1. Introduction

Electrical impedance tomography (EIT) is a method in which an image of the internal conductivity distribution of an object is reconstructed from potential measurements made at the electrodes placed around its boundary [

1,

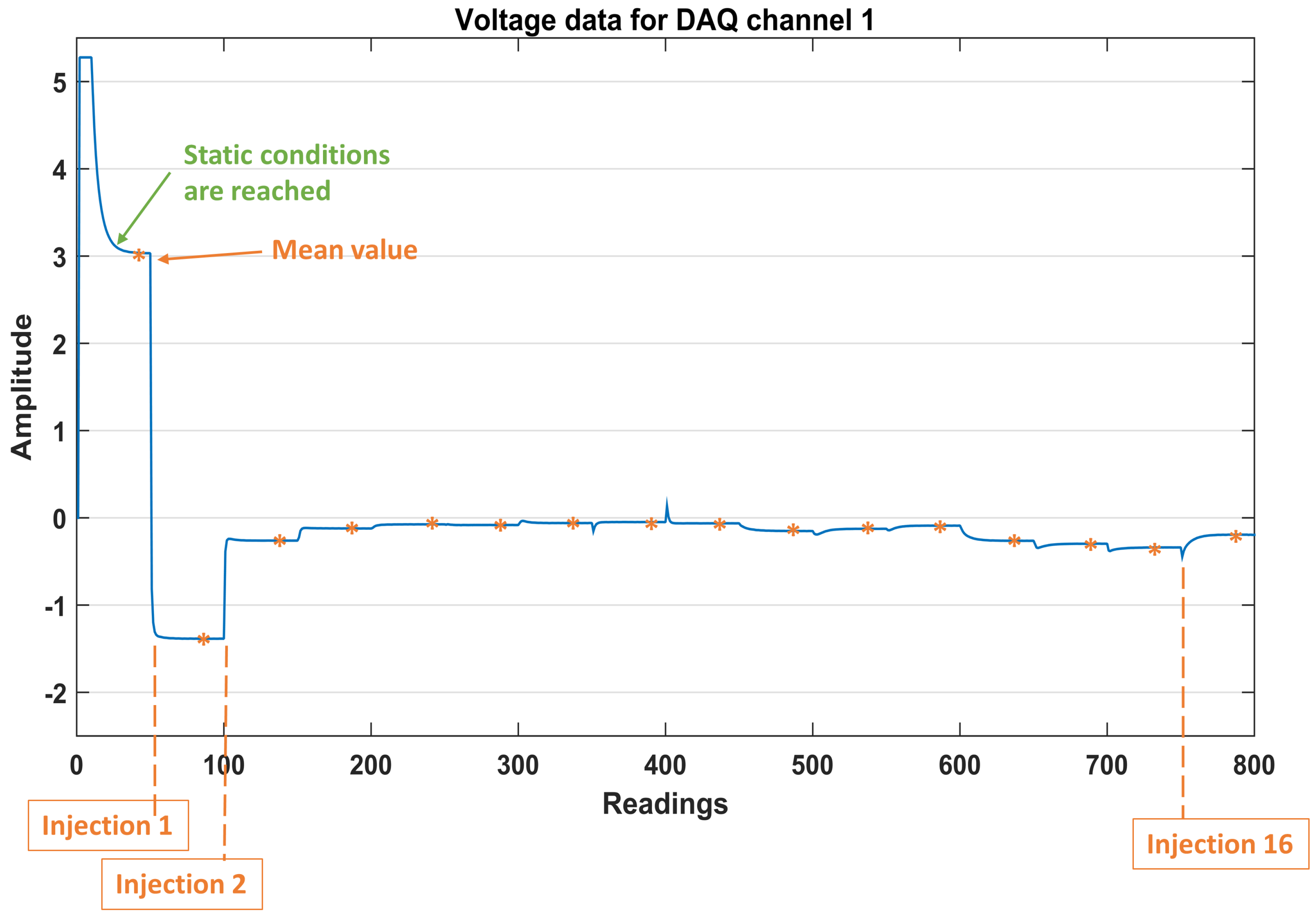

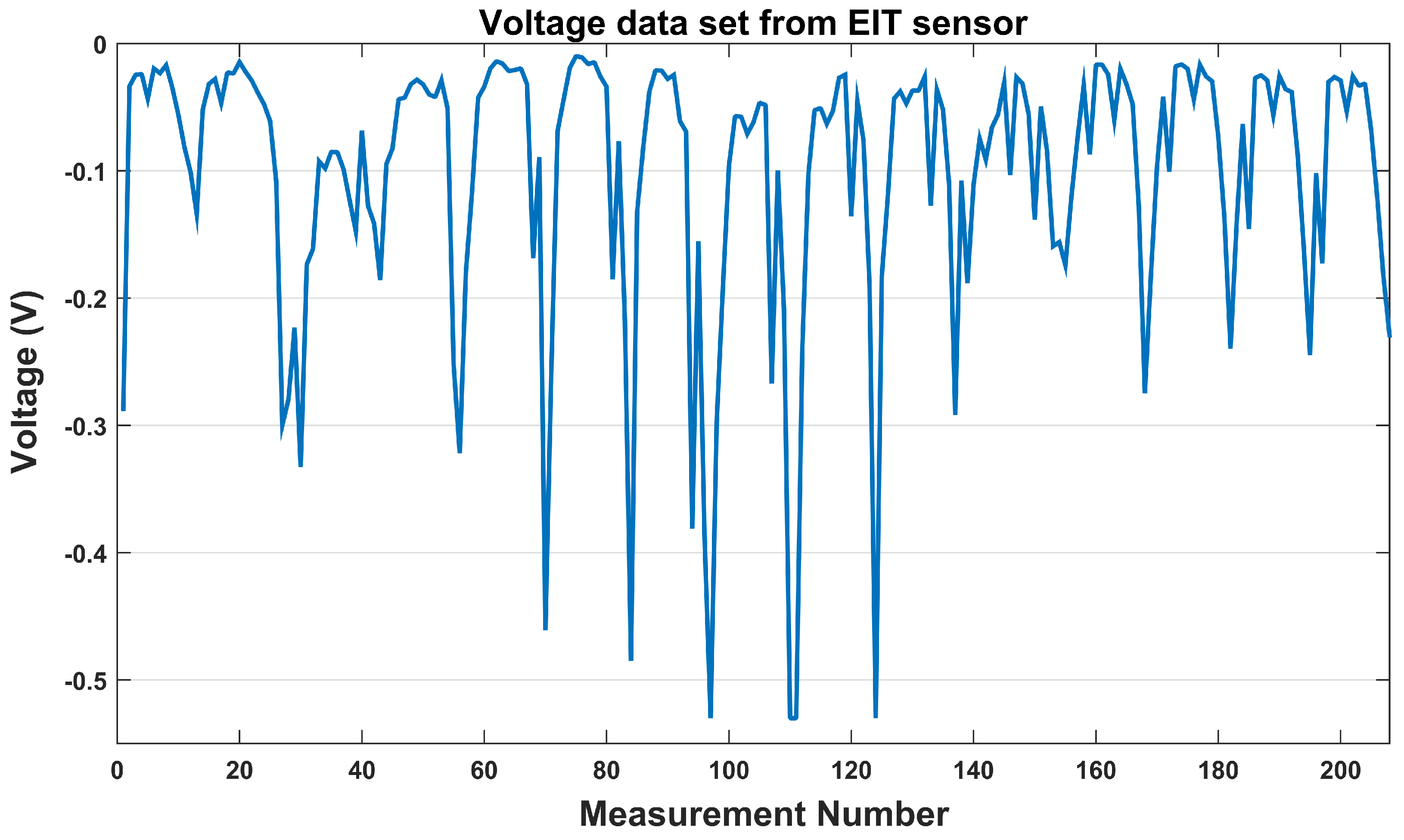

2]. In a typical procedure, a low-frequency or DC drive current is injected between two of these electrodes, and the resulting voltage data are collected from the remaining electrodes. The current injection and voltage measurements are then systematically repeated until every electrode pair has served for current injection. Once the voltage data are collected, the reconstruction of the conductivity is performed by solving the Laplacian elliptic partial differential equation [

1]. Then, a finite element (FE) model of the sensor is computed, resulting in an image of the conductivity distribution.

EIT is mainly used in clinical applications for patient monitoring [

3,

4]; other applications include damage detection [

5] and pressure sore prevention [

6]. Recently, EIT has been also employed for showing the internal impedance distribution of conductive fabrics that respond to touch with local changes in conductivity, and was therefore used for developing an artificial skin as a large-area pressure sensor [

7]. Such sensors have the advantage of being stretchable, and can be placed over surfaces with a different topology. In [

8,

9], an EIT-based sensor was placed over a mannequin arm in order to detect different types of touches. This demonstrated that these sensors have the potential of being used as wearable devices, and can now be used in robotic applications, whereby a robotic system is equipped with sensors that do not interfere with its mechanics.

