1. Introduction

New technology is always developed by conducting further research on previous research done, which is expected to change the behavior of the users. One of the aims of research on the fluid flows passing through an object is reducing drag force on the object. Some researchers used one passive control, which is placed in front of the object, two passive controls or more with various places and shapes such as a cylindrical cylinder, a Type-I cylinder, a Type-D cylinder, etc.

Industrial chimneys, offshore structures, flyover structures and others are such designed examples in the group. A circular cylinder, elliptical cylinder or others are objects commonly used as passive controls. The different shapes will produce different drag coefficients. The fluid flowing through one object or more also produces different drag coefficients because of the interaction between the fluid flow and the object.

If the fluid flows through an object, the fluid flow around the object will flow slowly, or even stop flowing because of the friction between the fluid and the object. On the other side, the fluid flows faster while interacting with other streams. This indicates that an increase in shear stress will influence the flow velocity in the layer called the boundary layer.

Research has been conducted on the flow of fluids through a single object [

1], or a modified cylinder such as a Type-D cylinder or Type-I cylinder [

2,

3]. While research has been conducted on the fluid flow through a single object, i.e., fluid flow through more than one object with various shapes, sizes and configurations, other research has been done on fluid flow through a circular cylinder with a tandem configuration [

4,

5,

6,

7], a circular cylinder enclosed by a screen [

8] and an elliptical cylinder with a side-by-side configuration [

9]. The use of more than one object means that one object acts as the main object and the others act as passive controls. A single passive control can be formed by a circular cylinder [

4], a bluff body cut from a circular cylinder [

6] or a rod [

5,

7]. Another form of passive control is an enclosing screen [

8]. The above studies used the boundary layer concept. The concept can find the answer to the effect of shear stress having a very important role in the characteristics of the current around the object [

10].

The drag coefficient is one of many parameters affecting drag force when fluid flows through an object. One of many ways to reduce drag on an object passing by the fluid is by adding a small object called passive control. The addition of passive control is carried out to reduce the drag coefficient to 48% [

4] and is also done with different Reynolds numbers, resulting in a lower drag coefficient [

5]. The Type-I cylinder is a circular cylinder cut on the left and the right side by a certain angle, so that it looks like an I. The best cutting angle is

[

12]. At this angle, the wake is wider than the other angles and also forms wider and troublesome stronger flow on the wall of the main object.

The previous research on the reduction of the drag coefficient uses two passive controls with

[

11]. The passive control in front of the main object is fixed, while that at the rear has a varying distance. In this research, two passive controls are proposed, i.e., the passive control in front of the main object is the Type-I cylinder with a 53

cutting angle and at the rear of the object is an elliptical cylinder. The position of the passive control in front is perpendicular to the flow, whereas the position of the passive control at the rear is parallel. The distances between the passive control in the front and circular cylinder vary, as well as the distance between the passive control of the rear and circular cylinder. The Reynolds number used is 1000.

