Modeling Temperature-Dependent Thermoelectric Performance of Magnesium-Based Compounds for Energy Conversion Efficiency Enhancement Using Intelligent Computational Methods

Abstract

:1. Introduction

2. Mathematical Formulation and Background of the Implemented Algorithms

2.1. Support Vector Regression Description

2.2. Extreme Learning Machine Formulation

2.3. Genetic Meta-Heuristic Algorithm Principles

3. Details of the Computation and Model Description

3.1. Description and Acquisition of Modeling Magnesium-Based Thermoelectric Data Samples

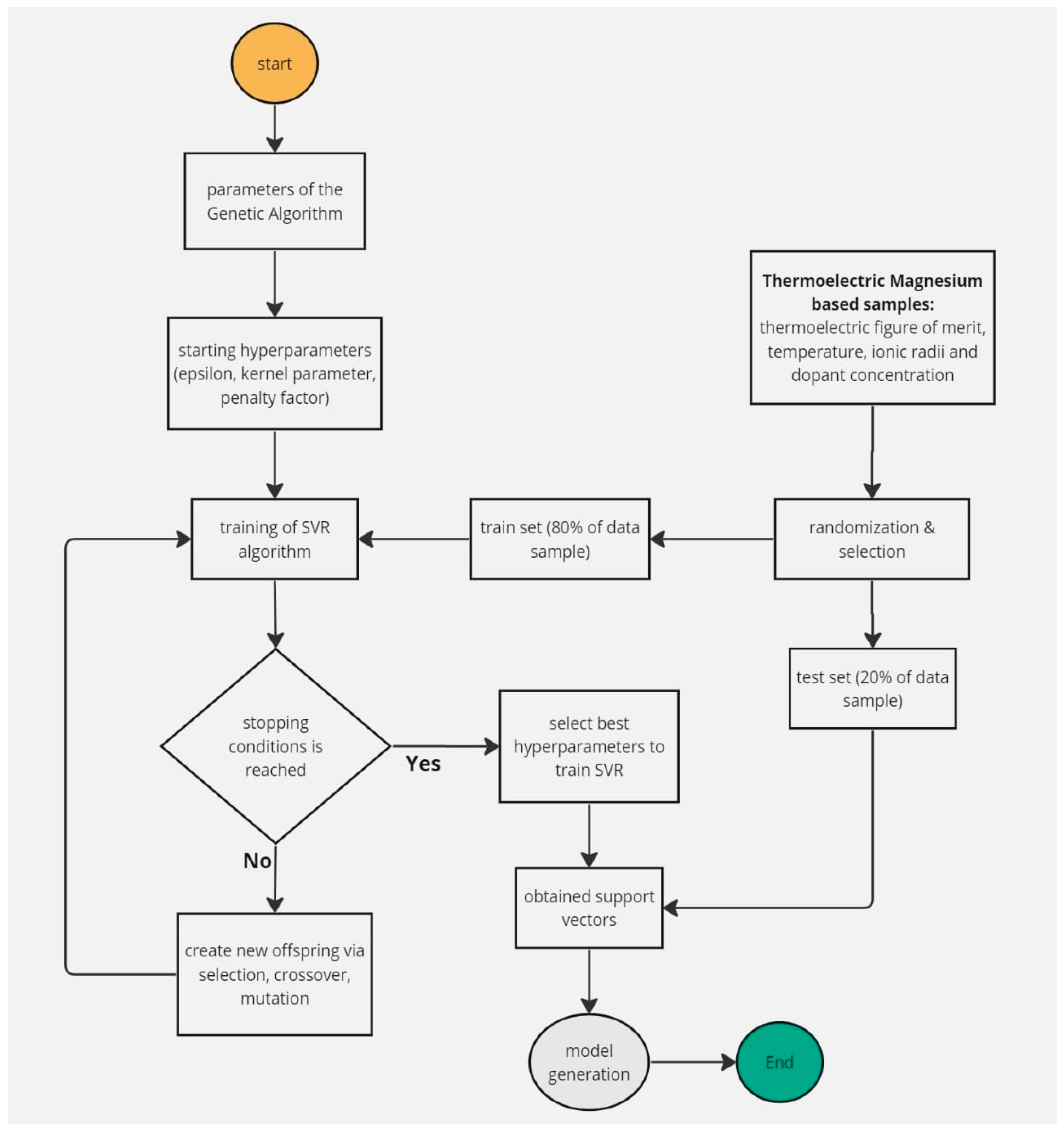

