Bionic Design of a Novel Portable Hand-Elbow Coordinate Exoskeleton for Activities of Daily Living

Abstract

:1. Introduction

2. Overall Mechanical Structure Design

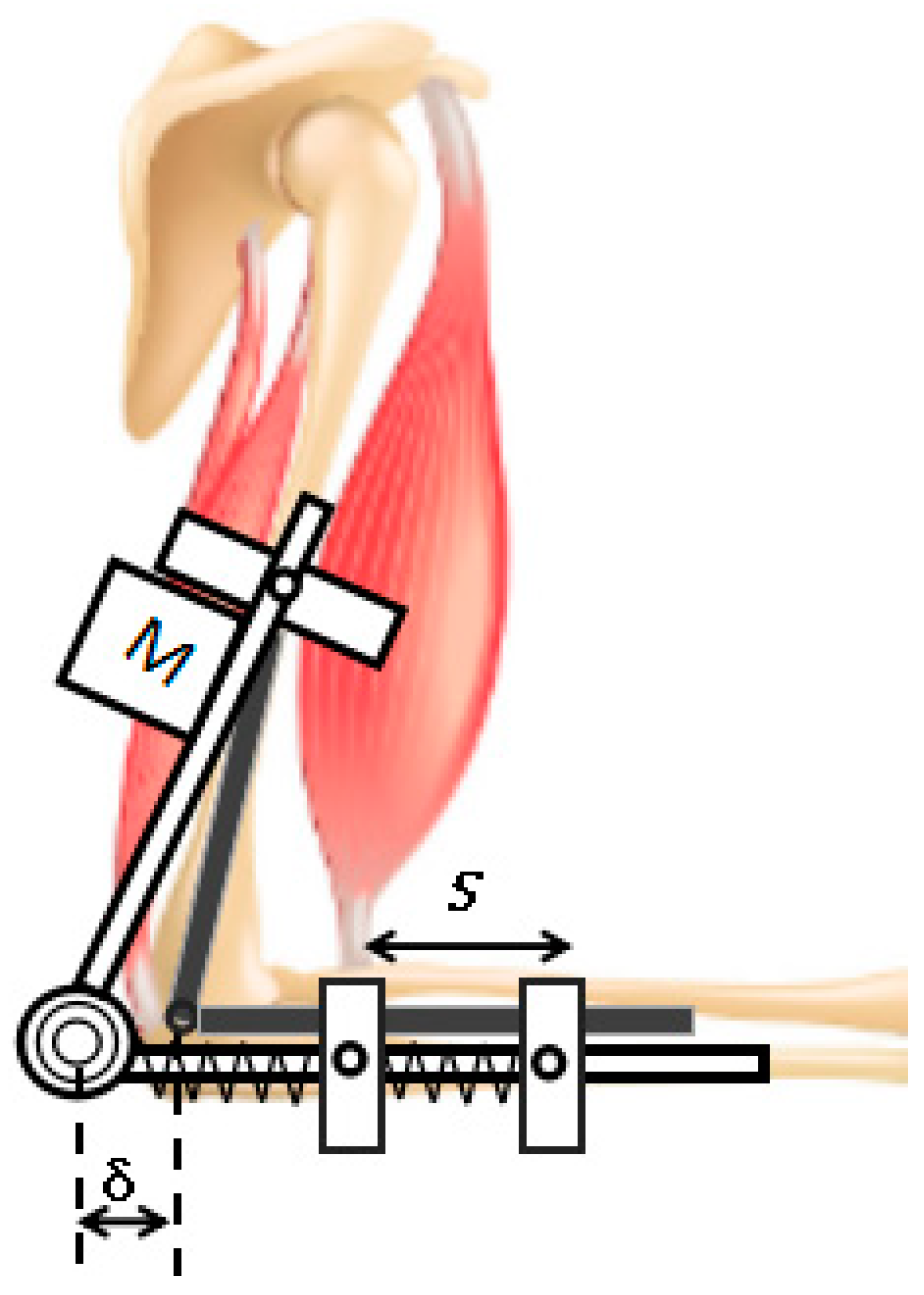

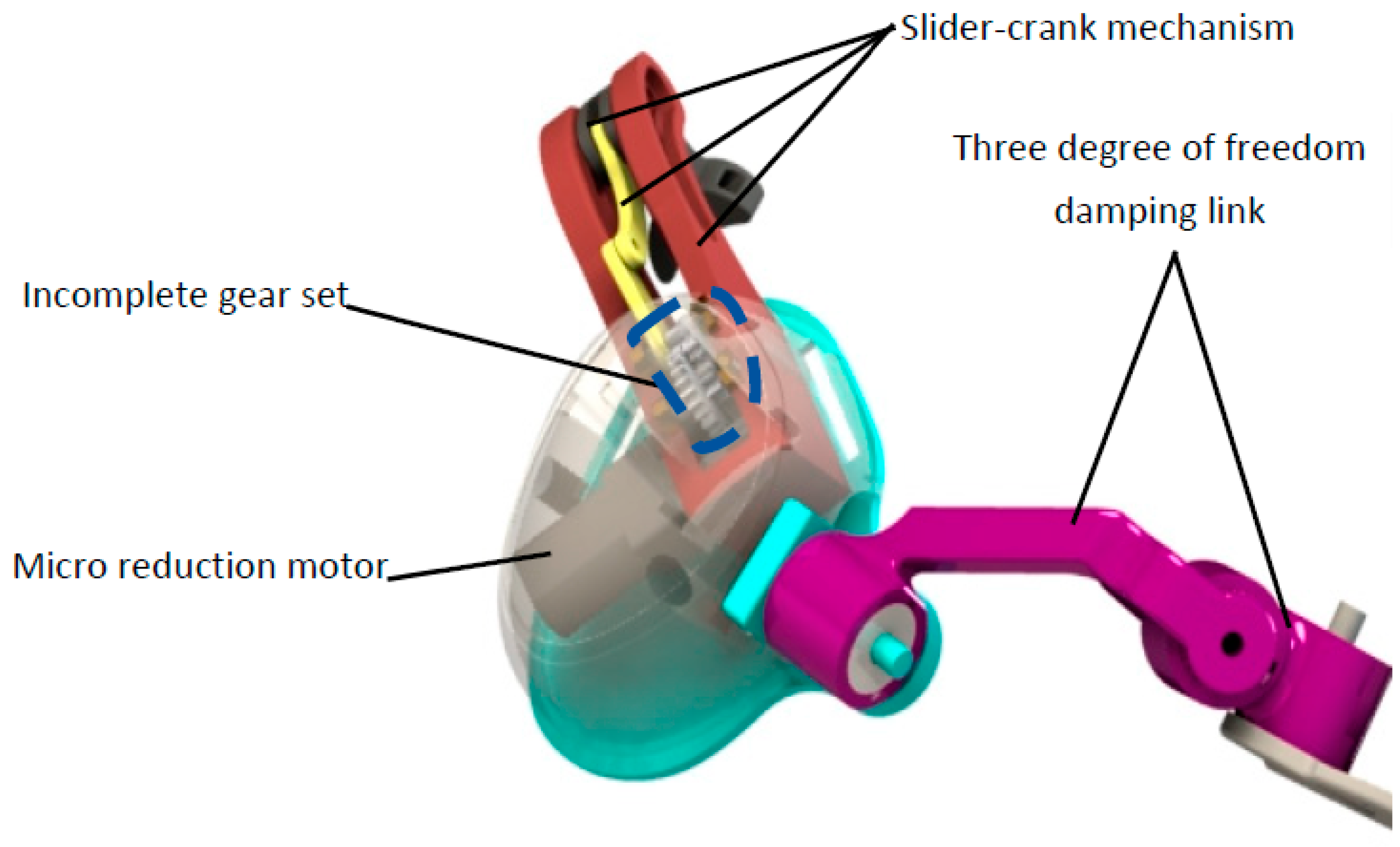

2.1. Elbow Function Module

2.2. Hand Function Module

3. Kinematic Simulation Analysis

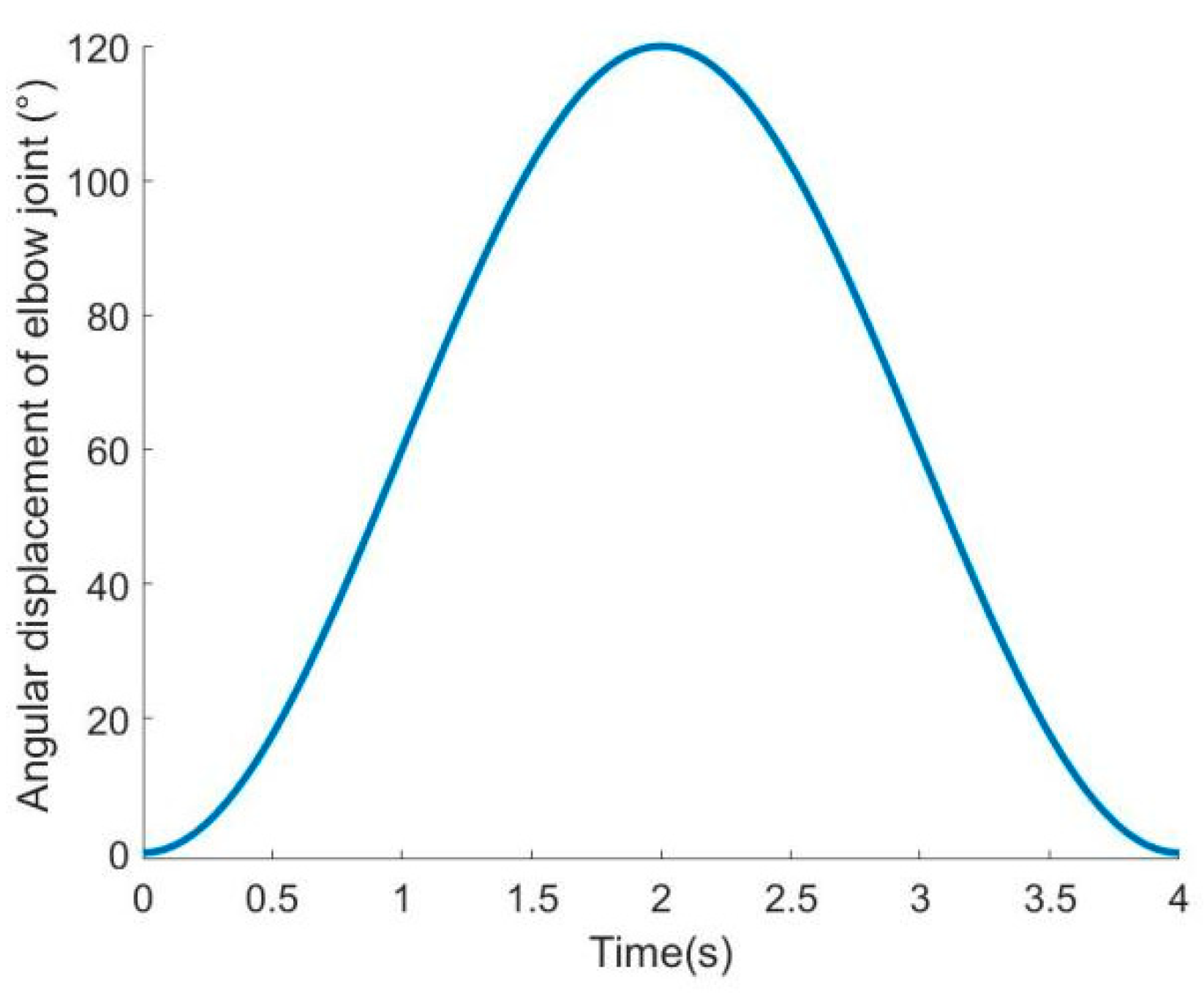

3.1. Motion Simulation of the Elbow Function Module