However, EIT still presents a major drawback; it is considered an inverse problem, as described in [

1]. Thus, EIT systems are mathematically severely ill-posed and non-linear, and are very sensitive to small changes in potential at the boundary measurements. Therefore, the image reconstruction of the internal conductivity of the body under examination is apt to errors, meaning EIT applications suffer from a low spatial resolution.

The spatial resolution can be improved by increasing the number of electrodes [

10]; this creates more information available for solving the inverse problem. However, this solution affects the time required for the data collection, and therefore decreases the temporal resolution of the system.

The general approach to compensate for such a drawback is to develop data collection systems that are faster and less sensitive to noise.

Various methods have been used to increase the temporal resolution of EIT systems. In [

11], the authors use a frequency-division multiplexing approach; they simultaneously inject currents at different frequencies from all the electrodes and measure the resulting voltage. In [

12], a similar approach is also presented, where a fast EIT system is achieved via parallel current excitation that uses orthogonal signals. The drive currents can be then isolated, as they present diverse frequencies. Nonetheless, these approaches require synchronous analogue detection hardware and digital processing techniques that complicate the system design and increase the cost and power consumption. In [

13], a fast EIT system is presented; it injects a switched DC current pulse into the drive electrode pairs and measures the voltage waveform, whereby parallel data acquisition is taken during the half part of the cycle. The problem with such a system is that, in order to achieve a fast response, the measurement time has to be small, limiting the measurement sensitivity.

A temporal resolution of 45 Hz is reported for an EIT-based sensor in [

14], alongside a power consumption of roughly 22 mW. In [

15], the use of a current of 10 mA at 2 kHz over a resistive material of 1 Ohm/sq results in a power loss of about 175 mW. In these approaches, the use of multiple analog switch controllers for current injection and voltage measurements complicates the hardware. Additionally, bearing in mind wearable applications, electronics should give minimum power consumption and be fit for battery-powered operation. In this paper, we present our electronic design of a printed circuit board (PCB) for 16-electrode high-speed EIT sensor applications. A video of our EIT sensor setup is available as

Supplementary Materials. It works by serially injecting a constant unidirectional DC current and collecting differential voltages concurrently from all the electrodes at each current injection cycle. Parallel data acquisition consents for a higher data capture rate; therefore, this design allows for an increased temporal resolution. It also decreases the electrical common-mode noise, as the voltage data are collected in the differential mode. Another advantage of this design is that it does not have a complex hardware setup. This makes the system low-cost and of a low power consumption; thus it is more suitable for wearable applications.

The remainder of this paper is organized as follows: the electronic design of our PCB is presented in

Section 2. In

Section 3, we present our 16-electrode sensor system. In

Section 4, we begin by showing the data acquisition frame rate along with an analysis of the voltage data; we then show different images corresponding to pressure inputs on the stretchable sensor. Finally,

Section 5 concludes the paper.

