Optimizing Inventory Management: A Comprehensive Analysis of Models Integrating Diverse Fuzzy Demand Functions

Abstract

:1. Introduction

2. Literature Review

- The study’s primary theme must center around developing a fuzzy mathematical model rather than solely applying a fuzzy solution approach. Therefore, we excluded papers that only applied fuzzy solution procedures from our analysis;

- Additionally, the study must exclusively study a problem within the inventory management field. Our objective was to account for all relevant papers in the field up to 2023 while adhering to these established criteria. We did so to ensure the review’s thoroughness and accuracy.

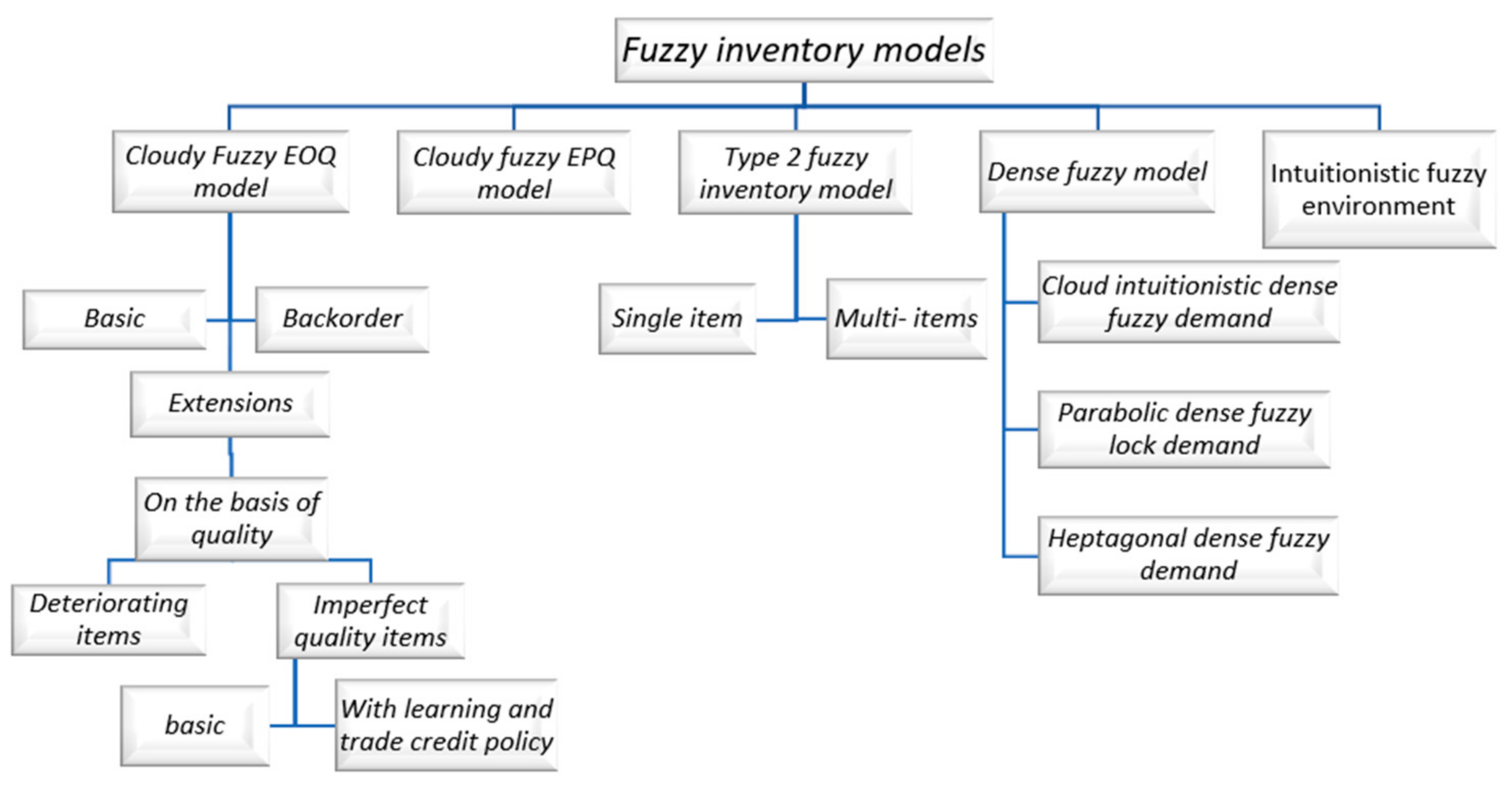

3. Content Analysis

3.1. Cloudy Fuzzy Economic Order Quantity Model

3.1.1. Basic Cloudy Fuzzy EOQ Model without Backorder

3.1.2. Cloudy Fuzzy EOQ Model with Backorder

3.1.3. Extensions

On the Basis of Quality

- Deteriorating items

- Imperfect quality

- Basic cloudy fuzzy EOQ model for imperfect quality items

- (1)

