A Chemical Safety Assessment of Lyocell-Based Activated Carbon Fiber with a High Surface Area through the Evaluation of HCl Gas Adsorption and Electrochemical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of ACF and Pore Characteristics

2.2. Mechanical Strength

2.3. Electrochemical HCl Gas Sensing

2.4. Analysis of HCl Adsorption

3. Results and Discussion

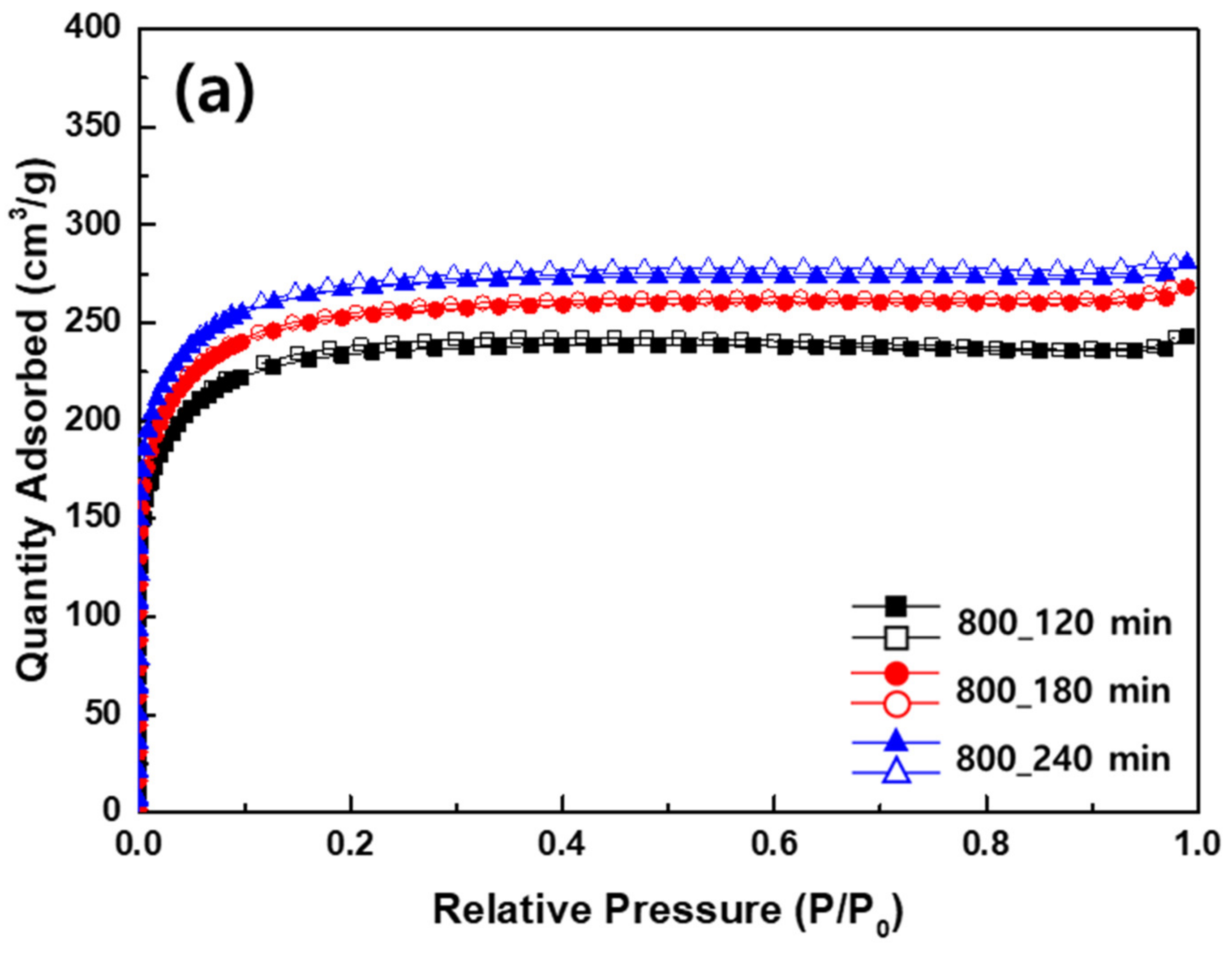

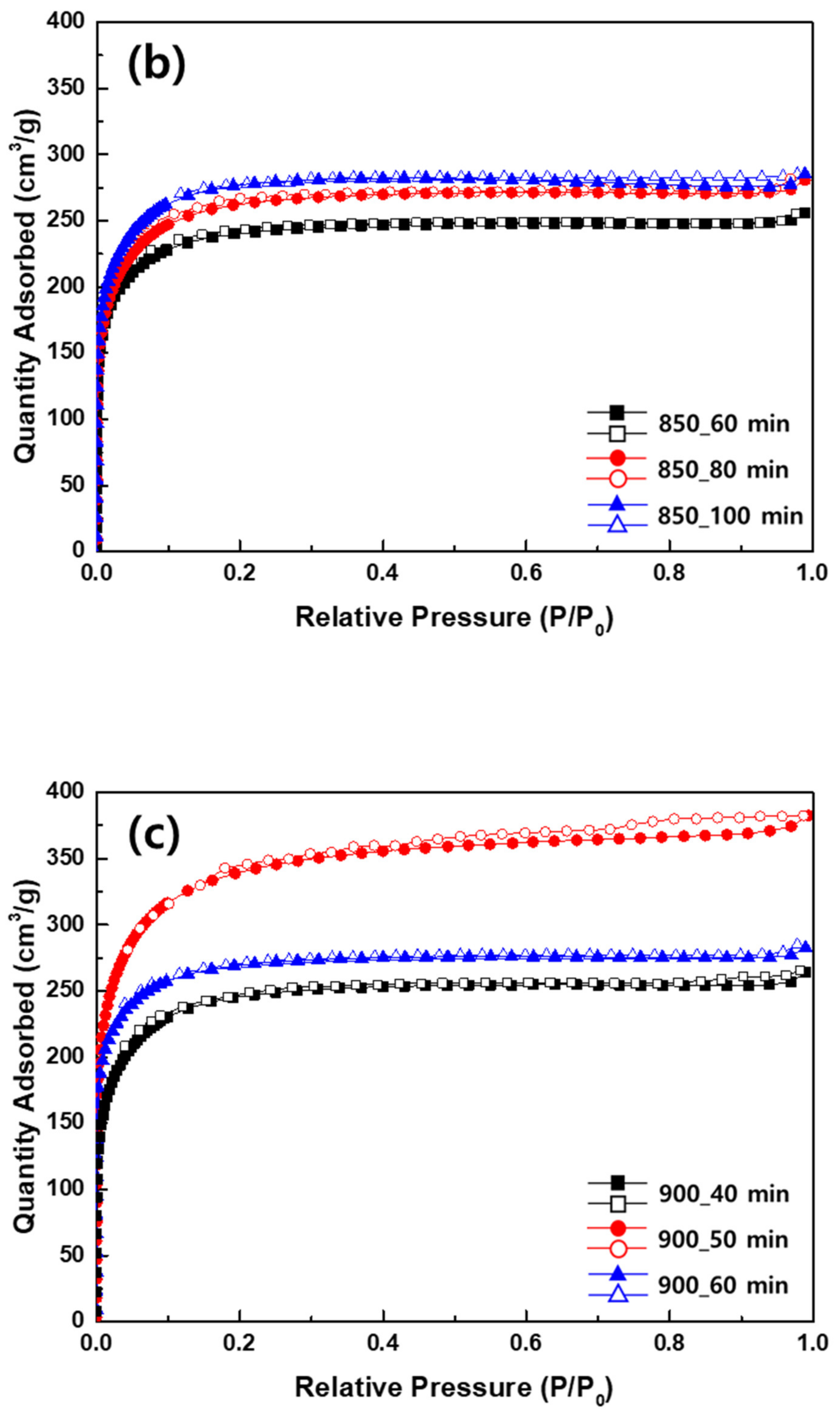

3.1. Pore Structure of ACFs with Steam Activation Temperature and Time

3.2. Analysis of Mechanical Strengths of ACFs

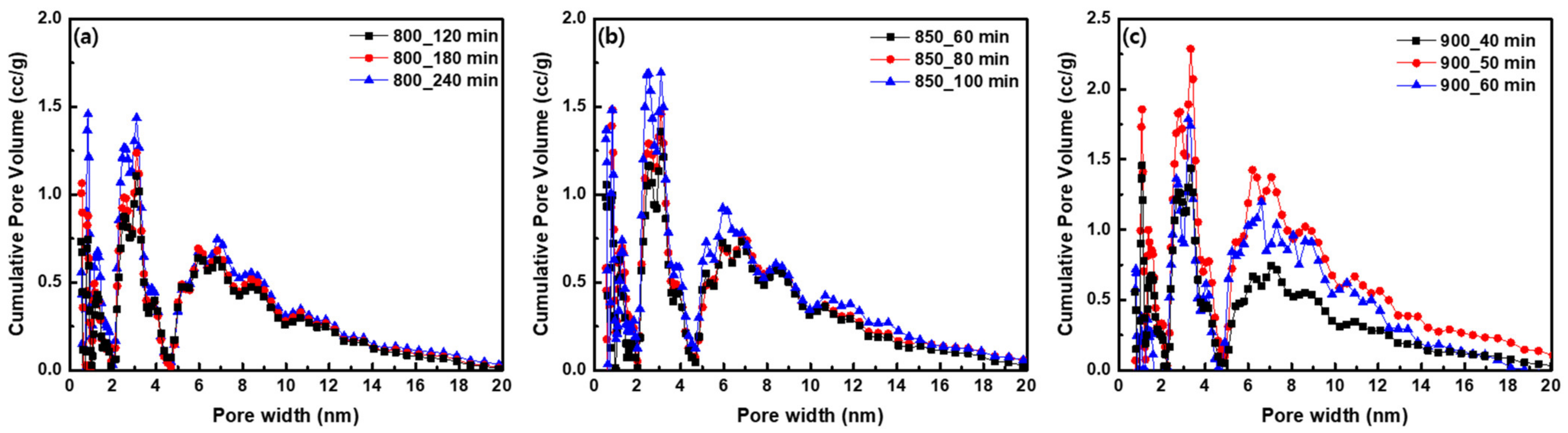

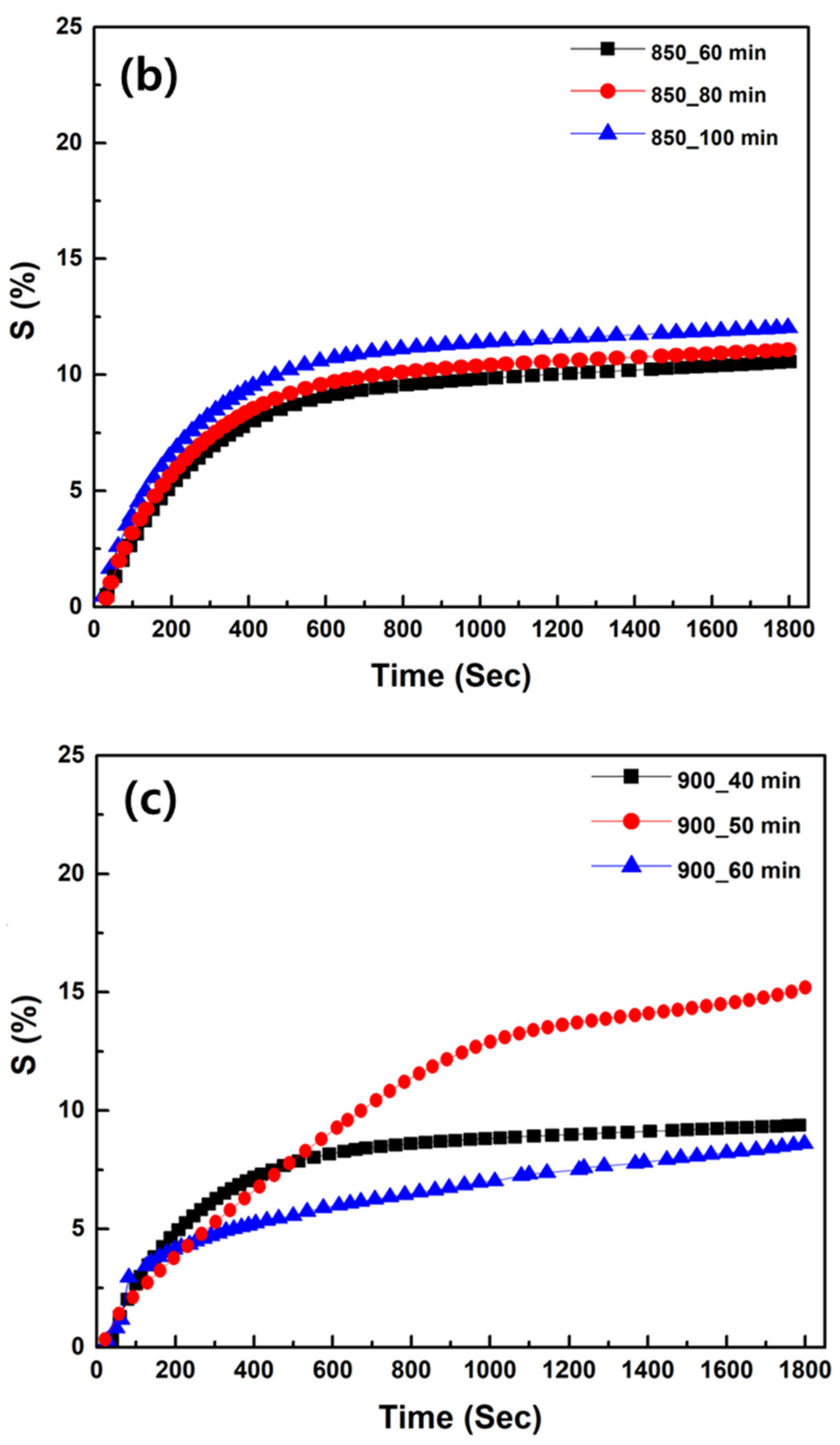

3.3. Analysis of Resistive Response of ACFs