2. Hardware Implementation

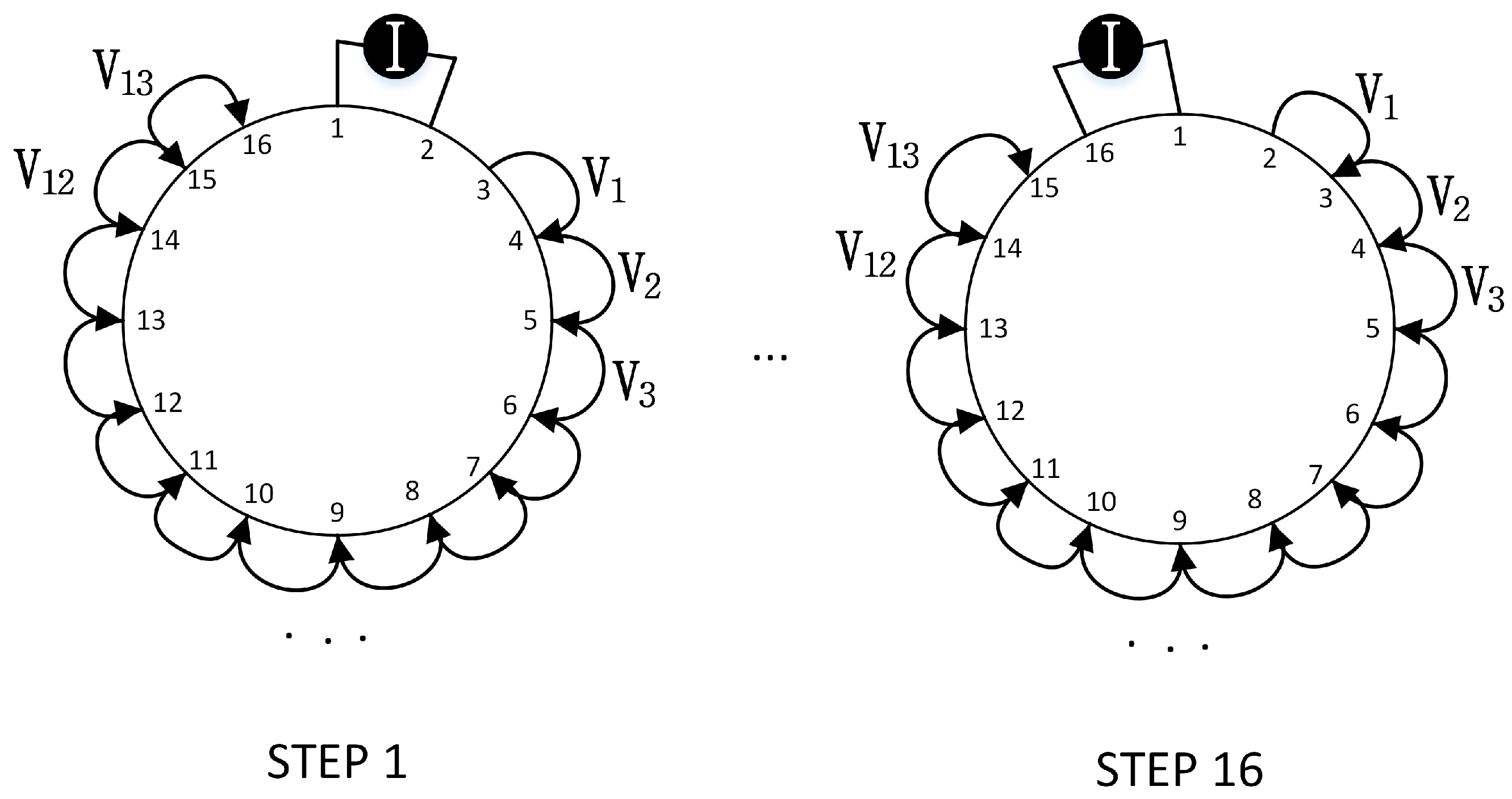

In EIT, a certain number of electrodes are located at the periphery of a conductive body. These electrodes serve for the application of either a small alternating or a DC current, and for performing voltage measurements; then, an image showing the internal conductivity is reconstructed using the voltage data and a FE model of the system. In

Figure 1 is shown a typical EIT current injection and voltage measurement cycle. In order to scan between all electrodes and obtain a full voltage data set, the current injection and voltage measurement are systematically repeated until every electrode pair has served for the current injection. To reduce the effects of noise due to the contact impedance, voltage measurements are not performed at electrodes carrying injected current. Therefore, for a generic

L-electrodes system, the number of measurements at the boundary is

. The voltage data sets are in the form of

, where

is the vector containing the voltage measurements and

K is the number of measurements. For a 16-electrode system,

. However, the total number of independent measurement is halved due to the reciprocity principle [

16], as we have a symmetrical commutation of current injection and potential measurement.

Electronic Circuit

Our hardware system for current injection and voltage measurement is a customized PCB, as shown in

Figure 2. It presents a power supply connector, a two-multiplexer mechanism connected to a Howland current pump constant current generator, a sensor block for connection with the sensor electrodes, and a connector for the National Instruments Data Acquisition (NI DAQ) USB card. The PCB can be powered with either USB or a wall block power supply.

The two multiplexers serve for the rotation of the current supply between the electrodes, and are digitally controlled by the DAQ card. They are two 16:1 ADG1606 multiplexers, presenting a typical on resistance of 4.5 and a transition time, when switching from one address state to another, of 143 ns. With 16 channels, the multiplexers each need to be controlled by 4 digital-bit variables and 1 enabling variable, for a total of 10 variables. The first of the multiplexers has its input connected to the current source, while the latter is connected to ground; their outputs are then connected to the different electrode pairs.