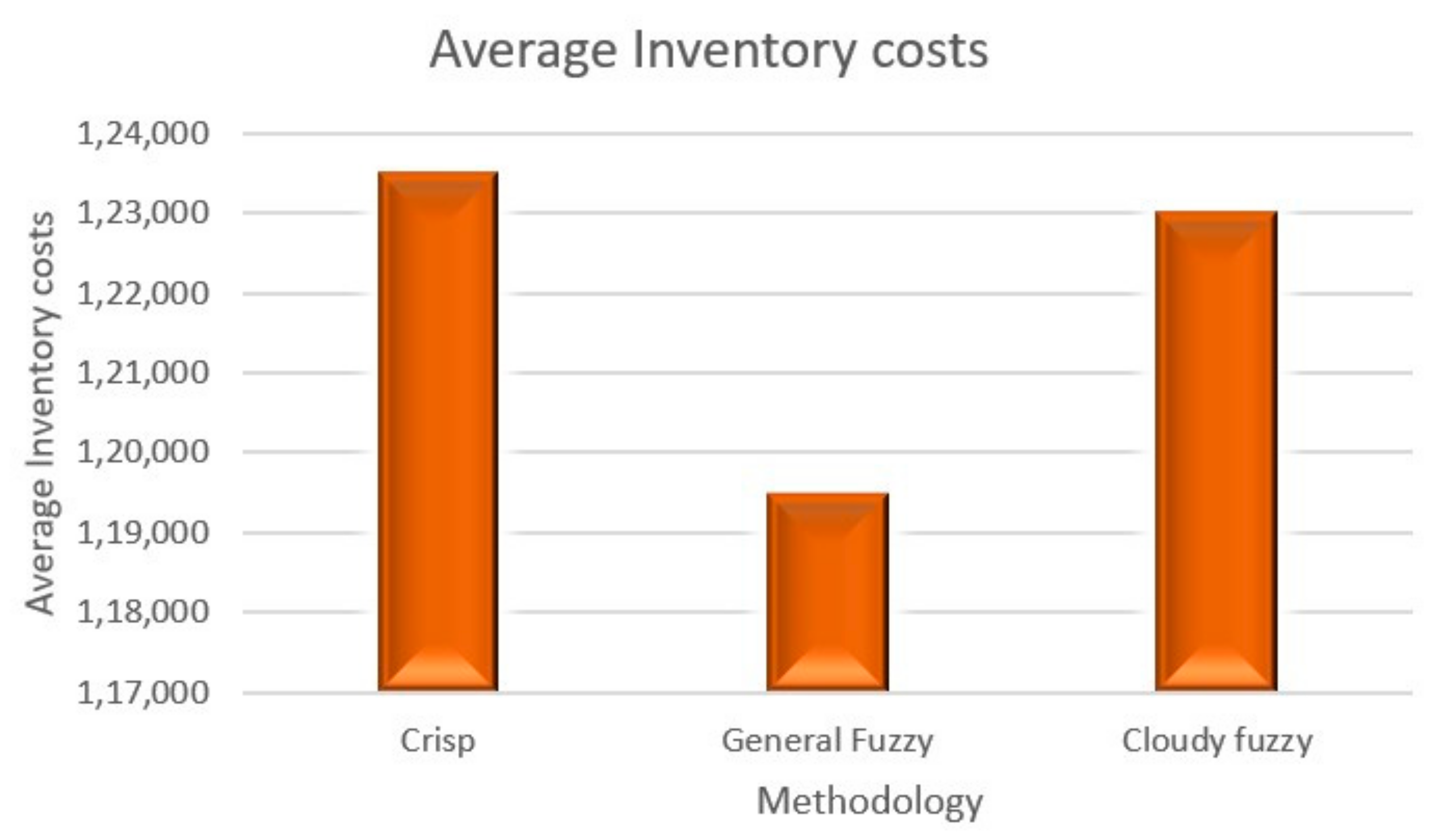

- The average maximum profit value of the model is always provided by the cloudy fuzzy model;

- (2)

- A model’s profitability is not increased by having fewer ambiguities (fuzziness);

- (3)

- Not all cost factors contribute equally to the improvement of the profit curve;

- (4)

- The ideal order amount and the chosen cycle duration can affect the overall choice made during the inventory process.

- 2.

