Neural Network Based Maximum Power Point Tracking Control with Quadratic Boost Converter for PMSG—Wind Energy Conversion System

Abstract

:1. Introduction

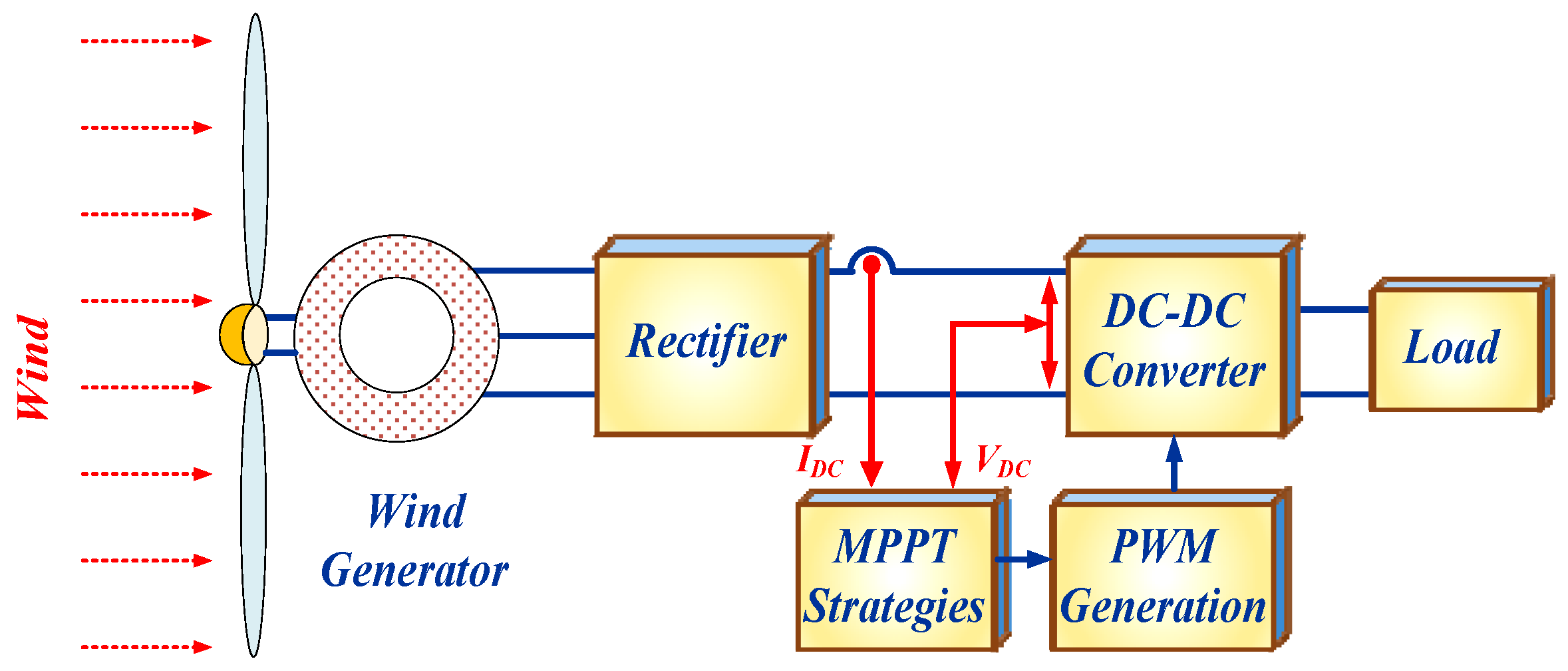

2. WECS Configuration

2.1. Wind Turbine Model

2.2. PMSG Model

3. MPPT Technique

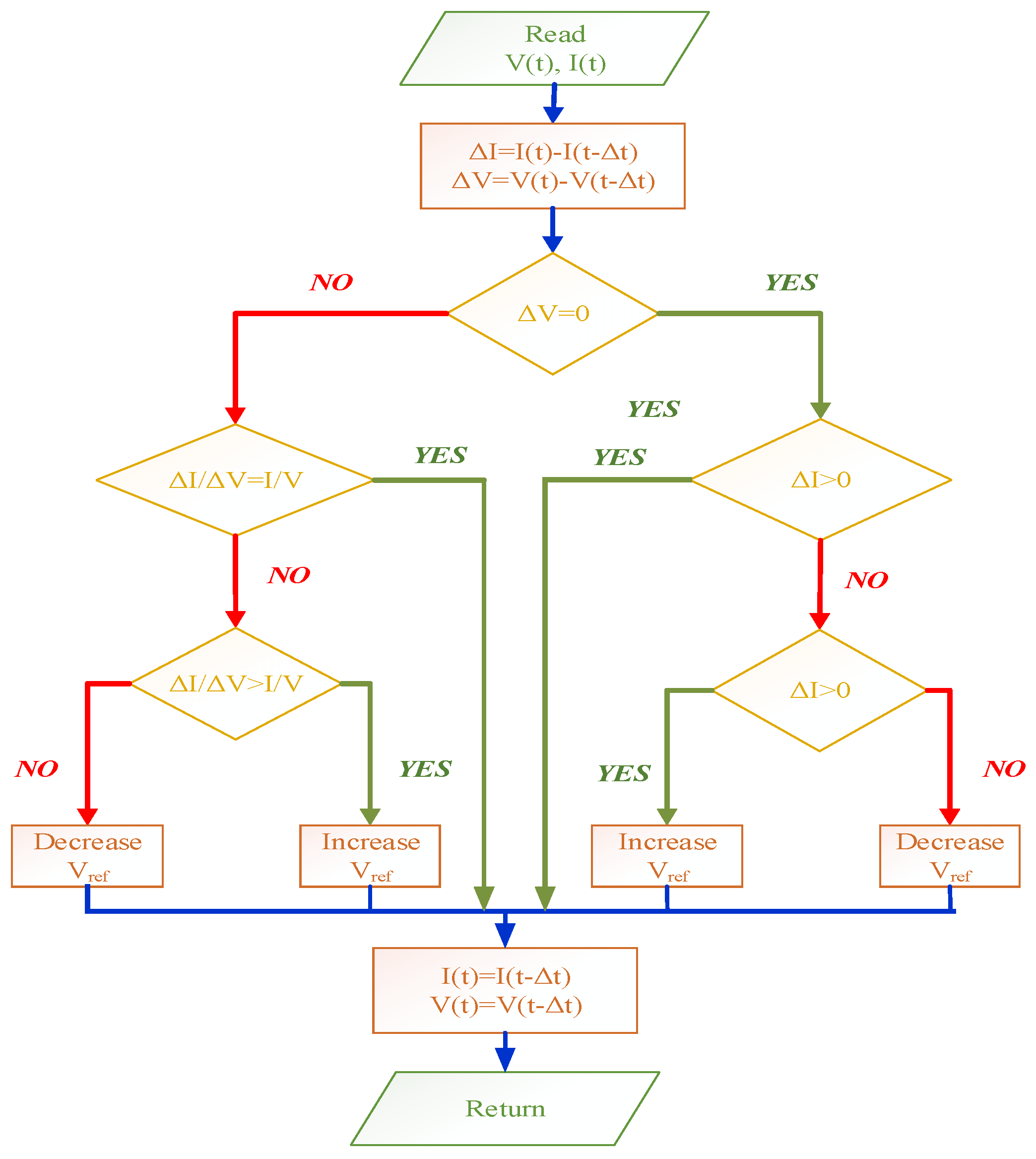

3.1. Perturb and Observe Algorithm

3.2. Back Propagation Algorithm

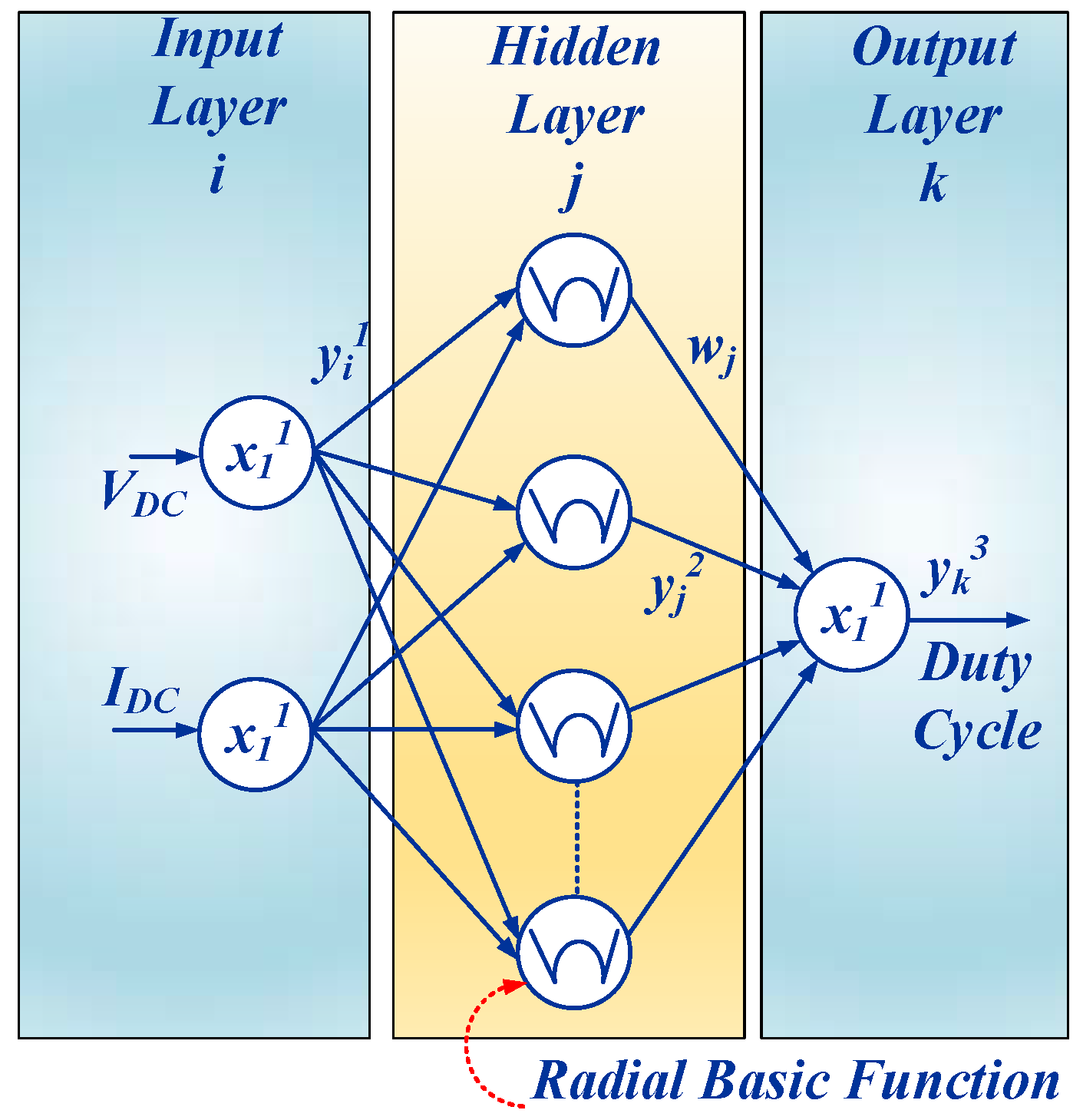

3.3. Radial Basis Function Network Algorithm

4. Converter Modelling

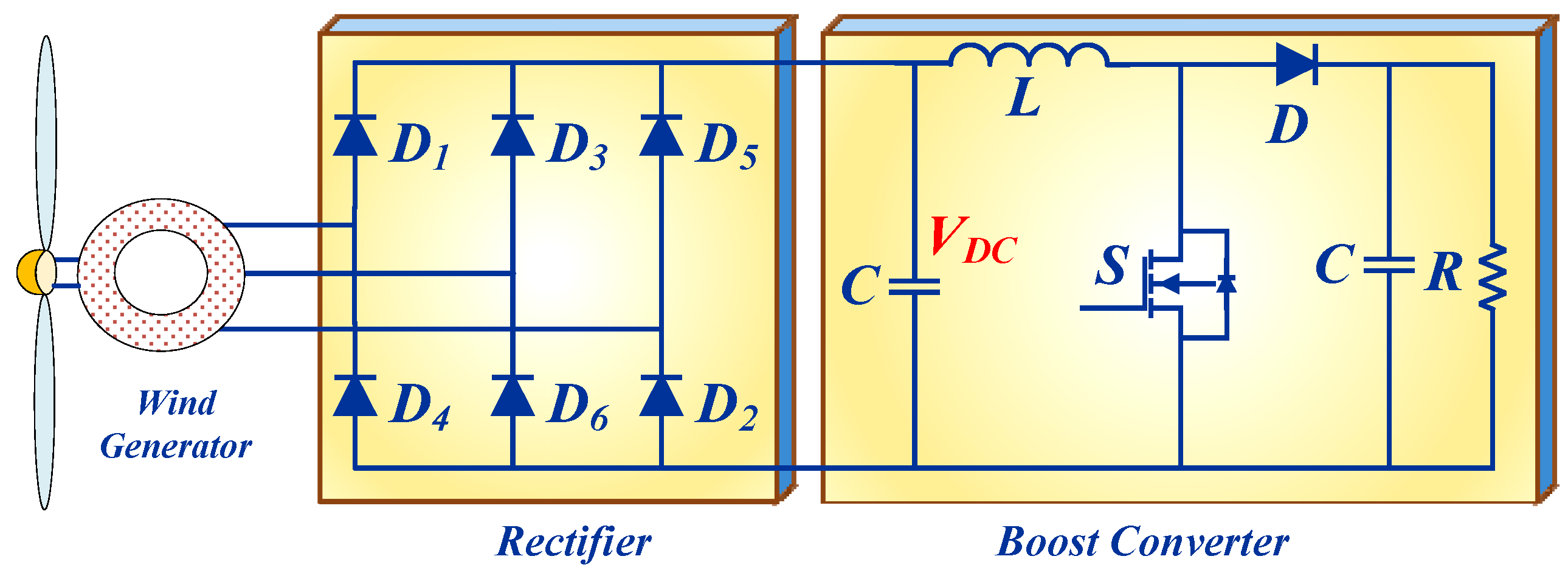

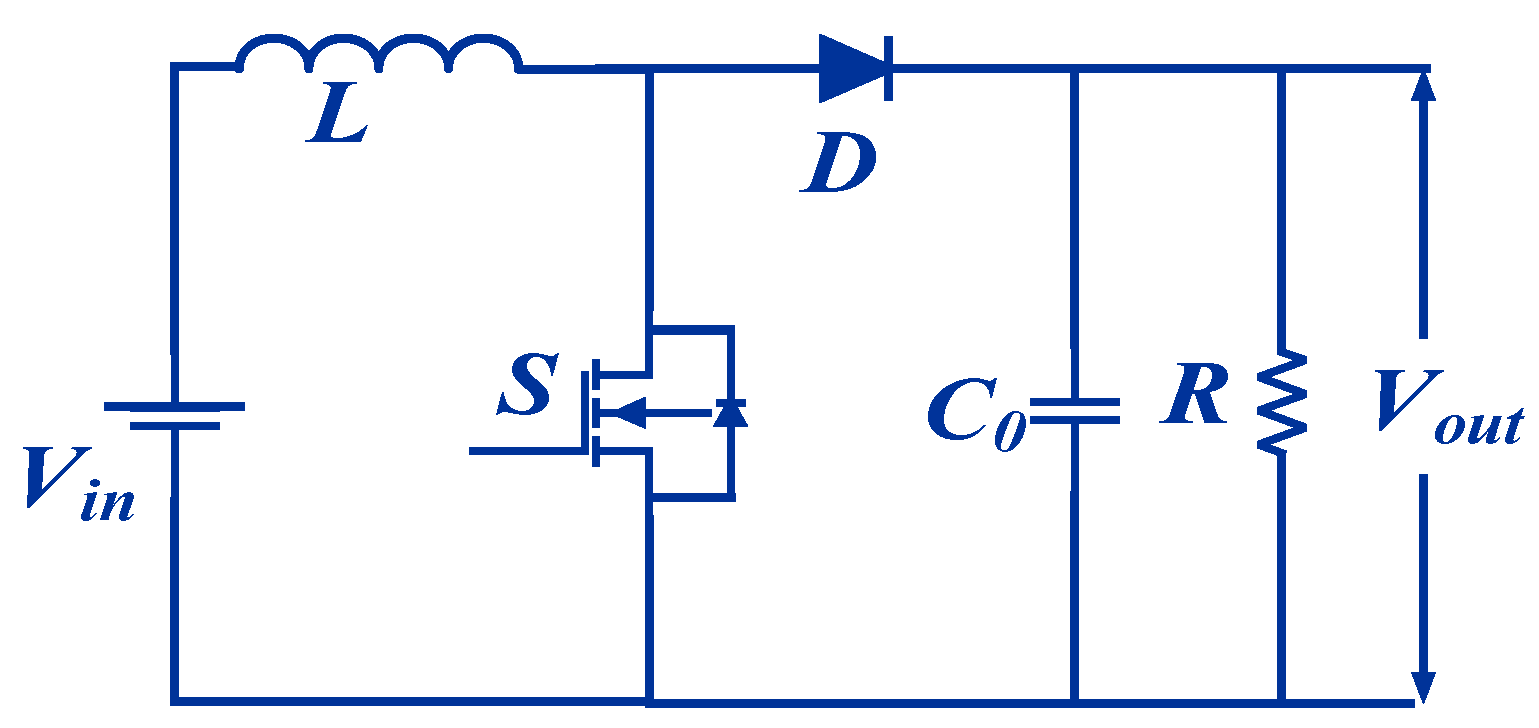

4.1. Boost Converter

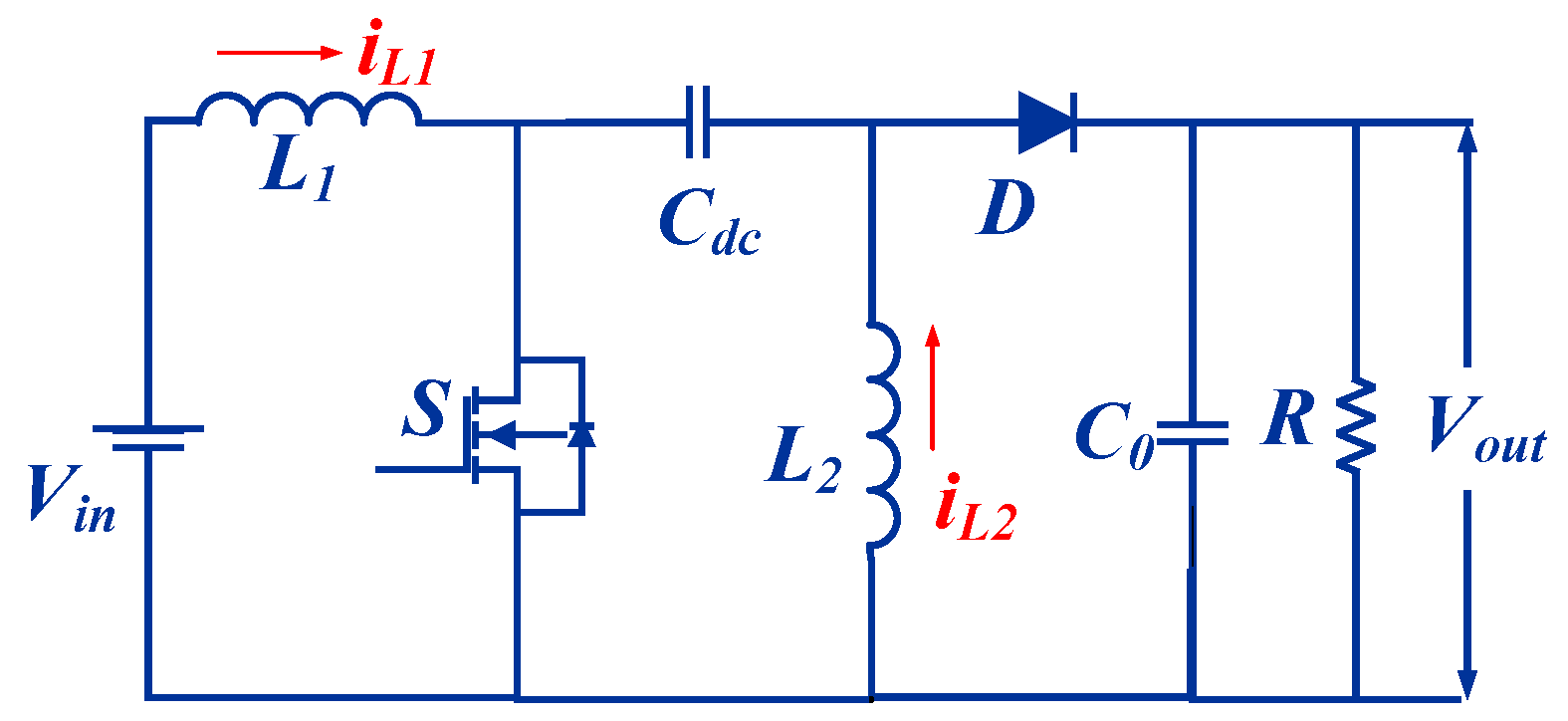

4.2. SEPIC Converter

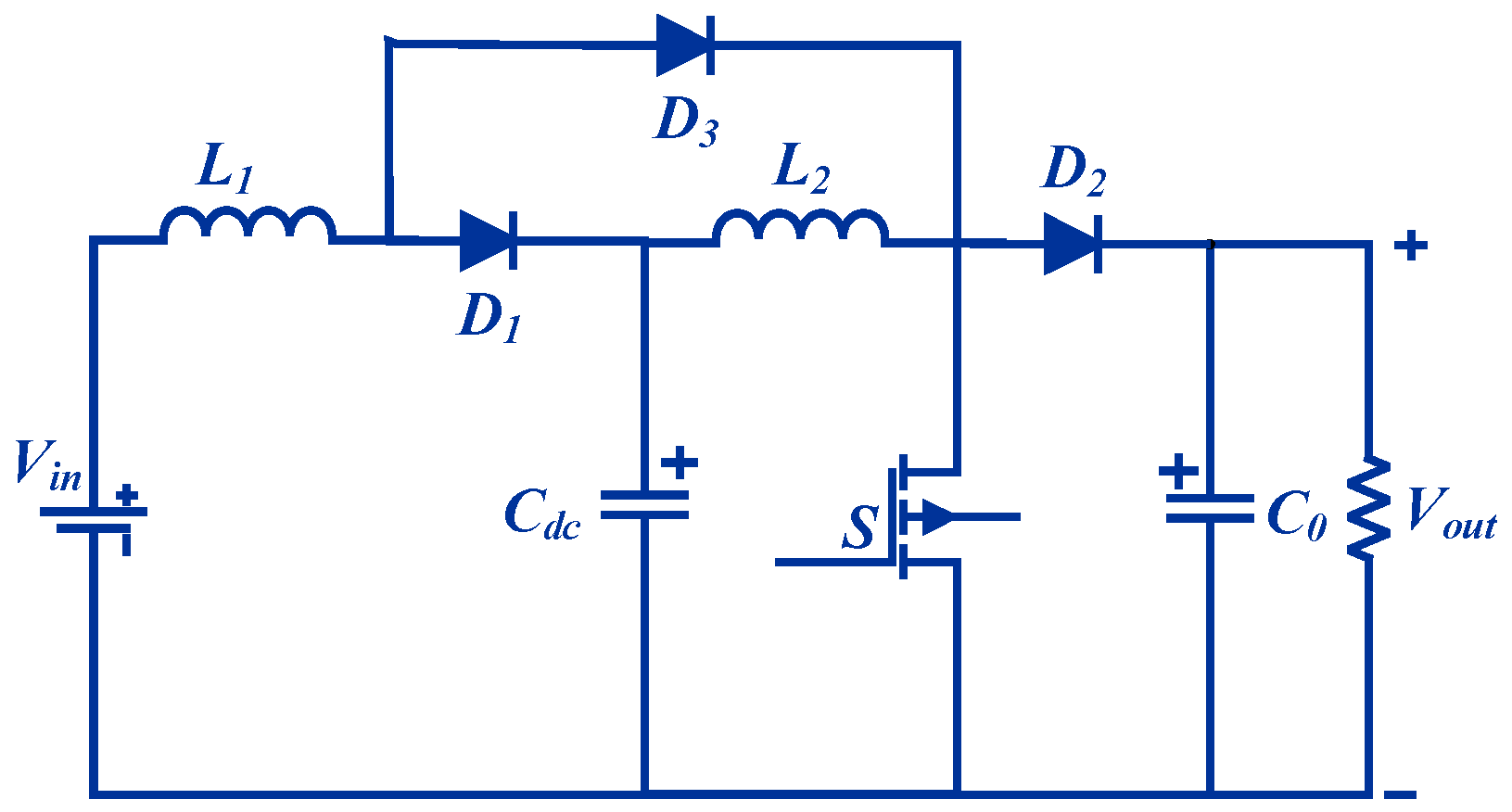

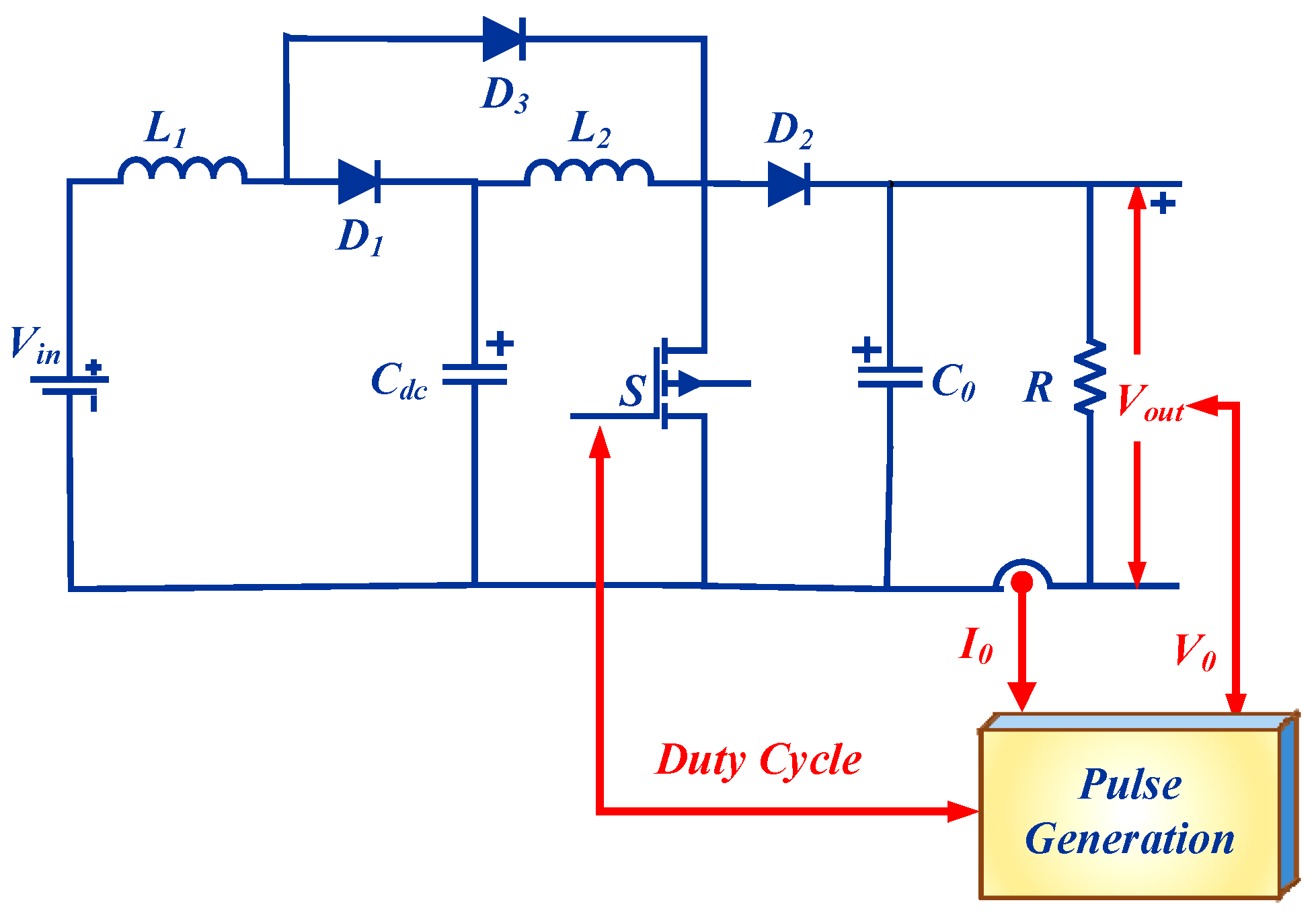

