Unevenness of Thin Liquid Layer by Contact Angle Variation of Substrate during Coating Process

Abstract

:1. Introduction

2. Numerical Simulation

2.1. Volume of Fluid

2.2. Simulation Model and Conditions

3. Results

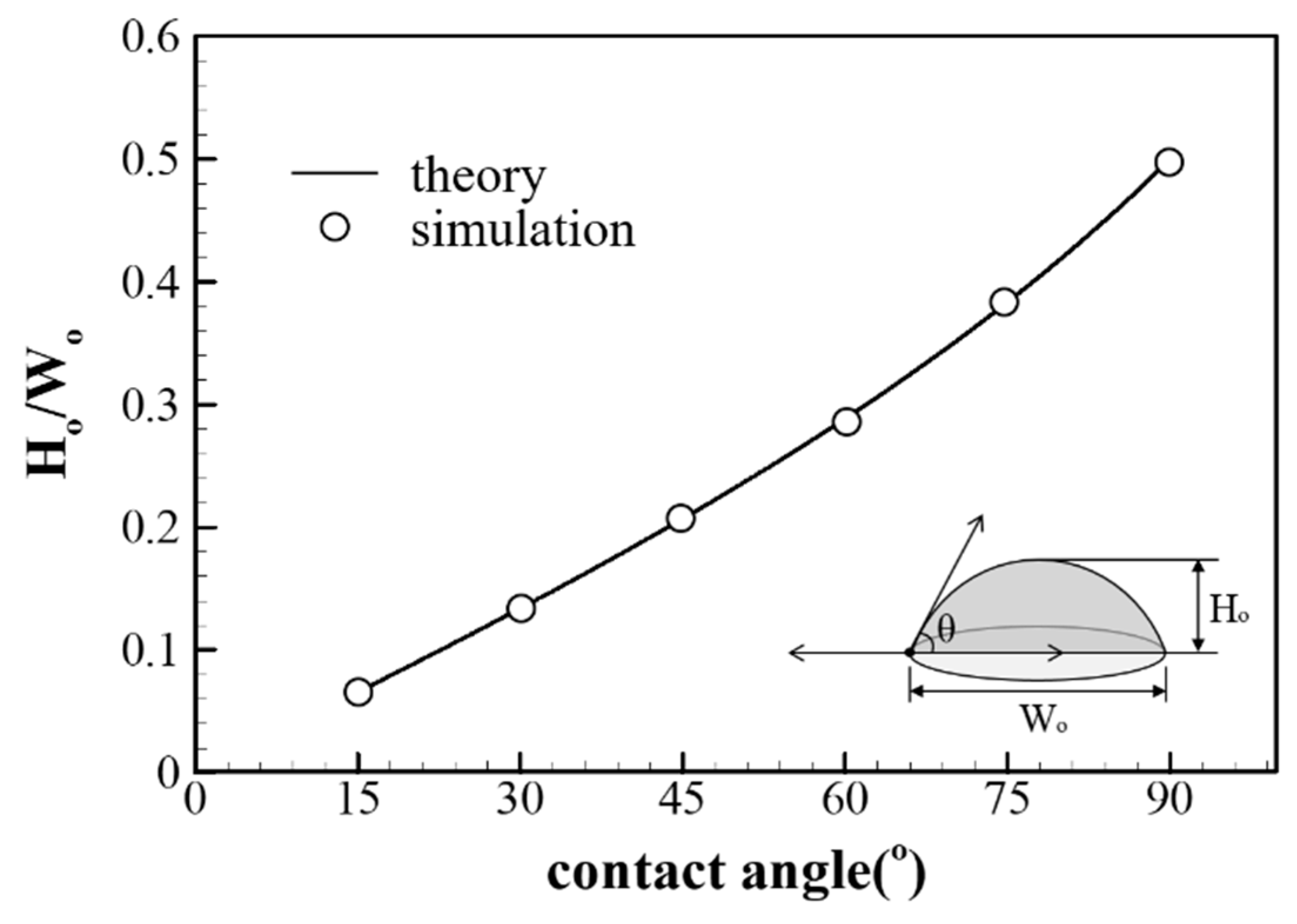

3.1. Validation of the Numerical Model

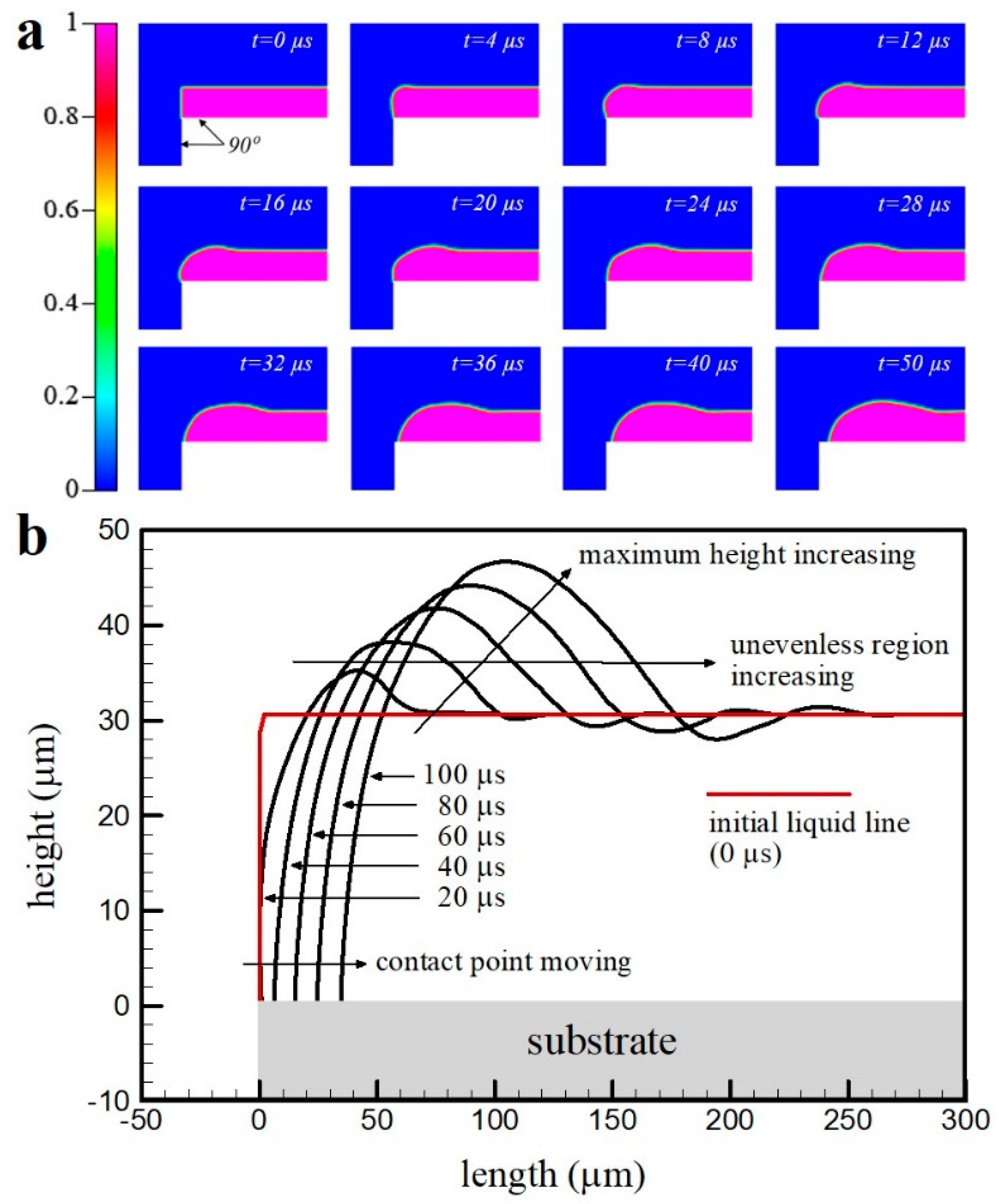

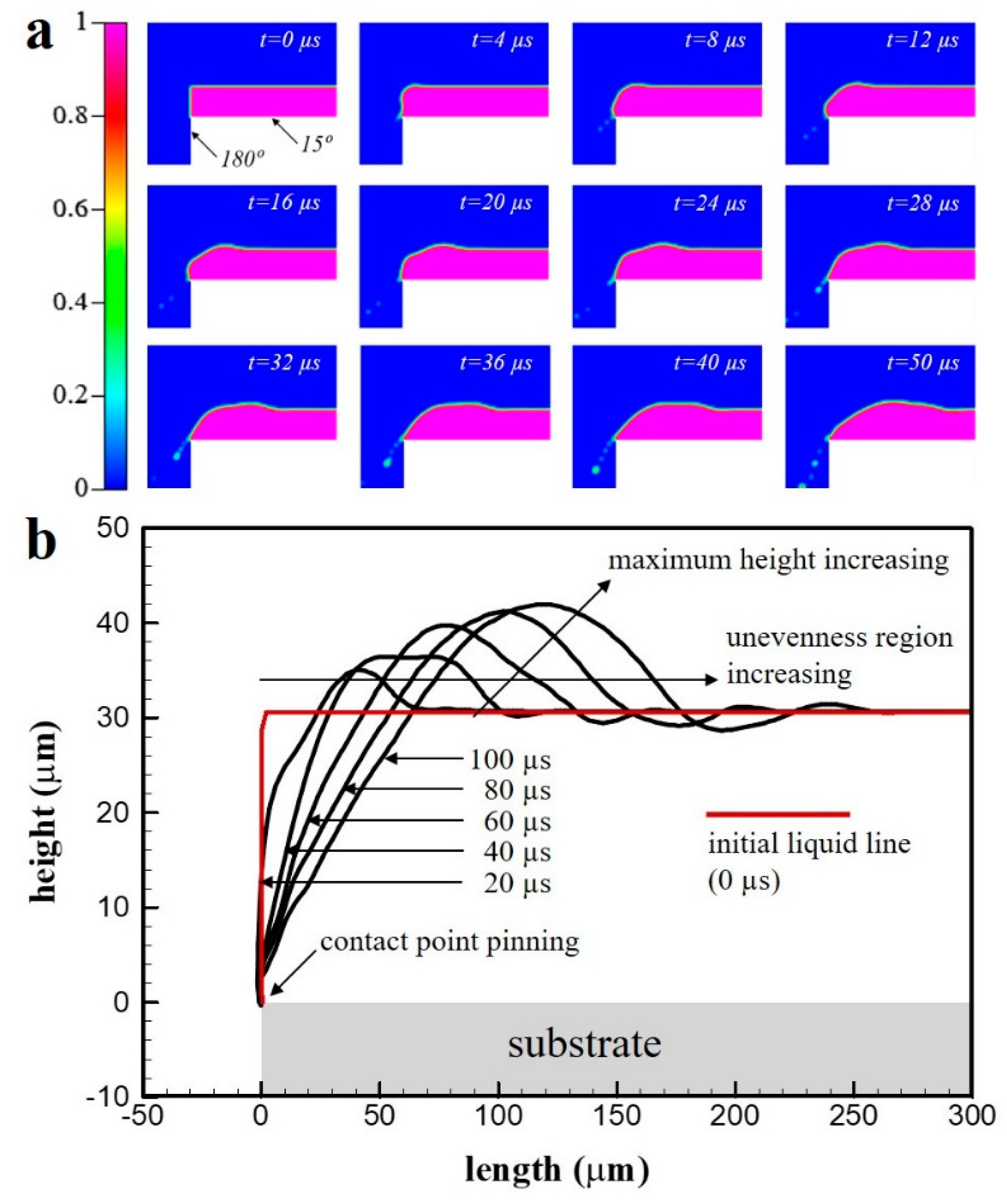

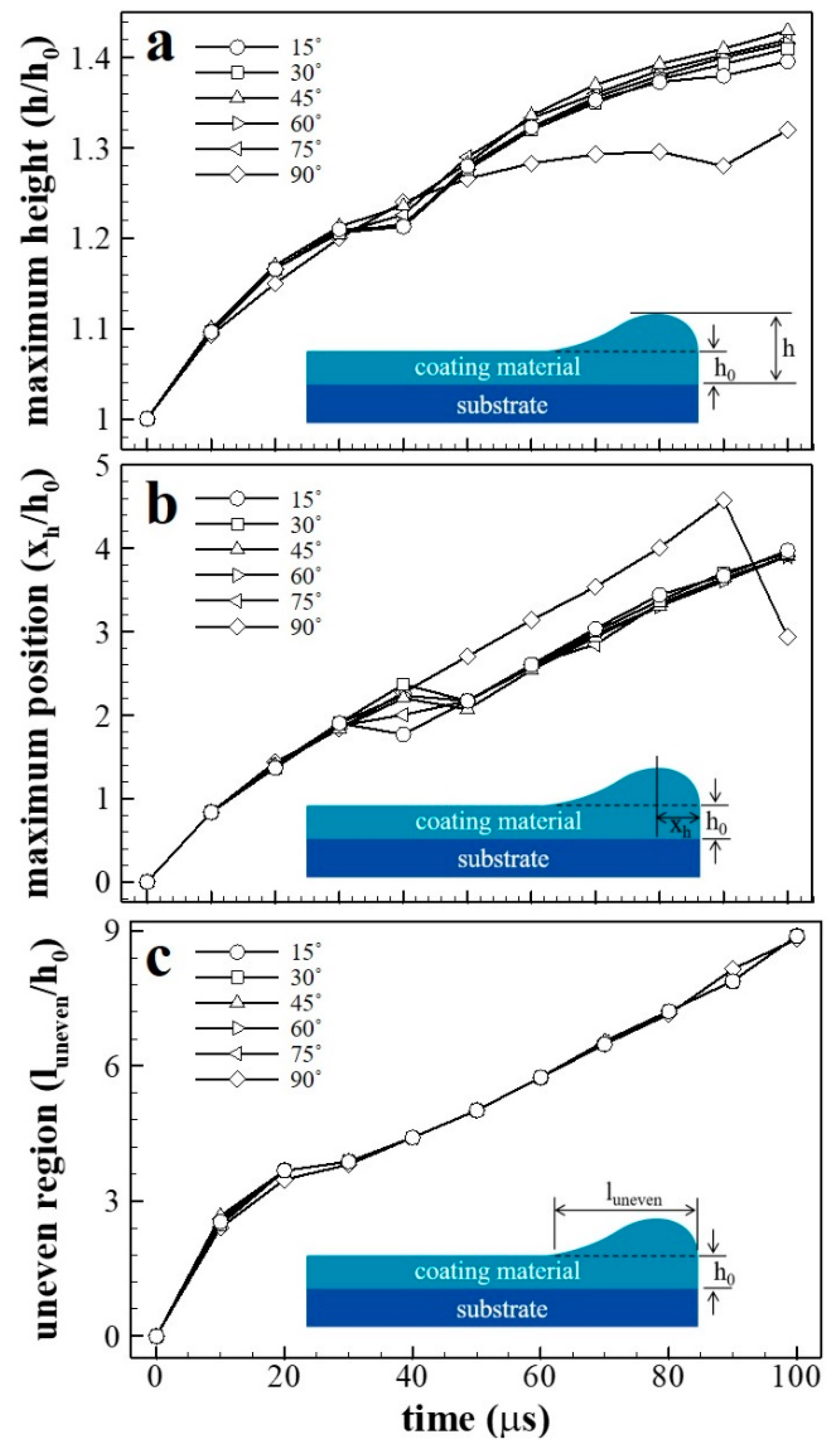

3.2. Same Wetting Condition

3.3. Different Wetting Condition

4. Conclusions

- When the contact angle of the substrate surface was equal to that of the sides, the length and height of the uneven region increased with the increase in the contact angle and passage of time. When the substrate contact angle ranged from 15° to 75°, a pinning effect was induced, with fixed parallel contact lines of the droplets on the substrate edge corner portion, and the coating fluid covered the sides of the substrate. Consequently, the substrate sides were also coated.