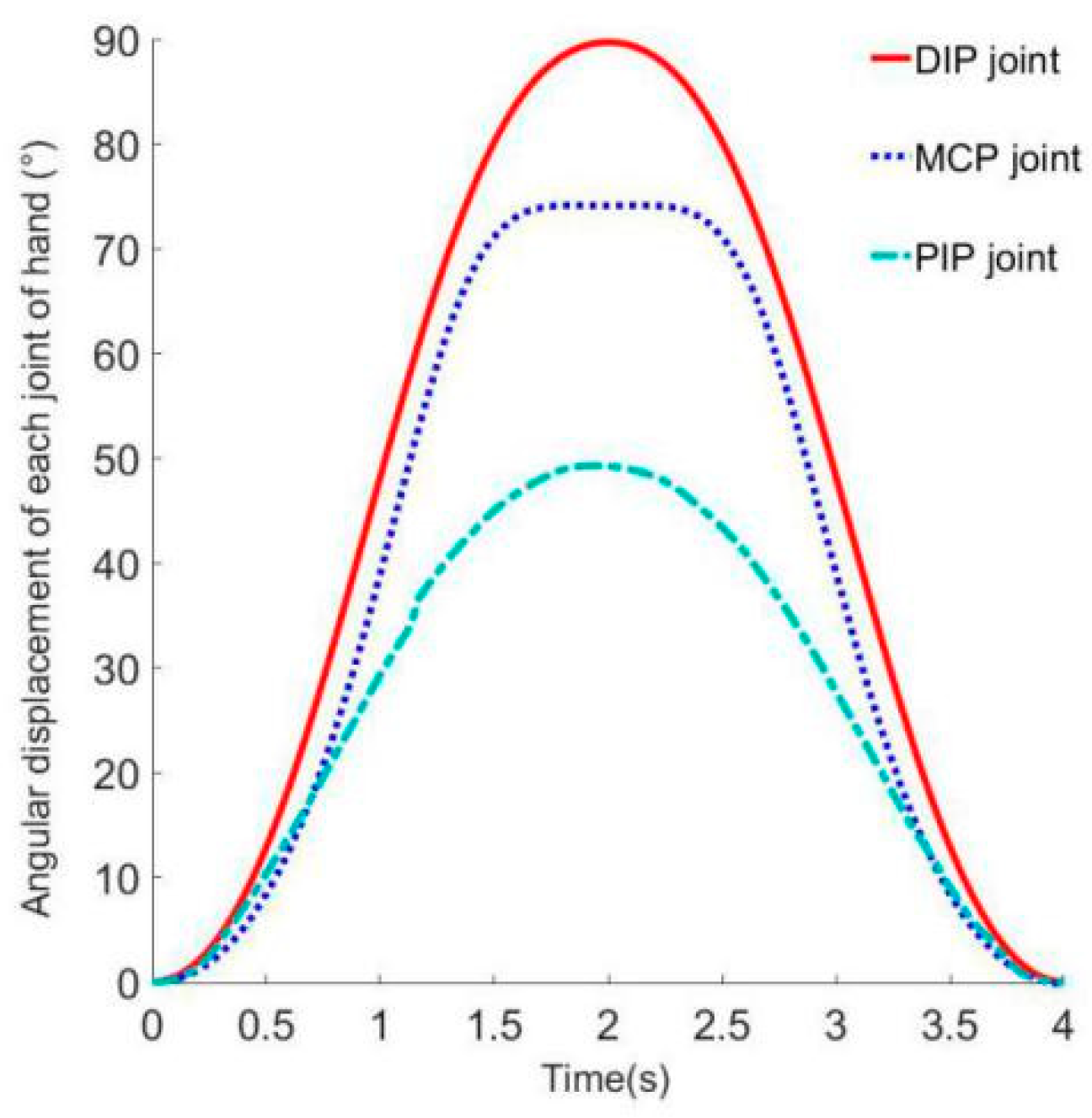

3.2. Motion Simulation of the Hand Function Module

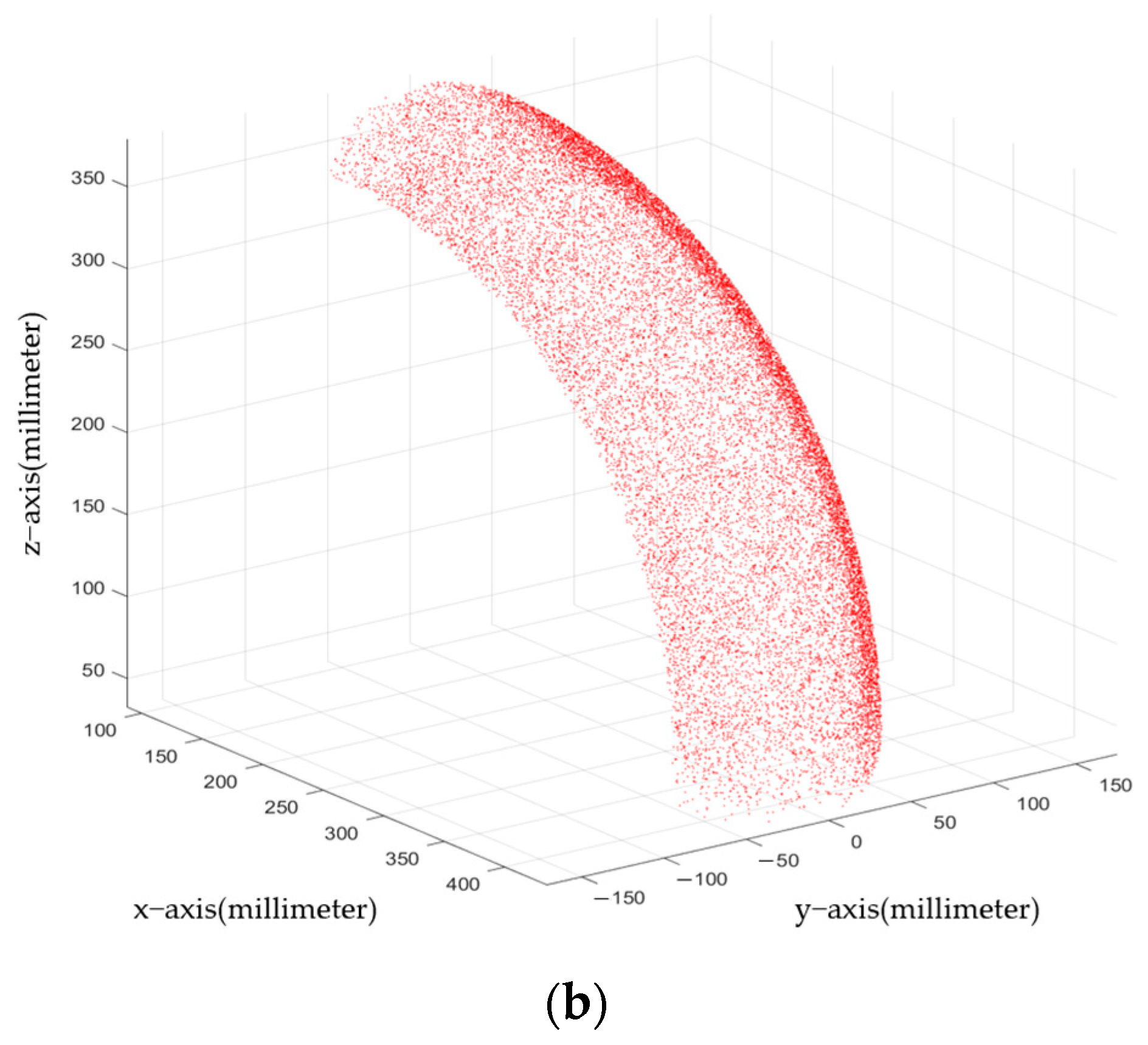

3.3. Workspace Analysis

4. Prototype Experiment

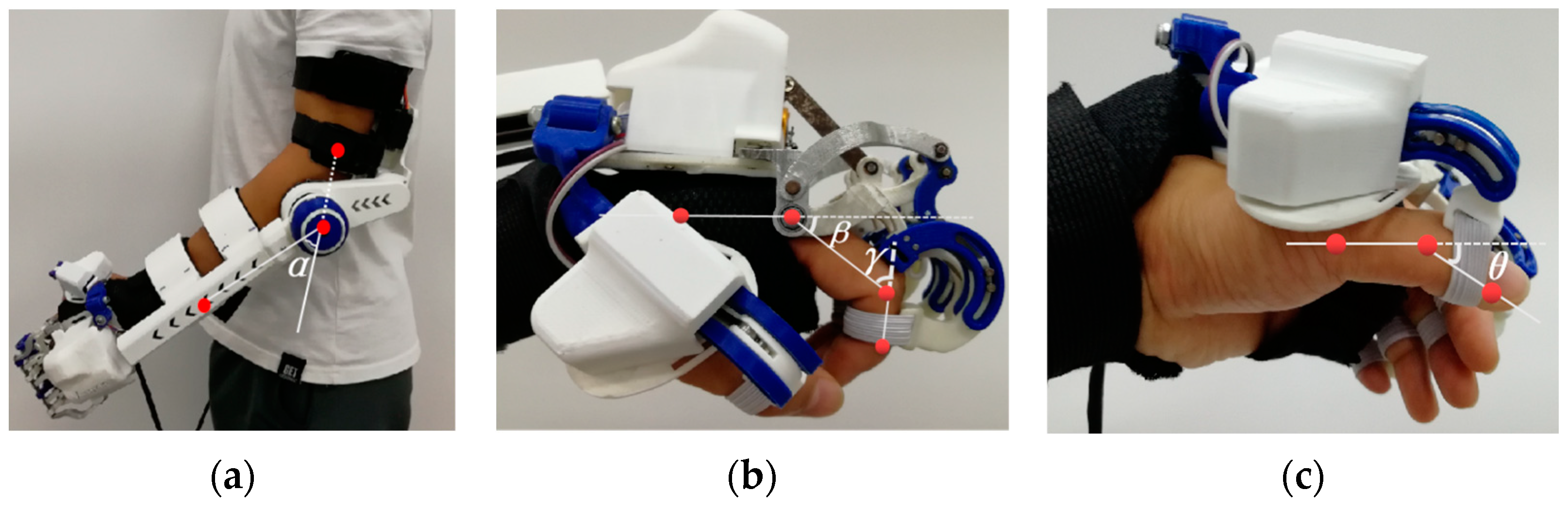

4.1. Joint Range of Motion Measurement Experiment

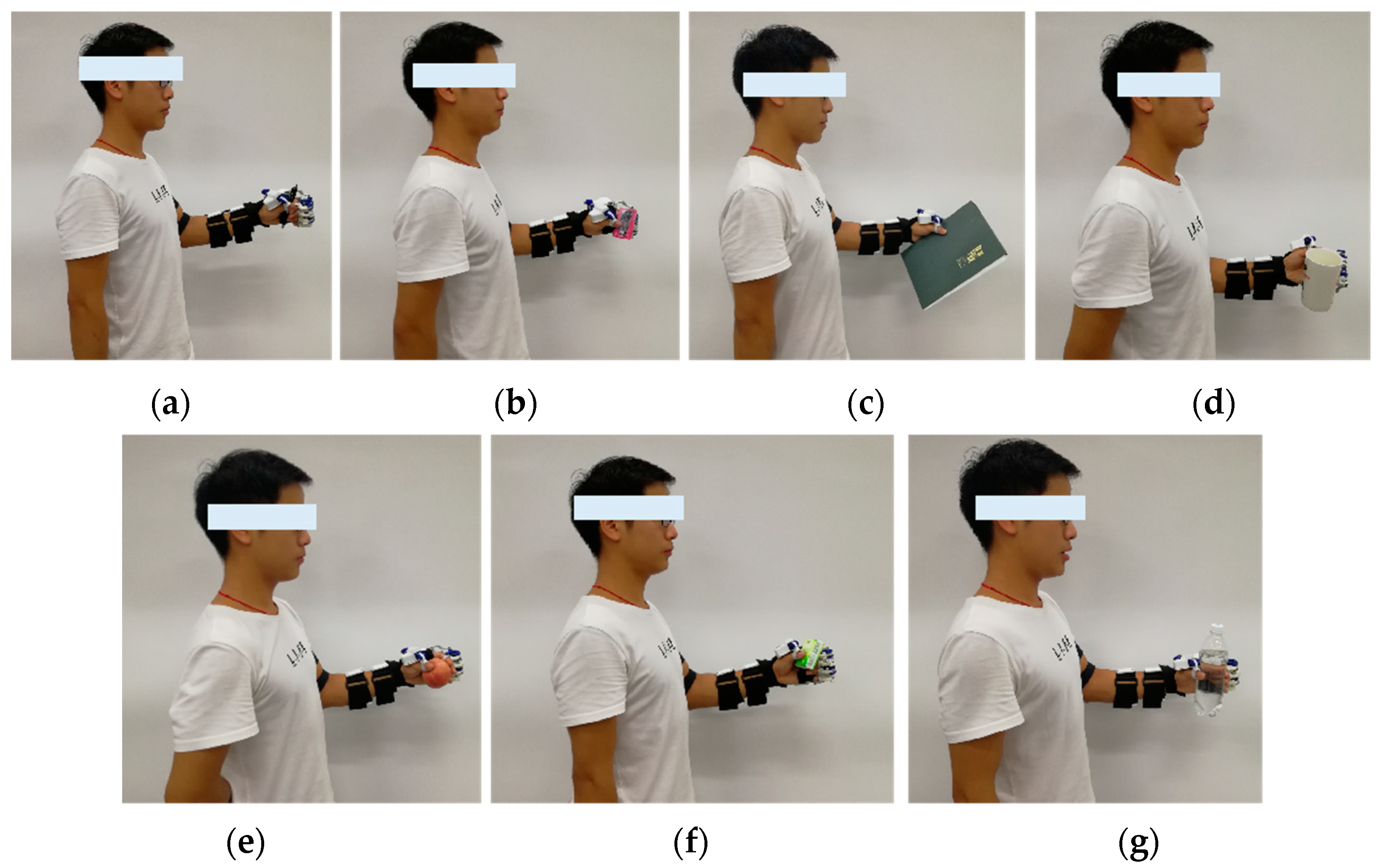

4.2. Grasping Experiment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Exoskeleton | Features |