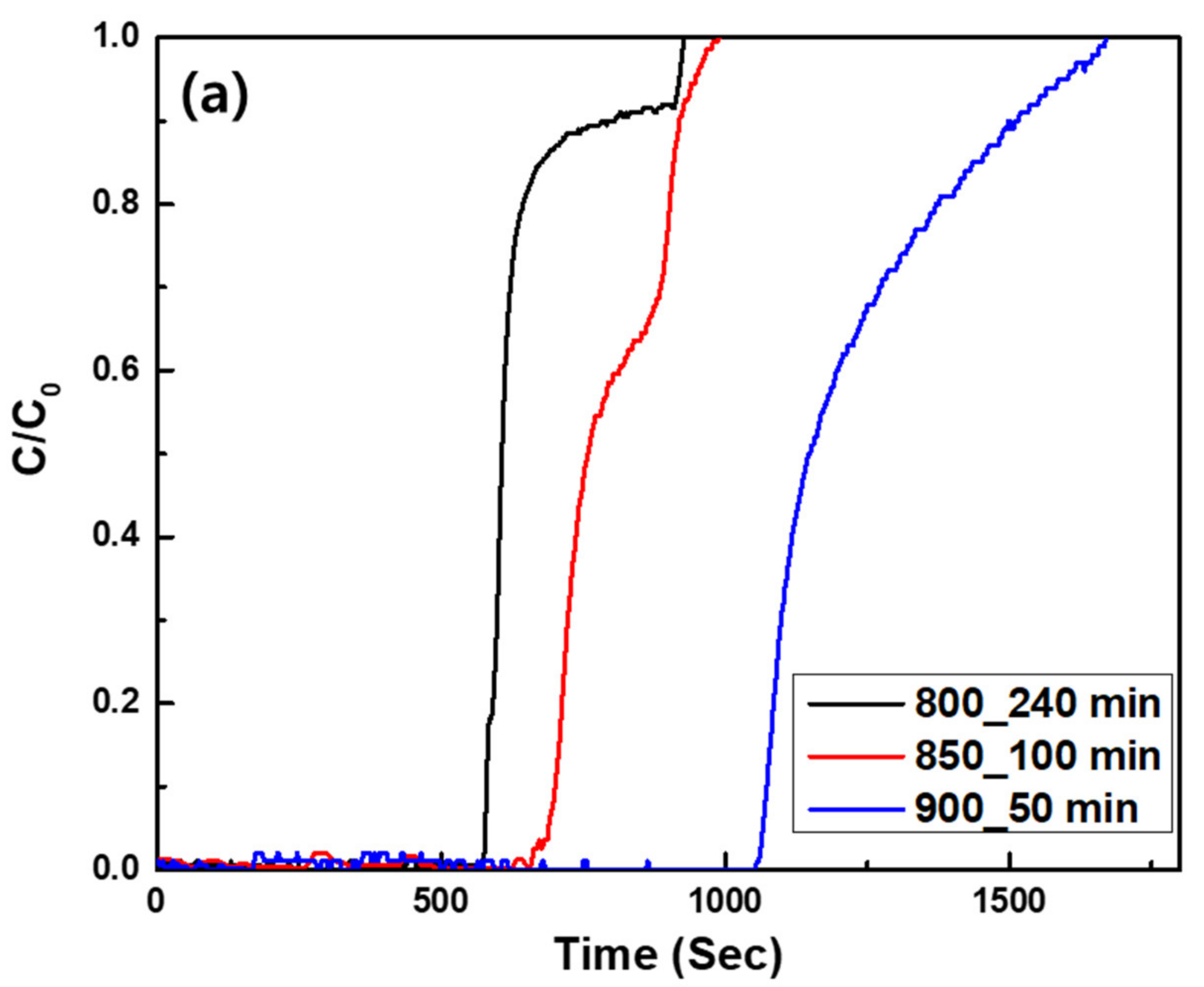

3.4. Analysis of the Adsorption of HCl Gas by ACFs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kelly, F.J.; Fussell, J.C. Air pollution and public health: Emerging hazards and improved understanding of risk. Environ. Geochem. Health 2015, 37, 631–649. [Google Scholar] [CrossRef]

- Wee, J.H.; Bae, Y.; Ahn, H.; Choi, Y.O.; Jeong, E.; Yeo, S.Y. Fibrous and granular activated carbon mixed media for effective gas removal as a cabin air filter. Carbon Lett. 2022, 32, 1111–1118. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, J.N.; Ma, G.X.; Zhang, Y.S. China tackles the health effects of airpollution. Lancet 2013, 382, 1959–1960. [Google Scholar] [CrossRef]

