1. Introduction

Jordan is ranked second in the world in water scarcity [

1]. The continual water stress situation is exacerbated by several factors, including geographical location. Jordan is classified as being a semi-arid region; 91% of Jordan’s area receives an average annual rainfall volume of below 200 mm [

2]. Therefore, in such a critical shortage in water, treated wastewater is considered as an attractive source of water for irrigated agriculture [

3,

4,

5].

Jordan is keen to apply the global best practices in wastewater treatment, management, and reuse [

1], especially in 2015 with the overwhelming pressure on water and sanitation as a result of hosting over 650,000 Syrian refugees and another over 750,000 Syrian residents [

2]. The proportion of the population with access to improved water supply (through the network) exceeds 94%. The influx of refugees into in Jordan coupled with increasing demand of water and energy, while energy supply in Jordan depends at about 96% on imports of oil, oil products, natural gas, and electricity, have caused significantly increased economic burden in Jordan [

6,

7,

8,

9,

10,

11,

12,

13,

14].

Prior 1960’s the discharged wastewater from residential buildings in Jordan was collected in a limited way while utilizing primitive physical processes, such as septic tanks and cesspits, which were mostly used with gray water often discharged to gardens. This practice created major environmental hazards, where many groundwater aquifers were polluted [

1]. In the 1960s, the wastewater was collected and treated using treatment plant, which was built at Ain Ghazal utilizing the conventional activated sludge process and the treated effluent was discharged to Seil Zarqa. However, currently, the sanitation coverage is 93% in urban and rural areas in Jordan, out of which 63% are connected to the sewerage system in 2014, which is expected to increase to 80% by 2030. The rest of those are relying on septic tanks [

15].

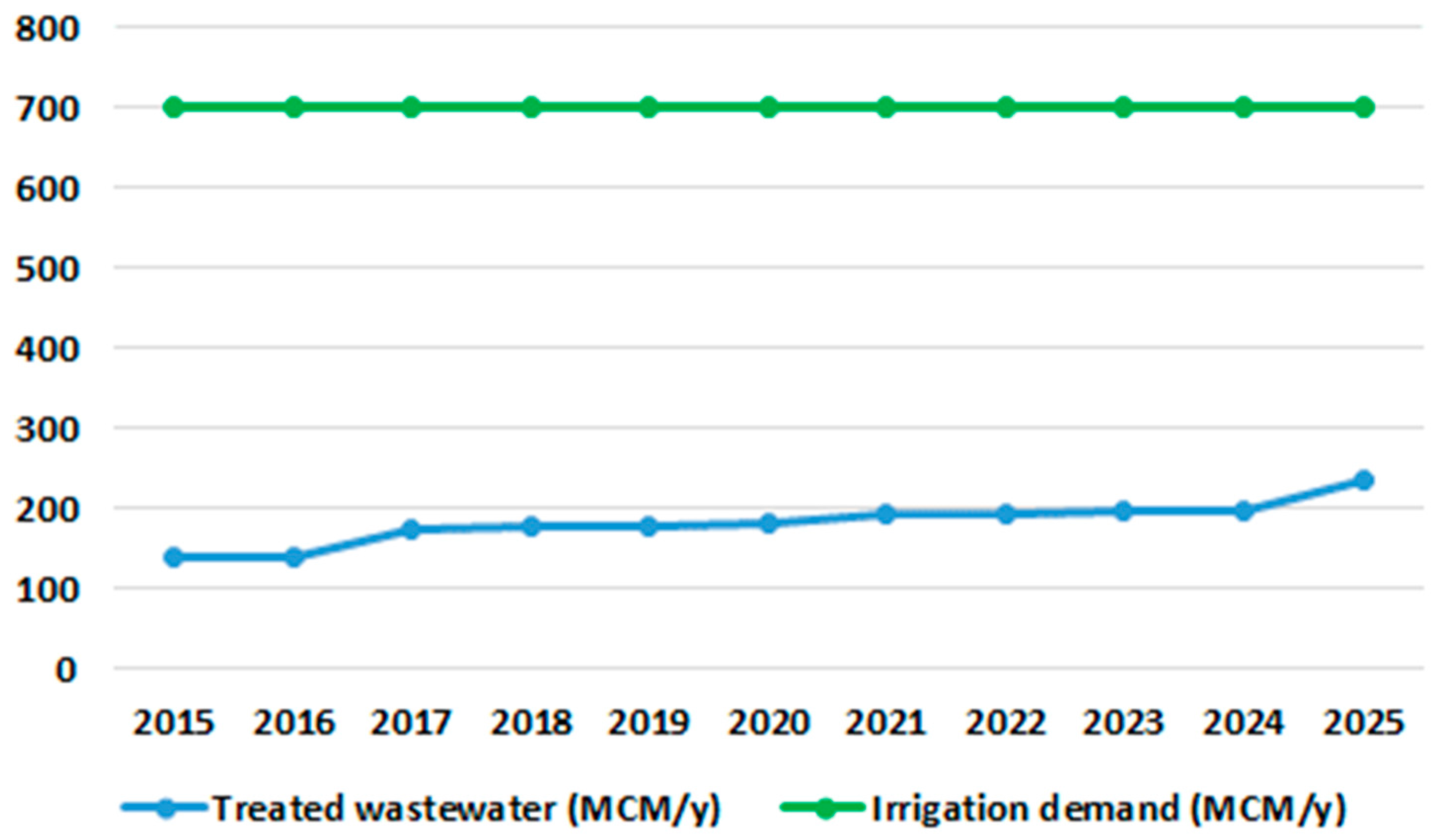

The agricultural water requirements represented around 60% of total national water needs, which is estimated to be 700 million m

3, as shown in

Figure 1, and the agricultural sector contributed about 3–4% to GDP in 2013. Recently, Jordan is reusing 91% of its treated wastewater in agriculture to reallocate fresh water for domestic purposes. As shown in

Figure 1, the volume of treated wastewater by 2025 will be 240 million m

3, hence, the monitored treated wastewater will drastically play a vital role as available freshwater resources become increasingly limited.

