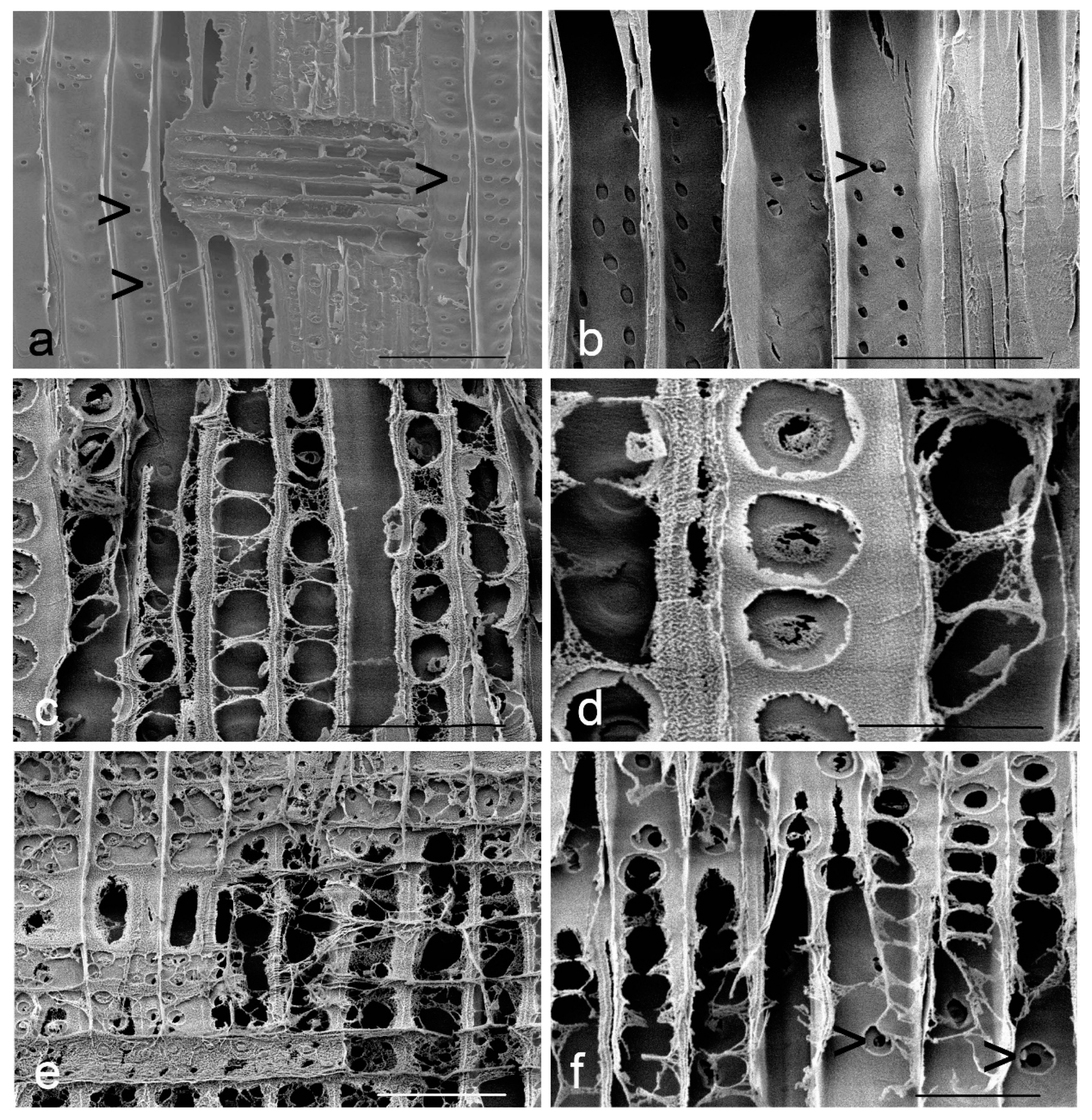

3.4. Microstructure and Surface Wettability of Black Spruce Wood

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Boenig, H.V. Plasma Science and Technology; Cornell University Press: New York, NY, USA, 1982. [Google Scholar]

- Mott-Smith, H.M. History of plasmas. Nature 1971, 233, 219. [Google Scholar] [CrossRef] [PubMed]

- Kaplan, S.L.; Rose, P.W. Plasma surface treatment of plastics to enhance adhesion. Int. J. Adhes. Adhes. 1991, 11, 109–113. [Google Scholar] [CrossRef]

- Suchentrunk, R.; Fuesser, H.J.; Staudigl, G.; Jonke, D.; Meyer, M. Plasma surface engineering—Innovative processes and coating systems for high-quality products. Surf. Coat. Technol. 1999, 112, 351–357. [Google Scholar] [CrossRef]

- Stecher, A. Pretreating with plasma. Industrial + Specialty Printing, 18–20 May/June 2013.