4.3. Quadratic Boost Converter

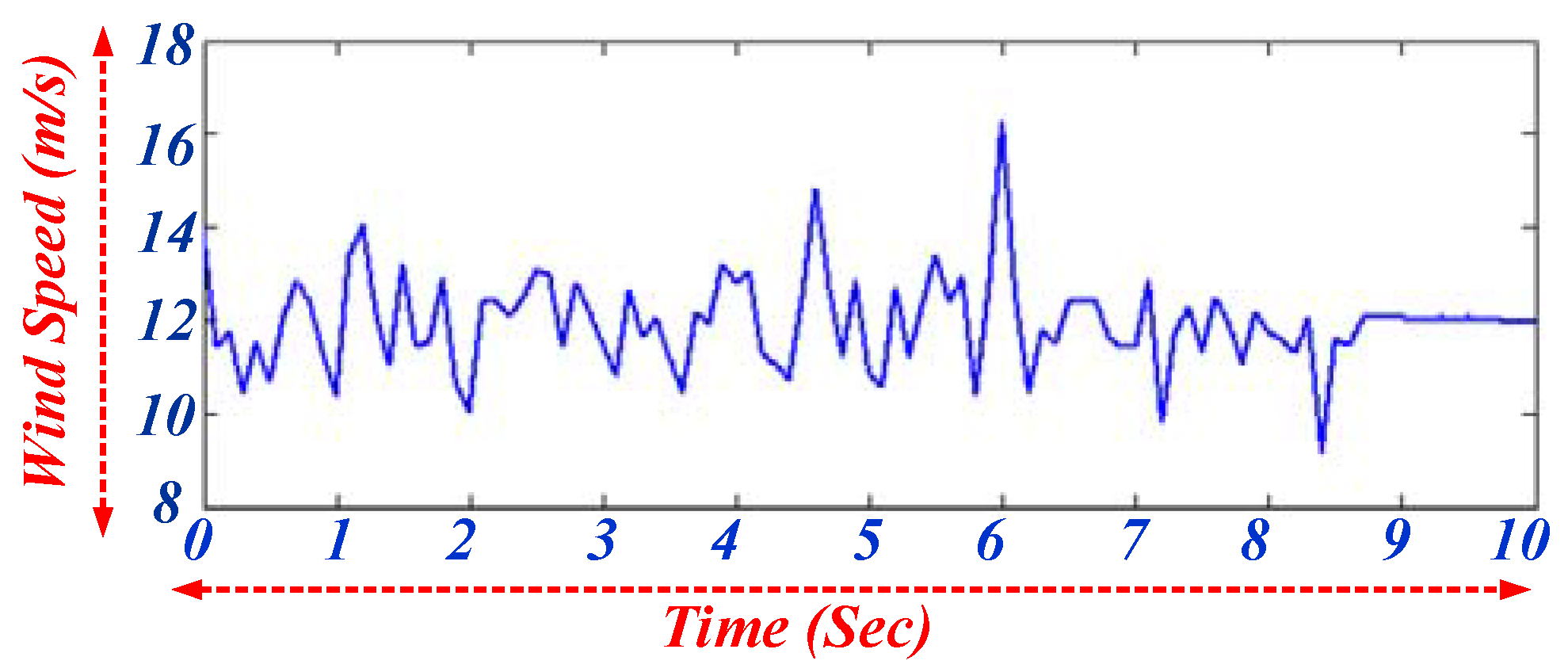

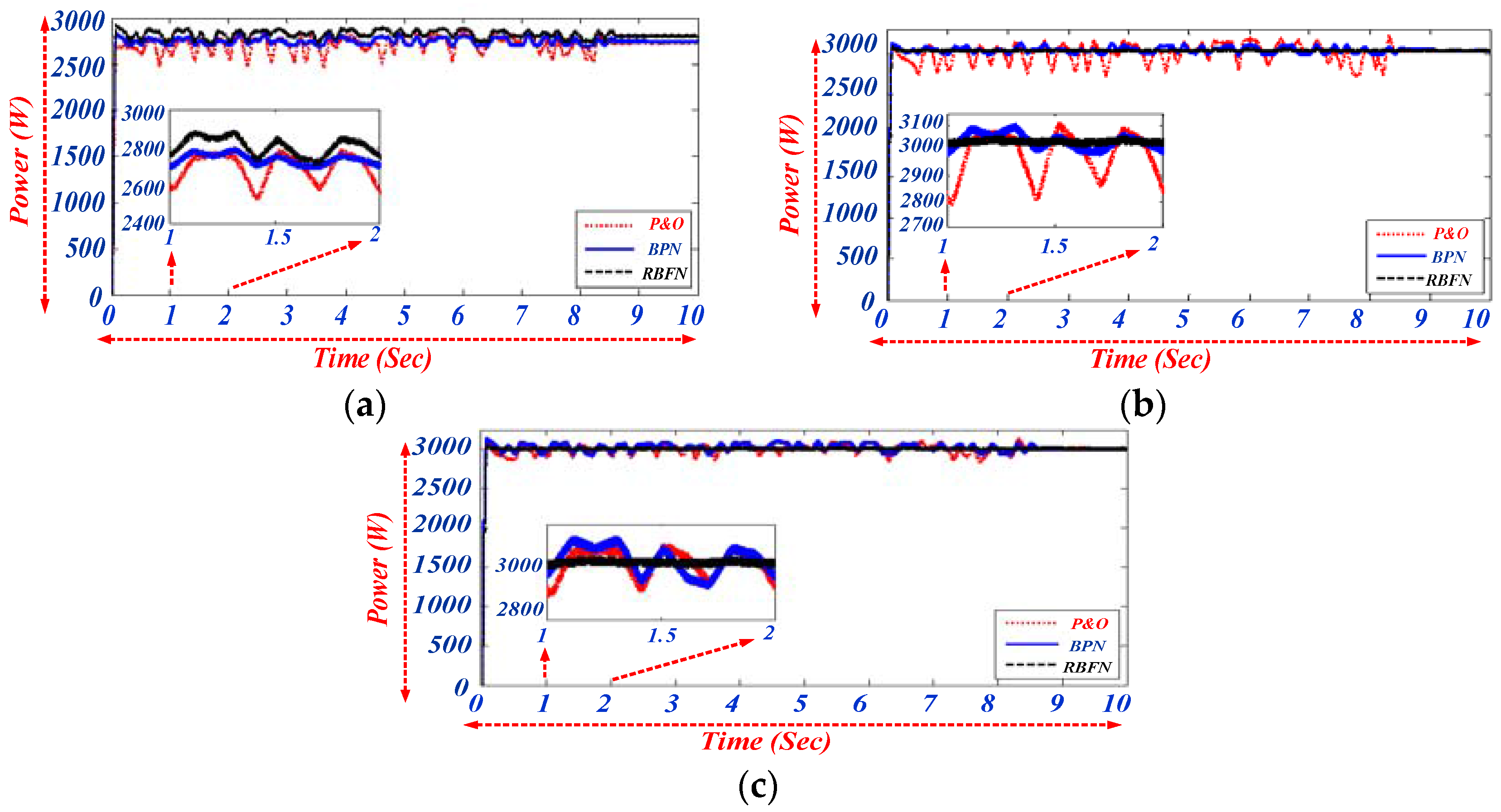

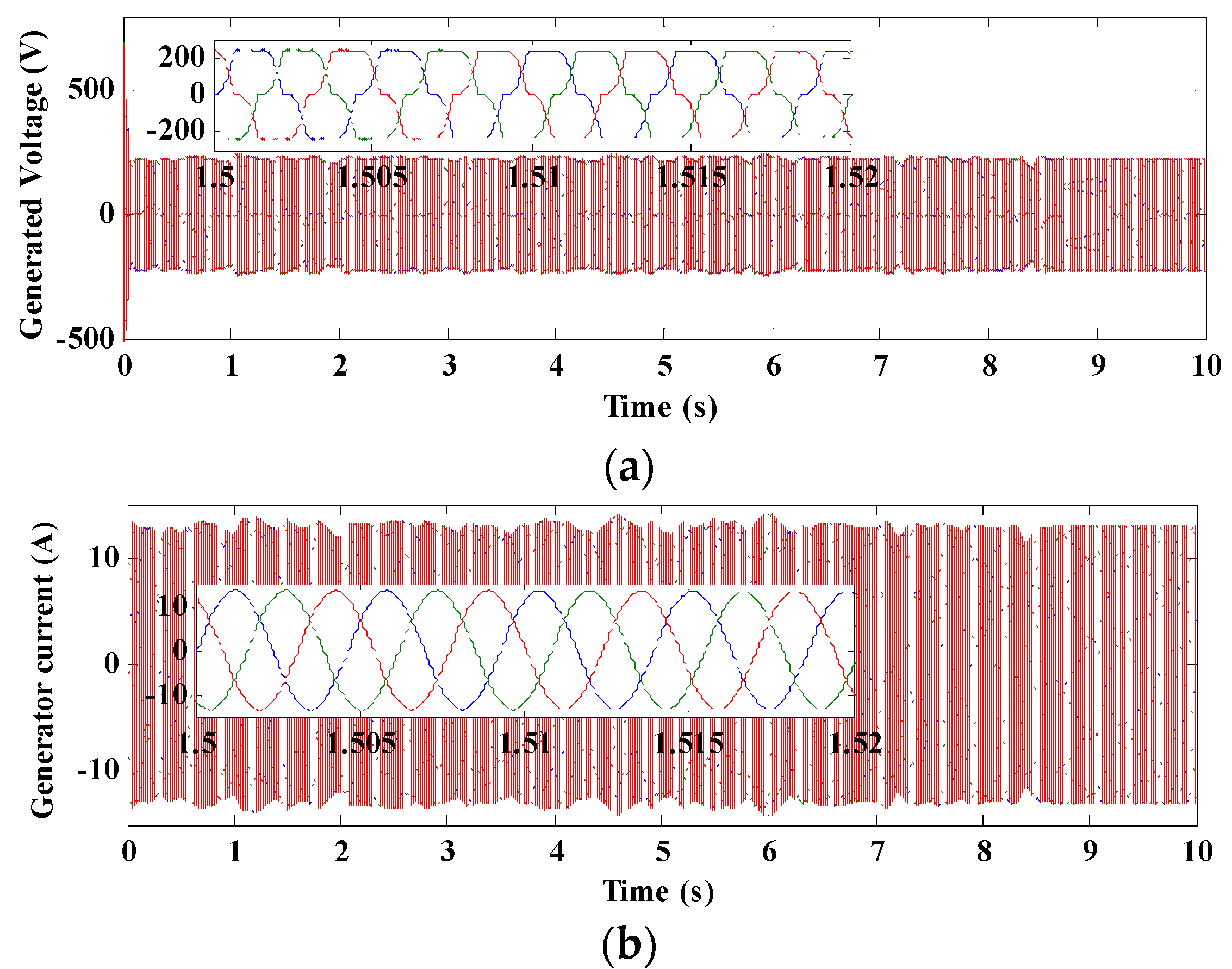

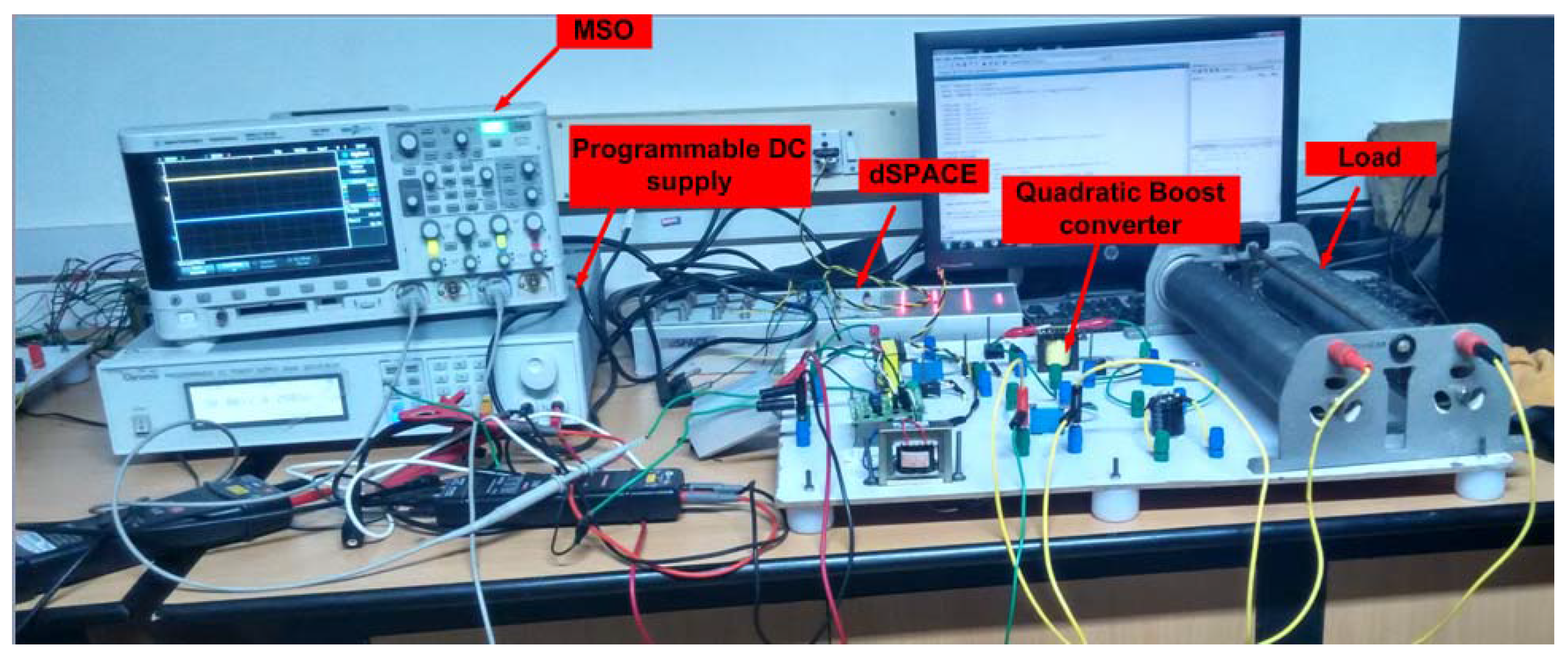

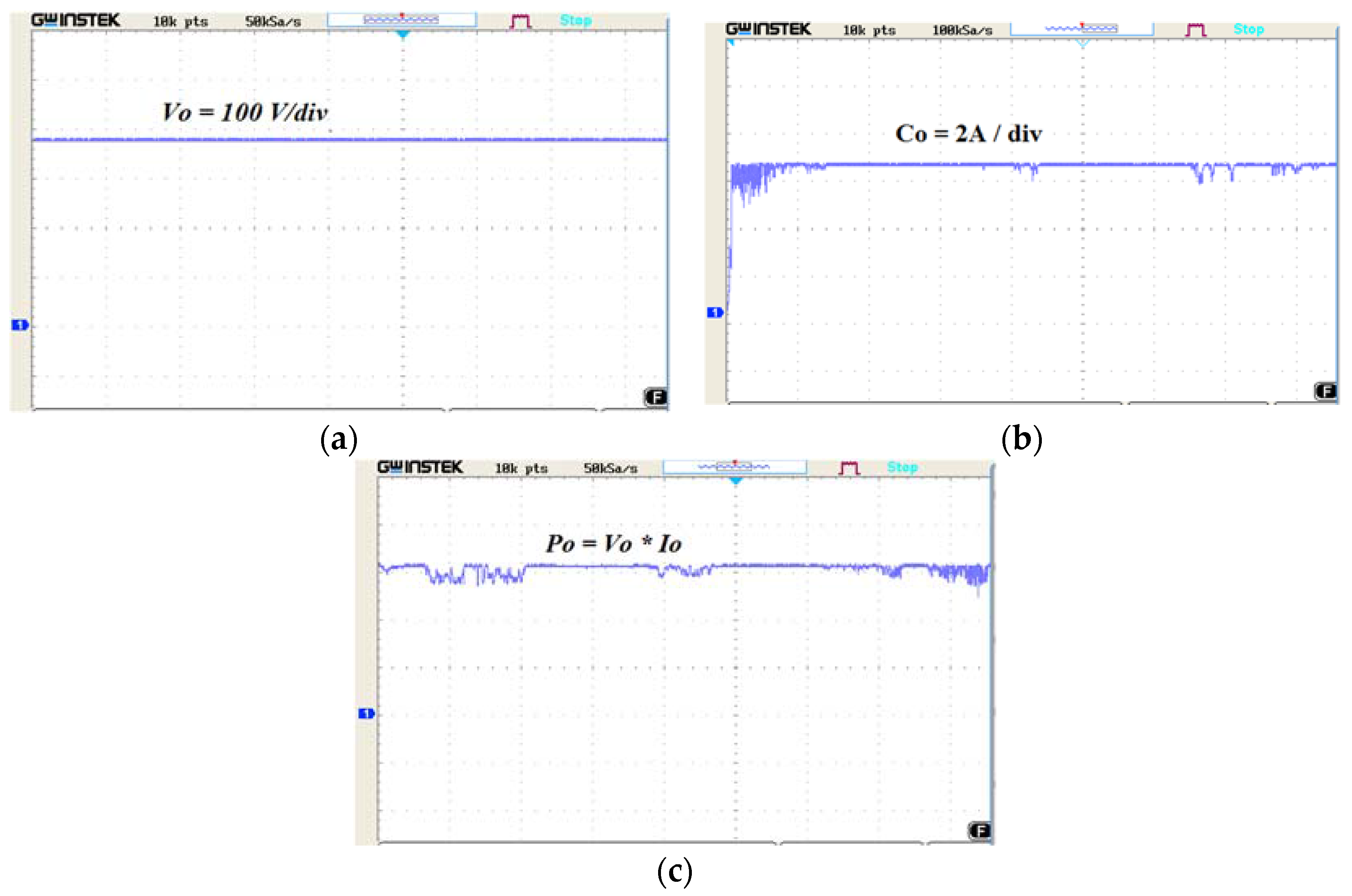

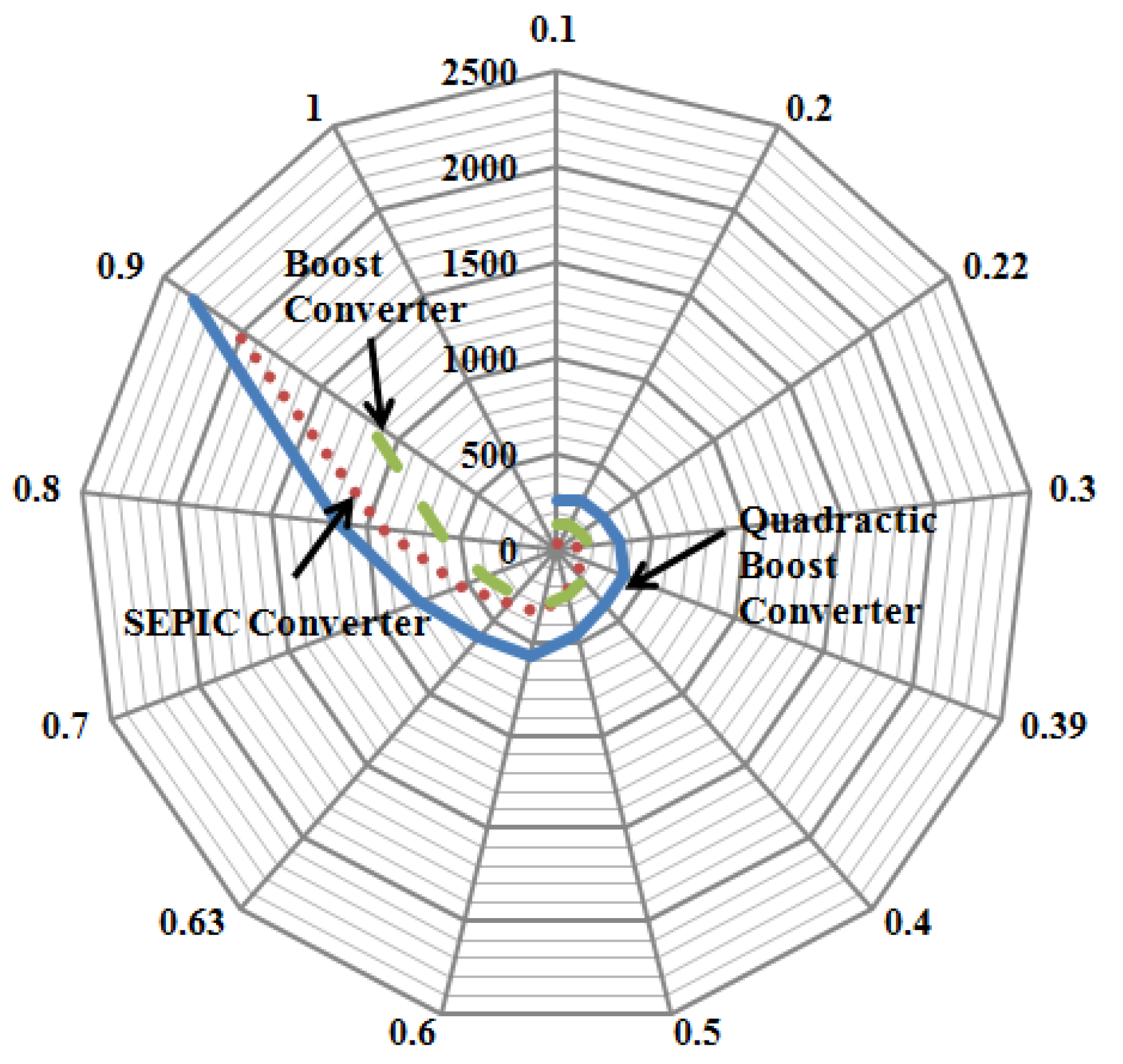

5. Results and Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tiwari, R.; Babu, N.R. Recent developments of control strategies for wind energy conversion system. Renew. Sustain. Energy Rev. 2016, 66, 268–285. [Google Scholar] [CrossRef]

- Tiwari, R.; Babu, N.R.; Sanjeevikumar, P.; Martirano, L.; Siano, P. Coordinated DTC and VOC control for PMSG based grid connected wind energy conversion system. In Proceedings of the 2017 IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Milan, Italy, 6–9 June 2017; pp. 1–6. [Google Scholar]

