Mechanical and Non-Destructive Study of CFRP Adhesive Bonds Subjected to Pre-Bond Thermal Treatment and De-Icing Fluid Contamination

Abstract

:1. Introduction

2. Materials

3. Methods and Results

3.1. Mechanical Testing

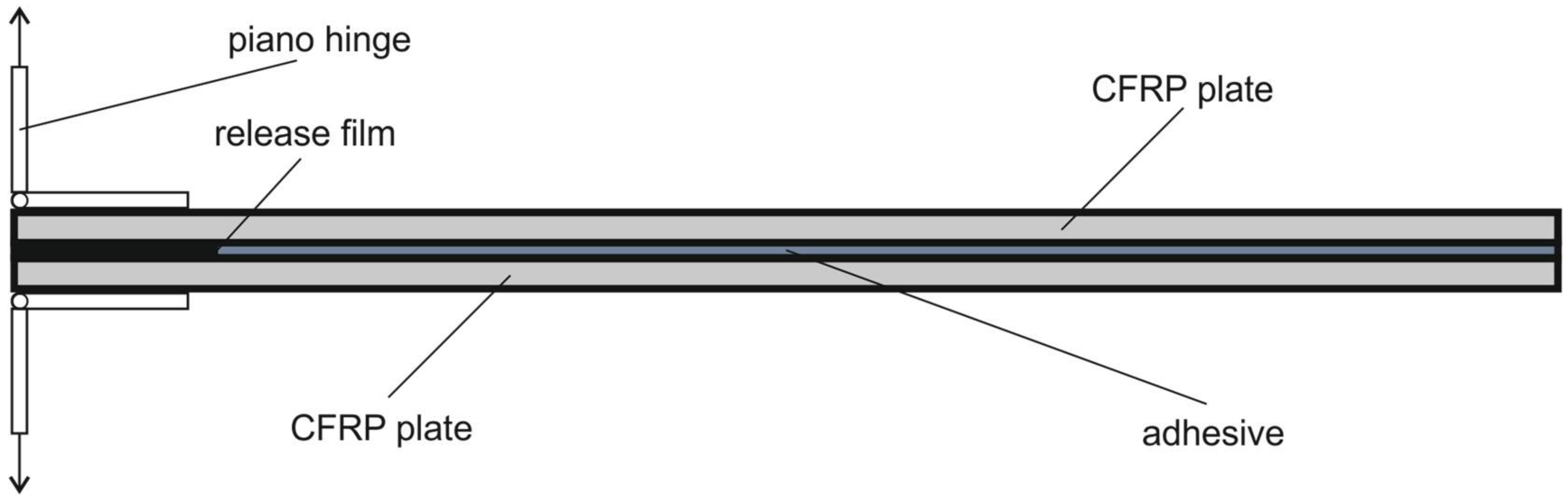

3.1.1. Mode-I Fracture Toughness Test

3.1.2. Mode-II Fracture Toughness Test

3.1.3. Centrifuge Tests

3.2. Ultrasound Testing

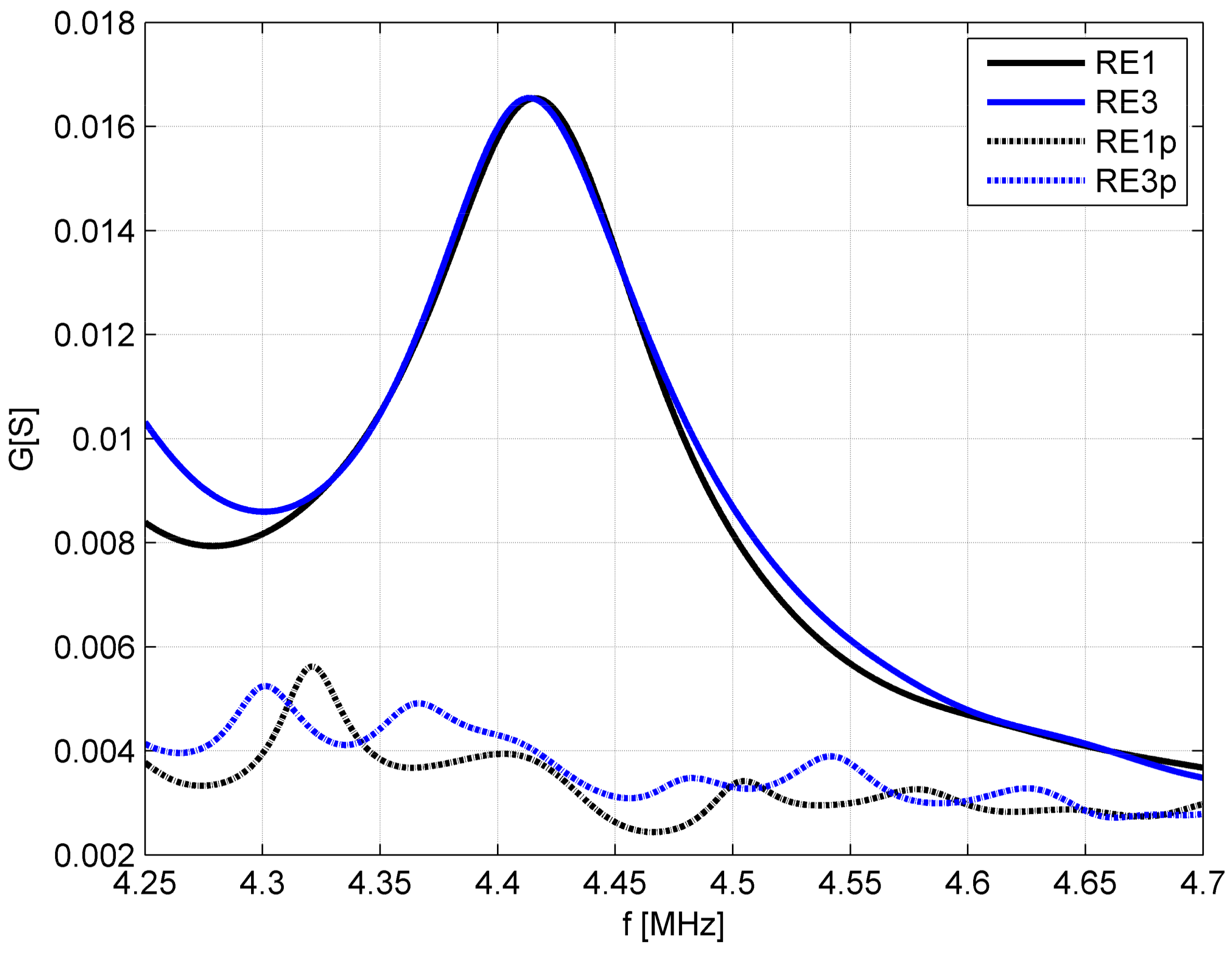

3.3. Electromechanical Impedance Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Eibl, S.; Wolfrum, J. Prospects to separately estimate temperature and duration of a thermal pre-load on a polymer matrix composite. J. Compos. Mater. 2013, 47, 3011–3025. [Google Scholar] [CrossRef]

- Heckner, S.; Geistbeck, M.; Grosse, C.; Eibl, S.; Helwig, A. FTIR Spectroscopy as a Nondestructive Testing Method for CFRP Surfaces in Aerospace. J. Nondestruct. Test. 2016, 21, 1–9. [Google Scholar]

- Tserpes, K.I.; Markatos, D.N.; Brune, K.; Hoffmann, M.; Rau, E. A detailed experimental study of the effects of pre-bond contamination with a hydraulic fluid, thermal degradation, and poor curing on fracture toughness of composite-bonded joints. J. Adhes. Sci. Technol. 2014, 28, 1865–1880. [Google Scholar] [CrossRef]