3. Results and Discussion

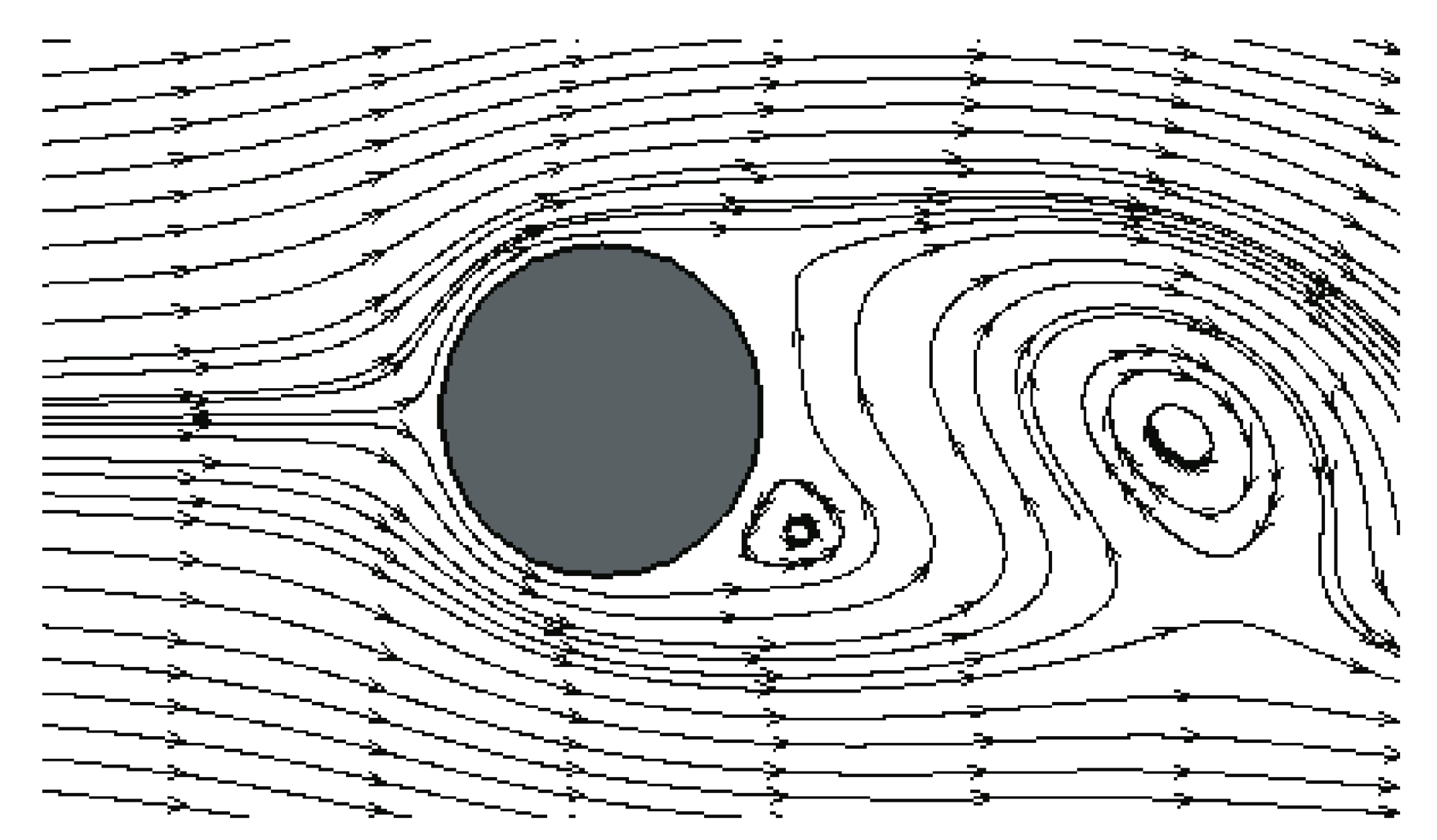

When the fluid flow passes an object, it will produce drag force. One of the parameters to calculate the drag force is the drag coefficient. The drag coefficient of a circular cylinder obtained by simulation is compared with experimental results and other simulations. The calculated drag coefficient of a circular cylinder without a passive control, as in

Figure 1, in our research with

is 1356, while the other calculations with the same

, such as Zulhidayat and Lima are 1.4 and 1.39, respectively [

13].