Currently, there are 33 different wastewater treatment plants that treat 98% of the collected wastewater and discharge approximately 137 million m

3 per year of effluent. This volume, combined with the decreased volumes of fresh water available for irrigated agriculture, caused the Ministry of Water and Irrigation (MWI) to adopt the water substitution and reuse policy which entails the increasing the amounts of treated wastewater and considering it as a potential water and revenue source in accordance with the quality guidelines and standards of the World Health Organization (WHO) and Food and Agriculture Organization (FAO), to produce an effluent that is fit for reuse in irrigation [

1].

Generally, suppliers tend to offer recycled water at concession prices in order to gain acceptance of water reuse. When freshwater irrigation process is subsidized, as it is the case in Jordan and other developing countries, willingness to pay can be low [

16,

17]. Steps toward reusing treated wastewater in Jordan evolved by delivering the wastewater treatment plants (WWTPs) effluent to farmers’ lands in the vicinity the WWTP’s as free of charge or in very low tariff, and mostly in excess amounts. The next step is to recover the cost of delivery of the treated effluent which certainly depends on many vital pillars, such as public acceptance, suitability and adequacy of high-quality water, sustainability, and enforcement of laws. For instance, the acceptability of treated wastewater reuse increases with certain attributes, like low salt, aesthetic appearances (i.e., lack of color and odor), and affordable price [

18].

Water need is, of course, the main reason for wastewater recycling and reuse in some Mediterranean countries [

19,

20]. The willingness for treated wastewater reuse decreases as the use moves from public areas (e.g., irrigation of parks) to houses (gardening) or to more personal uses, due to risk perception [

21,

22]. In light of the reluctance and fear of others to use such onsite wastewater treatment systems at the level of buildings and small facilities and reuse the treated water in irrigation of trees in the vicinity of these buildings and facilities, the scientific agencies should take upon themselves the attempt of investigating the fit-to-purpose of such on-site wastewater treatment systems based on research and development methods, and through a comprehensive risk management system. It is reported that educated people were more willing to use recycled water [

23].

The reliability of on-site wastewater treatment systems is of high significance in decentralized water systems and in deteriorated water infrastructure [

24]. It is reported that the decentralized wastewater treatment and reuse system can be a solution to ease the problem that is caused by centralized systems operating at or over capacity [

25,

26,

27,

28,

29]. The on-site treatment efficiencies of black water generated at residential facilities were investigated and proved to be a suitable alternative to the conventional septic tank [

30].

The objective of the present paper is to assess the performance of the on-site wastewater unit installed in the Water, Energy & Environment Center (WEEC) at the University of Jordan, and investigate its reuse suitability for the irrigation of plants in the vicinity of WEEC.

2. Materials and Methods

2.1. Unit Process Description

A well-engineered on-site wastewater treatment process has been installed underground at the WEEC, The University of Jordan, and in collaboration with Ishraq Company for Energy in Mid July 2017.

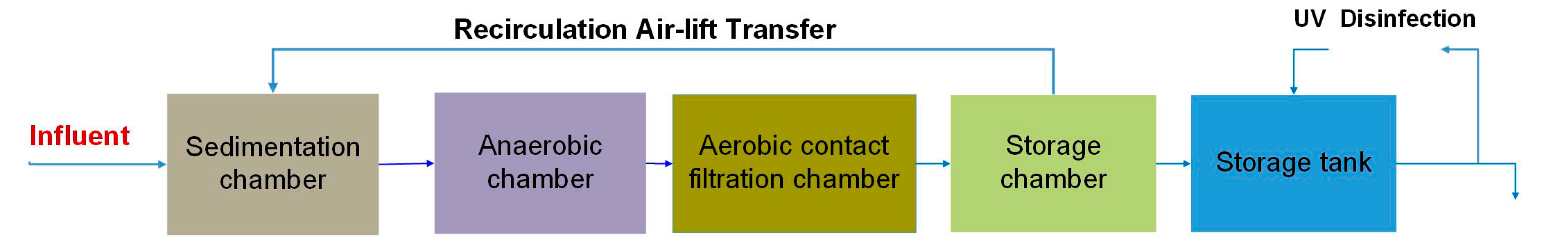

Figure 2 shows the block flow diagram of the treatment process.