The Howland current pump [

17] is made of an Operational amplifier (Opamp), and provides a high-output impedance constant current source. The circuit is able to supply a constant DC current, independent of the connected load resistivity, to various loads. The Opamp for the current generator is an OP727 dual-Opamp, with a good common-mode rejection ratio (CMRR) CMRR of 85 dB, rail-to-rail, and a low supply current of 300

A/amplifier. The DAQ card is a NI USB6353, which serves for both the multiplexer control and the parallel collection of the voltage data. The DAQ has a high input impedance, a multichannel maximum sample rate of 1.00 MS/s, and an ADC resolution of 16 bits. The DAQ is used for the differential voltage readings, where one input channel is connected to the positive input of the device’s programmable gain instrumentation amplifier (PGIA), and the other is connected to the negative input of the PGIA; low settling times at all gains ensure the maximum resolution of the ADC is used. Differently to other works, we do not use any multiplexers for the voltage readings, but collect the data simultaneously from all the electrodes, thus decreasing electrical noise and the settling time. Furthermore, our design guarantees the possibility of switching between different types of voltage reading modalities (i.e., collecting differential voltage data between either adjacent or non adjacent electrode pairs).

For the management of the DAQ card, we use the MATLAB Data Acquisition Toolbox to collect data and generate the 10 bit digital signal for the control of the two multiplexers. This approach allows for reading data into MATLAB for immediate analysis.