- Cloudy fuzzy EOQ model for imperfect quality items with learning and trade-credit policy

3.2. Cloudy Fuzzy Economic Production Quantity Model

3.3. Dense Fuzzy Inventory Model

3.3.1. Intuitionistic Dense Fuzzy Demand Rate

3.3.2. EOQ Model of Growing Items with a Parabolic Dense Fuzzy Lock Demand Rate

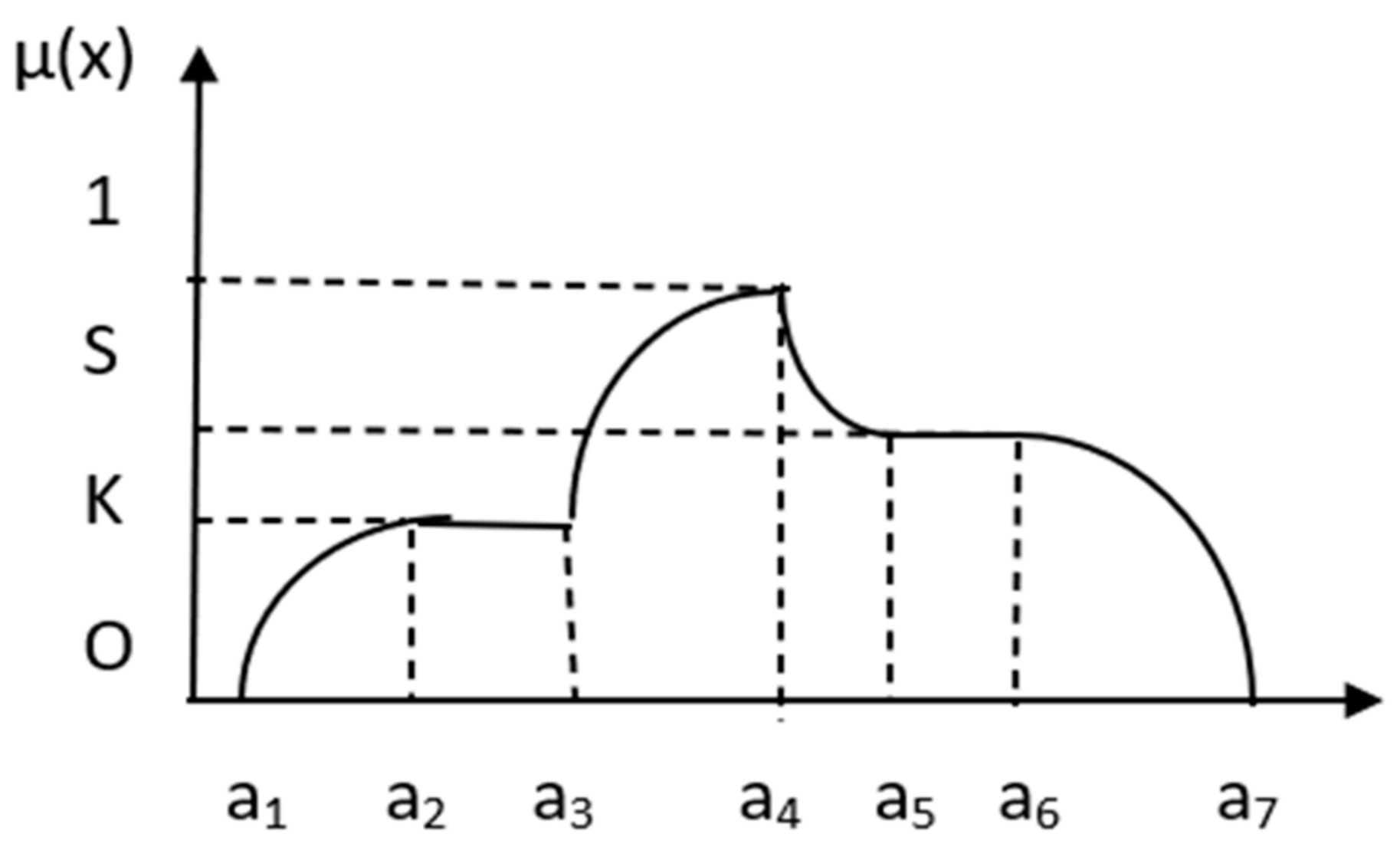

3.3.3. Backlogging EOQ Model with a Non-Linear Heptagonal Dense Fuzzy Environment

- µA(x) is a continuous function in the interval [0, 1];

- µA(x) is strictly increasing and continuous function on [a1, a2] and [a3, a4];

- µA (x) takes value k in the interval [a2, a3] and [a5, a6] where 0 < k < 1;

- µA (x) is strictly decreasing and continuous function on [a4, a5] and [a6, a7];

- µA (x) takes value 1 at the point a4.