- When the substrate contact angle was 90°, the substrate edge surface was not coated, because the applied fluid tended to reduce the contact area with the substrate. Moreover, the surface shape changed while the contact line at the corner portion was not fixed, as the contact angle between the coating fluid and the substrate was high. Because of this, the coating fluid on the substrate in the absence of the pinning effect experienced more severe unevenness than in its presence.

- When the contact angles of the substrate surface and sides were different, the formation of satellite droplets and the loss of application solution were observed in all the analysis cases. The satellite droplets could have led to problems in the coating process. They formed as they escaped from the cohesiveness of the coating fluid due to the difference in the fluid inertia, which created energy equilibrium, and the surface energy of the substrate side (non-wetting conditions).

- When the contact angles ranged from 15° to 75°, the pinning effect was generated at the edge corner portion, similar to that observed when the contact angle of the substrate contact surface was equal to that of the sides. However, the results were promising in cases where the substrate sides were not covered because of their high surface contact angle. Therefore, to reduce surface unevenness, it is necessary to actively control not only the wetting of the substrate surface but also of the side surface. The sides of the substrate must have a contact angle greater than 90°, and the substrate surface must have a surface contact angle lower than 90°.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Cui, H.; Zayat, M.; Parejo, P.G.; Levy, D. Highly efficient inorganic transparent UV-protective thin-film coating by low temperature sol-gel procedure for application on heat-sensitive substrates. Adv. Mater. 2008, 20, 65–68. [Google Scholar] [CrossRef]

- Yuan, Y.; Giri, G.; Ayzner, A.L.; Zoombelt, A.P.; Mannsfeld, S.C.; Chen, J.; Nordlund, D.; Toney, M.F.; Hunag, J.; Bao, Z. Ultra-high mobility transparent organic thin film transistors grown by an off-centre spin-coating method. Nat. Commun. 2014, 5, 3005. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Galeano, B.; Korff, E.; Nicholson, W.L. Inactivation of vegetative cells, but not spores, of Bacillus anthracis, B. cereus, and B. subtilis on stainless steel surfaces coated with an antimicrobial silver- and zinc-containing zeolite. Appl. Environ. Microbiol. 2003, 69, 4329–4331. [Google Scholar] [CrossRef] [PubMed]

- Kendig, M.; Scully, J. Basic aspects of electrochemical impedance application for the life prediction of organic coatings on metals. Corrosion 1990, 46, 22–29. [Google Scholar] [CrossRef]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and economical aspects of current thermal barrier coating systems for gas turbine engines by thermal spray and EBPVD: A review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Pham, V.H.; Cuong, T.V.; Hur, S.H.; Shin, E.W.; Kim, J.S.; Chung, J.S.; Kim, E.J. Fast and simple fabrication of a large transparent chemically-converted graphene film by spray-coating. Carbon 2010, 48, 1945–1951. [Google Scholar] [CrossRef]

- Li, J.; Wu, R.; Jing, Z.; Yan, L.; Zha, F.; Lei, Z. One-step spray-coating process for the fabrication of colorful superhydrophobic coatings with excellent corrosion resistance. Langmuir 2015, 31, 10702–10707. [Google Scholar] [CrossRef] [PubMed]