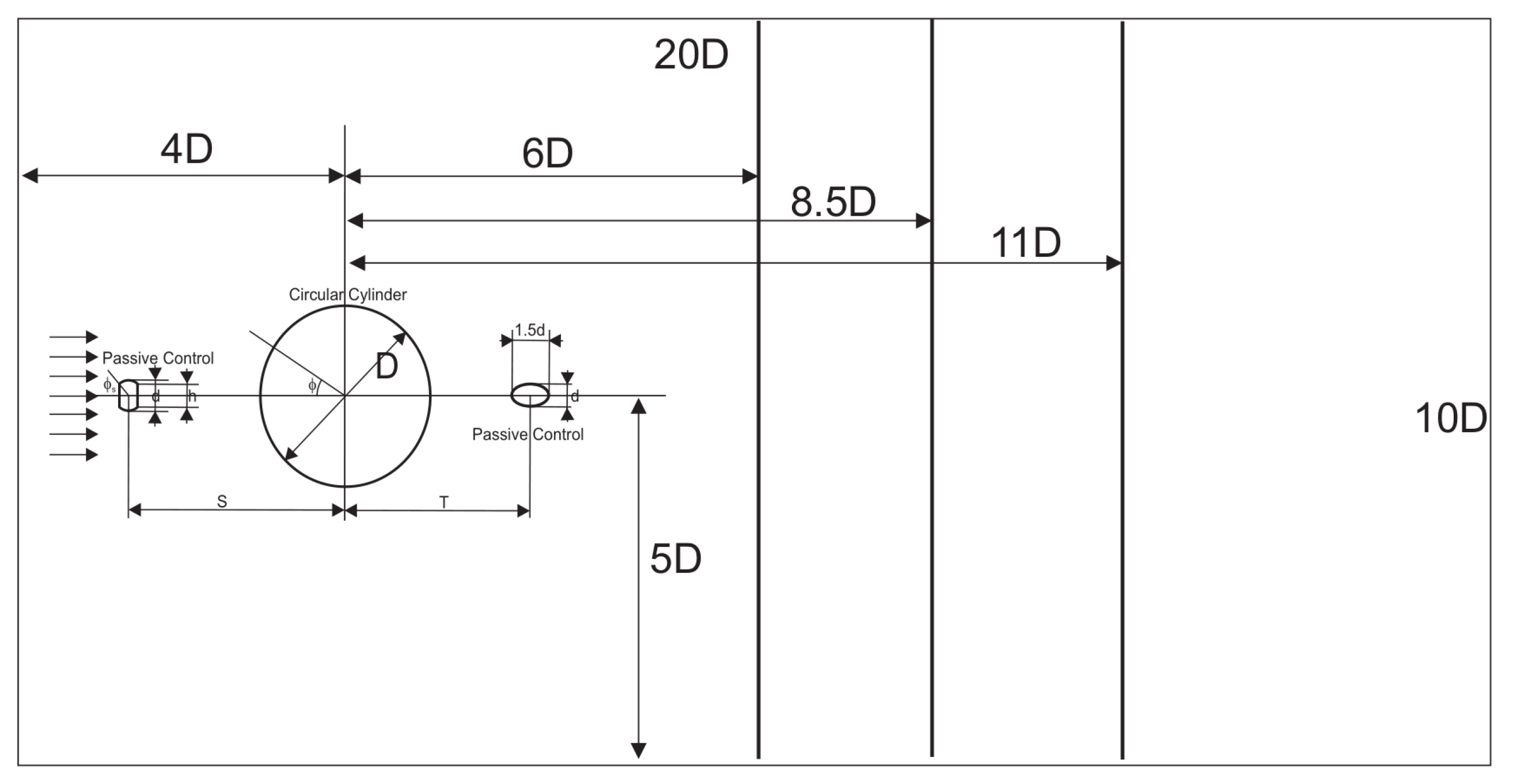

Our research system is

. The circular cylinder is placed at a distance

from the front of the system and in the center of the system as in

Figure 2. Beside that, we use two passive controls. The first passive control is the Type-I cylinder placed in front of the circular cylinder at various distances, i.e.,

, 1.2, 1.8, 2.4 and 3.0. The second passive control is an elliptical cylinder placed at the rear of the circular cylinder at various distances, i.e.,

, 0.9, 1.2, 1.5, 1.8 and 2.1, as in

Figure 3. We simulated the experiment by using C++, while plotted the model by using MATLAB R2013a.

