Group Acceptance Sampling Plan Using Marshall–Olkin Kumaraswamy Exponential (MOKw-E) Distribution

Abstract

:1. Introduction

Format of the Paper

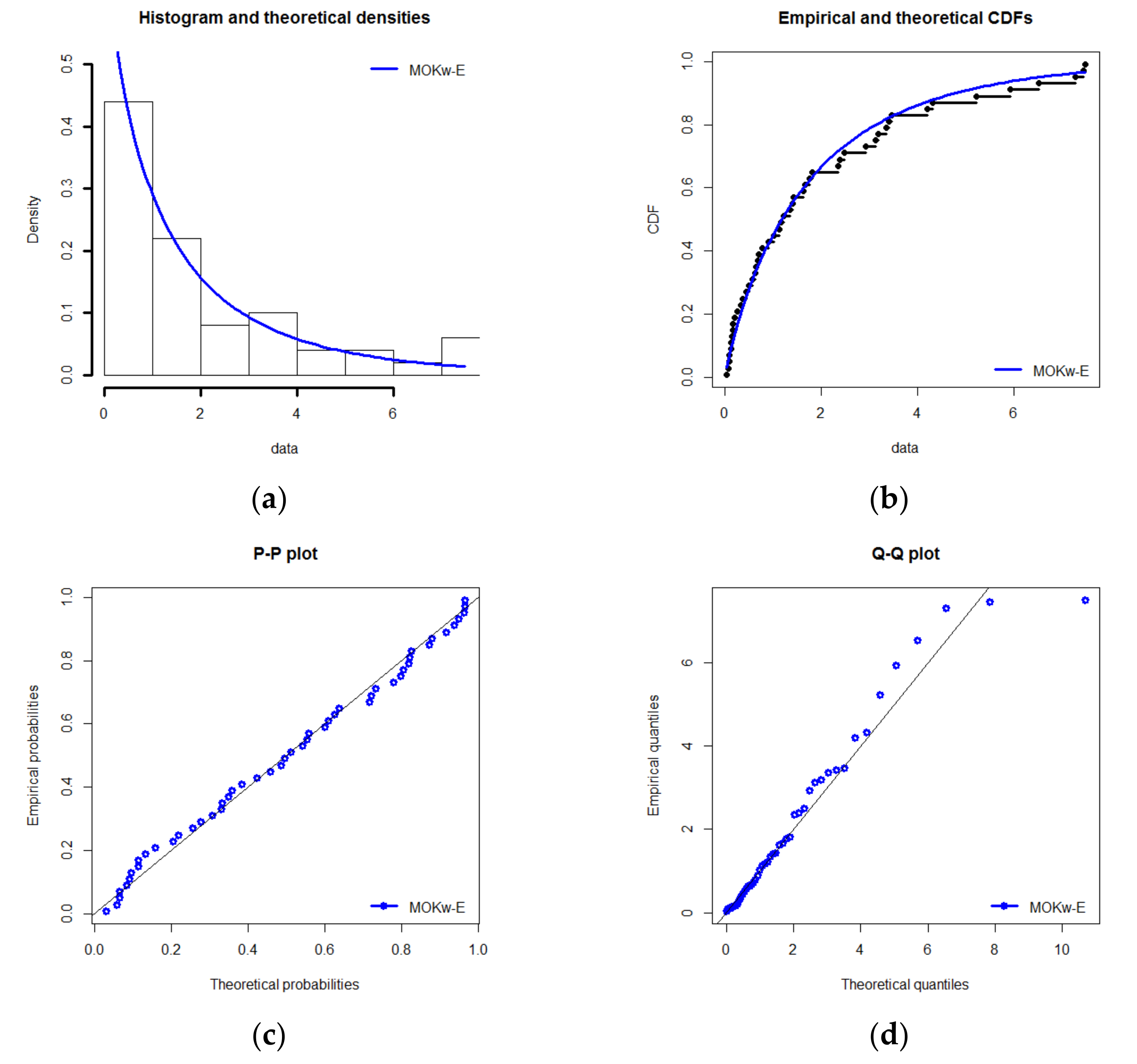

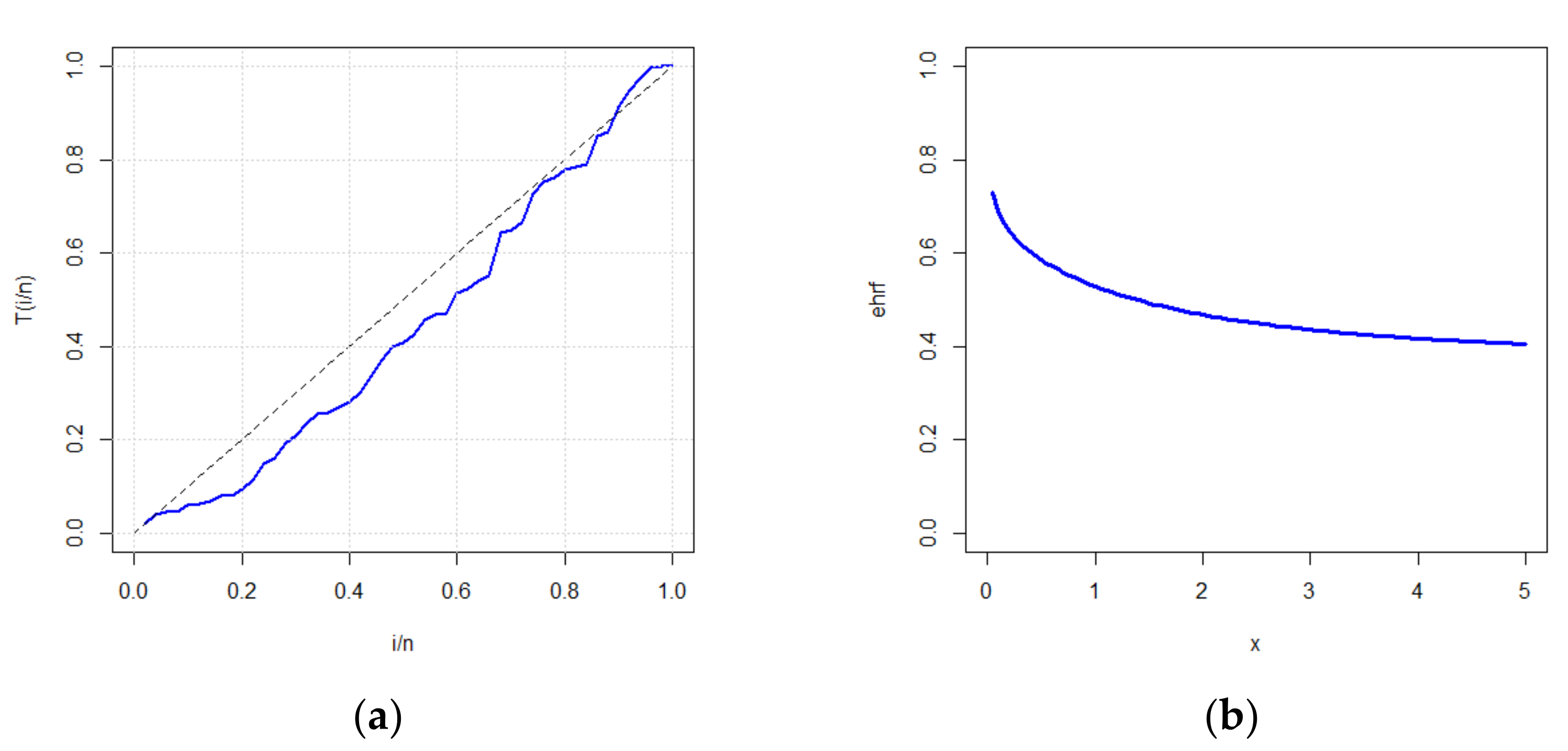

2. Marshall–Olkin Kumaraswamy Exponential (MOkw-E) Distribution

3. Description of the Gasp

- Selecting ‘g’ number of groups, and allocating predefining r items to each group. Thus, the sample size for a lot is obtained as ‘n’ = g × r.

- Selecting ‘c’ with reference to the acceptance number for a group with experiment time t0.

- Simultaneously performing the experiment for ‘g’ groups and recording the number of failures for each group.

- Accepting the lot if no more than ‘c’ failures occur in all groups.

- Truncating the experiment and refusing the lot if more than ‘c’ failures occur in any group.