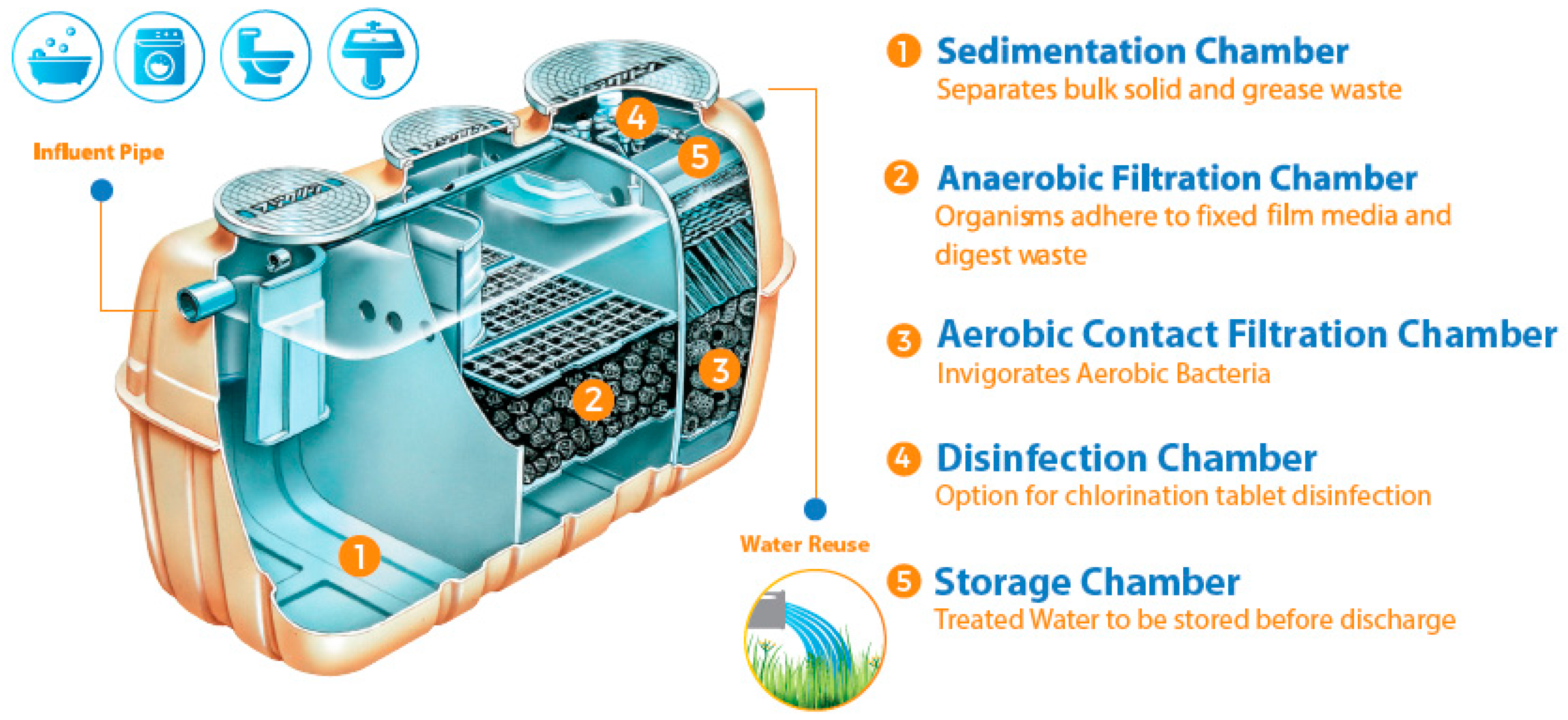

As shown in

Figure 3, the process consists of a controlled flow train through aerobic and anaerobic chambers that are in direct contact with three types of proprietary fixed film media on which biological digestion and mechanical filtration occur.

An external, continuously operating air pump introduces oxygen into the aerobic chamber and powers two internal air-lift pumps. One carries process water and solids back to the primary chambers for solids management and denitrification activity. The other regulates flow equalization and controls the metered outflow of treated effluent. Air-lift pumps are powered by a single, appropriately sized, reliable linear diaphragm blower (air pump) that was designed and manufactured by Fuji Clean (Brunswick, ME, USA). This air pump also supplies a steady source of oxygen to the aerobic chamber [

31]. Sludge return from storage (clarification) chamber to sedimentation (primary) chamber is also accomplished by an air-lift pump.

The treatment capacity of the unit is 1 m3/day. The wastewater generated from the WEEC is coming from point sources (i.e., toilets, sinks, etc.). However, the filling frequency of the treated water tank is every 36 h. The unit is automatically connected with drip irrigation system to regularly irrigate 203 trees in the vicinity of WEEC on weekly basis.

The on-site wastewater treatment unit has effluent sterilization (chlorine tablets) unit, however, in-line ultraviolet (UV) unit with 45.42 L/min is installed in the recirculating delivery system. In a recirculating system, water flows constantly from a storage tank, out to the pressurizing pump, then flows back to the storage tank in the recirculating loop for 20 min to provide control of bacterial growth. After that, the prior discharging of stored water through the drip irrigation system, water is again pumped through the in-line UV system into the irrigation piping. However, it is worth mentioning that the in-line UV unit cannot keep the water in such a system bacteria free. The UV unit may be working as specified, killing 99% or more of the bacteria passing through, but it can only kill bacteria at one point in the loop. If just one microorganism passes through the unit unharmed, then there is nothing to prevent it from attaching to downstream piping surfaces and subsequently multiplying.

2.2. Process Theory

Total nitrogen is removed through chemical and mechanical steps by the combination of aerobic and anaerobic biodegradation [

31,

33]. Four steps are required in order to achieve nitrogen removal, as described by Otowa and Tabata (2014) [

31]:

Firstly, the formation of ammonium nitrogen from protein and amino acid by anaerobic hydrolysis reaction. The second is a process in an anaerobic chamber, bacteria nitrify (oxidize) ammonium nitrogen to form nitrite and then nitrate ions (biological nitrification):

The third step, which is mechanical, liquid containing NO

2− and NO

3− ions is recycled back to the sedimentation chamber by an air-lift pump, and then to the anaerobic chamber. Finally, in the fourth step these ions are reduced to form nitrogen gas by anaerobic bacteria and organic substances (biological denitrification):

2.3. Water Sampling and Testing

To evaluate effluent quality characteristics of treated wastewater of WEEC’s on-site wastewater treatment unit, some parameters that were measured in the WEEC’s laboratory, which is internationally accredited in ISO 17025, during the monitored period were obtained. These parameters include biological oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), pH, and microbiological test (E-coli count).

Treated wastewater samples from the on-site wastewater treatment unit were collected weekly during August 2017 to January 2018. Water samples were taken manually for the influent and effluent streams after mixing well. The influent wastewater is preferably sampled at locations of highly turbulent flow in order to ensure good mixing. While effluent samples should be collected at a site downstream from all entering wastewater streams prior to discharge into the receiving waters.

The microbiological samples are collected after 24 h from chlorination, and directly into the prepared glass or plastic sample container, which should be kept unopened until it is to be filled.

COD of water samples is measured according to method No. 5220D [

34]. The BOD of water samples is measured according to method No. 5210D [

34]. The TSS of water samples is measured according to method No. 2540D [

34]. Samples pH is measured according to method No. 4500 H

+ B [

34].

TSS was determined by gravimetric method (dried at 103 °C). BOD was determined by the 5 Day BOD test, while COD was determined in the laboratory by the standard Closed Reflux Method. Other tests, such as pH, were directly measured using benchtop pH meter (WTW, InoLAB 1, Benchtop pH METER, Weilheim, Germany). Note that before each measurement, the pH meter was calibrated with reference buffer solution. Each analysis was carried out in triplicate and then the mean value was taken.

However, for ensuring measurement certainty, real samples have been tested for the provision of data used in the uncertainty assessment. Data analyzed to the 95% level of confidence for the duplicate results have been used for the chemical and biochemical parameters, and for the microbiological parameters data analyzed to the 95% level of confidence and Log10 for the duplicate results have been used.

Water and sanitation are regulated by MWI By-Law No. 14 of 2014; Water Authority of Jordan Law No. 18 of 1988 and its amendments; and Jordan Valley Authority By-Law No. 30 of 2001. Other relevant laws include Public Health Law No. 47 of 2008, Environmental Protection Law No. 85 of 2006, and Groundwater By-law No. 85 of 2002 and its amendments.