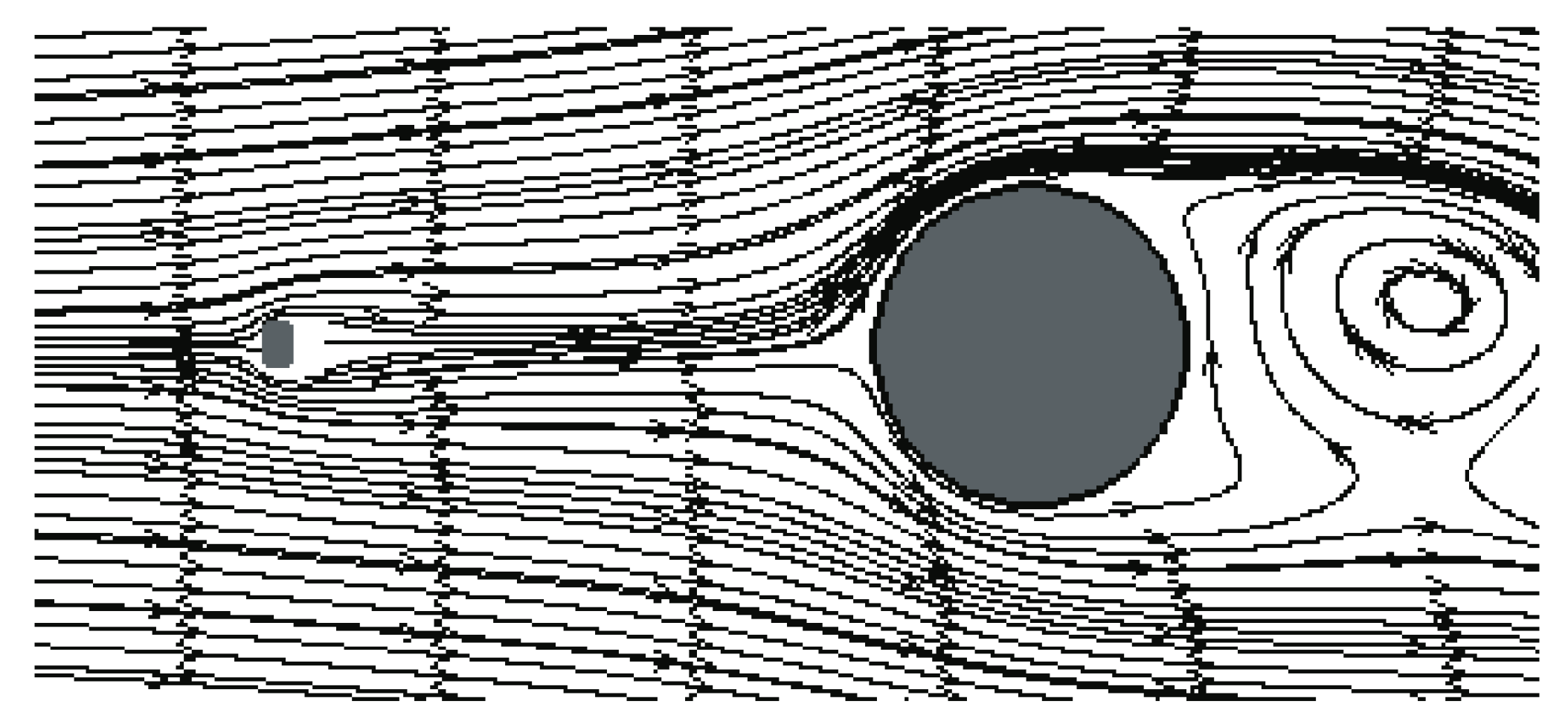

3.1. Single Passive Control

A passive control is a steady device used to reduce drag in the fluid flow. In our research, a passive control placed in front of the main object is a circular cylinder cut on the left and right side with a cutting angle of

so that it looks like an I, i.e., the type-I cylinder, as in

Figure 4. It is placed perpendicular to the incoming flow at various distances

and in a line with a front stagnation point.

When the fluid flows, it will hit the passive control first. The passive control also acts as a turbulence generator. The drag coefficient is high at

. This is caused by the turbulence produced by the passive control directly hitting the circular cylinder as the main object. When the distance between the passive control and circular cylinder (

) is larger, the direct hit turbulence is decreased such that the drag coefficient is reduced and maximum at

. When the value of

is larger than 2.4, the turbulence disappears and changes to laminar flow with the increasing velocity such that the drag coefficient is increased.

Table 1 shows the drag coefficient of a circular cylinder with various distances using a passive control Type-I cylinder placed in front. The best distance obtaining the minimum drag coefficient is

with the value of 0.894. The small value of drag coefficient shows that the received drag by the fluid flow is small. By using a passive control in front of the main object, the drag coefficient is reduced from 1.21 down to 0.894 with

at

. Hence, adding a passive control in front of circular cylinder is better than without passive control.