|---|---|

| Manufacturing Materials | Photosensitive Resin, Aluminum Alloy 6061 |

| Total Weight | 1.5 kg |

| Total Length | 520 mm |

| Hand Weight | 0.45 kg |

| Hand Length | 184 mm |

| Elbow Exoskeleton Drive Motor | EC-i-52, Swiss Maxon, EPOS4 Module 50/8, Swiss Maxon |

| Four-Finger Module Drive Motor | Motor (2224U006SR, Faulhaber, Stuttgart), Planetary Gearhead (gear ratio 9.7:1, Faulhaber, Stuttgart) |

| Thumb Module Drive Motor | ZGA20RU, Shenzhen Zhengke Motor |

| Motor Driver | A3950S (Allegro, MA) |

| Controller Main Chip | STM32F407ZGT6 |

| Torque Sensor | TJN-1, China TianGuang Sensor Company |

| IMU (Inertial Measurement Unit) | LPMS-ME1, LP-RSEARCH In |

References

- World Health Organization. World Report on Ageing And Health 2015; World Health Organization: Geneva, Switzerland, 2015; Volume 145, pp. 150–151. [Google Scholar]

- Feigin, V.L.; Stark, B.A.; Johnson, C.O.; Roth, G.A.; Bisignano, C.; Abady, G.G.; Hamidi, S. Global, regional, and 495 national burden of stroke and its risk factors, 1990–2019: A systematic analysis for the Global Burden of Disease 496 Study 2019. Lancet Neurol. 2021, 20, 795–820. [Google Scholar] [CrossRef]

- Coleman, E.R.; Moudgal, R.; Lang, K.; Hyacinth, H.I.; Awosika, O.O.; Kissela, B.M.; Feng, W.W. Early rehabilitation after stroke: A narrative review. Curr. Atheroscler. Rep. 2017, 19, 59–79. [Google Scholar] [CrossRef] [Green Version]

- Askim, T.; Bernhardt, J.; Salvesen, Ø.; Indredavik, B. Physical activity early after stroke and its association to functional outcome 3 months later. J. Stroke Cerebrovasc. Dis. 2014, 23, 5–12. [Google Scholar] [CrossRef]