4. Discussion and Example

4.1. Discussion

| m/m0 = r2 | 4 | 6 | 8 |

| G | 11 | 6 | 3 |

| C | 5 | 4 | 3 |

| P(a) | 0.9653 | 0.9758 | 0.9793 |

4.2. Example

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

g=sEquation(1,1000,1);c=c(0,1,2,3,4,5);lp2=double(length(g));

lp1=double(length(g));lp21=double(length(c)); lp22=double(length(c));

lp23=double(length(c));lp24=double(length(c));G1=double(length(c));

G2=double(length(c));G3=double(length(c));G4=double(length(c));

p=function(alp,p,ratio,a,b ){

nu=log(1-(((1-(1-((alp*p)/(1-(1-alp)*p)))^(1/b)))^(1/a)))

d=(1-((1-exp(nu*((ratio)^-1)*a1))^a))

y=(((1-d)^b)/(1-((1-alp)*(1-d)^b)));return(y)

}

p2=round(p(2,0.5,c(2,4,6,8,10),1,1,0.5),4);

p2; p1=round(p(2,0.5,1,1,1,0.5),4);p1

for(i in 1:length(c)){

for(j in 1:length(g)){

lp2[j]=(pbinom(c[i],10,p2[2]))^j

lp1[j]=(pbinom(c[i],10,p1))^j

}

G1[i]=min(which(lp2>=0.95 & lp1<0.25));lp21[i]=round(lp2[G1[i]],4);

G2[i]=min(which(lp2>=0.95 & lp1<0.10));lp22[i]=round(lp2[G2[i]],4);

G3[i]=min(which(lp2>=0.95 & lp1<0.05));lp23[i]=round(lp2[G3[i]],4);

G4[i]=min(which(lp2>=0.95 & lp1<0.01));lp24[i]=round(lp2[G4[i]],4);

}

cbind(c,G1,lp21,G2,lp22,G3,lp23,G4,lp24).

|

References

- Lu, J.C.; Jeng, S.L.; Wang, K. A review of statistical methods for quality improvement and control in nanotechnology. J. Qual. Technol. 2009, 41, 148–164. [Google Scholar] [CrossRef]

- Jun, C.H.; Balamurali, S.; Lee, S.H. Variables sampling plans for Weibull distributed lifetimes under sudden death testing. IEEE Trans. Reliab. 2006, 55, 53–58. [Google Scholar] [CrossRef]

- Aslam, M.; Jun, C.H. A Group Acceptance Sampling Plans for Truncated Life Tests based on The Inverse Rayleigh And Log-Logistic Distributions. Pak. J. Stat. 2009, 25, 107–119. [Google Scholar]

- Rao, G.S. A group acceptance sampling plans based on truncated life tests for Marshall-Olkin extended Lomax distribution. Electron. J. Appl. Stat. Anal. 2009, 3, 18–27. [Google Scholar]

- Rao, G.S. A group acceptance sampling plans for lifetimes following a Marshall–Olkin extended Weibull distribution. Stat. Appl. 2010, 8, 135–144. [Google Scholar]

- Aslam, M.; Kundu, D.; Jun, C.H.; Ahmad, M. Time truncated group acceptance sampling plans for generalized exponential distribution. J. Test. Eval. 2011, 39, 671–677. [Google Scholar]

- Sivakumar, D.C.U.; Kanaparthi, R.; Rao, G.S.; Kalyani, K. The Odd generalized exponential log-logistic distribution group acceptance sampling plan. Stat. Transit. New Ser. 2019, 20, 103–116. [Google Scholar] [CrossRef] [Green Version]

- Tahir, M.H.; Nadarajah, S. Parameter induction in continuous univariate distributions: Well-established G families. An. Acad. Bras. Ciências 2015, 87, 539–568. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh, M.; Tahir, M.H.; Cordeiro, G.M.; Zubair, M.; Hamedani, G.G. The Kumaraswamy Marshal-Olkin family of distributions. J. Egypt. Math. Soc. 2015, 23, 546–557. [Google Scholar] [CrossRef] [Green Version]

- Marshall, A.W.; Olkin, I. A new method for adding a parameter to a family of distributions with application to the exponential and Weibull families. Biometrika 1997, 84, 641–652. [Google Scholar] [CrossRef]

- Cordeiro, G.M.; de Castro, M. A new family of generalized distributions. J. Stat. Comput. Simul. 2011, 81, 883–898. [Google Scholar] [CrossRef]

- Handique, L.; Chakraborty, S. The Marshall-Olkin-Kumaraswamy-G family of distributions. arXiv 2015, arXiv:1509.08108. [Google Scholar] [CrossRef] [Green Version]

- Ghitany, M.E.; Al-Hussaini, E.K.; Al-Jarallah, R.A. Marshall–Olkin extended Weibull distribution and its application to censored data. J. Appl. Stat. 2005, 32, 1025–1034. [Google Scholar] [CrossRef]