- Uehara, T.; Jodai, S. Gluing of wood by corona-treatment. Mokuzai Gakkaishi 1987, 33, 777–784. (In Japanese) [Google Scholar]

- Rehn, P.; Wolkenhauer, A.; Bente, M.; Förster, S.; Viöl, W. Wood surface modification in dielectric barrier discharges at atmospheric pressure. Surf. Coat. Technol. 2003, 174, 515–518. [Google Scholar] [CrossRef]

- Wolkenhauer, A.; Avramidis, G.; Hauswald, E.; Militz, H.; Viöl, W. Plasma treatment of wood-plastic composites to enhance their adhesion properties. J. Adhes. Sci. Technol. 2008, 22, 2025–2037. [Google Scholar] [CrossRef]

- Wolkenhauer, A.; Militz, H.; Viöl, W. Increased PVA–glue adhesion on particle board and fibreboard by plasma treatment. Holz Roh Werkst. 2008, 66, 143–145. [Google Scholar] [CrossRef]

- Viöl, W.; Avramidis, G.; Militz, H. Plasma treatment of wood. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Rowell, R.M., Ed.; Taylor & Francis: Boca Raton, FL, USA, 2012; pp. 627–658. [Google Scholar]

- Riedl, B.; Angel, C.; Prégent, J.; Blanchet, P.; Stafford, L. Effect of wood surface modification by atmospheric-pressure plasma on waterborne coating adhesion. BioResources 2014, 9, 4908–4923. [Google Scholar] [CrossRef]

- Busnel, F.; Blanchard, B.; Prégent, J.; Stafford, L.; Riedl, B.; Blanchet, P.; Sarkissian, A. Modification of sugar maple (Acer saccharum) and black spruce (Picea mariana) wood surfaces in a dielectric barrier discharge (DBD) at atmospheric pressure. J. Adhes. Sci. Technol. 2010, 24, 1401–1413. [Google Scholar] [CrossRef]

- Blanchard, V.; Blanchet, P.; Riedl, B. Surface energy modification by radiofrequency inductive and capacitive plasma at low pressures on sugar maple: An exploratory study. Wood Fiber Sci. 2009, 41, 245–254. [Google Scholar]

- Back, E.L.; Danielson, S. Oxidative activation of wood and paper surfaces for bonding and for paint adhesion. Nordic Pulp Paper Res. J. 1987, 2, 53–62. [Google Scholar]

- Lukowsky, D.; Hora, G. Pretreatments of wood to enhance the performance of outdoor coatings. Macromol. Symp. 2002, 187, 77–85. [Google Scholar] [CrossRef]

- Acda, M.N.; Devera, E.E.; Cabangon, R.J.; Ramos, H.J. Effect of plasma on adhesion properties of wood. Int. J. Adhes. Adhes. 2012, 32, 70–75. [Google Scholar] [CrossRef]

- Cho, D.L.; Sjöblom, E. Plasma treatment of wood. J. Appl. Polym. Sci. Appl. Polym. Symp. 1990, 46, 461–472. [Google Scholar] [CrossRef]

- Podgorski, L.; Roux, M.L. Wood modification to improve the durability of coatings. Surf. Coat. Int. 1999, 82, 590–596. [Google Scholar] [CrossRef]

- Podgorski, L.; Chevet, B.; Onic, L.; Merlin, A. Modification of wood wettability by plasma and corona treatments. Int. J. Adhes. Adhes. 2000, 20, 103–111. [Google Scholar] [CrossRef]

- Blanchard, V.; Stirling, R. Plasma pre-treatment enhances field performance of exterior wood coatings. Wood Fiber Sci. 2013, 45, 228–231. [Google Scholar]

- Rijckaert, V.; Stevens, M.; Van Acker, J. Effect of some formulation parameters on the penetration and adhesion of water-borne primers into wood. Eur. J. Wood Wood Prod. 2001, 59, 344–350. [Google Scholar] [CrossRef]

- Van den Bulcke, J.; Van Acker, J.; Stevens, M. Experimental and theoretical behavior of exterior wood coatings subjected to artificial weathering. J. Coat. Technol. Res. 2008, 5, 221–231. [Google Scholar] [CrossRef]

- Meijer, M.D. Review on the durability of exterior wood coatings with reduced VOC-content. Prog. Org. Coat. 2001, 43, 217–225. [Google Scholar] [CrossRef]

- Evans, P.D.; Haase, J.G.; Seman, A.; Shakri, B.M.; Kiguchi, M. The search for durable exterior clear coatings for wood. Coatings 2015, 5, 830. [Google Scholar] [CrossRef]

- Ashton, H.E. Clear finishes for exterior wood, Field exposure tests. J. Paint Technol. 1967, 39, 212–224. [Google Scholar]

- Miniutti, V.P. Microscopic Observations of Ultraviolet Irradiated and Weathered Softwood Surfaces and Clear Coatings; United States Department of Agriculture, Forest Service: Madison, WI, USA, 1967; p. 33.