- Tabrizi, N.S.; Taleghani, M.S. Performance of CNT-CNP aerogel as an electrode in capacitive deionization system. Carbon Lett. 2023, 33, 1253–1263. [Google Scholar] [CrossRef]

- Lelieveld, J.; Evans, J.S.; Fnais, M.; Giannadaki, D.; Pozzer, A. The contribution of outdoor air pollution sources to premature mortality on a global scale. Nature 2015, 525, 367–371. [Google Scholar] [CrossRef] [PubMed]

- Brunekreef, B.; Holgate, S.T. Air pollution and health. Lancet 2002, 360, 1233–1242. [Google Scholar] [CrossRef] [PubMed]

- Samet, J.M.; Gruskin, S. Air pollution, health, and human rights. Lancet Resp. Med. 2015, 3, 98–100. [Google Scholar] [CrossRef]

- Natarajan, P.; Chandrababu, P.; Karmegam, P.M.; Madasamy, J.; Somasundaram, S. Tungsten-based activated carbon matrix for the catalytic oxidation of model volatile organic compounds (VOCs) and pharmaceutical VOCs from wastewater. Carbon Lett. 2023, 33, 1115–1132. [Google Scholar] [CrossRef]

- Sivaranjanee, R.; Kumar, P.S.; Rangasamy, G. A critical review on biochar for environmental applications. Carbon Lett. 2023, 33, 1407–1432. [Google Scholar] [CrossRef]

- Bal, M.; Reddy, T.T.; Meikap, B.C. Removal of HCl gas from off gases using self-priming venturi scrubber. J. Hazard. Mater. 2019, 364, 406–418. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, S.; Shao, L.; He, P. Estimating source strengths of HCl and SO2 emissions in the flue gas from waste incineration. J. Environ. Sci. 2019, 75, 370–377. [Google Scholar] [CrossRef]

- Qiao, S.; Sampaolo, A.; Patimisco, P.; Spagnolo, V.; Ma, Y. Ultra-highly sensitive HCl-LITES sensor based on a low-frequency quartz tuning fork and a fiber-coupled multi-pass cell. Photoacoustics 2022, 27, 100381. [Google Scholar] [CrossRef]

- Park, Y.K.; Oh, H.J.; Bae, J.H.; Lim, J.Y.; Lee, H.D.; Hong, S.I.; Son, H.S.; Kim, J.H.; Lim, S.J.; Lee, W. Colorimetric Textile Sensor for the Simultaneous Detection of NH3 and HCl Gases. Polymers 2020, 12, 2595. [Google Scholar] [CrossRef]