- Daly, P.A.; Morrison, J. Understanding the potential benefits of distributed generation on power delivery systems. In Proceedings of the Conference on Rural Electric Power, Little Rock, AR, USA, 29 April–1 May 2001; pp. 1–13. [Google Scholar]

- Dalala, Z.M.; Zahid, Z.U.; Yu, W.; Cho, Y.; Lai, J. Design and analysis of an MPPT technique for small-scale wind energy conversion systems. IEEE Trans. Energy Convers. 2013, 28, 756–767. [Google Scholar] [CrossRef]

- Barakati, S.M.; Kazerani, M.; Aplevich, J.D. Maximum power tracking control for a wind turbine system including a matrix converter. IEEE Trans. Energy Convers. 2009, 24, 705–713. [Google Scholar] [CrossRef]

- Li, D.Y.; Song, Y.D.; Gan, Z.X.; Cai, W.C. Fault-Tolerant Optimal Tip-Speed-Ratio Tracking Control of Wind Turbines Subject to Actuation Failures. IEEE Trans. Ind. Electron. 2015, 62, 7513–7523. [Google Scholar] [CrossRef]

- Nasiri, M.; Milimonfared, J.; Fathi, S.H. Modeling, analysis and comparison of TSR and OTC methods for MPPT and power smoothing in permanent magnet synchronous generator-based wind turbines. Energy Convers. Manag. 2014, 86, 892–900. [Google Scholar] [CrossRef]

- Daili, Y.; Gaubert, J.P.; Rahmani, L. Implementation of a new maximum power point tracking control strategy for small wind energy conversion systems without mechanical sensors. Energy Convers. Manag. 2015, 97, 298–306. [Google Scholar] [CrossRef]