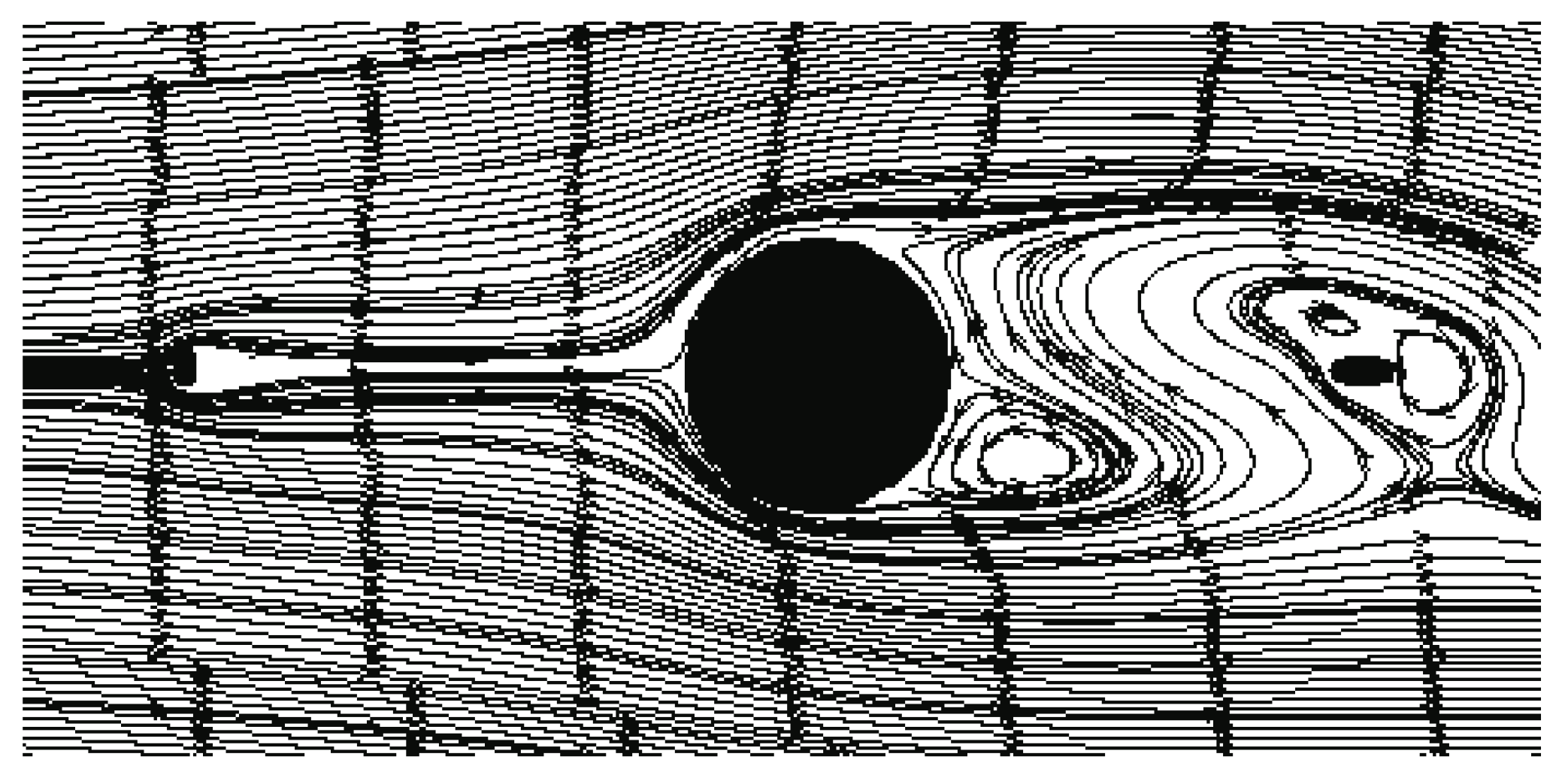

3.2. Two Passive Controls

Besides a passive control placed in front of the main object, we used another passive control placed at the rear of the main object. Another passive control is the elliptical cylinder. It is horizontal and in a line with the rear stagnation point as in

Figure 5. The size of the elliptical cylinder can be seen in

Figure 3.

When the fluid flow passes the circular cylinder, it causes downstream disturbance, called wake. The wake is produced at some distance at the rear of the circular cylinder. In order to reduce the drag coefficient, an elliptical cylinder is placed as the passive control at the rear of the circular cylinder. The small

makes no significant change to the drag coefficient with various

. When the value of

is increasing, it has the maximum reducing drag coefficient with configuration

and

, as shown in

Table 2. This means that at

, the wake is produced. The position of an elliptical cylinder at

breaks the wake forming. Hence, the drag coefficient is reduced from 0.894 down to 0.824. It can be concluded that using two passive controls is better than using one passive control.

3.3. Mathematical Modeling

Mathematical modeling is a way to allow a phenomenon to be written in mathematical language, usually called a mathematical model. The obtained model may help to make a prediction about the behavior of a phenomenon. Therefore, the phenomenon of the drag coefficient reduction as shown in

Table 2 can be predicted at other points by using its model without creating its program.