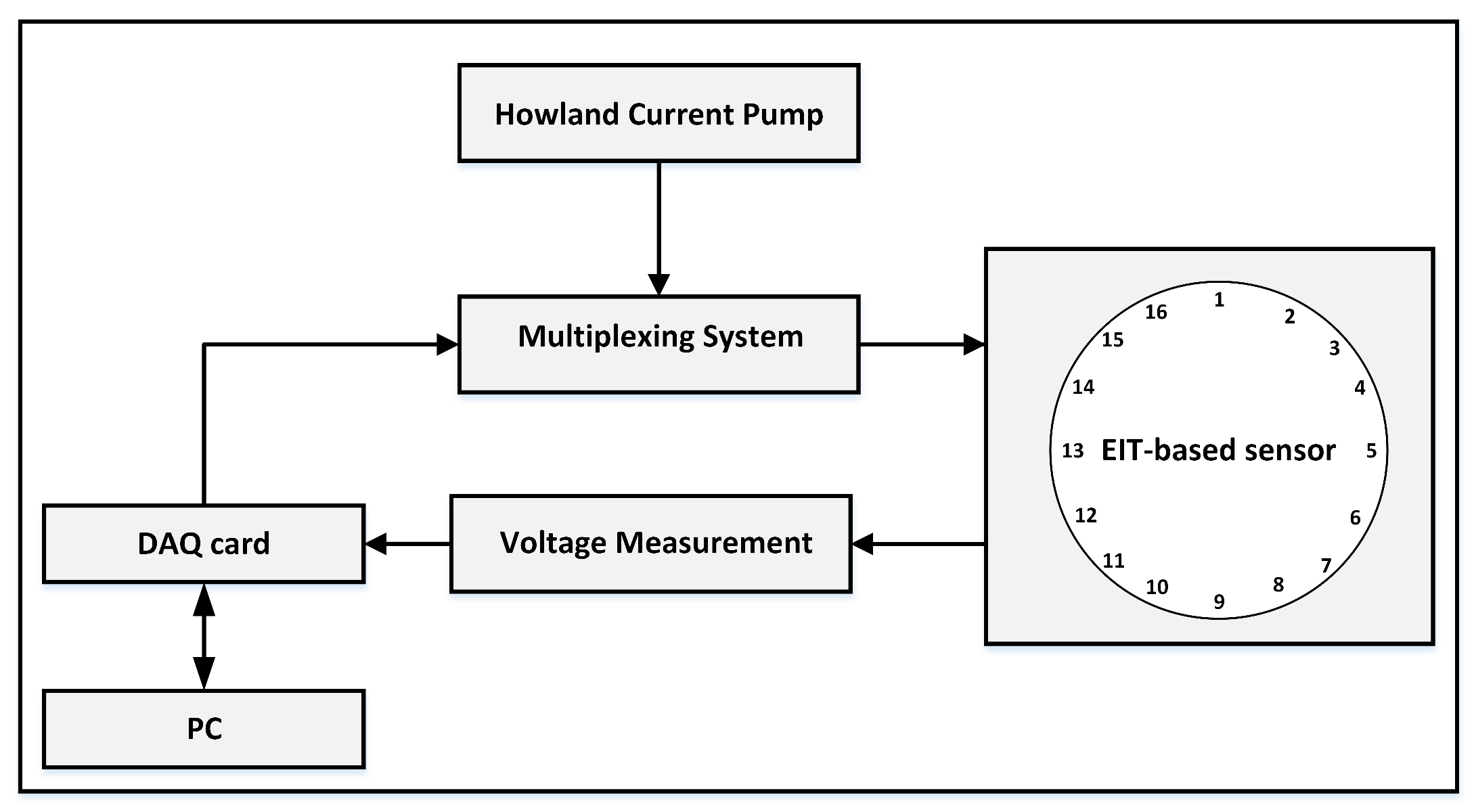

To further clarify the working principle of the system, a block diagram of our sensor system setup is shown in

Figure 3.