- Moutsompegka, E.; Tserpes, K.I.; Polydoropoulou, P.; Tornow, C.; Schlag, M.; Brune, K.; Mayer, B.; Pantelakis, S. Experimental study of the effect of pre-bond contamination with de-icing fluid and ageing on the fracture toughness of composite bonded joints. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1581–1591. [Google Scholar] [CrossRef]

- Singhal, T.; Kim, E.; Kim, T.-Y.; Yang, J. Weak bond detection in composites using highly nonlinear solitary waves. Smart Mater. Struct. 2017, 26, 055011. [Google Scholar] [CrossRef]

- Christopoulos, A.; Hristoforou, E.; Koulalis, I.; Tsamasphyros, G. Inductive strain sensing using magnetostrictive wires embedded in carbon fibre laminates. Smart Mater. Struct. 2014, 23, 08503. [Google Scholar] [CrossRef]

- Canal, L.P.; Sarfaraz, R.; Violakis, G.; Botsis, J.; Michaud, V.; Limberger, H.G. Monitoring strain gradients in adhesive composite joints by embedded fiber Bragg grating sensors. Compos. Struct. 2014, 112, 241–247. [Google Scholar] [CrossRef]

- Dugnani, R.; Zhuang, Y.; Kopsaftopoulos, F.; Chang, F.-K. Adhesive bond-line degradation detection via a cross-correlation electromechanical impedance-based approach. Struct. Health Monit. 2016, 15650–15667. [Google Scholar] [CrossRef]

- Dugnani, R.; Chang, F.-K. Analytical model of lap-joint adhesive with embedded piezoelectric transducer for weak bond detection. J. Intell. Mater. Syst. Struct. 2017, 28, 124–140. [Google Scholar] [CrossRef]

- Malinowski, P.; Wandowski, T.; Ostachowicz, W. The use of electromechanical impedance conductance signatures for detection of weak adhesive bonds of carbon fibre-reinforced polymer. Struct. Health. Monit. 2015, 14, 332–344. [Google Scholar] [CrossRef]

- Malinowski, P.; Ostachowicz, W.; Brune, K.; Schlag, M. Study of electromechanical impedance changes caused by modifications of CFRP adhesive bonds. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1592–1600. [Google Scholar] [CrossRef]

- AITM 1-0053. AITM, Airbus Test Method, Carbon Fibre Reinforced Plastics, Determination of Fracture Toughness Energy of Bonded Joints, Mode I; Airbus S.A.S.: Toulouse, France, 2006.

- AITM 1-0006. AITM, Airbus Industry Test Method, Carbon Fibre Reinforced Plastics, Determination of Interlaminar Fracture Toughness Energy, Mode II; Airbus S.A.S.: Toulouse, France, 1994.

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malinowski, P.H.; Tserpes, K.I.; Ecault, R.; Ostachowicz, W.M. Mechanical and Non-Destructive Study of CFRP Adhesive Bonds Subjected to Pre-Bond Thermal Treatment and De-Icing Fluid Contamination. Aerospace 2018, 5, 36. https://doi.org/10.3390/aerospace5020036

Malinowski PH, Tserpes KI, Ecault R, Ostachowicz WM. Mechanical and Non-Destructive Study of CFRP Adhesive Bonds Subjected to Pre-Bond Thermal Treatment and De-Icing Fluid Contamination. Aerospace. 2018; 5(2):36. https://doi.org/10.3390/aerospace5020036

Chicago/Turabian StyleMalinowski, Paweł H., Konstantinos I. Tserpes, Romain Ecault, and Wiesław M. Ostachowicz. 2018. "Mechanical and Non-Destructive Study of CFRP Adhesive Bonds Subjected to Pre-Bond Thermal Treatment and De-Icing Fluid Contamination" Aerospace 5, no. 2: 36. https://doi.org/10.3390/aerospace5020036