1. Introduction

Active flow control is one of the most promising methodologies for improving the aerodynamic characteristics of supersonic transport vehicles. A supersonic flow field is dominated by shock waves, and thus their formation and interaction with the boundary layer is an essential aspect of flow control to attain a desirable flow field around the vehicle [

1]. A micro vortex generator, or a micro ramp composed of triangular obstacles with a forward-facing compression ramp, has been studied both at supersonic [

2] and hypersonic speeds [

3] as a flow modification method. It provides a means of controlling boundary layer separation and shock-induced separation by forming an adverse pressure gradient along the surface. Supersonic flow over a compression ramp geometry has been studied for decades [

4,

5] because the ramp geometry is employed in aerodynamic shapes. The compression ramp can be regarded as a geometry composed of a supersonic vehicle body with its flap deflected outwards. The compression surface forms a shock wave which changes the pressure distribution and flow field in the vicinity of the ramp compared to the surface without a ramp. An important characteristic of supersonic flow over a compression ramp is the formation of flow separation and unsteadiness of the separation shock ahead of the ramp [

6,

7,

8]. Shock wave interaction with the supersonic boundary layer upstream of the ramp provides various flow field patterns depending on the ramp angles [

9]. Flow separation and unsteadiness of the separation shock wave significantly affect the aerodynamic forces acting on flaps.

The control methods for the flow field over a compression ramp have been investigated from various viewpoints. Micro air jets [

10] were studied as a means of controlling such a flow field with separation and oblique shock waves in front of the compression ramp at Mach-2 by introducing a pressure increase and wall-normal momentum addition to change the flow field ahead of the ramp. In recent years, another flow control method employing electric discharges has been gaining research attention. Plasma-based flow actuators have several significant advantages over conventional mechanical actuators [

11,

12] with deflecting surfaces such as flaps. Electric actuation has a shorter response time and provides rapid flow control operation with a time scale in the order of a characteristic gas-dynamic time. Electrodes flush-mounted on the surface provide a robust installation, since electric actuator lacks movable parts and is not protruding into the flow. The rapid response feature is highly beneficial to the prevention of operational delay when generating aerodynamic moments, especially for high speed vehicles such as supersonic/hypersonic transports. A supersonic vehicle may travel a few kilometers if the aerodynamic control is delayed for just a second or two, which may lead to deviation from the optimum trajectory. However, if the delay in aerodynamic control is reduced by plasma-assisted flow control, it will be profitable to keep close to the desired course, reducing fuel consumption.

In [

13,

14,

15,

16] and other publications, the plasma-based technique and the mechanisms of the plasma–flow interaction were examined in supersonic flow. It was found that the near-surface electric discharge is well applicable for the purposes of the modification of surface pressure distribution, flow field pattern, and shock wave formation. The quasi-DC (Q-DC) electric discharge [

15] forms filamentary plasma penetrating in the streamwise direction, which intensely and locally heats the gas, leading to a volumetric expansion and shock wave generation. The Q-DC electric discharge was also found to have great effectiveness in ignition and flame holding in scramjet engines [

17], flow modification inside a flame holding cavity [

18], boundary layer modification [

19], inlet control [

20], and oblique shock wave control [

21,

22].

In this study, the plasma actuator was placed upstream of a body–flap geometry, which has been found to be beneficial for the pitching moment control of high-speed vehicles. Watanabe and Suzuki investigated Mach-7 hypersonic flow control ahead of a 20° compression ramp geometry [

23,

24]. A schematic of such an approach is shown in

Figure 1. As illustrated in

Figure 1a, in these Mach-7 studies, a pair of electrodes were installed in front of a ramp geometry to replicate a simplified form of a space vehicle surface with a body flap on the downstream side. In this plasma actuation concept, plasma generation leads to flow separation and subsequently changes the pressure distribution over the flap/ramp, as shown in

Figure 1b. Plasma actuation, applied to the 20° ramp geometry, rapidly changed the pitching moment acting on the ramp surface, reducing it by 10–20% within 0.09 s. The main research interest of the current work was the experimental study of the Q-DC electric discharge employed upstream of a ramp geometry in the Mach-2 airflow.