- Ristić, M.M.; Kundu, D. Marshall-Olkin generalized exponential distribution. Metron 2015, 73, 317–333. [Google Scholar] [CrossRef]

- Gupta, S.S. Life test sampling plans for normal and lognormal distributions. Technometrics 1962, 4, 151–175. [Google Scholar] [CrossRef]

- Khan, K.; Alqarni, A. A group acceptance sampling plan using mean lifetime as a quality parameter for inverse Weibull distribution. Adv. Appl. Stat. 2020, 649, 237–249. [Google Scholar] [CrossRef]

- Singh, S.; Tripathi, Y.M. Acceptance sampling plans for inverse Weibull distribution based on truncated life test. Life Cycle Reliab. Saf. Eng. 2017, 6, 169–178. [Google Scholar] [CrossRef] [Green Version]

- Nichols, M.D.; Padgett, W.J. A bootstrap control chart for Weibull percentiles. Qual. Reliab. Eng. Int. 2006, 22, 141–151. [Google Scholar] [CrossRef]

| β | r2 | r = 5 | r = 10 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a1 = 0.5 | a1 = 1 | a1 = 0.5 | a1 = 1 | ||||||||||

| g | c | P(a) | g | c | P(a) | g | c | P(a) | g | c | P(a) | ||

| 0.25 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 41 | 3 | 0.9852 | 8 | 3 | 0.9678 | 3 | 3 | 0.9693 | 2 | 4 | 0.9620 | |

| 6 | 8 | 2 | 0.9809 | 3 | 2 | 0.9552 | 2 | 2 | 0.9552 | 1 | 3 | 0.9743 | |

| 8 | 8 | 2 | 0.9914 | 3 | 2 | 0.9786 | 2 | 2 | 0.9972 | 1 | 3 | 0.9897 | |

| 0.10 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 67 | 3 | 0.9760 | 83 | 4 | 0.9863 | 13 | 4 | 0.9840 | 6 | 5 | 0.9809 | |

| 6 | 13 | 2 | 0.9691 | 13 | 3 | 0.9869 | 5 | 3 | 0.9870 | 3 | 4 | 0.9878 | |

| 8 | 13 | 2 | 0.9861 | 4 | 2 | 0.9715 | 3 | 2 | 0.9681 | 2 | 3 | 0.9794 | |

| 0.05 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 88 | 3 | 0.9686 | 107 | 4 | 0.9823 | 17 | 4 | 0.9792 | 8 | 5 | 0.9746 | |

| 6 | 16 | 2 | 0.9621 | 16 | 3 | 0.9839 | 7 | 3 | 0.9818 | 4 | 4 | 0.9838 | |

| 8 | 16 | 2 | 0.9829 | 5 | 2 | 0.9645 | 3 | 2 | 0.9681 | 2 | 3 | 0.9794 | |

| 0.01 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 134 | 3 | 0.9526 | 165 | 4 | 0.9729 | 26 | 4 | 0.9683 | 11 | 5 | 0.9653 | |

| 6 | 134 | 3 | 0.9892 | 25 | 3 | 0.9749 | 10 | 3 | 0.9741 | 6 | 4 | 0.9758 | |

| 8 | 25 | 2 | 0.9734 | 25 | 3 | 0.9910 | 10 | 3 | 0.9907 | 3 | 3 | 0.9793 | |

| β | r2 | r = 5 | r = 10 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a1 = 0.5 | a1 = 1 | a1 = 0.5 | a1 = 1 | ||||||||||

| g | c | P(a) | g | c | P(a) | g | c | P(a) | g | c | P(a) | ||

| 0.25 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 39 | 3 | 0.9803 | 9 | 3 | 0.9553 | 3 | 3 | 0.9853 | 5 | 5 | 0.9786 | |

| 6 | 8 | 2 | 0.9747 | 9 | 3 | 0.9877 | 3 | 3 | 0.9888 | 1 | 3 | 0.9668 | |

| 8 | 8 | 2 | 0.9886 | 9 | 3 | 0.9726 | 2 | 2 | 0.9716 | 1 | 3 | 0.9860 | |

| 0.10 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 65 | 3 | 0.9674 | 109 | 4 | 0.9762 | 13 | 4 | 0.9763 | 7 | 5 | 0.9701 | |

| 6 | 12 | 2 | 0.9623 | 15 | 3 | 0.9797 | 5 | 3 | 0.9814 | 4 | 4 | 0.9773 | |

| 8 | 12 | 2 | 0.9826 | 5 | 3 | 0.9547 | 3 | 2 | 0.9576 | 2 | 3 | 0.9721 | |

| 0.05 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 85 | 3 | 0.9575 | 142 | 4 | 0.9691 | 17 | 4 | 0.9691 | 9 | 5 | 0.9617 | |