3.2. Computational Description of Hybrid Intelligent Models

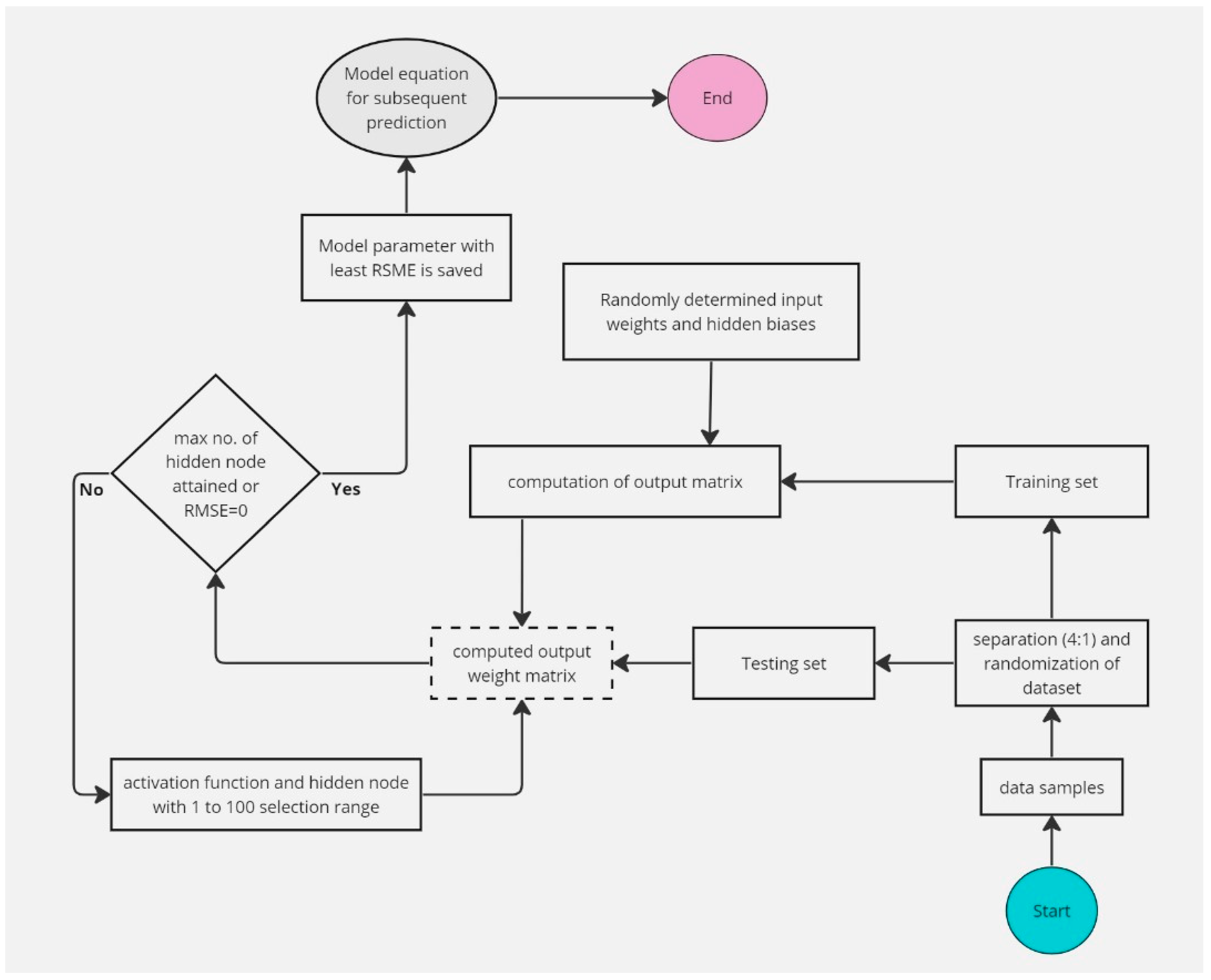

3.3. Methodology of the Proposed TFM-ELM-Based Models

4. Results and Discussion

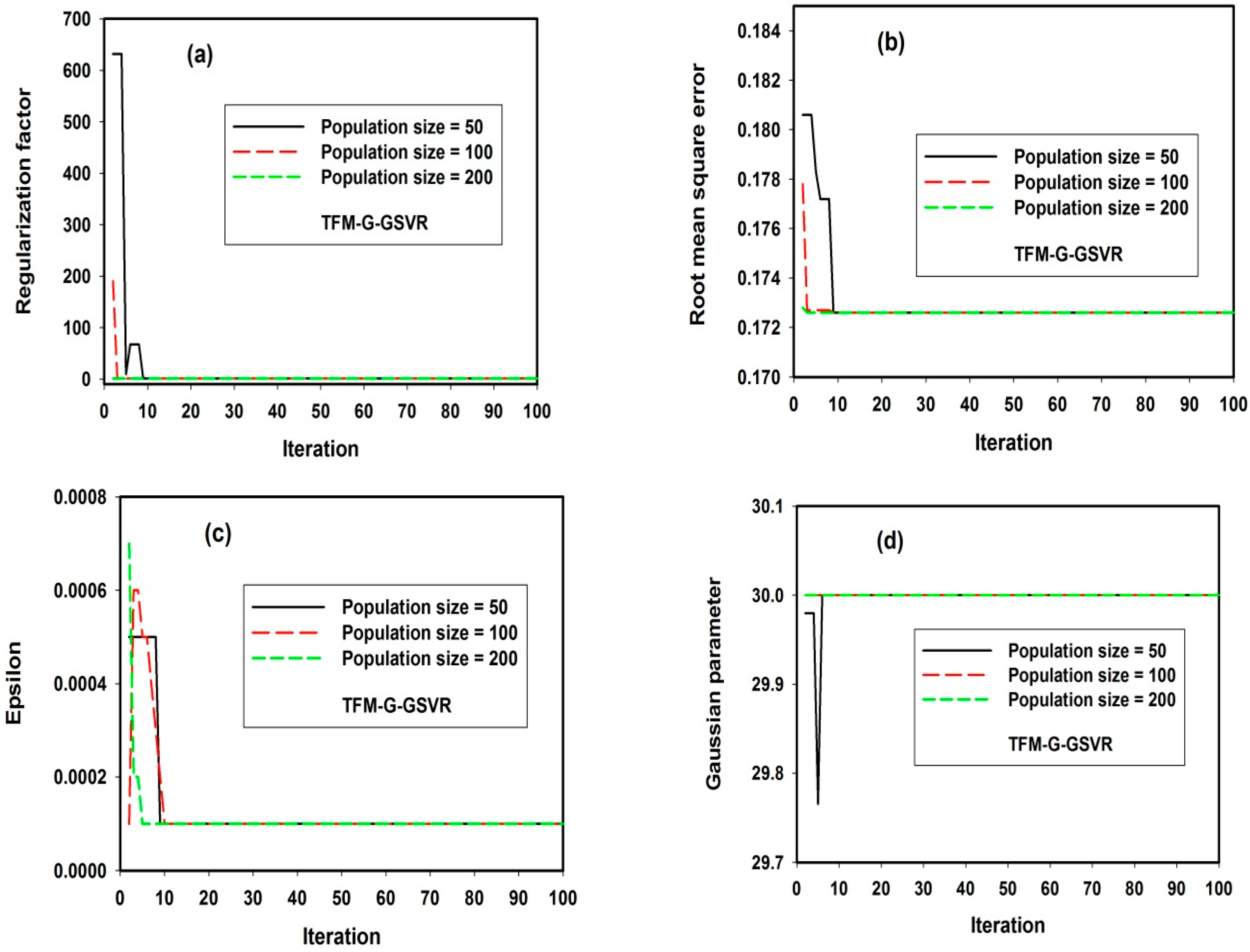

4.1. Dependence of Parameter Optimization on Population Size and Iteration Using Genetic Algorithm