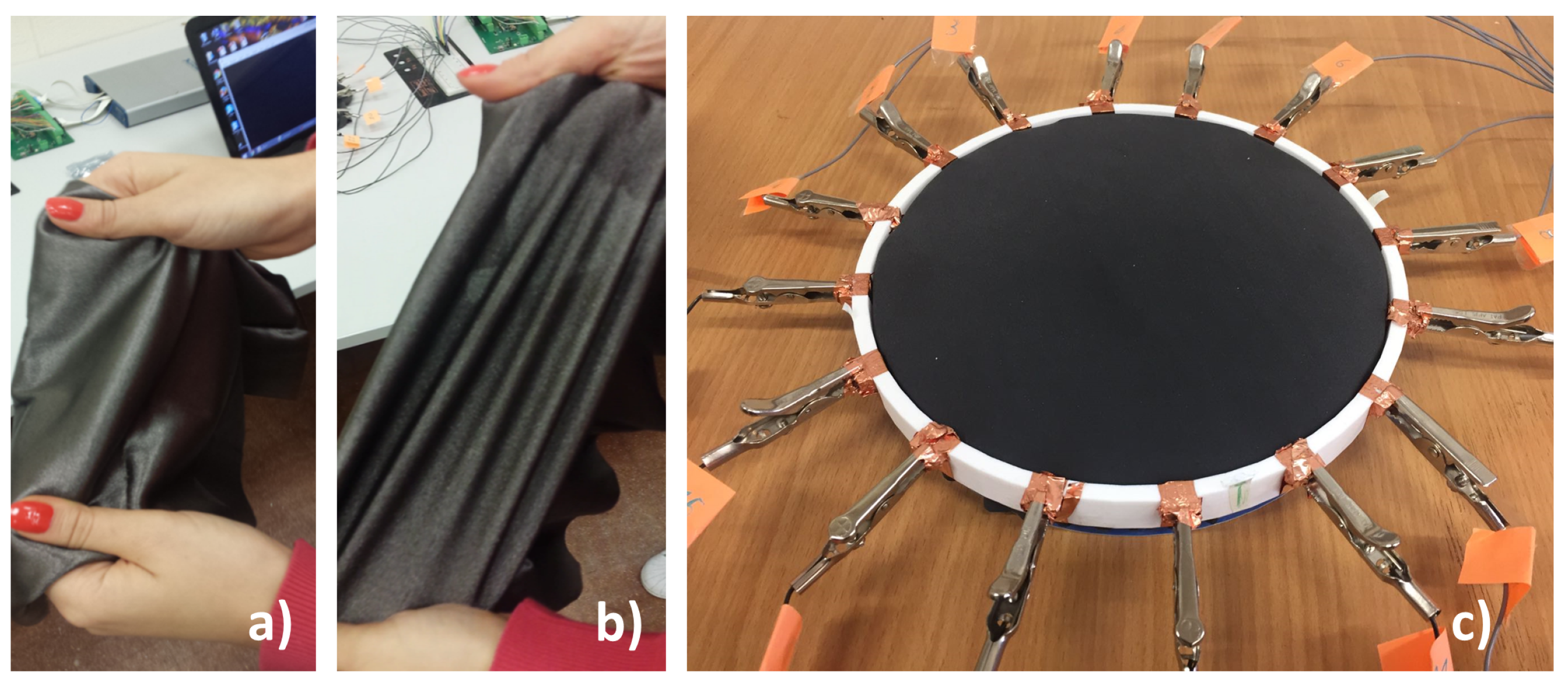

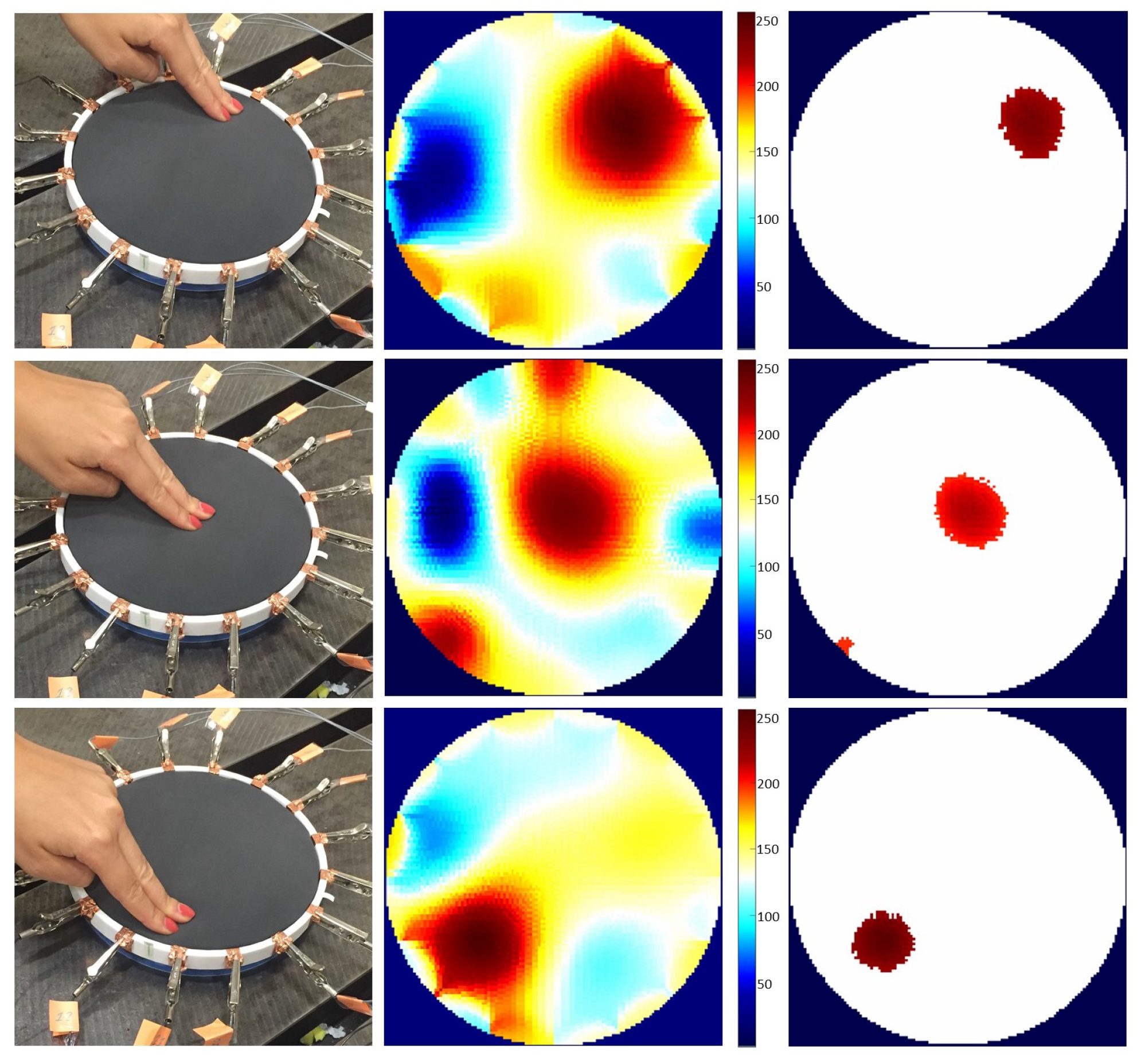

3. EIT-Based Stretchable Sensor

Our EIT-based sensor is realized using a thin, stretchable piezoresistive fabric material that translates touch pressure into local changes in its resistivity. We have taken inspiration from the work of [

9], and have followed our previous work [

18], in which we developed the first prototype of an eight-electrode pressure-responsive sensor based on EIT.