- Bai, B.C.; Im, J.S.; Lee, Y.S. Lyocell-based activated carbon fibers improved the adsorption of harmful gas properties when produced via dual-simultaneous treatments. Carbon Lett. 2017, 23, 69–73. [Google Scholar]

- Dubinin, M.M. Microporous structures and absorption properties of carbonaceous adsorbents. Carbon 1983, 21, 359–366. [Google Scholar] [CrossRef]

- Zhang, J.; Duan, Y.F.; Zhou, Q.; Zhu, C.; She, M.; Ding, W.K. Adsorptive removal of gas-phase mercury by oxygen non-thermal plasma modified activated carbon. Chem. Eng. J. 2016, 294, 281–289. [Google Scholar] [CrossRef]

- Ravina, M.; Marotta, E.; Cerutti, A.; Zanetti, G.; Ruffino, B.; Panepinto, D.; Zanetti, M. Evaluation of Ca-Based sorbents for gaseous HCl emissions adsorption. Sustainability 2023, 15, 10882. [Google Scholar] [CrossRef]

- Kim, M.J.; Lee, S.; Lee, K.M.; Jo, H.; Choi, S.S.; Lee, Y.S. Effect of CuO introduced on activated carbon fibers formed by electroless plating on the NO gas sensing. J. Ind. Eng. Chem. 2018, 60, 341–347. [Google Scholar] [CrossRef]

- Han, J. Preparation of a highly sensitive graphene-based sensor to investigate the effect of exercise on electrolytes in sweat in hot and humid environment. Carbon Lett. 2023, 33, 1959–1966. [Google Scholar] [CrossRef]

- Bai, B.C.; Kim, E.A.; Jeon, Y.P.; Lee, C.W.; In, S.J.; Lee, Y.S.; Im, J.S. Improved flame-retardant properties of lyocell fiber achieved by phosphorus compound. Mater. Lett. 2014, 135, 226–229. [Google Scholar] [CrossRef]

- Kang, S.C.; Im, J.S.; Lee, Y.S. Improved sensitivity of an NO gas sensor by chemical activation of electrospun carbon fibers. Carbon Lett. 2011, 12, 21–25. [Google Scholar] [CrossRef]

- Wang, H.; Wang, G.; Hu, L.; Ge, B.; Yu, X.; Deng, J. Porous polymer materials for CO2 capture and electrocatalytic reduction. Materials 2023, 16, 1630. [Google Scholar] [CrossRef] [PubMed]

- Saad, M.; Szymaszek, A.; Białas, A.; Samojeden, B.; Motak, M. SO2 Poisoning and recovery of copper-based activated carbon catalysts for selective catalytic reduction of NO with NH3 at low temperature. Catalysts 2020, 10, 1426. [Google Scholar] [CrossRef]

- Park, M.S.; Lee, S.; Jung, M.J.; Kim, H.G.; Lee, Y.S. NO gas sensing ability of activated carbon fibers modified by an electron beam for improvement in the surface functional group. Carbon Lett. 2016, 20, 19–25. [Google Scholar] [CrossRef]

- Aksu, Z.; Gönen, F. Biosorption of phenol by immobilized activated sludge in a continuous packed bed: Prediction of break-through curves. Process Biochem. 2004, 39, 599–613. [Google Scholar] [CrossRef]

- Miller, D.R.; Akbar, S.A.; Morris, P.A. Nanoscale metal oxide-based heterojunctions for gas sensing. A Rev. Sens. Act. B 2014, 204, 250–272. [Google Scholar] [CrossRef]

- Bai, J.; Huang, J.; Yu, Q.; Demir, M.; Akgul, E.; Altay, B.N.; Hu, X.; Wang, L. Fabrication of coconut shell-derived porous carbons for CO2 adsorption application. Front. Chem. Sci. Eng. 2023, 17, 1122–1130. [Google Scholar] [CrossRef]

- Hassan, M.F.; Sabri, M.A.; Fazal, H.; Hafeez, A.; Shezad, N.; Hussain, M. Recent trends in activated carbon fibers production from various precursors and applications—A comparative review. J. Anal. Appl. Pyrolysis 2020, 145, 104715. [Google Scholar] [CrossRef]

- Kawabuchi, Y.; Oka, H.; Kawano, S.; Mochida, I.; Yoshizawa, N. The modification of pore size in activated carbon fibers by chemical vapor deposition and its effects on molecular sieve selectivity. Carbon 1998, 36, 377–382. [Google Scholar] [CrossRef]