3. Results and Discussion

Table 1 shows the Jordanian standard maximum allowable concentrations for water reuse in irrigating of different classifications of plants as listed (

Table 1). The main design parameters of the on-site treatment unit are BOD and TSS, as shown in the technical sheet [

31], have been used for benchmarking. The average values of BOD (11 mg/L) and TSS (15 mg/L) of effluent wastewater were less than the design criteria (10–20 mg/L), respectively, as shown in

Table 1.

Based on the results that are shown in

Table 1, the effluent reclaimed water can be used for the irrigation of two classes of plants: (i) Fruit trees, road-green sides outside cities, and green landscape; (ii) Crops, commercial crops, and forest trees.

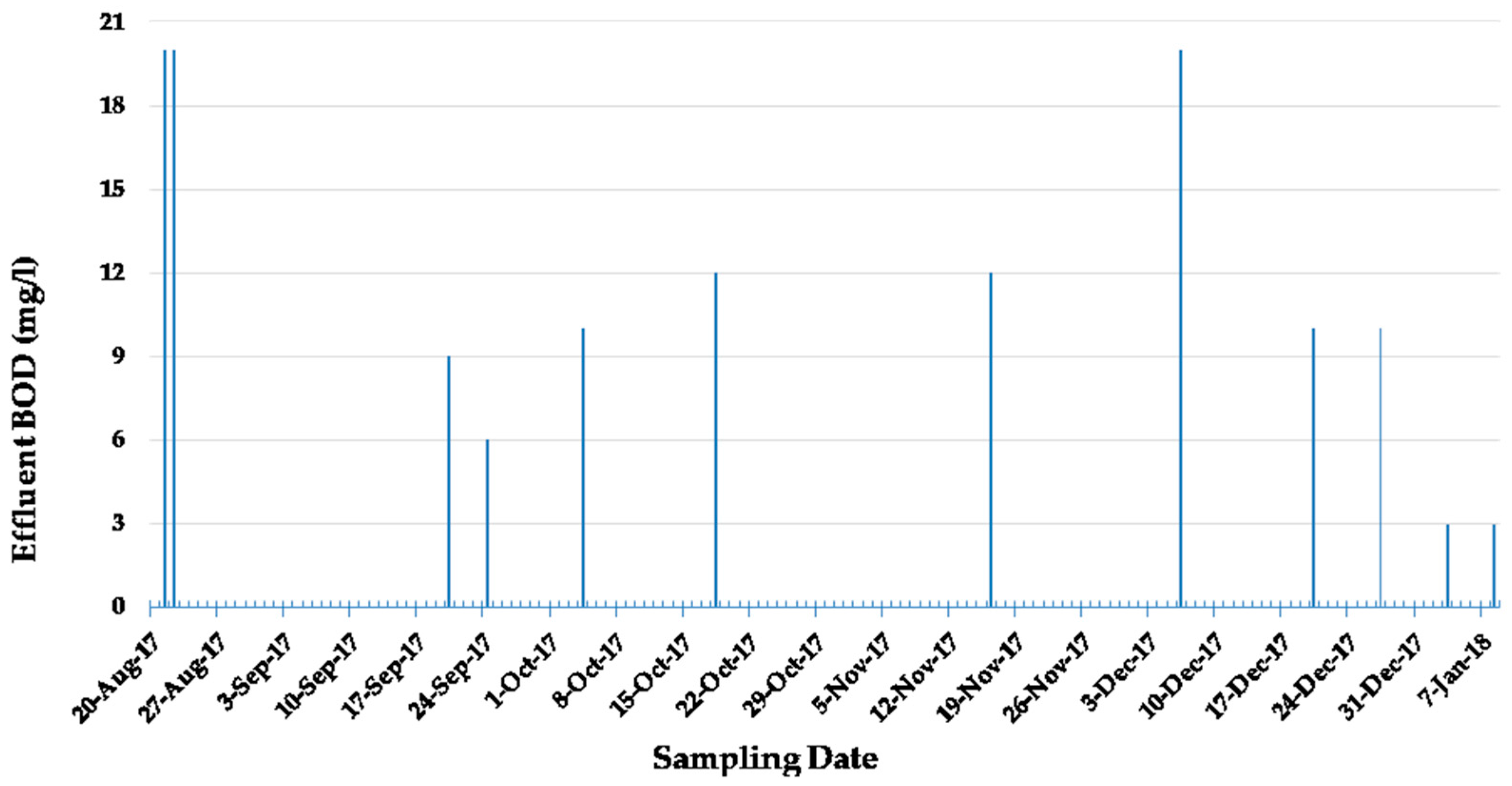

3.1. Effluent BOD

The results showed that BOD parameter average value of 11.25 mg/L (with a standard deviation of 6.0622) for all 12 effluent samples that were gathered from the treatment unit during the monitored period (21 August 2017 to 8 January 2018) on a weekly basis, as shown in

Figure 4. Based on the Jordanian standard, such a treated wastewater can be reused for irrigation of green landscape and forests that require BOD of 30 mg/L as maximum allowable values for irrigation water reuse, excluding flowers (since flowers require BOD less than 15 mg/L). The BOD measured values of the tested samples varied from 3 to 20 mg/L, as minimum and maximum values, respectively, and do not exceed the allowable value (30 mg/L). Moreover, the average BOD (11.25 mg/L) measured in the present study is very compatible with various BOD data reported for the same Fuji Clean CE1500EX system (Fuji Clean, Brunswick, ME, USA), which were collected in Japan (7668 samples) and Australia (76 samples), and the BOD average values for actual field effluent data (grab samples) were 11.2 mg/L and 8.35 mg/L, respectively [

31].