- Saravanan, S.; Babu, N.R. Modified High Step-Up Coupled Inductor based DC-DC Converter for PV Applications. Gazi Univ. J. Sci. 2016, 29, 981–986. [Google Scholar]

- Linus, R.M.; Damodharan, P. Maximum power point tracking method using a modified perturb and observe algorithm for grid connected wind energy conversion systems. IET Renew. Power. Gener. 2015, 9, 682–689. [Google Scholar] [CrossRef]

- Tiwari, R.; Babu, N.R. Fuzzy logic based MPPT for permanent magnet synchronous generator in wind energy conversion system. IFAC-PapersOnLine 2016, 49, 462–467. [Google Scholar] [CrossRef]

- Kumar, D.; Chatterjee, K. Design and analysis of artificial bee-colony-based MPPT algorithm for DFIG-based wind energy conversion systems. Int. J. Green Energy 2017, 14, 416–429. [Google Scholar] [CrossRef]

- Assareh, E.; Biglari, M. A novel approach to capture the maximum power from variable speed wind turbines using PI controller, RBF neural network and GSA evolutionary algorithm. Renew. Sustain. Energy Rev. 2015, 51, 1023–1037. [Google Scholar] [CrossRef]

- Babu, N.R.; Arulmozhivarman, P. Forecasting of wind speed using artificial neural networks. Int. Rev. Model. Simul. 2012, 5, 2276–2280. [Google Scholar]

- Poultangari, I.; Shahnazi, R.; Sheikhan, M. RBF neural network based PI pitch controller for a class of 5-MW wind turbines using particle swarm optimization algorithm. ISA Trans. 2012, 51, 641–648. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, S.; Babu, N.R. RBFN based MPPT algorithm for PV system with high step up converter. Energy Convers. Manag. 2016, 122, 239–251. [Google Scholar] [CrossRef]

- Yaramasu, V.; Wu, B. Predictive control of a three-level boost converter and an NPC inverter for high-power PMSG-based medium voltage wind energy conversion systems. IEEE Trans. Power Electron. 2014, 29, 5308–5322. [Google Scholar] [CrossRef]

- Koutroulis, E.; Kalaitzakis, K. Design of a maximum power tracking system for wind-energy-conversion applications. IEEE Trans. Ind. Electron. 2006, 53, 486–494. [Google Scholar] [CrossRef]

- Gules, R.; Dos Santos, W.M.; Dos Reis, F.A.; Romaneli, E.F.; Badin, A.A. A modified SEPIC converter with high static gain for renewable applications. IEEE Trans. Power Electron. 2014, 29, 5860–5871. [Google Scholar] [CrossRef]