3.4. Inventory Models under a Type 2 Fuzzy Environment

3.4.1. Inventory Models under a Type 2 Fuzzy Environment with Imperfect Quality Items and Backlogging

3.4.2. Inventory Model under Type 2 Fuzzy with Trade Credit Policy

3.4.3. Multi-Item Inventory Problem under a Type 2 Fuzzy Environment

- (i)

- The mean reduction methods were used to determine the expected value concerning the reciprocal of type 2 discrete and triangular fuzzy variables after discussing the expected value of the fuzzy variable;

- (ii)

- He created a multi-item single-period expected profit model, where type 2 fuzzy variations are used to characterize the uncertain demands in the inventory problem.

3.5. Optimization in an Intuitionistic Fuzzy Environment

4. Conclusions and Future Scope

Author Contributions

Funding

Conflicts of Interest

References

- Harris, F. Operations and Cost (Factory Management Series); A.W. Shaw Co.: Chicago, IL, USA, 1915; pp. 48–52. [Google Scholar]

- Hanssmann, F. Operations Research in Production and Inventory Control; John Wiley and Sons, Inc.: New York, NY, USA; London, UK, 1962; p. 254. [Google Scholar]

- Hadley, G.; Whitin, T.M. Analysis of Inventory Systems; Prentice Hall: Englewood Cliffs, NJ, USA, 1963. [Google Scholar]

- Ghare, P.M.; Schrader, G.P. A model for exponentially decaying inventory. J. Ind. Eng. 1963, 14, 238–243. [Google Scholar]

- Haneveld, W.K.; Teunter, R.H. Effects of discounting and demand rate variability on the EOQ. Int. J. Prod. Econ. 1998, 54, 173–192. [Google Scholar] [CrossRef]

- Hariga, M.A. Optimal EOQ models for deteriorating items with time-varying demand. J. Oper. Res. Soc. 1996, 47, 1228–1246. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–356. [Google Scholar] [CrossRef]

- Bellman, R.E.; Zadeh, L.A. Decision making in a fuzzy environment. Manag. Sci. 1970, 17, B141–B164. [Google Scholar] [CrossRef]

- Lee, H.M.; Yao, J.S. Economic order quantity in fuzzy sense for inventory without backorder model. Fuzzy Sets Syst. 1999, 105, 13–31. [Google Scholar] [CrossRef]

- Bjork, K.M. An analytical solution to a fuzzy economic order quantity problem. Int. J. Approx. Reason. 2009, 50, 485–493. [Google Scholar] [CrossRef]

- Mahata, G.C. A production-inventory model with imperfect production process and partial backlogging under learning considerations in fuzzy random environments. J. Intell. Manuf. 2015, 28, 883–897. [Google Scholar] [CrossRef]

- Kazemi, N.; Shekarian, E.; Cárdenas-Barrón, L.E.; Olugu, E.U. Incorporating human learning into a fuzzy EOQ inventory model with backorders. Comput. Ind. Eng. 2015, 87, 540–542. [Google Scholar] [CrossRef]

- Kazemi, N.; Olugu, E.U.; Salwa Hanim, A.-R.; Ghazilla, R.A.B.R. Development of a fuzzy economic order quantity model for imperfect quality items using the learning effect on fuzzy parameters. J. Intell. Fuzzy Syst. 2015, 28, 2377–2389. [Google Scholar] [CrossRef]

- Kazemi, N.; Olugu, E.U.; Salwa Hanim, A.-R.; Ghazilla, R.A.B.R. A fuzzy EOQ model with backorders and forgetting effect on fuzzy parameters: An emperical study. Comput. Ind. Eng. 2016, 96, 140–148. [Google Scholar] [CrossRef]

- Yager, R.R. A procedure for ordering fuzzy subsets of the unit interval. Inf. Sci. 1981, 24, 143–161. [Google Scholar] [CrossRef]

- Jaggi, C.K.; Yadavalli, V.S.S.; Sharma, A.; Tiwari, S. A fuzzy EOQ model with allowable shortage under different trade credit terms. Appl. Math. Inf. Sci. 2016, 10, 785–805. [Google Scholar] [CrossRef]

- Jain, S.; Tiwari, S.; Cardenas Barron, L.E.; Shaikh, A.A.; Singh, S.R. A fuzzy imperfect production and repair inventory model with time dependent demand, production and repair rates under inflationary conditions. RAIRO-Oper. Res. 2018, 52, 217–239. [Google Scholar] [CrossRef]