- Barrows, A.T.; Pearson, A.J.; Kwak, C.K.; Dunbar, A.D.; Buckley, A.R.; Lidzey, D.G. Efficient planar heterojunction mixed-halide perovskite solar cells deposited via spray-deposition. Energy Environ. Sci. 2014, 7, 2944–2950. [Google Scholar] [CrossRef]

- Chen, L.M.; Hong, Z.; Kwan, W.L.; Lu, C.H.; Lai, Y.F.; Lei, B.; Liu, C.P.; Yang, Y. Multi-source/component spray coating for polymer solar cells. ACS Nano 2010, 4, 4744–4752. [Google Scholar] [CrossRef] [PubMed]

- Galagan, Y.; de Vries, I.G.; Langen, A.P.; Andriessen, R.; Verhees, W.J.; Veenstra, S.C.; Kroon, J.M. Technology development for roll-to-roll production of organic photovoltaics. Chem. Eng. Process. 2011, 50, 454–461. [Google Scholar] [CrossRef]

- Lu, Y.; Ganguli, R.; Drewien, C.A.; Anderson, M.T.; Brinker, C.J.; Gong, W.; Guo, Y.; Soyez, H.; Dunn, B.; Huang, M.H.; et al. Continuous formation of supported cubic and hexagonal mesoporous films by sol–gel dip-coating. Nature 1997, 389, 364–368. [Google Scholar] [CrossRef]

- Brinker, C.J.; Frye, G.C.; Hurd, A.J.; Ashley, C.S. Fundamentals of sol-gel dip coating. Thin Solid Films 1991, 201, 97–108. [Google Scholar] [CrossRef]

- Kim, D.J.; Hahn, S.H.; Oh, S.H.; Kim, E.J. Influence of calcination temperature on structural and optical properties of TiO2 thin films prepared by sol–gel dip coating. Mater. Lett. 2002, 57, 355–360. [Google Scholar] [CrossRef]

- Asri, R.I.M.; Harun, W.S.W.; Hassan, M.A.; Ghani, S.A.C.; Buyong, Z. A review of hydroxyapatite-based coating techniques: Sol–gel and electrochemical depositions on biocompatible metals. J. Mech. Behav. Biomed. Mater. 2016, 57, 95–108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dehghanghadikolaei, A.; Ansary, J.; Ghoreishi, R. Sol-gel process applications: A mini-review. Proc. Nat. Res. Soc. 2018, 2, 02008. [Google Scholar] [CrossRef]

- Mehta, P.; Al-Kinani, A.A.; Haj-Ahmad, R.; Arshad, M.S.; Chang, M.W.; Alany, R.G.; Ahmad, Z. Electrically atomised formulations of timolol maleate for direct and on-demand ocular lens coatings. Eur. J. Pharm. Biopharm. 2017, 119, 170–184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sedransk, K.L.; Tenhaeff, W.E.; Gleason, K.K. Grafting CVD of poly(vinyl pyrrolidone) for durable scleral lens coatings. Chem. Vapor Depos. 2010, 16, 23–28. [Google Scholar] [CrossRef]

- Li, B.; Blaschke, H.; Ristau, D. Combined laser calorimetry and photothermal technique for absorption measurement of optical coatings. Appl. Opt. 2006, 45, 5827–5831. [Google Scholar] [CrossRef] [PubMed]

- Malherbe, L.; Mandin, C. VOC emissions during outdoor ship painting and health-risk assessment. Atmos. Environ. 2007, 41, 6322–6330. [Google Scholar] [CrossRef]

- Dik, J.; Janssens, K.; Van Der Snickt, G.; van der Loeff, L.; Rickers, K.; Cotte, M. Visualization of a lost painting by Vincent van Gogh using synchrotron radiation based X-ray fluorescence elemental mapping. Anal. Chem. 2008, 80, 6436–6442. [Google Scholar] [CrossRef] [PubMed]

