1. Introduction

With advancement in technology, energy consumption and lack in energy supply are inevitable. In 2015, the energy consumption for lighting in various types of buildings in Taiwan was 10%–30% of the total energy consumed, as shown in

Figure 1 [

1].

Figure 2 presents the statistical results of energy consumption by each electrical device in the buildings presented in

Figure 1. We can clearly see that the energy used for artificial light is approximately 18.8% of the total energy consumed. In recent years, to reduce energy consumption and greenhouse gas emissions, various scholars have been striving to propose developments in two following directions: The development of energy-conserving light sources [

2,

3] and the effective use of sunlight for indoor lighting [

4,

5,

6,

7,

8,

9]. Sunlight is an essential resource for illumination and is unlikely to run out in the foreseeable future. Thus, sunlight guiding systems have the potential to be developed for conserving energy.

Conventional sunlight guiding systems include applying a flat panel [

4,

5,

6], prismatic refractors [

7], and a sunlight guiding panel [

8,

9]. The three systems are based on the properties of light refraction and reflection. Comparing the three systems, the sunlight guiding panel has the advantages of low cost and low volume. However, in the sunlight guiding panel device, a change in the path of sunlight is based on a microscale or nanoscale light guide structure. Thus, a reliable micromachining or nanomachining technique is required for manufacturing a sunlight guiding panel. Due to the difficulty in producing a sunlight guiding panel, a sunlight guiding panel has to be placed on the outdoor surface of a window glass in most designs of sunlight guiding panels [

8,

9]. This type of design is inconvenient for assembling and cleaning.

Among the conventional microprocessing or nanoprocessing technologies, nanoimprint lithography [

10] has the advantages of high throughput and high-precision dimension control. Note that UV nanoimprint lithography has the excellent advantage of high-throughput efficiency because no heating and cooling processes are required and because of the minimal deformation of the imprint patterns realized using thermal expansion and contraction [

11]. However, a mold with a pattern of the light-guiding structure has to be fabricated using nanoimprint lithography for manufacturing a light-guiding structure. To obtain a high-quality sunlight guiding panel, high-precision mold processing technology has to be considered for the fabrication of the patterns of the light-guiding structure. Moreover, various materials have been applied to fabricate the molds, such as silicon, silicon oxide, silicon nitride, nickel, and diamond [

12].

The reliable technologies for fabricating the mold used in imprinting process that have been developed so far include e-beam lithography [

10,

13], LIGA (German Acronym for Lithografie, Galvanoformung, Abformung) and LIGA-like processes [

14], and ultraprecision machining technology [

15]. In ultraprecision machining technology, the machining profile of the ultraprecision machining technology is controlled via the relative motion of the cutting tool and the workpiece or the shape of a tool tip. As the ultraprecision machining technology advances, formability and product accuracy have greatly improved. The processing feature size and machining surface roughness in ultraprecision machining technology was confirmed to be better than 100 and 10 nm, respectively [

16,

17]. Based on the machinable features, dimensions, and precision of the ultraprecision machining technology, the technology is suitable for manufacturing light-guiding structures of a sunlight guiding panel. The aim of this study is to develop a novel sunlight guiding panel, which can be placed on the indoor surface of window glass. The production of the sunlight guiding panel will be implemented through nanoimprint technology and ultraprecision machining technology.

2. Principle and Method

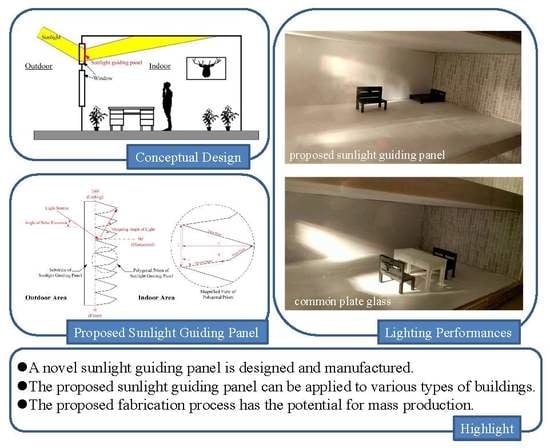

In this study, a novel sunlight guiding panel was proposed.

Figure 3 displays the conceptual design of the proposed sunlight guiding panel. To enhance the practicality of the sunlight guiding panel, we attempted to place the panel on the indoor surface of a window glass.

Figure 4 displays the feature of the proposed sunlight guiding panel and the predicted optical path of sunlight.

Figure 4a illustrates the feature of the proposed sunlight guiding panel. The panel has four structural parameters that are denoted as

L1,

L2,

R, and θ and are used to define the sunlight guiding panel’s polygonal prism shape.