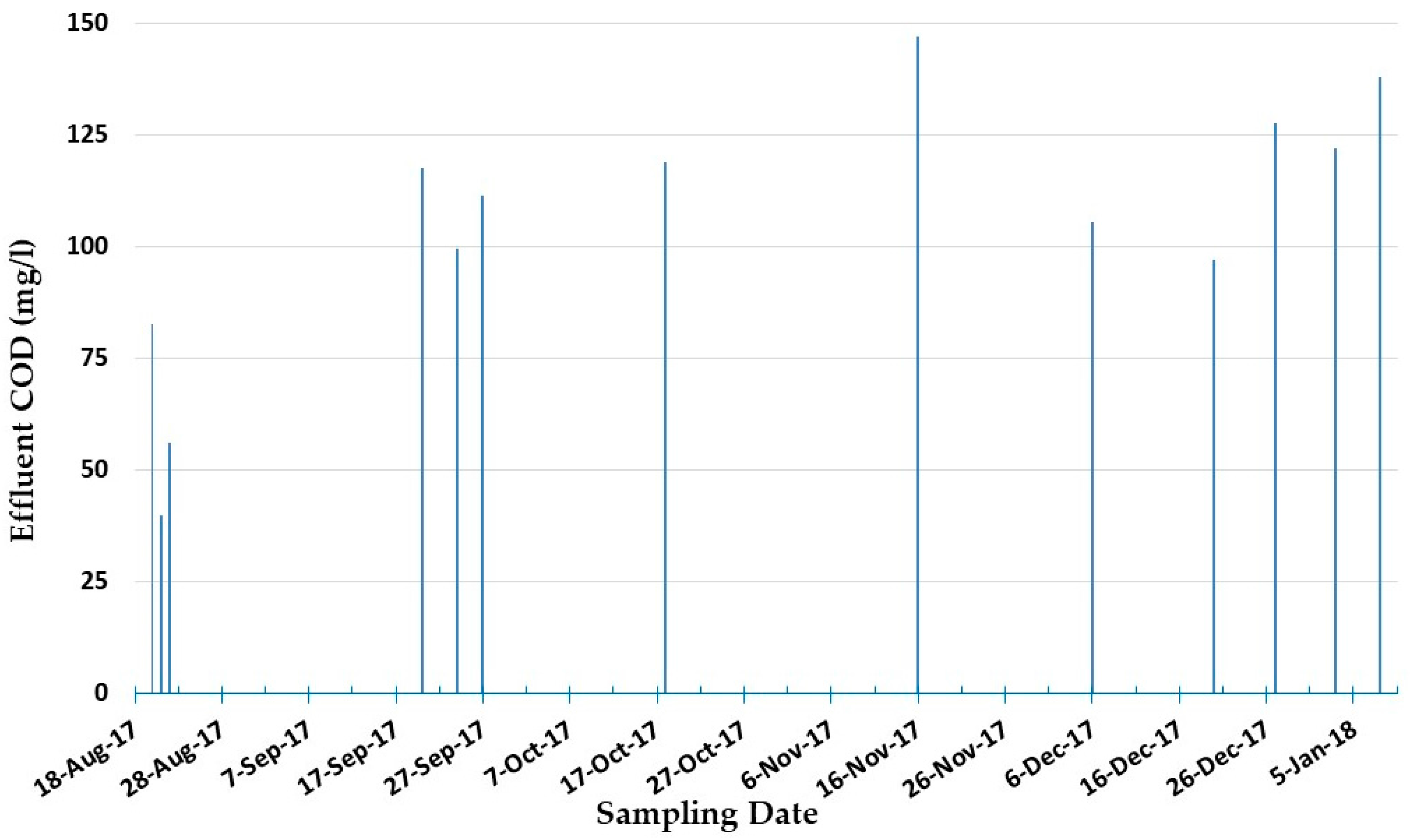

3.2. Effluent COD

The average value of COD during the monitored period (between 20 August 2017 and 8 January 2018) is 104.85 mg/L (with a standard deviation of 30.6447) for all 13 effluent samples that were gathered from the treatment unit on weekly basis, as shown in

Figure 5. Based on the Jordanian standard, such a treated wastewater can be reused for the irrigation of green landscape and forests, which require COD of 500 mg/L as maximum allowable values for irrigation water reuse, excluding flowers (since flowers require COD less than 50 mg/L). The COD values of the tested samples varied from 40 to 147 mg/L, as minimum and maximum values, respectively, and do not exceed the allowable value (500 mg/L).