- Osticioli, I.; Zoppi, A.; Castellucci, E.M. Fluorescence and Raman spectra on painting materials: Reconstruction of spectra with mathematical methods. J. Raman Spectrosc. 2006, 37, 974–980. [Google Scholar] [CrossRef]

- Celebi, U.B.; Vardar, N. Investigation of VOC emissions from indoor and outdoor painting processes in shipyards. Atmos. Environ. 2008, 42, 5685–5695. [Google Scholar] [CrossRef]

- Krebs, F.C.; Fyenbo, J.; Jørgensen, M. Product integration of compact roll-to-roll processed polymer solar cell modules: methods and manufacture using flexographic printing, slot-die coating and rotary screen printing. J. Mater. Chem. 2010, 20, 8994–9001. [Google Scholar] [CrossRef]

- Krebs, F.C. Polymer solar cell modules prepared using roll-to-roll methods: knife-over-edge coating, slot-die coating and screen printing. Sol. Energy Mater. Sol. Cells 2009, 93, 465–475. [Google Scholar] [CrossRef]

- Ahn, S.H.; Guo, L.J. High-speed roll-to-roll nanoimprint lithography on flexible plastic substrates. Adv. Mater. 2008, 20, 2044–2049. [Google Scholar] [CrossRef]

- Sonawane, R.S.; Kale, B.B.; Dongare, M.K. Preparation and photo-catalytic activity of Fe–TiO2 thin films prepared by sol–gel dip coating. Mater. Chem. Phys. 2004, 85, 52–57. [Google Scholar] [CrossRef]

- Smith, S.; Stolle, D. Nonisothermal two-dimensional film casting of a viscous polymer. Polym. Eng. Sci. 2000, 40, 1870–1877. [Google Scholar] [CrossRef]

- Pollentier, I.; Somanchi, A.; Burkeen, F.; Vedula, S. Influence of immersion lithography on wafer edge defectivity. Solid State Technol. 2008, 51, 38–42. [Google Scholar]

- Zhang, X.; Li, B. Calibration optimization of laser-induced deflection signal for measuring absorptance of laser components. Appl. Opt. 2015, 54, 1861–1869. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Lee, K.; Ahn, B.; Xu, J.; Xu, L.; Oh, K.W. A new fabrication process for uniform SU-8 thick photoresist structures by simultaneously removing edge bead and air bubbles. J. Micromech. Microeng. 2011, 21, 125006. [Google Scholar] [CrossRef]

- Park, H.W.; Kim, H.J.; Roh, J.H.; Choi, J.K.; Cha, K.R. Simple and cost-effective method for edge bead removal by using a taping method. J. Korean Phys. Soc. 2018, 73, 1473–1478. [Google Scholar] [CrossRef]

- Uddin, M.A.; Chan, H.P.; Chow, C.K.; Chan, Y.C. Effect of spin coating on the curing rate of epoxy adhesive for the fabrication of a polymer optical waveguide. J. Electron. Mater. 2004, 33, 224–228. [Google Scholar] [CrossRef]

- Sharma, A.; Verheijen, M.A.; Wu, L.; Karwal, S.; Vandalon, V.; Knoops, H.C.; Sundaram, R.S.; Hofmann, J.P.; Kessels, W.M.M.; Bol, A.A. Low-temperature plasma-enhanced atomic layer deposition of 2-D MoS2: large area, thickness control and tuneable morphology. Nanoscale 2018, 10, 8615–8627. [Google Scholar] [CrossRef] [PubMed]

- Ye, Q.; Pulli, K. Numerical and experimental investigation on the spray coating process using a pneumatic atomizer: influences of operating conditions and target geometries. Coatings 2017, 7, 13. [Google Scholar] [CrossRef]