- Phipps, S.; Richardson, P. Occupational therapy outcomes for clients with traumatic brain injury and stroke using the Canadian occupational performance measure. Am. J. Occup. Ther. 2007, 61, 28–34. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ada, L.; Preston, E.; Langhammer, B.; Canning, C.G. Profile of upper limb recovery and development of secondary impairments in patients after stroke with a disabled upper limb: An observational study. Physiother. Theor. Pract. 2020, 36, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Oubre, B.; Daneault, J.F.; Jung, H.T.; Whritenour, K.; Miranda, J.G.V.; Park, J.; Ryu, T.; Kim, Y.; Lee, S.I. Estimating upper-limb impairment level in stroke survivors using wearable inertial sensors and a minimally-burdensome motor task. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 601–611. [Google Scholar] [CrossRef] [PubMed]

- Pramod, B.M.; Akhil, V.M. Upper Limb Exoskeleton for Rehabilitation-A Study. In Proceedings of the 2022 International Conference on Applied Artificial Intelligence and Computing (ICAAIC), Salem, India, 9–11 May 2022; pp. 1597–1603. [Google Scholar]

- Cappello, L.; Binh, D.K.; Yen, S.C.; Masia, L. Design and preliminary characterization of a soft wearable exoskeleton for upper limb. In Proceedings of the IEEE RAS and EMBS International Conference on Biomedical Robotics and Biomechatronics, Singapore, 26–29 June 2016; pp. 623–630. [Google Scholar]

- Zeiaee, A.; Zarrin, R.S.; Eib, A.; Langari, R.; Tafreshi, R. CLEVERarm: A Lightweight and Compact Exoskeleton for Upper-Limb Rehabilitation. IEEE Robot. Autom. Lett. 2022, 7, 1880–1887. [Google Scholar] [CrossRef]

- Huysamen, K.; Bosch, T.; de Looze, M.; Stadler, K.S.; Graf, E.; O’Sullivan, L.W. Evaluation of a passive exoskeleton for static upper limb activities. Appl. Ergon. 2018, 70, 148–155. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Choi, I.S.; Han, K.L.; Choi, J.Y.; Chung, G.; Suh, J. Development of a upper-limb exoskeleton robot for refractory construction. Control Eng. Pract. 2018, 72, 104–113. [Google Scholar] [CrossRef]

- Nef, T.; Mihelj, M.; Riener, R. ARMin: A robot for patient-cooperative arm therapy. Med. Biol. Eng. Comput. 2007, 45, 887–900. [Google Scholar] [CrossRef] [Green Version]

- Kan, P.; Huq, R.; Hoey, J.; Goetschalckx, R.; Mihailidis, A. The development of an adaptive upper-limb stroke rehabilitation robotic system. J. Neuroeng. Rehabil. 2011, 8, 33. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, D.; Meng, Q.Y.; Meng, Q.L.; Li, X.; Yu, H. Design and Development of a Portable Exoskeleton for Hand Rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 2376–2386. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Yu, H.; Wu, J.; Meng, Q.; Lin, Q. Integrating fuzzy based QFD and AHP for the design and implementation of a hand training device. J. Intell. Fuzzy Syst. 2019, 36, 3317–3331. [Google Scholar] [CrossRef]

- Lu, Z. Design and Research of Upper Limb Assisted Exoskeleton; Nanjing University of Science & Technology: Nanjing, China, 2017. [Google Scholar]

- Xie, Q.; Meng, Q.; Zeng, Q.; Fan, Y.; Dai, Y.; Yu, H. Human-Exoskeleton Coupling Dynamics of a Multi-Mode Therapeutic Exoskeleton for Upper Limb Rehabilitation Training. IEEE Access 2021, 9, 61998–62007. [Google Scholar] [CrossRef]

- Meng, Q.L.; Shen, Z.; Nie, Z.; Meng, Q.Y.; Wu, Z.; Yu, H. Modeling and Evaluation of a Novel Hybrid-Driven Compliant Hand Exoskeleton Based on Human-Machine Coupling Model. Appl. Sci. 2021, 11, 10825. [Google Scholar] [CrossRef]

- Haarman, C.J.W.; Hekman, E.E.G.; Rietman, J.S.; Van Der Kooij, H. Mechanical Design and Feasibility of a Finger Exoskeleton to Support Finger Extension of Severely Affected Stroke Patients. IEEE Trans. Neural Syst. Rehabil. Eng. 2023, 31, 1268–1276. [Google Scholar] [CrossRef]

- Thomas, F.; Ian, M.; Aaron, M.D. Analysis of human grasping behavior: Object characteristics and grasp type. IEEE Trans. Haptics 2014, 7, 311–323. [Google Scholar]