For the purpose of applying this plasma-assisted flow control method for the aerodynamic control of actual supersonic vehicles, it was necessary to clarify its flow control characteristics with a multielectrode system arranged in the crossflow/spanwise direction. A preliminary study [

25] was conducted to examine the Reynolds number effects on flow control authority. The objective of the current work was to examine changes in flow structure, ramp pressure (which is an indicator of force acting on a flap), and plasma power to correlate ramp pressure change with plasma and flow parameters.

3. Results and Discussion

A snapshot image of the plasma filaments is shown in

Figure 5. The supersonic flow moves from left to right and the plasma filament was convected downstream to form the U-shaped discharge path. Although periodical change in the location of the transverse portion of the plasma filaments was confirmed in the images, the change in the position of the streamwise portion of filaments was negligible. This pattern occurred because a separation zone formed ahead of the ramp on the downstream side of the electrodes. The transverse filament was partially trapped in the separation and exhibited periodical change.

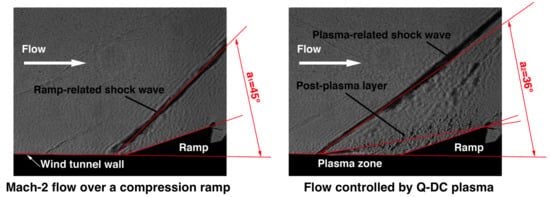

Due to significant gas heating near/within the plasma filaments, it was expected that the flow field would be modified in the vicinity of the ramp. The schlieren images in

Figure 6 provide a clear insight into the flow structure modification by plasma actuation. The flow structure exhibited significant change in shock wave positions and angle. The plasma-related shock wave oscillated because of the motion of the plasma filaments, but its position remained at almost the same location when averaged in time. Without plasma actuation, the shock wave at the ramp formed at 45° to the wall, illustrated as a

1 in

Figure 6a. This shock wave originated slightly ahead of the leading edge of the ramp. This is because the selected ramp angle of 19.4° was close to critical shock detachment angle of 23° for Mach-2.04. Since there was a 1° wall inclination and −0.3° boundary layer expansion, the actual turn angle of Mach-2.04 supersonic flow was 19.4° − (1° − 0.3°) = 18.7°. According to the oblique shock relation for the Mach number, and turn- and wave angles, the wave angle to the flow was calculated as 49.8°, and thereby the wave angle to the wall was 49.8° + 0.3° = 50.1°. This angle was greater than a

1 = 45° measured from the schlieren image because of a small separation zone that formed in front of the ramp’s leading edge. When the plasma was turned on, the shock location shifted upstream and formed ahead of the electrode row, as shown in

Figure 6b. The plasma-induced shock wave had the angle a

2 = 36° to the wall. Due to a separation zone formed between plasma and the ramp, the turn angle of the flow was estimated to be 9.8°, as shown in

Figure 6b, and the effective turn angle became 9.8° − (1° − 0.3°) = 9.1°. From the oblique shock relation, the wave angle was calculated to be 37.5° to the flow, and thereby 37.5° + 0.3° = 37.8° to the wall, which was slightly larger than the angle a

2 = 36° measured from the schlieren image. The difference in measured shock angles and those calculated from theoretical relation is explained by the fact that the separation zone had a more complex shape than a plane wedge, representing a gradually increased effective angle. The resulting shape of the shock wave was also curved, demonstrating a higher angle further into the freestream, see

Figure 6b.

The significant change in shock locations, as shown in

Figure 6, suggests that there was a remarkable pressure change at the rear side of the electrodes and along the surface of the compression ramp. Typical pressure timeseries are shown in

Figure 7. A pressure increase was observed downstream of the electrodes, which was consistent with past studies without the ramp [

15]. A significant pressure drop was observed along the surface of the ramp at ports 2 and 3. This is clear evidence that the plasma actuation ahead of a ramp (flap) can control pressure force and thereby cause a change in the pitching moment acting on the flaps. It should be noted that the pressure curves of ports 2 and 3 were almost identical and hence, and separation ahead of the ramp was insignificant without plasma actuation. In the following results and discussion, the pressure drop on the ramp surface was evaluated based on the pressure at port 2 and quantified according to the definition of pressure decrease illustrated in

Figure 7b.