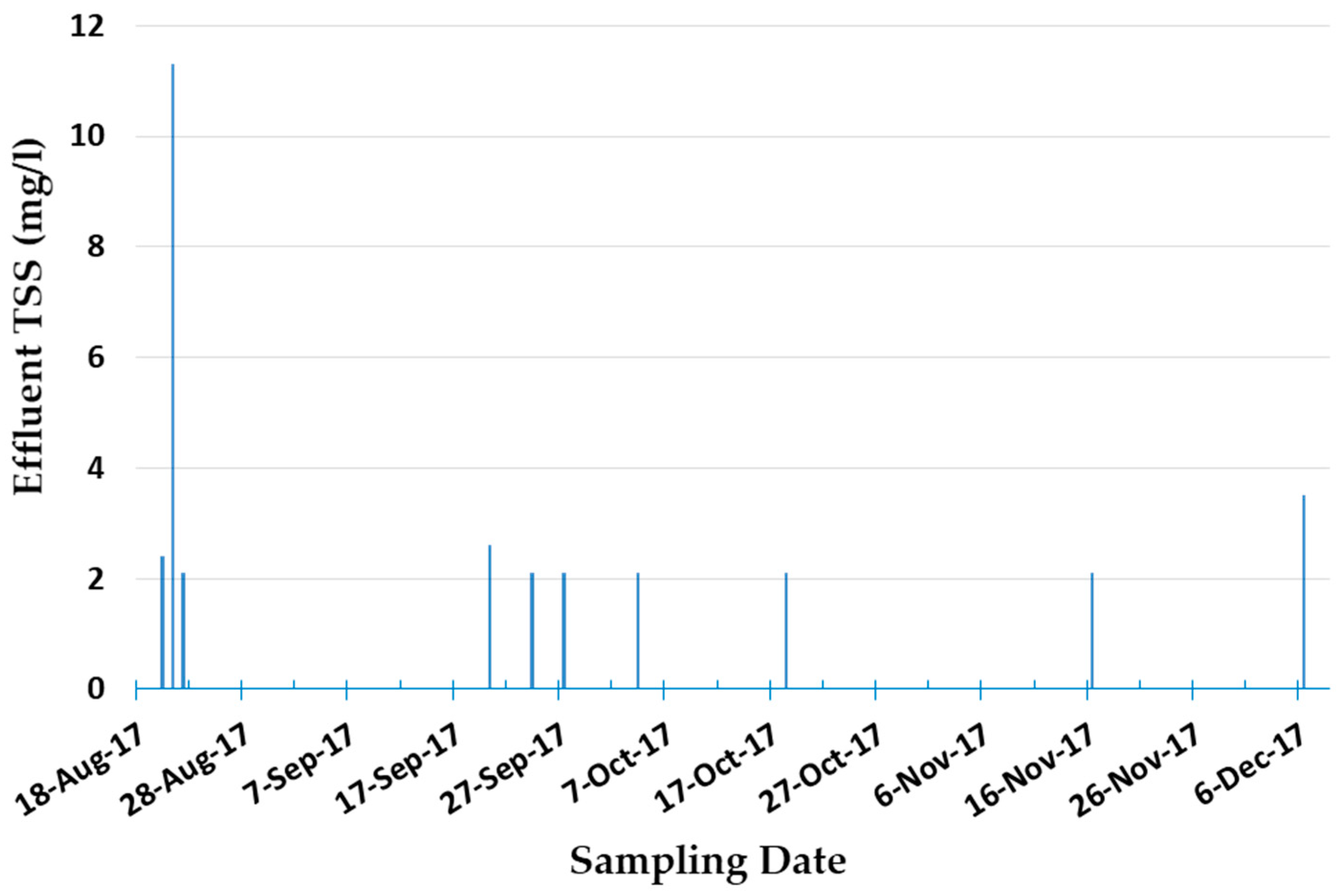

3.3. Effluent TSS

The average value of TSS during the monitored period (from 20 August 2017 to 6 December 2017) is 3.24 mg/L (with a standard deviation of 2.8664) for all 10 effluent samples that were gathered from the treatment unit on weekly basis, as shown in

Figure 6. Based on the Jordanian standard, such a treated wastewater can be reused for the irrigation of green landscape and forests that require TSS of 300 mg/L as a maximum allowable value for irrigation water reuse, while flowers require TSS less than 15 mg/L. The TSS values of the tested samples varied from less than 2.1 to 11.3 mg/L, as minimum and maximum values, respectively, and do not exceed the allowable value (300 mg/L). Moreover, the average TSS (3.24 mg/L) that was measured in the present study is less than various TSS data reported for the same Fuji Clean CE1500EX system, which were collected in Japan (48 samples in the course of obtaining AS/NZS1546.3 accreditation) and Australia (76 actual fields samples) and the TSS average values for grab samples were 4.27 mg/L and 14.9 mg/L, respectively [

31].

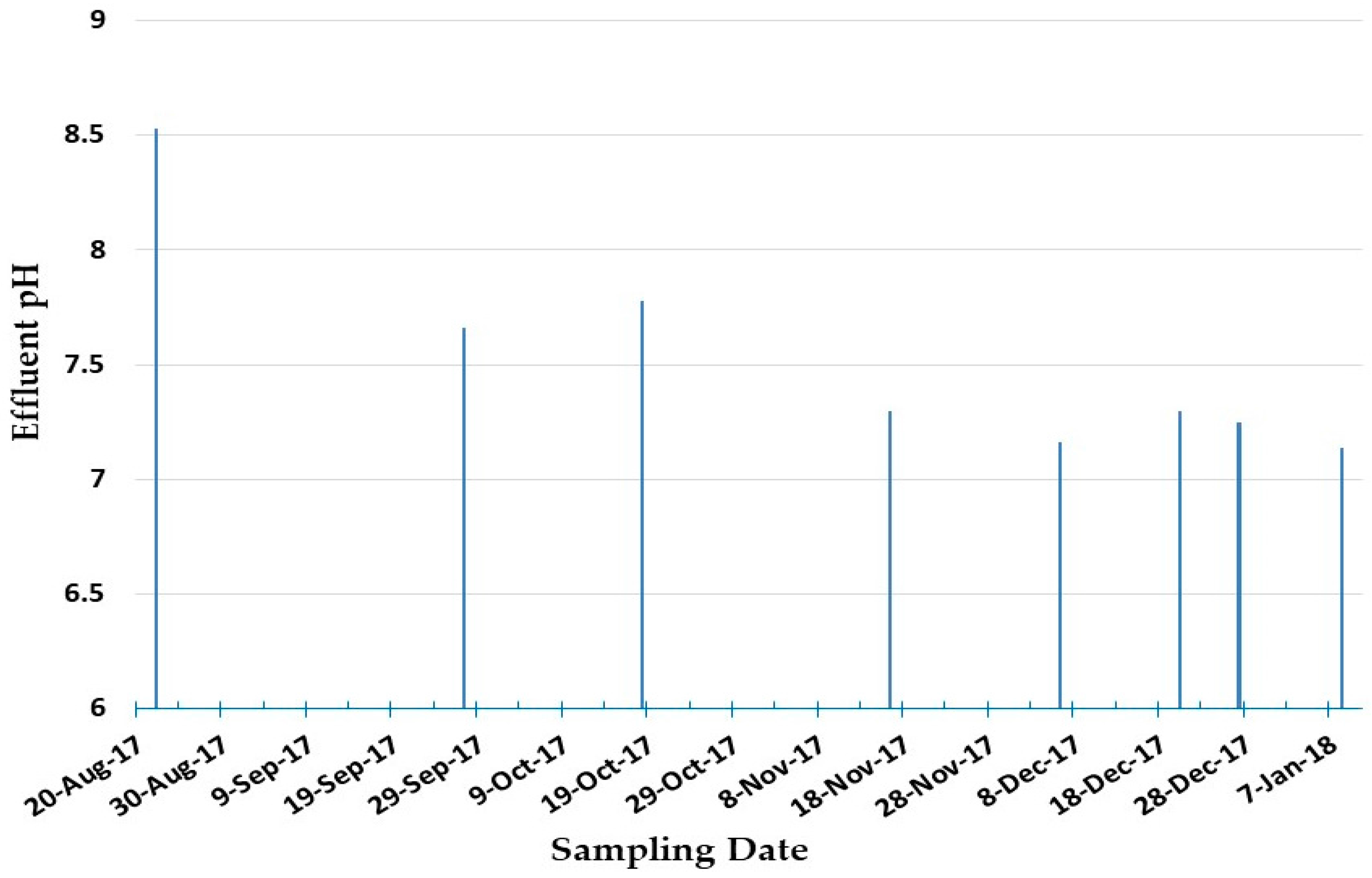

3.4. Effluent pH

The results showed that pH average value is 7.51 (with a standard deviation of 0.4707) for all eight effluent samples that were gathered from the treatment unit during the monitored period (from 22 August 2017 to 8 January 2018) on a weekly basis as shown in

Figure 7. Based on the Jordanian standard, such a treated wastewater can be reused for the irrigation of green landscape and forests (including flowers), which require pH of 6–9 as a range of allowable values for irrigation water reuse. The pH values of the tested samples varied from 7.14 to 8.53, as minimum and maximum values, respectively.