- Ko, T.H.; Chiranairadul, P.; Lu, C.K.; Lin, C.H. The effects of activation by carbon dioxide on the mechanical properties and structure of PAN-based activated carbon fibers. Carbon 1992, 30, 647–655. [Google Scholar] [CrossRef]

- Bai, B.C.; Kim, E.A.; Lee, C.W.; Lee, Y.S.; Im, J.S. Effects of surface chemical properties of activated carbon fibers modified by liquid oxidation for CO2 adsorption. Appl. Surf. Sci. 2015, 353, 158–164. [Google Scholar] [CrossRef]

- Bannov, A.G.; Manakhov, A.M.; Shtansky, D.V. Plasma functionalization of multi-walled carbon nanotubes for ammonia gas sensors. Materials 2022, 15, 7262. [Google Scholar] [CrossRef]

- Nag, A.; Alahi, M.E.E.; Mukhopadhyay, S.C.; Liu, Z. Multi-walled carbon nanotubes-based sensors for strain sensing applications. Sensors 2021, 21, 1261. [Google Scholar] [CrossRef]

| T (°C) | t (min) | Yield (%) | SBET (m2/g) | Vmicro (cm3/g) | Vtotal (cm3/g) |

|---|---|---|---|---|---|

| 800 | 120 | 54.15 | 949 | 0.36 | 0.41 |

| 180 | 48.33 | 1021 | 0.39 | 0.44 | |

| 240 | 40.02 | 1113 | 0.44 | 0.50 | |

| 850 | 60 | 45.98 | 1066 | 0.42 | 0.46 |

| 80 | 39.20 | 1119 | 0.44 | 0.52 | |

| 100 | 34.69 | 1204 | 0.48 | 0.56 | |

| 900 | 40 | 42.44 | 869 | 0.34 | 0.38 |

| 50 | 36.66 | 1403 | 0.57 | 0.66 | |

| 60 | 30.11 | 1044 | 0.41 | 0.48 |

| Sample | Superficial Velocity | Initial Concentration | Total Time | Breakthrough Time | Saturation Time | Effluent Volume | Total Amount Removed | Total Removal | Adsorption Capacity |

|---|---|---|---|---|---|---|---|---|---|

| Q | C0 | ttotal | t0.05 | t0.95 | Veff | mtotal | Rtotal | qtotal | |

| (L/min) | (mg/L) | (min) | (min) | (min) | (L) | (mg/g) | (%) | (mg/g) | |

| 800_ 240 min | 4000 | 20.03 | 15.42 | 9.65 | 15.32 | 61,680 | 1235.45 | 68.63 | 847.89 |

| 850_ 100 min | 4000 | 20.03 | 16.49 | 11.50 | 15.83 | 65,960 | 1321.18 | 80.09 | 1058.07 |

| 900_ 50 min (1st) | 4000 | 20.03 | 27.83 | 17.75 | 26.43 | 111,320 | 2229.74 | 72.93 | 1626.20 |

| 900_ 50 min (2nd) | 4000 | 20.03 | 22.85 | 11.51 | 22.11 | 91,400 | 1830.74 | 70.20 | 1285.15 |

| 900_ 50 min (3rd) | 4000 | 20.03 | 15.47 | 8.10 | 14.01 | 61,880 | 1239.46 | 68.36 | 847.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.G.; Bai, B.C. A Chemical Safety Assessment of Lyocell-Based Activated Carbon Fiber with a High Surface Area through the Evaluation of HCl Gas Adsorption and Electrochemical Properties. Separations 2024, 11, 79. https://doi.org/10.3390/separations11030079

Kim JG, Bai BC. A Chemical Safety Assessment of Lyocell-Based Activated Carbon Fiber with a High Surface Area through the Evaluation of HCl Gas Adsorption and Electrochemical Properties. Separations. 2024; 11(3):79. https://doi.org/10.3390/separations11030079

Chicago/Turabian StyleKim, Jong Gu, and Byong Chol Bai. 2024. "A Chemical Safety Assessment of Lyocell-Based Activated Carbon Fiber with a High Surface Area through the Evaluation of HCl Gas Adsorption and Electrochemical Properties" Separations 11, no. 3: 79. https://doi.org/10.3390/separations11030079