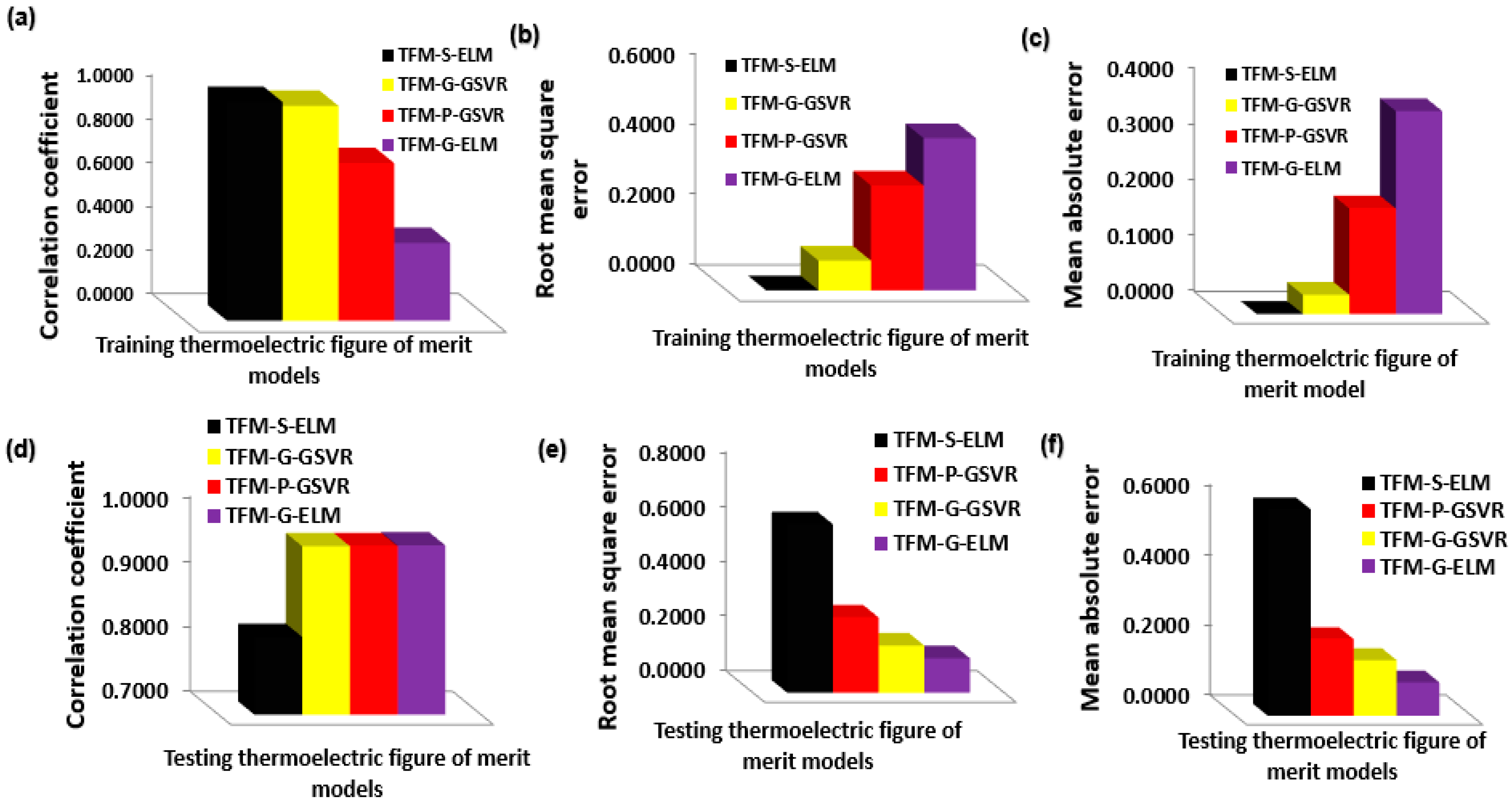

4.2. Performance Assessment Comparison for TFM-G-GSVR and TFM-P-GSVR Models

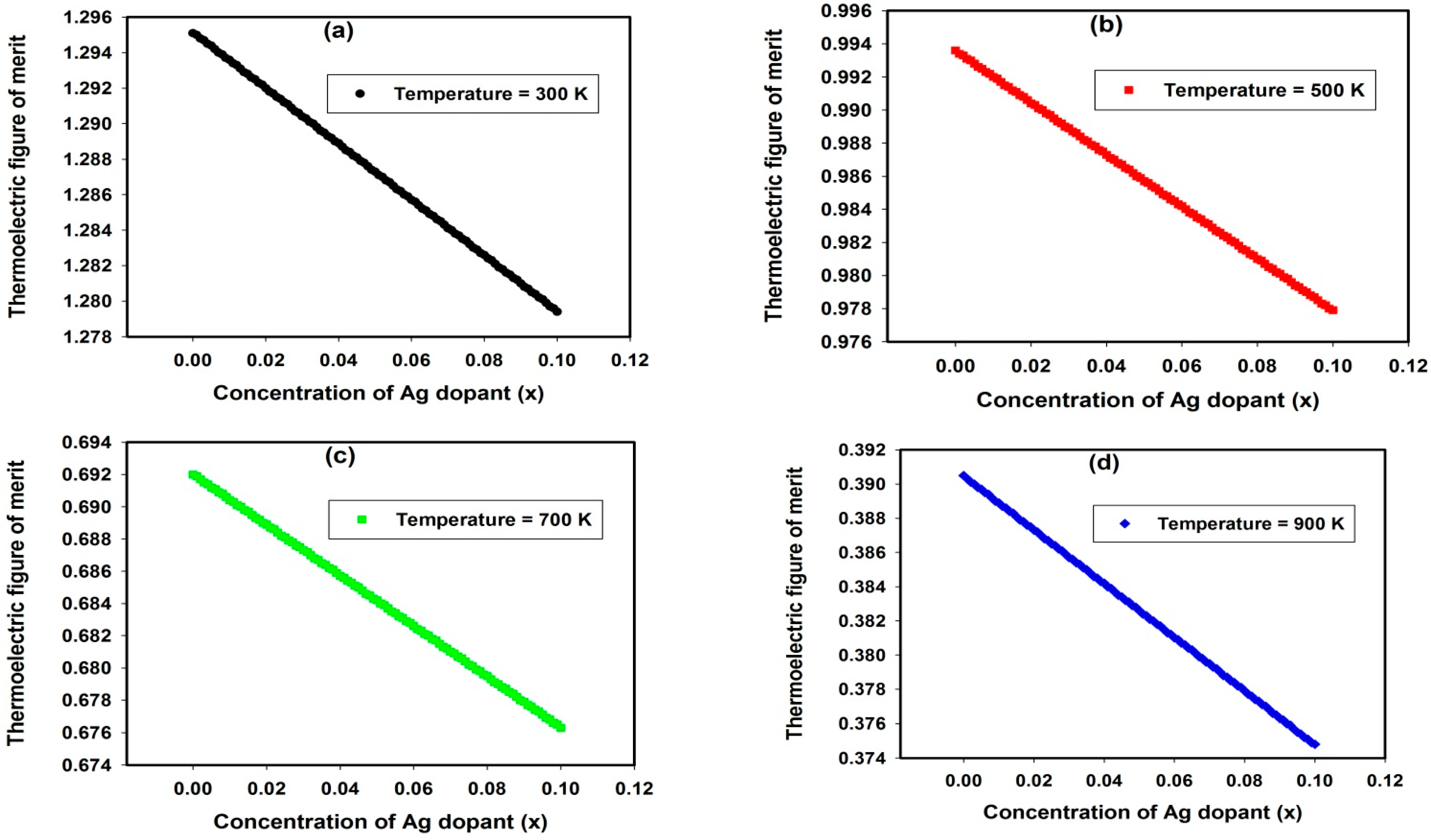

4.3. Influence of Temperature and Dopant Concentration on Magnesium-Based Thermoelectric Materials Using Developed TFM-P-SVR Model

5. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Conflicts of Interest

References

- Yin, Z.; Liu, Z.; Yu, Y.; Zhang, C.; Chen, P.; Zhao, J.; He, P.; Guo, X. Synergistically Optimized Electron and Phonon Transport of Polycrystalline BiCuSeO via Pb and Yb Co-Doping. Appl. Mater. Interfaces 2021, 13, 57638–57645. [Google Scholar] [CrossRef] [PubMed]

- Novitskii, A.; Serhiienko, I.; Novikov, S.; Kuskov, K.; Pankratova, D.; Sviridova, T.; Voronin, A.; Bogach, A.; Skryleva, E.; Parkhomenko, Y.; et al. Correlation between structural and transport properties of electron beam irradiated PrMnO3compounds. Solid State Commun. 2018, 270, 30–37. [Google Scholar]

- Sviridova, T.; Voronin, A.; Bogach, A.; Skryleva, E.; Parkhomenko, Y. Thermoelectric properties of Sm-doped BiCuSeO oxyselenides fabricated by two-step reactive sintering. J. Alloys Compd. 2022, 912, 165208. [Google Scholar]

- Zhang, J.; Song, L.; Iversen, B.B. Probing Efficient N-Type Lanthanide Dopants for Mg3Sb2 Thermoelectrics. Adv. Sci. 2020, 7, 2002867. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Gao, W.; Mao, J.; Geng, H.; Shuai, J.; Cai, W.; Sui, J.; Ren, Z. The influence of doping sites on achieving higher thermoelectric performance for nanostructured α-MgAgSb. Nano Energy 2017, 31, 194–200. [Google Scholar] [CrossRef]

- Song, L.; Zhang, J.; Iversen, B.B. Simultaneous improvement of power factor and thermal conductivity via Ag doping in p-type Mg3Sb2 thermoelectric materials. J. Mater. Chem. A 2017, 5, 4932–4939. [Google Scholar] [CrossRef]

- Feng, B.; Li, G.; Pan, Z.; Hu, X.; Liu, P.; He, Z. Enhanced thermoelectric performance in BiCuSeO oxyselenides via Ba/Te dual-site substitution and 3D modulation doping. J. Solid State Chem. 2018, 266, 297–303. [Google Scholar] [CrossRef]

- Ying, P.; Liu, X.; Fu, C.; Yue, X.; Xie, H.; Zhao, X.; Zhang, W.; Zhu, T. High Performance α-MgAgSb Thermoelectric Materials for Low Temperature Power Generation. Chem. Mater. 2015, 27, 909–913. [Google Scholar] [CrossRef]

- Kamila, H.; Sankhla, A.; Yasseri, M.; Mueller, E. Non-Rigid Band Structure in Mg2Ge for Improved Thermoelectric Performance. Adv. Sci. 2020, 7, 2000070. [Google Scholar] [CrossRef]

- Santos, R.; Yamini, S.A.; Dou, S.X. Recent progress in magnesium-based thermoelectric materials. J. Mater. Chem. A 2018, 6, 3328–3341. [Google Scholar] [CrossRef]

- Han, G.; Lu, Y.; Jia, H.; Ding, Z.; Wu, L.; Shi, Y.; Wang, G.; Luo, Q.; Wang, J.; Huang, G.; et al. Magnesium-based energy materials: Progress, challenges, and perspectives. J. Magnes. Alloys 2023, 11, 3896–3925. [Google Scholar] [CrossRef]

- Li, A.; Fu, C.; Zhao, X.; Zhu, T. High-Performance Mg3Sb2-xBix Thermoelectrics: Progress and Perspective. Research 2020, 2020, 1934848. [Google Scholar] [CrossRef]

- Xiao, S.; Peng, K.; Zhou, Z.; Wang, H.; Zheng, S.; Lu, X.; Han, G.; Wang, G.; Zhou, X. Realizing Cd and Ag codoping in p-type Mg3Sb2 toward high thermoelectric performance. J. Magnes. Alloys 2023, 11, 2486–2494. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, J.; Guo, F.; Qin, H.; Liu, Y.; Zhang, Q.; Liu, Z.; Cai, W.; Sui, J. Electronic Orbital Alignment and Hierarchical Phonon Scattering Enabling High Thermoelectric Performance p-Type Mg3Sb2 Zintl Compounds. AAAS Res. 2022, 2022, 9842949. [Google Scholar]