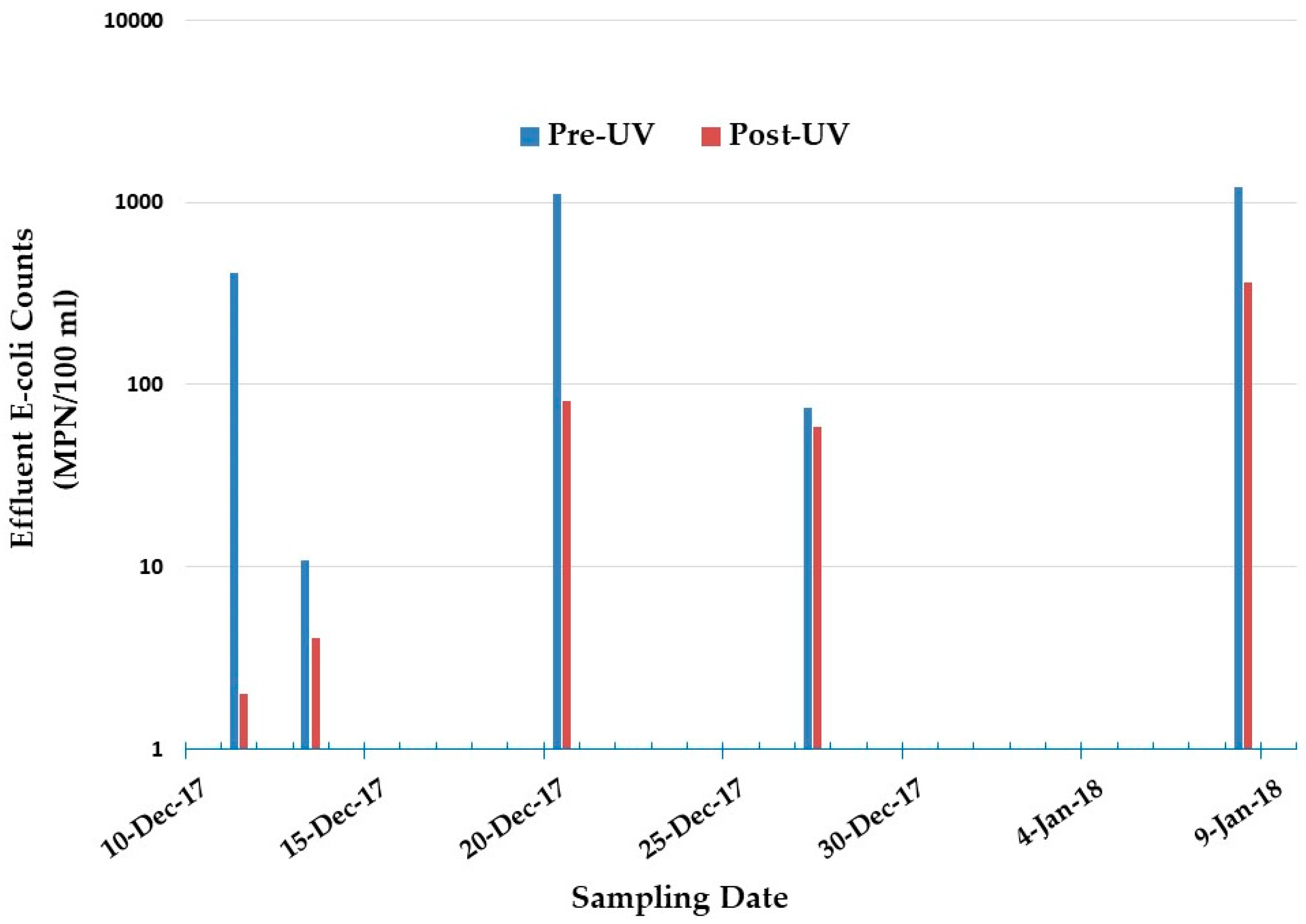

3.5. Effluent E-coli

Water samples were taken prior- and post UV disinfection in order to investigate the efficiency of the in-line UV disinfection unit. The results showed that the average value of

E-coli disinfection efficiency is 68.97% (with a standard deviation of 0.3117) for all five effluent samples that were gathered during the monitored period (from 11 December 2017 to 8 January 2018) on a weekly basis, as shown in

Figure 8. The

E-coli disinfection efficiency values of the tested samples varied from 20.5% to 99.5%, as minimum and maximum values, respectively. The of

E-coli measured counts of the tested samples post-UV disinfection unit varied from 2 to 364 MPN/100 mL, as minimum and maximum values, respectively, and do not exceed the allowable value (1000 MPN/100 mL) for irrigation of green landscape and forests according to the Jordanian standards.

3.6. The Need for Such Treatment Process in Jordan

Jordan is an upper-middle income and non-oil producing country with a population of 9.53 million inhabitants [

6]. Forty-two percent of the population is under 15 years of age; 30% are non-Jordanians, and 30% are registered as refugees [

35]. According to the MWI, the sanitation coverage in 2014 for both the urban and rural population was 93%. Out of which, 63% are connected to the sewerage system, while the rest were having access to improved sanitation using traditional on-site sanitation systems (i.e., septic tanks) [

15].