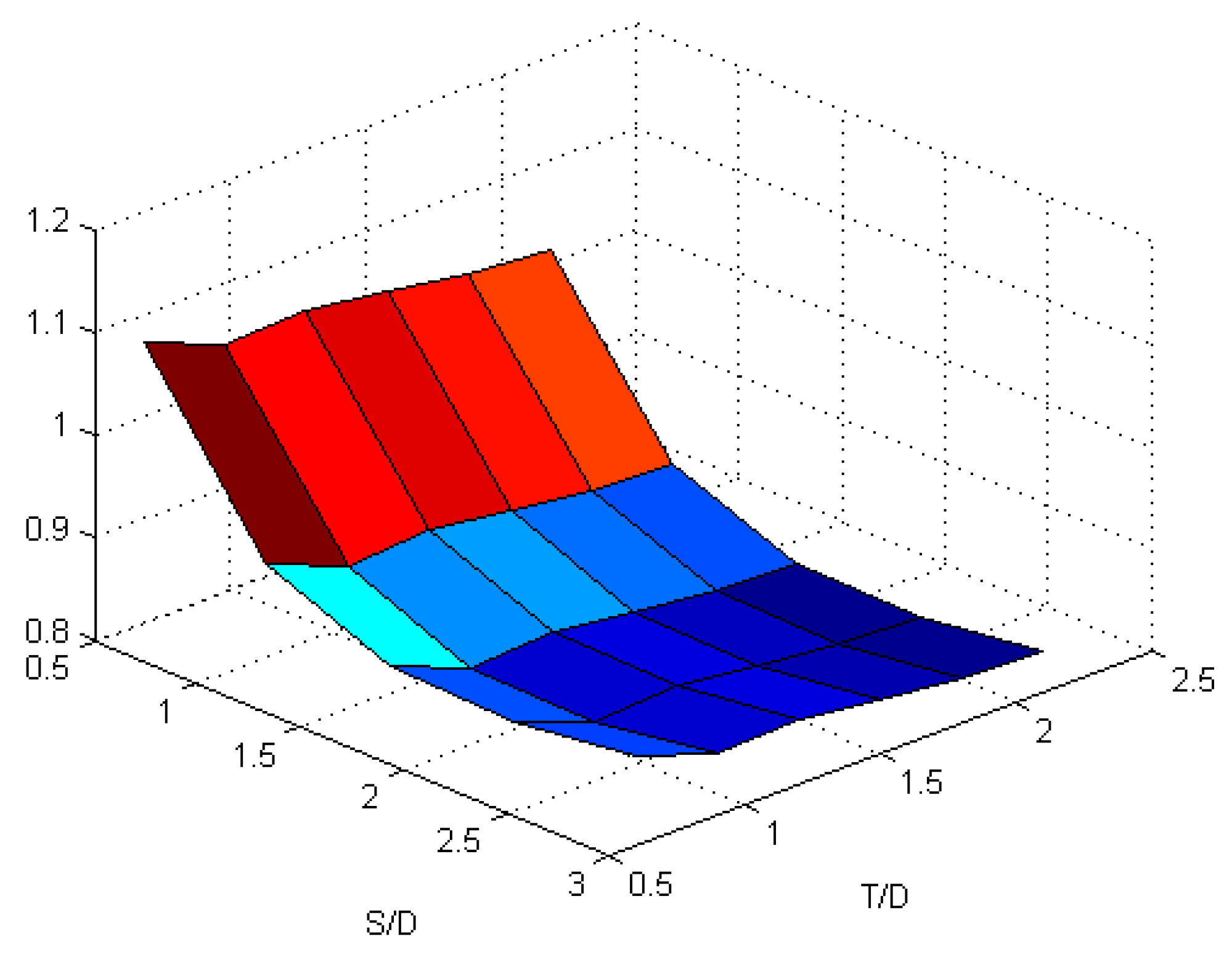

Table 2 can be plotted as

Figure 6. Let us consider

as

x,

as

y and

as

z. Because there are two variables, bilinear interpolation can be used. Assume

where

and

. First, we do linear interpolation in the

x-direction.

or it can be written as:

where for

,

Then, we proceed with the linear interpolation in the

y-direction:

where for

,

Assume

,

and

, then Equation (

9) can be written as:

By substituting every point in

Table 2 into Equation (

10), we obtain:

The plot of the equation above can be seen in

Figure 7. The range value of

is between 0.6 and 3.0, while the range value of

is between 0.6 and 2.1. The meshing size used is

. The best drag coefficient reduction by using Equation (

11) is 0.822 with the configuration

or

and

. Equation (

11) is only used with the configuration

between 0.6 and 3.0 and

between 0.6 and 2.1. If the value of

and

is far from the points of those approximated, the value of

is not true.

Let

be the function approximated with bilinear interpolation, then:

where

is the remainder, which can be written as:

with

m the number of points on the

x-axes and

n the number of points on the

y-axes. As a consequence,

where

and

.