- Zhang, J.; Song, L.; Mamakhel, A.; Ry, M.; Jørgensen, V. High-Performance Low-Cost n-Type Se-Doped Mg3Sb2-Based Zintl Compounds for Thermoelectric Application. Chem. Mater. 2017, 29, 5371–5383. [Google Scholar] [CrossRef]

- Tamaki, H.; Sato, H.K.; Kanno, T. Isotropic Conduction Network and Defect Chemistry in Mg3+δSb2-Based Layered Zintl Compounds with High Thermoelectric Performance. Adv. Mater. 2016, 01, 10182–10187. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Tan, X.; Yin, K.; Liu, H.; Tang, X.; Shi, J.; Zhang, Q.; Uher, C. Convergence of Conduction Bands as a Means of Enhancing Thermoelectric Performance of n-Type Mg2Si1−xSnx Solid Solutions. Phys. Rev. Lett. 2012, 108, 166601. [Google Scholar] [CrossRef]

- Xin, J.; Zhang, Y.; Wu, H.; Zhu, T.; Fu, T.; Shen, J.; Pennycook, S.J.; Zhao, X. Multiscale Defects as Strong Phonon Scatters to Enhance Thermoelectric Performance in Mg2Sn1−xSbx Solid Solutions. Small Methods 2019, 3, 1900412. [Google Scholar] [CrossRef]

- Murillo-Escobar, J.; Sepulveda-Suescun, J.P.; Correa, M.A.; Orrego-Metaute, D. Urban Climate Forecasting concentrations of air pollutants using support vector regression improved with particle swarm optimization: Case study in Aburrá Valley, Colombia. Urban Clim. 2019, 29, 100473. [Google Scholar] [CrossRef]

- Zhang, Z.; Ding, S.; Sun, Y. Neurocomputing A support vector regression model hybridized with chaotic krill herd algorithm and empirical mode decomposition for regression task. Neurocomputing 2020, 410, 185–201. [Google Scholar] [CrossRef]

- Owolabi, T.O. Modeling magnetocaloric effect of doped EuTiO3 perovskite for cooling technology using swarm intelligent based support vector regression computational method. Mater. Today Commun. 2023, 36, 106688. [Google Scholar] [CrossRef]

- Owolabi, T.O.; Akande, K.O.; Olatunji, S.O. Estimation of Superconducting Transition Temperature Tc for Superconductors of the Doped MgB2 System from the Crystal Lattice Parameters Using Support Vector Regression. J. Supercond. Nov. Magn. 2014, 28, 75–81. [Google Scholar] [CrossRef]

- Owolabi, T.O.; Akande, K.O.; Olatunji, S.O. Estimation of average surface energies of transition metal nitrides using computational intelligence technique. Soft Comput. 2017, 21, 20. [Google Scholar] [CrossRef]

- Owolabi, T.O.; Akande, K.O.; Olatunji, S.O. Application of computational intelligence technique for estimating superconducting transition temperature of YBCO superconductors. Appl. Soft Comput. 2016, 43, 143–149. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, S.; Zhang, Y.; Wang, C.; Zhang, S.; Yang, Z. Optimization of low-power femtosecond laser trepan drilling by machine learning and a high-throughput multi-objective genetic algorithm. Opt. Laser Technol. 2021, 148, 107688. [Google Scholar] [CrossRef]

- Okoye, P.C.; Azi, S.O.; Owolabi, T.O.; Adeyemi, O.W.; Souiyah, M.; Latif, M.B.; Olusayo, O. Modeling Energy Gap of Doped Tin (II) Sulfide Metal Semiconductor Nanocatalyst Using Genetic Algorithm-Based Support Vector Regression. J. Nanomater. 2022, 2022, 8211023. [Google Scholar] [CrossRef]

- Israel, E.E.; Adamu, U.; Eyije, A.S. Multi-Target In-Silco Study of 5,6-Dihydro-2-Pyrones, Indole Β-Diketo Acid, Diketo Acid and Carboxamide Derivatives against Various Anti-HIV-1 Strain at PM3 Semi-Empirical Level. Ewemen J. Pharm. 2016, 1, 1–13. [Google Scholar]

- Shi, Q.; Niu, G.; Lin, Q.; Xu, T.; Li, F.; Duan, Y. Quantitative analysis of sedimentary rocks using laser-induced breakdown spectroscopy: Comparison of support vector regression and partial least squares regression chemometric methods. J. Anal. At. Spectrom. 2015, 30, 2384–2393. [Google Scholar] [CrossRef]

- Do, H.T.; Van Bach, N.; Van Nguyen, L.; Tran, H.T.; Nguyen, M.T. A design of higher-level control based genetic algorithms for wastewater treatment plants. Eng. Sci. Technol. Int. J. 2021, 24, 872–878. [Google Scholar] [CrossRef]