The flow parameters were varied independently to form the test matrix: P

0 = 1, 2, 3 bar and T

0 = 294, 400, 500, and 600 K. This led to variation in plasma power in the range of 2.5–11.8 kW and an appropriate pressure decrease on the ramp.

Figure 8 shows the pressure effect vs. average plasma power. The uncertainty of the pressure change reading was almost 10 mbar, represented as error bars in the plot. Since the pressure change value was always negative, the

y axis denotes −ΔP (mbar). The fill color of the dots in

Figure 8 indicates the stagnation pressure in each test case and a circle at the origin illustrates the no-plasma case with no pressure change.

Figure 8 demonstrates that the ramp pressure change was linearly dependent on the average plasma power. An increase in plasma power produces an increase in the heat energy deposited to the flow, this intense and local heating proceeds through multiple relaxation pathways to a pressure increase, and thus an increase in plasma power increases the flow control effect over the ramp [

15]. It should be noted that the gray shaded area in

Figure 8, indicating a low plasma–power zone with Wpl < 2.1 kW, corresponds to an unstable discharge pattern because of insufficient electric power to maintain steady plasma filaments. There was also a trend of the ramp pressure impact (−ΔP) increasing with an increase in stagnation pressure, which implies that the pressure change ratio −ΔP/P

static could be an important parameter correlated against other flow control parameters.

Since the pressure change ratio −ΔP/P

static is a non-dimensional parameter, a correlation was found between another non-dimensional parameter related to plasma power.

Figure 9 shows the relation between pressure change ratio −ΔP/P

static and relative plasma power W

pl/(h

0·ṁ), where h

0 is the specific enthalpy of the freestream and ṁ denotes the mass flux through the wind tunnel test section. The uncertainty of −ΔP/P

static was (2–7) × 10

−2 depending on the stagnation pressure.

Figure 9 shows that the pressure change ratio gradually increased with an increase in relative plasma power. The curve fit with a power curve was also illustrated in

Figure 9.

The main focus of this study was the pressure control on the ramp, and the quantity of the pressure change ratio divided by the relative plasma power, η = [−ΔP/P

static]/[W

pl/(h

0·ṁ)], can be defined as “task-related effectiveness”. The straight line, η = 1 in

Figure 9, shows the task-related effectiveness to be unity. In all tests, η was always higher than 1 and almost attained 25 at lower relative power. At a higher relative power of around 0.02, η was higher than 1 and reached around 17.5, but the increment decreased within the scope of plasma power attained in this study.

4. Conclusions

Plasma-assisted flow control over a 19.4° compression ramp was examined with Mach-2 supersonic wind tunnel experiments using quasi-DC electric discharge flow parameters in the range of P0 = 1–3 bar and T0 = 294–600 K. It was concluded that the pressure force on a ramp surface can be reduced by 9–16% with the aid of plasma actuation. The pressure increase on the surface in front of the ramp was observed to be 20–60%. Schlieren visualization showed that the shock angle at the ramp without plasma actuation was about 45° to the flow direction, which was smaller than the angle obtained by oblique shock relations because the shock attachment point was located slightly upstream of the ramp’s leading edge. When plasma actuation was applied, the shock position moved upstream to the electrode location, forming an oblique shock with an angle of approximately 36°, which was almost equal to but slightly smaller than the angle of 37.8°, calculated based on a visibly equivalent geometric shape. Within the scope of the test conditions, the ramp pressure decrease was linearly dependent on the plasma power. The pressure change ratio was a rise function of the relative plasma power attaining a task-related effectiveness, η, of 17.5–25.

Within the range of the test parameters, no relation was found between the plasma control effect and the Reynolds number. Further research will assume a wider range of the flow Reynolds number to extend the test conditions to the laminar and transitional operation mode.