- Shaikh, A.A.; Bhunia, A.K.; Cardenas Barron, L.E.; Sahoo, L.; Tiwari, S. A fuzzy inventory model for a deteriorating item with variable demand, permissible delay in payments and partial backlogging with shortage follows inventory (SFI) policy. Int. J. Fuzzy Syst. 2018, 20, 1606–1623. [Google Scholar] [CrossRef]

- De, S.K.; Mahata, G. Decision of a fuzzy inventory with fuzzy backorder model under cloudy fuzzy demand rate. Int. J. Appl. Comput. Math. 2017, 3, 2593–2609. [Google Scholar] [CrossRef]

- Barman, H.; Pervin, M.; Roy, S.K.; Weber, G.W. Back-ordered inventory model with inflation in a cloudy fuzzy environment. J. Ind. Manag. Optim. 2021, 17, 1913–1941. [Google Scholar] [CrossRef]

- De, S.K.; Beg, I. Triangular dense fuzzy sets and new defuzzification methods. Int. J. Intell. Fuzzy Syst. 2016, 31, 469–477. [Google Scholar] [CrossRef]

- Karmakar, S.; De, S.K.; Goswami, A. A pollution sensitive dense fuzzy economic production quantity model with cycle time dependent production rate. Int. J. Clean. Prod. 2017, 154, 139–150. [Google Scholar] [CrossRef]

- De, S.K. Triangular dense fuzzy lock sets. Soft Comput. 2017, 22, 7243–7254. [Google Scholar] [CrossRef]

- Atanassov, K.T. Intuitionistic fuzzy sets. Fuzzy Sets Syst. 1986, 20, 87–96. [Google Scholar] [CrossRef]

- Bhunia, A.K.; Maiti, M. Deterministic inventory models for variable production. J. Oper. Res. Soc. 1997, 48, 221–224. [Google Scholar] [CrossRef]

- Balkhi, Z.T.; Benkherouf, L. A production lot size inventory model for deteriorating and arbitrary production demand rates. Eur. J. Oper. Res. 1998, 31, 52–60. [Google Scholar] [CrossRef]

- Abad, P.L. Optimal lot-size for a perishable good under conditions of finite production and partial backordering and lost sale. CAIE 2000, 38, 457–465. [Google Scholar] [CrossRef]

- Mandal, M.; Maiti, M. Inventory of damageable items with variable replenishment and stock-dependent demand. Asia-Pac. J. Oper. 2000, 17, 41–54. [Google Scholar]

- Roy, A.; Kar, S.; Maiti, M. A volume flexible production policy for randomly deteriorating item with trended demand and shortages. Int. J. Prod. Econ. 2010, 128, 188–199. [Google Scholar] [CrossRef]

- Das, D.; Roy, A.; Kar, S. Improving production policy for a deteriorating item under permissible delay in payments with stock-dependent demand rate. Comp. Math. Appl. 2010, 60, 1973–1985. [Google Scholar] [CrossRef]

- Das, D.; Roy, A.; Kar, S. Optimal payment time for a retailer under permitted delay of payment by the wholesaler with dynamic demand and hybrid number cost parameters. Opsearch 2011, 46, 171–196. [Google Scholar] [CrossRef]

- Das, D.; Roy, A.; Kar, S. A volume flexible economic production lot-sizing problem with imperfect quality and random machine failure in fuzzy-stochastic environment. Comp. Math. Appl. 2011, 61, 2388–2400. [Google Scholar] [CrossRef]

- Das, D.; Kar, M.B.; Roy, A.; Kar, S. Two-warehouse production model for deteriorating inventory items with stock dependent demand under inflation over a random planning horizon. Cent. Eur. J. Oper. 2012, 20, 251–280. [Google Scholar] [CrossRef]

- Guiffrida, A.L.; Nagi, R. Fuzzy set theory applications in production management research: A literature survey. J. Intell. Manuf. 1998, 9, 39–56. [Google Scholar] [CrossRef]

- Mula, J.; Poler, R.; Garcia-Sabater, J.; Lario, F.C. Models for production planning under uncertainty: A review. Int. J. Prod. Econ. 2006, 103, 271–285. [Google Scholar] [CrossRef]

- Aissaoui, N.; Haouari, M.; Hassini, E. Supplier selection and order lot sizing modeling: A review. COR 2007, 34, 3516–3540. [Google Scholar] [CrossRef]

- Ko, M.; Tiwari, A.; Mehnen, J. A review of soft computing applications in supply chain management. Appl. Soft Comput. 2010, 10, 661–674. [Google Scholar] [CrossRef]

- Khan, M.; Jaber, M.; Guiffrida, A.; Zolfaghari, S. A review of the extensions of a modified EOQ model for imperfect quality items. Int. J. Prod. Econ. 2011, 132, 1–12. [Google Scholar] [CrossRef]