L1 is the period of the polygonal prism,

L2 is the horizontal length of the polygonal prism,

R is the radius of the arc that comprises the main and second slopes, and θ is the main slope’s angle of inclination.

Figure 4b shows the predicted optical path of sunlight that is determined by the law of reflection (θ

i = θ

r, where θ

i and θ

r are the angles of incidence and reflection, respectively) and the law of refraction (Snell’s law,

ni × sin θ

i =

nr × sin θ

r, where

ni and

nr are the indices of refraction for the medium containing the incident ray and refracted ray, respectively, and θ

i and θ

r are the angles of incidence and refraction, respectively). Thus, the polygonal prism of the sunlight guiding panel has the potential to alter the direction of incoming sunlight toward the room’s ceiling. Moreover, when the sunlight is directed to a room’s ceiling, the brightness in the core area of the room can be increased.

The polygonal prism that is periodically arranged on the surface of the sunlight guiding panel is a key component for changing the path of sunlight. The effect of the geometrical dimensions of the polygonal prism on the light-guiding efficiency was simulated using a ray-tracing technique. In this study, the Advanced Systems Analysis Program software (version 2015, ASAP, Breault Research Organization, Inc., Tucson, AZ, USA), an optical simulation software, was used to simulate the path of sunlight through the proposed guiding panel and its light-guiding efficiency. The simulation model is as described in

Figure 4a. The center wavelength of the sunlight spectrum was set to 550 nm for analysis. Four structural parameters—

L1,

L2,

R, and θ—that are presented in

Figure 4a were used to define the shape of the polygonal prism and optimize light-guiding efficiency. Moreover, the refractive indices of the substrate of the sunlight guiding panel and the polygonal prism were set to 1.5 and 1.47, respectively. The refractive indices of the outdoor and indoor areas were set to 1. Based on the optical properties of sunlight, the light source was assumed to comprise parallel rays in the simulation model. Moreover, ray tracing of 1,000,000 rays [

18,

19] was selected to obtain accurate analysis results. The effective light for indoor lighting was determined using the outgoing angle of light through the proposed guiding panel. Based on the description in

Figure 4a, the outgoing light angles between 120° and 180° are effective for indoor lighting. Moreover, the solar elevation angle varies with the time of the day. To understand the performance of the sunlight guiding panel at different times, the angle of solar elevation was varied from 20° to 80° in the simulation model.

The fabrication of the sunlight guiding panel is conducted based on the simulation analysis results. The fabrication of the sunlight guiding panel can be divided into three procedures: Cutting the pattern of the polygonal prism on the surface of the electroless nickel mold, transferring the surface pattern of the electroless nickel mold to the polydimethylsiloxane mold (PDMS), and imprinting the sunlight guiding panel through the PDMS mold, as shown in

Figure 5a–c, respectively.

Figure 5a displays the schematic diagram of the processing procedure of the polygonal prism pattern. The structural shape and size optimization of the polygonal prism are conducted on the surface of an electroless nickel mold through the ultraprecision machining technology. A precision end-cutting machine was used to cut the polygonal prism pattern through a single crystal diamond tool. The angle formed by the adjacent polygonal prism is shaped according to the tip profile of the single crystal diamond tool. After cutting the angle formed by the adjacent triangles, the single crystal diamond tool turns to cut the profile of the second slope. To maintain the surface quality of the polygonal prism and avoid tool wear-associated damage, the cutting depth is controlled to be <10 µm. In our study case, the fabrication of the angle between adjacent polygonal prisms was performed using 10 repetitive cuts.

After completing the fabrication of the electroless nickel mold, the pattern of the electroless nickel mold was transferred to the PDMS mold, as shown in

Figure 5b. The PDMS mold was fabricated by coating a 10:1 mixture of PDMS prepolymer and curing agent (Sylgard 184, Dow Corning, Midland, MI, USA) and then curing for 72 h at a temperature of 20–25 °C. After completing the fabrication of the PDMS mold, the sunlight guiding panel was fabricated using nanoimprint lithography, as shown in

Figure 5c. The PDMS mold was used to form the polygonal prism pattern of the sunlight guiding panel. Here, the imprinted material was UV glue (FL060, Everwide Chemical Co., Ltd., Taiwan), and the substrate of the sunlight guiding panel was polyethylene terephthalate (PET) thin-film.

After the completion of the fabrication of the sunlight guiding panel, an experimental measurement was conducted for verifying the simulation results.