| 6 | 16 | 2 | 0.9501 | 20 | 3 | 0.9730 | 7 | 3 | 0.9741 | 5 | 4 | 0.9717 | |

| 8 | 16 | 2 | 0.9768 | 20 | 3 | 0.9898 | 3 | 2 | 0.9576 | 3 | 3 | 0.9585 | |

| 0.01 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 132 | 3 | 0.9876 | 218 | 4 | 0.9530 | 25 | 4 | 0.9549 | 10 | 5 | 0.9607 | |

| 6 | 125 | 3 | 0.9846 | 30 | 3 | 0.9597 | 10 | 3 | 0.9632 | 7 | 4 | 0.9606 | |

| 8 | 24 | 2 | 0.9654 | 30 | 3 | 0.9848 | 10 | 3 | 0.9862 | 5 | 3 | 0.9872 | |

| β | r2 | r = 5 | r = 10 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a1 = 0.5 | a1 = 1 | a1 = 0.5 | a1 = 1 | ||||||||||

| g | c | P(a) | g | c | P(a) | g | c | P(a) | g | c | P(a) | ||

| 0.25 | 2 | - | - | - | - | - | - | - | - | - | 17 | 5 | 9575 |

| 4 | 33 | 2 | 0.9785 | 6 | 2 | 0.9715 | 6 | 2 | 0.9650 | 3 | 3 | 0.9813 | |

| 6 | 7 | 1 | 0.9576 | 6 | 2 | 0.9917 | 6 | 2 | 0.9896 | 2 | 2 | 0.9728 | |

| 8 | 7 | 1 | 0.9764 | 2 | 1 | 0.9717 | 2 | 1 | 0.9714 | 2 | 2 | 0.9882 | |

| 0.10 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 63 | 2 | 0.9646 | 10 | 2 | 0.9530 | 31 | 3 | 0.9873 | 4 | 3 | 0.9752 | |

| 6 | 63 | 2 | 0.9900 | 10 | 2 | 0.9861 | 9 | 2 | 0.9845 | 2 | 2 | 0.9728 | |

| 8 | 11 | 1 | 0.9632 | 3 | 1 | 0.9578 | 9 | 2 | 0.9935 | 2 | 2 | 0.9882 | |

| 0.05 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 81 | 2 | 0.9547 | 62 | 3 | 0.9872 | 41 | 5 | 0.9832 | 5 | 3 | 0.9691 | |

| 6 | 81 | 2 | 0.9872 | 13 | 2 | 0.9820 | 12 | 2 | 0.9793 | 3 | 2 | 0.9595 | |

| 8 | 14 | 1 | 0.9534 | 13 | 2 | 0.9926 | 12 | 2 | 0.9914 | 3 | 2 | 0.9824 | |

| 0.01 | 2 | - | - | - | - | - | - | - | - | - | - | - | - |

| 4 | 138 | 2 | 0.9635 | 94 | 3 | 0.9806 | 62 | 5 | 0.9747 | 8 | 3 | 0.9510 | |

| 6 | 125 | 2 | 0.9803 | 19 | 2 | 0.9738 | 18 | 2 | 0.9692 | 8 | 3 | 0.9896 | |

| 8 | 125 | 2 | 0.9920 | 19 | 2 | 0.9892 | 18 | 2 | 0.9871 | 4 | 2 | 0.9765 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almarashi, A.M.; Khan, K.; Chesneau, C.; Jamal, F. Group Acceptance Sampling Plan Using Marshall–Olkin Kumaraswamy Exponential (MOKw-E) Distribution. Processes 2021, 9, 1066. https://doi.org/10.3390/pr9061066

Almarashi AM, Khan K, Chesneau C, Jamal F. Group Acceptance Sampling Plan Using Marshall–Olkin Kumaraswamy Exponential (MOKw-E) Distribution. Processes. 2021; 9(6):1066. https://doi.org/10.3390/pr9061066

Chicago/Turabian StyleAlmarashi, Abdullah M., Khushnoor Khan, Christophe Chesneau, and Farrukh Jamal. 2021. "Group Acceptance Sampling Plan Using Marshall–Olkin Kumaraswamy Exponential (MOKw-E) Distribution" Processes 9, no. 6: 1066. https://doi.org/10.3390/pr9061066