- Wong, B.K.; Lai, V.S. A survey of the application of fuzzy set theory in production and operations management: 1998–2009. Int. J. Prod. Econ. 2011, 129, 157–168. [Google Scholar] [CrossRef]

- Bakker, M.; Riezebos, J.; Teunter, R.H. Review of inventory systems with deterioration since 2001. Eur. J. Oper. Res. 2012, 221, 275–284. [Google Scholar] [CrossRef]

- Aloulou, M.A.; Dolgui, A.; Kovalyov, M.Y. A bibliography of non-deterministic lot-sizing models. Int. J. Prod. Res. 2014, 52, 2293–2310. [Google Scholar] [CrossRef]

- Andriolo, A.; Battini, D.; Grubbström, R.W.; Persona, A.; Sgarbossa, F. A century of evolution from Harris׳ s basic lot size model: Survey and research agenda. Int. J. Prod. Econ. 2014, 155, 16–38. [Google Scholar] [CrossRef]

- Janssen, L.; Claus, T.; Sauer, J. Literature review of deteriorating inventory models by key topics from 2012 to 2015. Int. J. Prod. Econ. 2016, 182, 86–112. [Google Scholar] [CrossRef]

- Shekarian, E.; Kazemi, N.; Abdul-Rashid, S.H.; Olugu, E.U. Fuzzy inventory models: A comprehensive review. Appl. Soft Comput. 2017, 55, 588–621. [Google Scholar] [CrossRef]

- Lakshmi, M.D.; Pandian, P. A review on inventory models in fuzzy environment. Int. J. Pure Appl. Math. 2018, 119, 113–123. [Google Scholar]

- Karmakar, S.; De, S.K.; Goswami, A. A Study of an EOQ Model Under Cloudy Fuzzy Demand Rate. In Proceedings of the Mathematics and Computing: 4th International Conference, ICMC 2018, Varanasi, India, 9–11 January 2018. [Google Scholar]

- De, S.K.; Mahata, G.C. A cloudy fuzzy economic order quantity model for imperfect-quality items with allowable proportionate discounts. J. Ind. Eng. Int. 2019, 15, 571–583. [Google Scholar] [CrossRef]

- Shah, H.; Patel, M. An EOQ model for deteriorating items when demand is cloud fuzzy. Int. J. Logist. Syst. Manag. 2021, 42, 140–152. [Google Scholar] [CrossRef]

- Salameh, M.; Jaber, M.Y. Economic production quantity model for items with imperfect quality. Int. J. Prod. Econ. 2000, 64, 59–64. [Google Scholar] [CrossRef]

- Jayaswal, M.K.; Mittal, M.; Alamri, O.A.; Khan, F.A. Learning EOQ Model with Trade-Credit Financing Policy for Imperfect Quality Items under Cloudy Fuzzy Environment. Mathematics 2022, 10, 246. [Google Scholar] [CrossRef]

- Maiti, A.K. Cloudy fuzzy inventory model under imperfect production process with demand dependent production rate. JMA 2021, 8, 741–763. [Google Scholar] [CrossRef]

- Rajput, N.; Pandey, R.K.; Chauhan, A. Fuzzy optimization of a Production Model with CNTFN Demand Rate under Trade-Credit Policy. IJMOR 2022, 21, 200–220. [Google Scholar] [CrossRef]

- Rajput, N.; Chauhan, A.; Pandey, R.K. Optimisation of finite economic production quantity model under cloudy normalised triangular fuzzy number. IJOR 2022, 43, 168–187. [Google Scholar] [CrossRef]

- Maity, S.; De, S.K.; Mondal, S.P. A Study of a Backorder EOQ Model for Cloud-Type Intuitionistic Dense Fuzzy Demand Rate. Int. J. Fuzzy Syst. 2020, 22, 201–211. [Google Scholar] [CrossRef]

- Chakraborty, A.; Pal, S.; Mondal, S.P. Nonlinear pentagonal intuitionistic fuzzy number and its application in EPQ model under learning and forgetting. Complex Intell. Syst. 2022, 8, 1307–1322. [Google Scholar] [CrossRef]

- Swethaa, S.; Felix, A. Haar and Yager’s Ranking Methods for Intuitionistic Dense Fuzzy Set. J. Phys. Conf. Ser. 2022, 2267, 012065. [Google Scholar] [CrossRef]

- Maity, S.; Chakraborty, A.; De, S.K.; Pal, M. A study of an EOQ model of green items with the effect of carbon emission under pentagonal intuitionistic dense fuzzy environment. Soft Comput. 2023, 27, 15033–15055. [Google Scholar] [CrossRef]