- Tong, K.Y.; Ho, S.K.; Pang, P.M.K.; Hu, X.L.; Tam, W.K.; Fung, K.L.; Wei, X.J.; Chen, P.N.; Chen, M. An Intention Driven Hand Functions Task Training Robotic System. In Proceedings of the 2010 Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC’10), Buenos Aires, Argentina, 31 August–4 September 2010; pp. 3406–3409. [Google Scholar]

- Zhan, Q.; Wang, L. Timing and strategies for early management and rehabilitation of acute ischemic stroke. J. Neurol. Neurorehabil. 2016, 12, 1–7. [Google Scholar]

- Zhong, M.; Fen, N.; Chen, Z.; Jin, D. Design of structure and control system for progressive finger-rehabilitation robot. J. Mech. Des. 2022, 39, 27–33. [Google Scholar]

- Zhang, M.; He, N.; Song, W. Kinematics simulation of 6-DOF platform based on SolidWorks motion. Mech. Des. Manuf. Eng. 2016, 45, 36–39. [Google Scholar] [CrossRef]

- Tiboni, M.; Borboni, A.; Faglia, R.; Pellegrini, N. Robotics rehabilitation of the elbow based on surface electromyography signals. Adv. Mech. Eng. 2018, 10, 1687814018754590. [Google Scholar] [CrossRef]

- Ang, B.W.K.; Yeow, C.H. Print-it-Yourself (PIY) glove: A fully 3D printed soft robotic hand rehabilitative and assistive exoskeleton for stroke patients. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2017), Vancouver, BC, Canada, 24–28 September 2017; pp. 1219–1223. [Google Scholar]

- Yap, H.K.; Khin, P.M.; Koh, T.H.; Sun, Y.; Liang, X.; Lim, J.H.; Yeow, C.H. A Fully Fabric-Based Bidirectional Soft Robotic Glove for Assistance and Rehabilitation of Hand Impaired Patients. IEEE Robot. Autom. Lett. 2017, 2, 1383–1390. [Google Scholar] [CrossRef]

| Joint | Angular Range (°) | Healthy Human Joint Range (°) |

|---|---|---|

| Elbow Joint | Flexion/Extension 0–120 | Flexion/Extension 0–135 |

| Four-Finger MCP | Flexion 0–84 | Flexion 0–90 |

| Four-Finger PIP | Flexion 0–73 | Flexion 0–110 |

| Thumb IP | Flexion 0–49 | Flexion 0–70 |

| ID | Gender | Age | Height | Weight |

|---|---|---|---|---|

| 1 | Male | 24 | 175 cm | 60 kg |

| 2 | Male | 25 | 177 cm | 65 kg |

| 3 | Male | 26 | 175 cm | 58 kg |

| 4 | Female | 43 | 162 cm | 62 kg |

| 5 | Female | 25 | 158 cm | 42 kg |

| 6 | Male | 27 | 170 cm | 71 kg |

| Angle | 1 | 2 | 3 | 4 | 5 | Average Value |

|---|---|---|---|---|---|---|

| α | 114.6 | 114.9 | 115.5 | 115.3 | 115.7 | 115.2 |

| β | 76.2 | 76.0 | 75.8 | 75.4 | 75.7 | 75.8 |

| γ | 71.9 | 71.5 | 72.2 | 71.4 | 71.7 | 71.7 |

| θ | 37.5 | 37.8 | 38.1 | 38.2 | 37.9 | 37.9 |

| Angle | 1 | 2 | 3 | 4 | 5 | Average Value |

|---|---|---|---|---|---|---|

| α | 115.3 | 114.7 | 114.4 | 115.6 | 115.0 | 115.0 |

| β | 75.5 | 76.2 | 76.0 | 75.6 | 75.5 | 75.7 |

| γ | 71.1 | 71.4 | 72.3 | 71.6 | 71.5 | 71.5 |

| θ | 37.7 | 37.6 | 38.0 | 38.2 | 38.5 | 38.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Q.; Liu, G.; Meng, Q.; Xu, X.; Qin, L.; Yu, H. Bionic Design of a Novel Portable Hand-Elbow Coordinate Exoskeleton for Activities of Daily Living. Electronics 2023, 12, 3326. https://doi.org/10.3390/electronics12153326

Meng Q, Liu G, Meng Q, Xu X, Qin L, Yu H. Bionic Design of a Novel Portable Hand-Elbow Coordinate Exoskeleton for Activities of Daily Living. Electronics. 2023; 12(15):3326. https://doi.org/10.3390/electronics12153326

Chicago/Turabian StyleMeng, Qingyun, Guanxin Liu, Qiaoling Meng, Xin Xu, Liang Qin, and Hongliu Yu. 2023. "Bionic Design of a Novel Portable Hand-Elbow Coordinate Exoskeleton for Activities of Daily Living" Electronics 12, no. 15: 3326. https://doi.org/10.3390/electronics12153326