- Chen, Z. PI and sliding mode control of a Cuk converter. IEEE Trans. Power Electron. 2012, 27, 3695–3703. [Google Scholar] [CrossRef]

- Balamurugan, T.; Manoharan, S. Fuzzy controller design using soft switching boost converter for MPPT in hybrid system. Int. J. Soft Comput. Eng. 2012, 2, 87–94. [Google Scholar]

- Tiwari, R.; Babu, N.R. Comparative Analysis of Pitch Angle Controller Strategies for PMSG Based Wind Energy Conversion System. Int. J. Intell. Syst. Appl. 2017, 9, 62–73. [Google Scholar]

- Babu, N.R.; Arulmozhivarman, P. Wind energy conversion systems-a technical review. J. Eng. Sci. Technol. 2013, 8, 493–507. [Google Scholar]

- Alizadeh, M.; Kojori, S.S. Augmenting effectiveness of control loops of a PMSG (permanent magnet synchronous generator) based wind energy conversion system by a virtually adaptive PI (proportional integral) controller. Energy 2015, 91, 610–629. [Google Scholar] [CrossRef]

- Beddar, A.; Bouzekri, H.; Babes, B.; Afghoul, H. Experimental enhancement of fuzzy fractional order PI+ I controller of grid connected variable speed wind energy conversion system. Energy Convers. Manag. 2016, 123, 569–580. [Google Scholar] [CrossRef]

- Eldahab, Y.E.; Saad, N.H.; Zekry, A. Enhancing the tracking techniques for the global maximum power point under partial shading conditions. Renew. Sustain. Energy Rev. 2017, 73, 1173–1183. [Google Scholar] [CrossRef]

- Yilmaz, A.S.; Özer, Z. Pitch angle control in wind turbines above the rated wind speed by multi-layer perceptron and radial basis function neural networks. Expert Syst. Appl. 2009, 36, 9767–9775. [Google Scholar] [CrossRef]

- Chen, C.H.; Hong, C.M.; Ou, T.C. Hybrid fuzzy control of wind turbine generator by pitch control using RNN. Int. J. Ambient Energy 2012, 33, 56–64. [Google Scholar] [CrossRef]

- Babu, N.R.; Arulmozhivarman, P. Improving forecast accuracy of wind speed using wavelet transform and neural network. J. Electr. Eng. Technol. 2013, 8, 559–564. [Google Scholar] [CrossRef]

- Rahimi, M. Modeling, control and stability analysis of grid connected PMSG based wind turbine assisted with diode rectifier and boost converter. Int. J. Electr. Power Energy Syst. 2017, 93, 84–96. [Google Scholar] [CrossRef]

- Kumar, K.; Babu, N.R.; Prabhu, K.R. Design and Analysis of an Integrated Cuk-SEPIC Converter with MPPT for Standalone Wind/PV Hybrid System. Int. J. Renew. Energy Res. 2017, 7, 96–106. [Google Scholar]

- Lee, S.W.; Do, H.L. Zero-Ripple Input-Current High-Step-Up Boost–SEPIC DC–DC Converter With Reduced Switch-Voltage Stress. IEEE Trans. Power Electron. 2017, 32, 6170–6177. [Google Scholar] [CrossRef]

- Malik, M.Z.; Xu, Q.; Farooq, A.; Chen, G. A new modified quadratic boost converter with high voltage gain. IEICE Electron. Express 2017, 14, 20161176. [Google Scholar] [CrossRef]

- Ozdemir, S.; Altin, N.; Sefa, I. Fuzzy logic based MPPT controller for high conversion ratio quadratic boost converter. Int. J. Hydrog. Energy 2017, 42, 17748–17759. [Google Scholar] [CrossRef]

- Ramji, T.; Sanjeevikumar, P.; Ramesh Babu, N. Co-ordinated Control Strategies for Permanent Magnet Synchronous Generator Based Wind Energy Conversion System. Energies 2017, 10, 1493. [Google Scholar] [CrossRef]

- Kalaivani, C.; Sanjeevikumar, P.; Rajambal, K.; Bhaskar, M.S.; Mihet-Popa, L. Grid Synchronization of Seven-phase Wind Electric Generator using d-q PLL. Energies 2017, 10, 929. [Google Scholar] [CrossRef]

| Parameters | Ratings |

|---|---|

| Rated Power | 3 kW |

| Rated wind speed | 12 m/s |

| Cut-in wind speed | 3.0 m/s |

| Cut-out wind speed | 25 m/s |

| Frequency | 50 Hz |

| Voltage | 220–240 V |

| Rotor diameter | 5.0 m |

| Generator type | Three phase PMSG |

| Stator phase Resistance | 0.425 Ω |

| Armature Inductance | 0.000835 H |

| Number of Poles | 4 |

| Rotor blade radius | 2.4 m |

| Components/Converters | Boost | SEPIC | Quadratic Boost Converter |

|---|---|---|---|

| Inductor | 146.11 μH | 63.52 mH | L1 = 77.3 μH, L2 = 99.73 μH |

| Output Capacitor | 27.875 μF | 16.86 mF | 0.19 μF |

| Capacitor | NA | 33.752 mF | 0.31 μF |

| Diode | 390 V/27.875 A | 390 V/27.875 A | 390 V/27.875 A |

| Switching frequency | 24 kHz | 24 kHz | 24 kHz |

| Control Strategy | Boost Converter | SEPIC | Quadratic Boost Converter | |||

|---|---|---|---|---|---|---|

| Below Rated Wind Speed | Above Rated Wind Speed | Below Rated Wind Speed | Above Rated Wind Speed | Below Rated Wind Speed | Above Rated Wind Speed | |

| P&O | 2541 W | 2766 W | 2876 W | 3097 W | 2897 W | 3073 W |

| BPN | 2626 W | 2812 W | 2901 W | 3036 W | 2948 W | 3049 W |

| RBFN | 2726 W | 2884 W | 2982 W | 3008 W | 2994 W | 3003 W |

| Control Strategy | Boost Converter | SEPIC | Quadratic Boost Converter | |||

|---|---|---|---|---|---|---|

| Below Rated Wind Speed | Above Rated Wind Speed | Below Rated Wind Speed | Above Rated Wind Speed | Below Rated Wind Speed | Above Rated Wind Speed | |

| P&O | 309 V | 412 V | 359 V | 394 V | 361 V | 387 V |

| BPN | 369 V | 393 V | 374 V | 393 V | 377 V | 393 V |

| RBFN | 376 V | 389 V | 380 V | 380 V | 380 V | 380 V |

| Converter | Switching Power Loss | Diode Power Loss | ||

|---|---|---|---|---|

| Equation | Theoretical Value | Equation | Theoretical Value | |

| Boost Converter | Ploss = IDRAIN2 RON | 246.7 W | Ploss = IRMS VD | 64.56 W |

| SEPIC | Ploss = IOUT2 RON | 135.2 W | Ploss = VD IOUT | 62.4 W |

| Quadratic Boost Converter | Ploss = IDRAIN2 RON | 51.9 W | Ploss = IRMS VD | 21.5 W |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiwari, R.; Krishnamurthy, K.; Neelakandan, R.B.; Padmanaban, S.; Wheeler, P.W. Neural Network Based Maximum Power Point Tracking Control with Quadratic Boost Converter for PMSG—Wind Energy Conversion System. Electronics 2018, 7, 20. https://doi.org/10.3390/electronics7020020

Tiwari R, Krishnamurthy K, Neelakandan RB, Padmanaban S, Wheeler PW. Neural Network Based Maximum Power Point Tracking Control with Quadratic Boost Converter for PMSG—Wind Energy Conversion System. Electronics. 2018; 7(2):20. https://doi.org/10.3390/electronics7020020

Chicago/Turabian StyleTiwari, Ramji, Kumar Krishnamurthy, Ramesh Babu Neelakandan, Sanjeevikumar Padmanaban, and Patrick William Wheeler. 2018. "Neural Network Based Maximum Power Point Tracking Control with Quadratic Boost Converter for PMSG—Wind Energy Conversion System" Electronics 7, no. 2: 20. https://doi.org/10.3390/electronics7020020