Figure 6 illustrates the optical measurement system. The system comprises of a diode laser (650 nm) as a light source, two reflecting mirrors, a diaphragm, a polarizer, a 1/4 λ wave plate, a lens, two co-axial rotation stages (SGSP-60YAW, Sigma-Koki, Tokyo, Japan), and a power detector (PD300, Ophir Optronics Ltd., Jerusalem, Israel). Here, the flat mirrors were used to adjust the ray path for obtaining a proper optical path. The polarizer and 1/4 λ wave plate were used to make the light source characteristics similar to those of sunlight. The diaphragm and lens were used to control the beam size of the light beam and improve the divergence of the light beam, respectively.

To measure the intensity of the outgoing light at different angles of solar elevation, the sunlight guiding panel and detector were fixed on the inner and outer rotation stages, respectively. The penetration spectra at different solar elevation angles were obtained by rotating the two co-axial rotation stages. The rotation of the inner rotation stage represents the variation in the solar elevation angles, and the rotation of the outside rotation stage was used to collect light intensity data at different angles of the outgoing light.

3. Optical Analysis

The analysis results of the structural optimization of the polygonal prism are presented in

Figure 7, in which the horizontal axis is the solar elevation angle and the vertical axis is the light-guiding efficiency.

Figure 7a shows the influence of

L1 on light-guiding efficiency of the sunlight guiding panel.

L1 was varied from 50 to 60 μm.

L2,

R, and θ are fixed at 60, 160 μm, and 83°, respectively. The results revealed that

L1 values of 50 and 55 μm exhibited a better light-guiding efficiency than

L1 values of 60 μm. We attempted to further compare the cases with

L1 values of 50 and 55 μm, although the

L1 value of 55 μm had a better light-guiding efficiency in the solar elevation angle range of 50° to 60°, the

L1 value of 50 μm had a relatively uniform light-guiding efficiency in the solar elevation angle range of 20° to 80°. Thus, a

L1 value of approximately 50 µm was selected for the experimental study.

Figure 7b presents the influence of the

L2 length of the sunlight guiding panel on light-guiding efficiency. The length of

L2 varies from 50 to 70 µm.

L1,

R, and θ are fixed at 55, 160 μm, and 83°, respectively. The results revealed that an increase in

L2 resulted in an increase in the light-guiding efficiency. Moreover, in this study, the pattern of the polygonal prism on the electroless nickel mold was manufactured using the ultraprecision machining technology. Based on the processing mechanism, an increase in the cutting depth may reduce the cutting accuracy and surface quality, and the aspect ratio of the cutting trench should not exceed 2. Thus, a

L2 value of approximately 70 µm was selected for the experimental study.

Figure 7c presents the influence of

R of the light guiding panel on light-guiding efficiency.

R was varied from 140 to 180 μm.

L1,

L2, and θ are fixed at 55, 60 μm, and 83°, respectively. The cases with

R values of 160 and 180 µm exhibited a similar spectra for the analyzed solar elevation angles, and the light-guiding efficiencies in these cases was better than that in the case with a

R value of 140 µm. Moreover, by analyzing the different cases, it was found that the case with a

R value of 180 µm exhibited the best light-guiding efficiency with solar elevation angles between 50° and 60°. Based on the above analysis results and discussion, a

R value of approximately 180 µm was selected for the experimental study.

Figure 7d presents the influence of θ of the light-guiding panel’s light-guiding efficiency. θ was varied from 79 to 87°.

L1,

L2, and

R are fixed at 55, 60, and 160 μm, respectively. A solar elevation angle that can cause the best light-guiding efficiency is highly affected by θ. A lower θ value results in a lower solar elevation angle with the best light-guiding efficiency. The best light-guiding efficiencies were 96%, 95%, and 89%, when θ was set to 79°, 83°, and 87°, respectively. However, in the solar elevation angle range of 20° to 80°, the overall light-guiding efficiency at 83° was slightly better than that at 79°. Thus, the θ value of 83° was proposed for experimental study.

Figure 8 shows the light-guiding efficiency of the proposed sunlight guiding panel after structural optimization. Here,

L1,

L2,

R, and θ were 50, 70, 180 μm, and 83°, respectively. The proposed sunlight guiding panel can maintain a light-guiding efficiency >60% in a solar elevation angle range of 35° to 65°. The average light-guiding efficiency was 68% in a solar elevation angle range of 20° to 80°. The simulation results confirmed the feasibility of placing the sunlight panel on the indoor surface of a window glass. However, the aspect ratio of the polygonal prism of the sunlight guiding panel was 1.4, which is very higher than that of the sunlight guiding panel installed outdoors (e.g., the aspect ratio is 1 in reference [

8]). The manufacturing of the proposed sunlight guiding panel is more difficult than previous designs.