In this paper, we present our 16-electrode sensor, which is based on a conductive stretchable fabric from the Eeonyx Corporation, made with nylon and coated with conductive doped polypyrrole (

Figure 4a,b). The material has a surface resistance of 30 K

, and it is low-cost and lightweight. A 3D-printed circular frame made of two disc layers is used to house the conductive sheet. The frame presents 16 extrusions, where conductive copper stripes are placed to create the electrodes. The conductive fabric is then placed between the two discs, firmly in contact with the surrounding electrodes, as shown in

Figure 4c.

Although a mathematical framework for an EIT-based pressure-sensor membrane was presented in [

19], this model was also based on the hypothesis of incompressibility, which is not sufficient for the conductive fabric employed in this work. Here, we have relied on the model of [

1], which presents a more general approach to solve the EIT inverse problem.

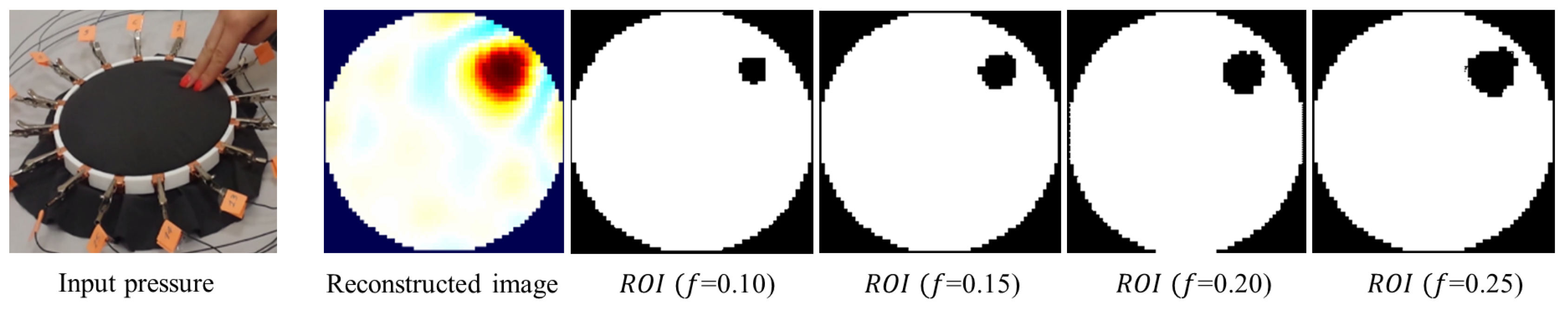

The image of the pressure contacts over the sensor is reconstructed by comparing two voltage data sets: is used as a background reference and is the resulting potential measured when pressure is applied. Additionally, as the DAQ card is constantly updating , this method guarantees that no initial calibration is needed.

Image Reconstruction

The image reconstruction is carried out using a MATLAB program based on the EIDORS package [

20], which is available under a General Public License. After the image

of the conductivity changes is reconstructed, it requires post-processing, as it presents artefacts due to noise and possible electrode movement. To minimize these effects, we work on the image pixel values

and select the region of interest (ROI) in which the maximum amount of conductivity change has taken place. The processed image (

) is found as follows:

where

are the pixel values of (

), and

f is the threshold for the selection. The ROI is therefore the region of (

) for which the pixels of (

) are non-zero.

Is it clear that, because the choice of

f determines the size of the ROI, it has a great impact on the final image, as shown in

Figure 5. A number of studies have been conducted regarding the best choice of the threshold factor [

7,

21], but still heuristic selection is very common. In our case, we choose

f = 0.10, as it performed best in our experiments.

5. Conclusions

A high-speed EIT system that concurrently implements constant current injection and differential potential measurements has been developed for EIT-based sensor applications.

Our customized PCB design implements a Howland current pump and two analog multiplexers for the constant current injection. They are controlled using a 10 bit digital signal originating from the DAQ. The voltage data measured at the electrodes placed around the fabric sensor show the multiplexers operating in the required sequence, and also show that the data is successfully acquired for reconstructing the image of the pressure input on the stretchable sensor. The reconstructed images for different contact points over the sensor demonstrate the efficiency of our EIT-based sensor.

Our system is able to capture data at 78 frames/s and its power consumption can be brought down to 3 mW when using a current of 10 A supplied at 5 V.

The advantages of this approach in contrast to those found in the literature are the following: (a) the less complicated hardware design makes it low-cost and more suitable for wearable systems, and (b) it has a low power consumption. Furthermore, our design is advantageous for touch-sensing applications, as its high speed guarantees that the voltage data collection is complete before any noticeable change in conductivity occurs.