- Lehringer, C.; Richter, K.; Schwarze, F.W.M.R.; Militz, H. A review on promising approaches for liquid permeability improvement in softwoods. Wood Fiber Sci. 2009, 41, 373–385. [Google Scholar]

- Evans, P.D.; Vollmer, S.; Kim, J.D.W.; Chan, G.; Kraushaar Gibson, S. Improving the performance of clear coatings on wood through the aggregation of marginal gains. Coatings 2016, 6, 66. [Google Scholar] [CrossRef]

- Williams, L.J.; Hervé, A. Fisher’s least significant difference (LSD) test. In Encyclopedia of Research Design; Salkind, N., Ed.; SAGE: Thousand Oaks, CA, USA, 2010; p. 6. [Google Scholar]

- Long, T.M.; Prakash, S.; Shannon, M.A.; Moore, J.S. Water-vapor plasma-based surface activation for trichlorosilane modification of PMMA. Langmuir 2006, 22, 4104–4109. [Google Scholar] [CrossRef] [PubMed]

- ISO 4624:2002 Paints and Varnishes—Pull-off Test for Adhesion; ISO: Geneva, Switzerland, 2002.

- Kiguchi, M.; Kataoka, Y.; Suzuki, M.; Imamura, Y. Progress towards the service life prediction of coatings for exterior wood by weathering test trials. In Service Life Prediction: Challenging the Status Quo; Martin, J.W., Ryntz, R.A., Dickie, R.A., Eds.; Federation of Societies for Coatings Technology: Bluebell, PA, USA, 2005; pp. 123–134. [Google Scholar]

- Podgorski, L.; Arnold, M.; Hora, G. A reliable artificial weathering test for wood coatings. Coat. World 2003, 5, 39–48. [Google Scholar]

- Podgorski, L.; Bousta, C.; Schambourg, F.; Maguin, J.; Chevet, B. Surface modification of wood by plasma polymerization. Pigment Resin Technol. 2001, 31, 33–40. [Google Scholar] [CrossRef]

- Singh, A.P.; Gallagher, S.S.; Schmitt, U.; Daeson, B.S.; Kim, Y.S. Ponding of radiata pine (Pinus radiata). 2. The effect of ponding on coating penetration into wood. In Proceedings of the International Research Group on Wood Preservation Meeting, Maastricht, The Netherlands, 14–19 June 1998; p. 8. [Google Scholar]

- Dunleavy, J.A. The use of spruce for transmission poles: Current research at IIRS. Technol. Irel. 1973, 5, 9–17. [Google Scholar]

- Nussbaum, R.M.; Sutcliffe, E.J.; Hellgren, A. Microautoradiographic studies of the penetration of alkyd, alkyd emulsion and linseed oil coatings into wood. J. Coat. Technol. 1998, 70, 49–57. [Google Scholar] [CrossRef]

- Meijer, M.D. A review of interfacial aspects in wood coatings: Wetting, surface energy, substrate penetration and adhesion. COST E18 Final Seminar; European Cooperation in Science and Technology: Brussels, Belgium, 2005. [Google Scholar]

| Board Number | Number of Growth Rings/cm | Density (kg m−3) * | |

|---|---|---|---|

| Minimum | Maximum | ||

| 1 | 15 | 17 | 471 (13.3) |

| 2 | 25 | 28 | 494 (0.6) |

| 3 | 9 | 10 | 438 (2.0) |

| 4 | 22 | 24 | 505 (16.5) |

| 5 | 8 | 11 | 415 (1.8) |

| 6 | 11 | 20 | 453 (5.8) |

| 7 | 7 | 11 | 464 (6.9) |

| 8 | 7 | 9 | 417 (16.0) |

| 9 | 8 | 10 | 422 (15.4) |

| 10 | 6 | 8 | 431 (15.6) |

| 11 | 8 | 9 | 413 (6.5) |

| 12 | 8 | 10 | 418 (26.2) |

| 13 | 7 | 8 | 439 (17.6) |

| Name | Solvent | Viscosity a (P) | Solids Content b (%) |

|---|---|---|---|

| Minwax® Helmsman® Spar Urethane | White spirit | 1.1 | 52.2 |

| Varathane® Diamond™ Spar Urethane | Water | 0.7 | 28.1 |

| Treatment | Adhesion Strength (MPa) | Percentage Wood on Test Cylinders | ||

|---|---|---|---|---|

| W/B Polyurethane | S/B Polyurethane | W/B Polyurethane | S/B Polyurethane | |

| Untreated | 7.2 a | 3.4 b | 73.1 a | 45.5 b |

| Plasma-treated * | 6.7 a | 3.5 b | 66.9 a | 38.7 b |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haase, J.G.; Leung, L.H.; Evans, P.D. Plasma Pre-treatments to Improve the Weather Resistance of Polyurethane Coatings on Black Spruce Wood. Coatings 2019, 9, 8. https://doi.org/10.3390/coatings9010008

Haase JG, Leung LH, Evans PD. Plasma Pre-treatments to Improve the Weather Resistance of Polyurethane Coatings on Black Spruce Wood. Coatings. 2019; 9(1):8. https://doi.org/10.3390/coatings9010008

Chicago/Turabian StyleHaase, Jonathan G., Lukie H. Leung, and Philip D. Evans. 2019. "Plasma Pre-treatments to Improve the Weather Resistance of Polyurethane Coatings on Black Spruce Wood" Coatings 9, no. 1: 8. https://doi.org/10.3390/coatings9010008