- Garg, H.; Ansha. Arithmetic Operations on Generalized Parabolic Fuzzy Numbers and Its Application. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2016, 88, 15–26. [Google Scholar] [CrossRef]

- Faritha Asma, A.; Priya, G. Optimizing Triangular Parabolic Fuzzy EOQ Model With Shortage Using Nearest Interval Approximation. Int. J. Future Revolut. Comput. Sci. Commun. Eng. 2017, 3, 92–96. [Google Scholar]

- Maity, S.; De, S.K.; Pal, M.; Mondal, S.P. A Study of an EOQ Model of Growing Items with Parabolic Dense Fuzzy Lock Demand Rate. Appl. Syst. Innov. 2021, 4, 81. [Google Scholar] [CrossRef]

- Maity, S.; Chakraborty, A.; De, S.K.; Mondal, S.P.; Alam, S. A comprehensive study of a backlogging EOQ model with nonlinear heptagonal dense fuzzy environment. RAIRO-Oper. Res. 2020, 54, 267–286. [Google Scholar] [CrossRef]

- Shah, N.; Patel, M.; Shah, P. A New Defuzzification Method for Cost Analysis of Economic Order Quantity under Cloud Pentagonal Fuzzy Demand. Int. J. Fuzzy Syst. Appl. 2022, 11, 1–17. [Google Scholar] [CrossRef]

- Hemalatha, S.; Annadurai, K. Optimization of a Fuzzy Inventory Model with Pentagonal Fuzzy Numbers. Int. J. Math Comput. Sci. 2023, 11, 3277–3287. [Google Scholar] [CrossRef]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate resoning II. Inf. Sci. 1975, 8, 301–357. [Google Scholar] [CrossRef]

- Mizumoto, M.; Tanaka, K. Fuzzy sets of type-2 under algebraic product and algebraic sum. Fuzzy Sets Syst. 1981, 5, 277–280. [Google Scholar] [CrossRef]

- Dubois, D.; Prade, H. Fuzzy Sets and Systems: Theory and Applications; Academic Press: New York, NY, USA, 1980. [Google Scholar]

- Martnez, J.S.; John, R.I.; Hissel, D.; Pera, M.C. A survey-based type-2 fuzzy logic system for energy management in hybrid electrical vehicles. Inf. Sci. 2012, 190, 192–207. [Google Scholar] [CrossRef]

- Sharan, S.; Tiwary, S.P.; Yadav, V.K. Interval type-2 fuzzy rough sets and interval type-2 fuzzy closure spaces. Int. J. Fuzzy Syst. 2015, 12, 113–125. [Google Scholar]

- Karnik, N.N.; Mendel, J.M. Centroid of a type-2 fuzzy set. Inf. Sci. 2001, 132, 195–220. [Google Scholar] [CrossRef]

- Qin, R.; Liu, Y.K.; Liu, Z.Q. Methods of critical value reduction for type-2 fuzzy variables and their applications. J. Comput. Appl. Math. 2011, 235, 1454–1481. [Google Scholar] [CrossRef]

- Castillo, O.; Melin, P. Optimization of type-2 fuzzy systems based on bio-inspired methods: A concise review. Inf. Sci. 2012, 205, 1–19. [Google Scholar] [CrossRef]

- Chen, T.Y.; Chang, C.H.; Lu, J.R. The extended QUALIFLEX method for multiple criteria decision analysis based on interval type-2 fuzzy sets and applications to medical decision making. Eur. J. Oper. Res. 2013, 226, 615–625. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, X. Linear combinations of T2 fuzzy variables. J. Uncertain Syst. 2014, 8, 78–80. [Google Scholar]

- Bai, X.; Liu, Y. Minimum risk facility location allocation problem with type-2 fuzzy variables. Sci. World J. 2014, 2014, 472623. [Google Scholar] [CrossRef]

- Turk, S.; Ozcan, E.; John, R. Multi-objective optimisation in inventory planning with supplier selection. Expert Syst. Appl. 2017, 78, 51–63. [Google Scholar] [CrossRef]

- Kumar, R.S. Modelling a type-2 fuzzy inventory system considering items with imperfect quality and shortage backlogging. Sādhanā 2018, 43, 1–10. [Google Scholar] [CrossRef]

- Debnath, B.K.; Majumder, P.; Bera, U.K. Inventory model with demand as type-2 fuzzy number: A fuzzy differential equation approach. Int. J. Fuzzy Syst. 2018, 15, 1–24. [Google Scholar]

- Li, Y. Modeling Multi-item Inventory Problem under Type-2 Fuzzy Demand. IFAC-Pap. Online 2019, 52, 147–152. [Google Scholar] [CrossRef]