- Owolabi, T.O.; Gondal, M.A. Development of hybrid extreme learning machine based chemo-metrics for precise quantitative analysis of LIBS spectra using internal reference pre-processing method. Anal. Chim. Acta 2018, 1030, 33–41. [Google Scholar] [CrossRef]

- Alqahtani, A. Engineering the Energy Gap of Cupric Oxide Nanomaterial Using Extreme Learning Machine and Stepwise Regression Algorithms. J. Nanomater. 2021, 2021, 4797686. [Google Scholar] [CrossRef]

- Owolabi, T.O. Extreme learning machine and swarm-based support vector regression methods for predicting crystal lattice parameters of pseudo-cubic/cubic perovskites Extreme learning machine and swarm-based support vector regression methods for predicting crystal lat. J. Appl. Phys. 2020, 127, 245107. [Google Scholar] [CrossRef]

- Cao, Y.; Wakil, K.; Alyousef, R.; Jermsittiparsert, K.; Si, L. Application of extreme learning machine in behavior of beam to column connections. Structures 2020, 25, 861–867. [Google Scholar] [CrossRef]

- Shamsah, S.M.I.; Owolabi, T.O. Newtonian mechanics based hybrid machine learning method of characterizing energy band gap of doped zno semiconductor. Chin. J. Phys. 2020, 68, 493–506. [Google Scholar] [CrossRef]

- Vapnik, V.N. Statistical Learning Theory; Wiley-Interscience: New York, NY, USA, 1998. [Google Scholar]

- Akomolafe, O.; Owolabi, T.O.; Rahman, M.A.A.; Kechik, M.M.A.; Yasin, M.N.M.; Souiyah, M. Modeling superconducting critical temperature of 122-iron-based pnictide intermetallic superconductor using a hybrid intelligent computational method. Materials 2021, 14, 4604. [Google Scholar] [CrossRef] [PubMed]

- Shamsah, S.M.I.; Owolabi, T.O. Modeling the Maximum Magnetic Entropy Change of Doped Manganite Using a Grid Search-Based Extreme Learning Machine and Hybrid Gravitational Search-Based Support Vector Regression. Crystals 2020, 10, 310. [Google Scholar] [CrossRef]

- Owolabi, T.O.; Amiruddin, M.; Rahman, A. Prediction of Band Gap Energy of Doped Graphitic Carbon Nitride Using Genetic Algorithm-Based Support Vector Regression and Extreme Learning Machine. Symmetry 2021, 13, 411. [Google Scholar] [CrossRef]

- Owolabi, T.O.; Amiruddin, M.; Rahman, A. Energy Band Gap Modeling of Doped Bismuth Ferrite Multifunctional Material Using Gravitational Search Algorithm Optimized Support Vector Regression. Crystals 2021, 11, 246. [Google Scholar] [CrossRef]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Owolabi, T.O.; Gondal, M.A. Quantitative analysis of LIBS spectra using hybrid chemometric models through fusion of extreme learning machines and support vector regression. J. Intell. Fuzzy Syst. 2018, 35, 6277–6286. [Google Scholar] [CrossRef]

- Oyeneyin, O.E.; Obadawo, B.S.; Olanrewaju, A.A.; Owolabi, T.O.; Gbadamosi, F.A.; Ipinloju, N.; Modamori, H.O. Predicting the bioactivity of 2-alkoxycarbonylallyl esters as potential antiproliferative agents against pancreatic cancer (MiaPaCa-2) cell lines: GFA-based QSAR and ELM-based models with molecular docking. J. Genet. Eng. Biotechnol. 2021, 19, 38. [Google Scholar] [CrossRef]

- Alqahtani, A.; Saliu, S.; Owolabi, T.O.; Aldhafferi, N.; Almurayh, A.; Oyeneyin, O.E. Modeling the magnetic cooling efficiency of spinel ferrite magnetocaloric compounds for magnetic refrigeration application using hybrid intelligent computational methods. Mater. Today Commun. 2022, 33, 104310. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Y. Extreme learning machine based transfer learning for aero engine fault diagnosis. Aerosp. Sci. Technol. 2022, 121, 107311. [Google Scholar] [CrossRef]

- Agbi, J.I.; Owolabi, T.O.; Abajiigin, D.D. Exploration and quantification of magnetocaloric effect in EuTiO3 perovskite using extreme learning machine intelligent computational method. Mater. Today Commun. 2023, 37, 107297. [Google Scholar] [CrossRef]

- Yan, J.; Chen, F.; Liu, T.; Zhang, Y.; Peng, X.; Yi, D. Knowledge-Based Systems Subspace alignment based on an extreme learning machine for electronic nose drift compensation. Knowl. Based Syst. 2022, 235, 107664. [Google Scholar] [CrossRef]

- Olubosede, O.; Abd Rahman, M.A.; Alqahtani, A.; Souiyah, M.; Latif, M.B.; Oke, W.A.; Aldhafferi, N.; Owolabi, T.O. Tailoring the Energy Harvesting Capacity of Zinc Selenide Semiconductor Nanomaterial through Optical Band Gap. Crystals 2022, 12, 36. [Google Scholar] [CrossRef]