- Joshi, A.; James, S. Molecular dynamics simulation study of cold spray process. J. Manuf. Process. 2018, 33, 136–143. [Google Scholar] [CrossRef]

- de Lamotte, A.; Delafosse, A.; Calvo, S.; Toye, D. Identifying dominant spatial and time characteristics of flow dynamics within free-surface baffled stirred-tanks from CFD simulations. Chem. Eng. Sci. 2018, 192, 128–142. [Google Scholar] [CrossRef]

- Wu, L.; Gong, M.; Wang, J. Development of a DEM–VOF model for the turbulent free-surface flows with particles and its application to stirred mixing system. Ind. Eng. Chem. Res. 2018, 57, 1714–1725. [Google Scholar] [CrossRef]

- Li, L.; Liu, Z.; Cao, M.; Li, B. Large eddy simulation of bubbly flow and slag layer behavior in ladle with discrete phase model (DPM)–Volume of fluid (VOF) coupled model. JOM 2015, 67, 1459–1467. [Google Scholar] [CrossRef]

- Muzaferija, S.; Peri´ c, M. Computation of free-surface flows using the finite-volume method and moving grids. Numer. Heat Transf. Part B 1997, 32, 369–384. [Google Scholar] [CrossRef]

- Laadhari, A.; Székely, G. Fully implicit finite element method for the modeling of free surface flows with surface tension effect. Int. J. Numer. Methods Eng. 2017, 111, 1047–1074. [Google Scholar] [CrossRef]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Hirsch, C. Consistency, stability and error analysis of numerical schemes. In Numerical Computation of Internal and External Flows, 2nd ed.; John Wiley & Sons: Oxford, UK, 2007; pp. 291–292. [Google Scholar]

- Kang, H.W.; Sung, H.J.; Lee, T.M.; Kim, D.S.; Kim, C.J. Liquid transfer between two separating plates for micro-gravure-offset printing. J. Micromech. Microeng. 2008, 19, 015025. [Google Scholar] [CrossRef]

| Case | Contact Angle of Substrate (°) | Contact Angle of Side Wall (°) | Liquid Properties |

|---|---|---|---|

| same_15° | 15 | 15 | ρ = 997 kg/m3 σ = 0.0236 N/m |

| same_30° | 30 | 30 | |

| same_45° | 45 | 45 | |

| same_60° | 60 | 60 | |

| same_75° | 75 | 75 | |

| same_90° | 90 | 90 |

| Case | Contact Angle of Substrate (°) | Contact Angle of Side Wall (°) | Liquid Properties |

|---|---|---|---|

| diff_15° | 15 | 180 | ρ = 997 kg/m3 σ = 0.0236 N/m |

| diff_30° | 30 | 180 | |

| diff_45° | 45 | 180 | |

| diff_60° | 60 | 180 | |

| diff_75° | 75 | 180 | |

| diff_90° | 90 | 180 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, N.K.; Kang, D.H.; Kang, H.W. Unevenness of Thin Liquid Layer by Contact Angle Variation of Substrate during Coating Process. Coatings 2019, 9, 162. https://doi.org/10.3390/coatings9030162

Kim NK, Kang DH, Kang HW. Unevenness of Thin Liquid Layer by Contact Angle Variation of Substrate during Coating Process. Coatings. 2019; 9(3):162. https://doi.org/10.3390/coatings9030162

Chicago/Turabian StyleKim, Na Kyong, Dong Hee Kang, and Hyun Wook Kang. 2019. "Unevenness of Thin Liquid Layer by Contact Angle Variation of Substrate during Coating Process" Coatings 9, no. 3: 162. https://doi.org/10.3390/coatings9030162

APA StyleKim, N. K., Kang, D. H., & Kang, H. W. (2019). Unevenness of Thin Liquid Layer by Contact Angle Variation of Substrate during Coating Process. Coatings, 9(3), 162. https://doi.org/10.3390/coatings9030162