- Angelov, P.P. Optimization in intuitionistic fuzzy environment. Fuzzy Sets Syst. 1997, 86, 299–306. [Google Scholar] [CrossRef]

- Nayak, P.K.; Pal, M. The Bi-matrix games with interval pay-offs and its Nash Equilibrium strategy. J. Fuzzy Math. 2009, 17, 421–435. [Google Scholar]

- Nayak, P.K.; Pal, M. Bi-matrix games with intuitionistic fuzzy goals. Int. J. Fuzzy Syst. 2010, 1, 65–79. [Google Scholar]

- Chakrabortty, S.; Pal, M.; Nayak, P.K. Intuitionistic fuzzy optimization technique for the solution of an EOQ model. Notes Intuitionistic Fuzzy Sets 2011, 17, 52–64. [Google Scholar]

- Chakrabortty, S.; Pal, M.; Nayak, P.K. Intuitionistic fuzzy optimization technique for Pareto optimal solution of manufacturing inventory models with shortages. Eur. J. Oper. Res. 2013, 228, 381–387. [Google Scholar] [CrossRef]

- De, S.K.; Goswami, A.; Sana, S.S. An interpolating by pass to Pareto optimality in intuitionistic fuzzy technique for a EOQ model with time sensitive backlogging. Appl. Math. Comput. 2014, 230, 664–674. [Google Scholar] [CrossRef]

- Bhaya, S.; Pal, M.; Nayak, P.K. Intuitionistic Fuzzy Optimization Technique in EOQ Model with Two Types of Imperfect Quality Items. AMO 2014, 16, 1. [Google Scholar]

- Mondal, B.; Garai, A.; Roy, T.K. Issue: Optimization of EOQ model with space constraint: An intuitionistic fuzzy geometric programming approach. Notes Intuitionistic Fuzzy Sets 2018, 24, 172–189. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, T. An intuitionistic fuzzy inventory model with waste disposal using the triangular intuitionistic fuzzy numbers. J. Phys. Conf. Ser 2022, 2223, 012004. [Google Scholar] [CrossRef]

- Sahoo, S.; Acharya, M.; Patnaik, S. Sustainable intuitionistic fuzzy inventory models with preservation technology investment and shortages. Int. J. Reason.-Based Intell. Syst. 2022, 14, 8–18. [Google Scholar] [CrossRef]

| Study Published | Area of Research | Aspects of Research | Year |

|---|---|---|---|

| Guiffrida and Nagi [34] | Production management | Fuzzy set theory | Until 1977 |

| Mula et al. [35] | Production planning | Uncertain models | 1983–2004 |

| Aissaoui et al. [36] | Operational research models | Supply selection and order allocation | Until 2005 |

| Ko et al. [37] | Supply chain management | Soft computing applications | 1990–2009 |

| Khan et al. [38] | Economic order quantity | Imperfect quality items | 2000–2011 |

| Wong and Lai [39] | Production and operations | Fuzzy set theory applications | 1998–2009 |

| Bakker et al. [40] | Inventory systems | Deteriorating items | 2001–2011 |

| Aloulou et al. [41] | Lot-sizing models | Non-deterministic models | 2000–2013 |

| Andriolo et al. [42] | Lot-sizing models | Deterministic, stochastic and fuzzy models | 1913–2012 |

| Janssen et al. [43] | Inventory models | Deteriorating items | 2012–2017 |

| Shekarian et al. [44] | Inventory models | Fuzzy set theory | Until 2017 |

| Lakshmi et al. [45] | Inventory models | Fuzzy environment | 2018 |

| Present review | Inventory models | Various fuzzy demand functions | Until 2023 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mittal, M.; Jain, V.; Pandey, J.T.; Jain, M.; Dem, H. Optimizing Inventory Management: A Comprehensive Analysis of Models Integrating Diverse Fuzzy Demand Functions. Mathematics 2024, 12, 70. https://doi.org/10.3390/math12010070

Mittal M, Jain V, Pandey JT, Jain M, Dem H. Optimizing Inventory Management: A Comprehensive Analysis of Models Integrating Diverse Fuzzy Demand Functions. Mathematics. 2024; 12(1):70. https://doi.org/10.3390/math12010070

Chicago/Turabian StyleMittal, Mandeep, Vibhor Jain, Jayanti Tripathi Pandey, Muskan Jain, and Himani Dem. 2024. "Optimizing Inventory Management: A Comprehensive Analysis of Models Integrating Diverse Fuzzy Demand Functions" Mathematics 12, no. 1: 70. https://doi.org/10.3390/math12010070