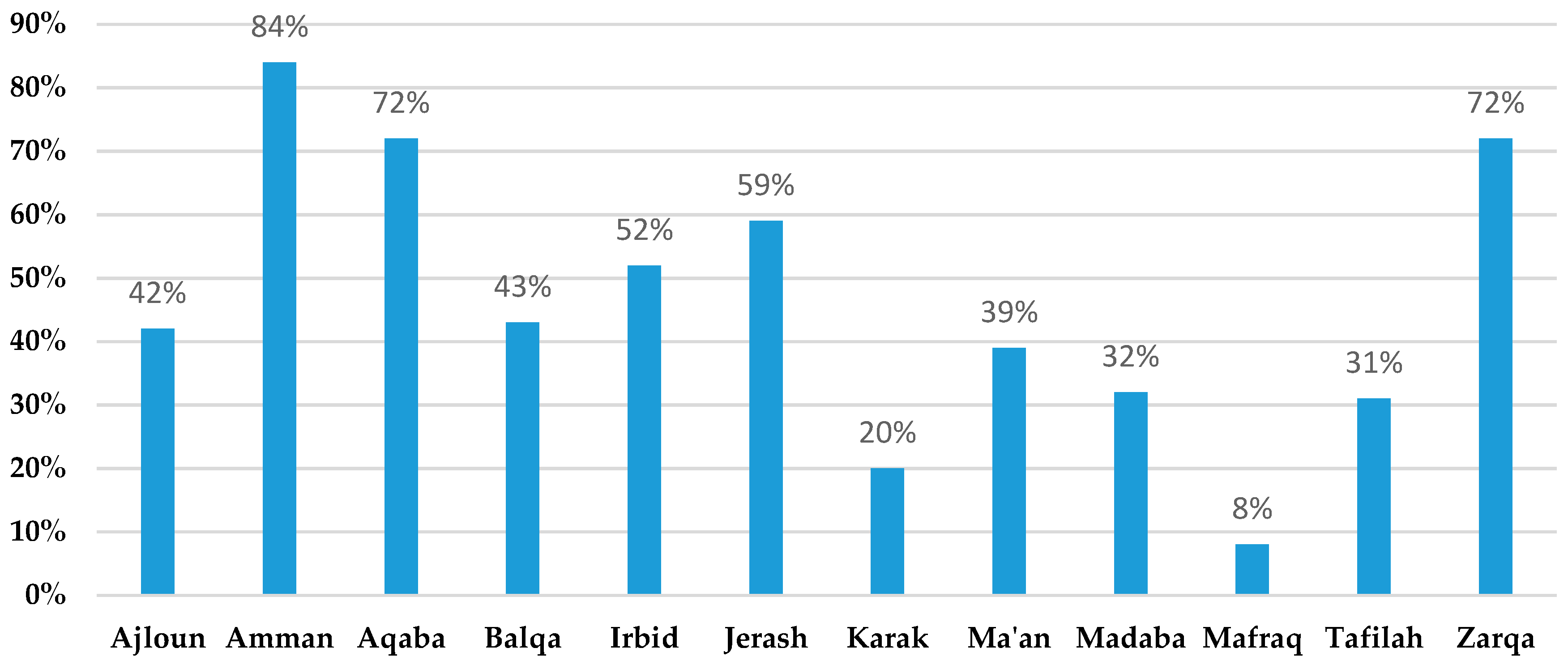

Figure 9 shows the percentage of the population that is connected to the sewerage network by for each governorate in Jordan. The septic tanks are poorly designed and managed since they are not lined or capped properly. This in return poses serious health concerns due to leaching of wastewater that might penetrate into soil and pollute scarce groundwater aquifers. Most importantly, water reuse is a lost opportunity in this case, as wastewater is contained in these septic tanks.

To relatively compare the water characteristics (BOD, COD, TSS, and pH) of the on-site treatment process that are presented in

Table 1, and stated again in

Table 2 to facilitate data comparison with the same water average characteristics of wastewater treatment plants effluents in Jordan, as shown in

Table 2, then it is clear that the on-site treatment process is a suitable alternative for wastewater treatment and reuse in Jordan.

Despite the facts that are illustrated earlier in the present work concerning the value of treated wastewater, little research has examined micro and macro policy interventions for water substitution. Cultural, political, environmental, and fiscal constraints make fresh water substitution more difficult than theories based on simplified assumptions [

1]. In the predominantly Muslim societies in the Middle East and North Africa, the use of treated wastewater is culturally nuanced [

37]. However, it is decreed by the Council of Leading Islamic Scholars that treated wastewater could be considered pure if it was treated properly. Nevertheless, some people still object to wastewater reuse on religious grounds [

38]. Another key concern is human health hazards, such as the presence of bacterial pathogens and chemical contaminants on irrigated food [

39,

40]. Awareness campaigns and educational programs are highly recommended. This shall target residential sector and main actors in the agriculture sector, taking into consideration the belief and perception of the public based on scientific and logical proofs. Therefore, encouraging the residential sector to promote the using of such on-site wastewater treatment process will cost-effectively maximize water savings, replace freshwater for agricultural activities, and thus decrease the strain on groundwater.

On the other hand, in 2017 groups of seven to nine households were connected to 979 communal septic tanks, which were constructed in the Za’atari Syrian refugees’ camp and were connected via roughly 98,000 m of piping to the toilets and showers of some 6400 houses in the camp, as reported by ACTED Jordan [

41]. In case these septic tanks are modified and connected with such on-site wastewater treatment system, then this can resolve the sanitation crisis that was looming in the camp under the form of grey and black water, which run along the streets and stagnate in unsightly and unsanitary pools.

Therefore, on the basis of a simple design and construction cost, easy operation and maintenance, and much better treatment efficiency, the on-site wastewater treatment unit is a suitable alternative to the conventional septic tank in the refugees’ camps in Jordan, where the centralized treatment facilities are still not functional.

4. Conclusions

This paper deals with the evaluation of on-site treatment of institutional building’s wastewater. For this purpose, many samples were collected on a weekly basis during the monitored period, followed by determination of minimum, maximum, and average values for the parameters of wastewater pollution (BOD, COD, TSS, pH, and E-coli) and investigation of the effluent quality of the 1 m3/day on-site wastewater treatment process. The process has been modified by installation of in-line UV unit to ensure the high disinfection of treated water. According to the Jordanian standard of treated wastewater quality for irrigation water reuse, four classifications of plants have been proposed, with determined maximum values water parameters being permissible for each plants classification. The results showed that the treated wastewater is suitable for water reuse in irrigation of two plants classifications out of four, based on Jordanian standards and criteria. Hence, such a treatment process can be utilized in refugees’ camps where no centralized wastewater treatment plants are installed.