- Oke, W.A.; Aldhafferi, N.; Saliu, S.; Owolabi, T.O.; Alqahtani, A.; Almurayh, A.; Qahtan, T.F. Modeling the magnetocaloric effect of spinel ferrites for magnetic refrigeration technology using extreme learning machine and genetically hybridized support vector regression computational methods. Cogent Eng. 2023, 10, 2257955. [Google Scholar] [CrossRef]

- Owolabi, T.O. Determination of the Velocity of Detonation of Primary Explosives using Genetically Optimized Support Vector Regression. Propellants Explos. Pyrotech. 2019, 44, 1282–1292. [Google Scholar] [CrossRef]

- Dodangeh, E.; Panahi, M.; Rezaie, F.; Lee, S.; Tien, D. Novel hybrid intelligence models for flood-susceptibility prediction: Meta optimization of the GMDH and SVR models with the genetic algorithm and harmony search. J. Hydrol. 2020, 590, 125423. [Google Scholar] [CrossRef]

- Liang, G.; Xu, J.; Liu, L. QSPR analysis for melting point of fatty acids using genetic algorithm based multiple linear regression (GA-MLR). Fluid Phase Equilibria 2013, 353, 15–21. [Google Scholar] [CrossRef]

- Nili-Ahmadabadi, M.; Aghabozorgi, F.; Cho, D.S.; Kim, K.C. Development and validation of a hybrid aerodynamic design method for curved diffusers using genetic algorithm and ball-spine inverse design method. Alex. Eng. J. 2021, 60, 3021–3036. [Google Scholar] [CrossRef]

- Al-Sodani, K.A.A.; Adewumi, A.A.; Mohd Ariffin, M.A.; Maslehuddin, M.; Ismail, M.; Salami, H.O.; Owolabi, T.O.; Mohamed, H.D. Experimental and modelling of alkali-activated mortar compressive strength using hybrid support vector regression and genetic algorithm. Materials 2021, 14, 3049. [Google Scholar] [CrossRef] [PubMed]

- Ren, Z.; Shuai, J.; Mao, J.; Zhu, Q.; Song, S.; Ni, Y. Significantly enhanced thermoelectric properties of p-type Mg3Sb2 via co-doping of Na and Zn. Acta Mater. 2018, 143, 265–271. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, Y.; Zheng, Y.; Peng, K.; Huang, T.; Lu, X.; Wang, G.; Wang, S.; Zhou, X. Improving thermoelectric performance of p-type Ag-doped Mg2Si0.4Sn0.6 prepared by unique melt spinning method. Appl. Therm. Eng. 2017, 111, 1396–1400. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, C.; Yao, H.; Bai, F.; Yin, L.; Li, X.; Li, S.; Xue, W.; Wang, Y.; Cao, F.; et al. High-Performance N-type Mg3Sb2 towards Thermoelectric Application near Room Temperature. Adv. Funct. Mater. 2020, 30, 1906143. [Google Scholar] [CrossRef]

- Huo, Y.; Xiao, S.; Dai, L.; Huang, Y.; Zheng, S.; Wang, Z.; Chen, P.; Han, G.; Lu, X.; Zhou, X.; et al. Enhanced Thermoelectric Performance in SmMg2Bi2 via Ca-Alloying and Ge-Doping. Appl. Energy Mater. 2022, 5, 5182–5190. [Google Scholar] [CrossRef]

- Zhou, Z.; Han, G.; Lu, X.; Wang, G.; Zhou, X. High-performance magnesium-based thermoelectric materials: Progress and challenges. J. Magnes. Alloys 2022, 10, 1719–1736. [Google Scholar] [CrossRef]

- Xinfeng, S.; Chem, P.; Phys, C. Low effective mass and carrier concentration optimization for high performance p-type Mg2(1−x)Li2xSi0.3Sn0.7 solid solutions. Phys. Chem. Chem. Phys. 2014, 16, 23576–23583. [Google Scholar]

- Huang, L.; Liu, T.; Mo, X.; Yuan, G.; Wang, R.; Liu, H.; Lei, X.; Zhang, Q.; Ren, Z. Thermoelectric performance improvement of p-type Mg3Sb2-based materials by Zn and Ag co-doping. Mater. Today Phys. 2021, 21, 100564. [Google Scholar] [CrossRef]

- Huang, Y.; Zheng, S.; Liao, H.; Qiao, S.; Han, G.; Wang, G.; Huang, Z.; Li, J.; Lu, X.; Zhou, X. Synergistic modulation of the thermoelectric performance of melt-spun p-type Mg2Sn via Na2S and Si alloying. J. Mater. Chem. A 2022, 10, 5452–5459. [Google Scholar] [CrossRef]

- Xu, F.; Li, A.; Rao, Y.; Huang, Z.; Wei, S. Effect of Aluminum Doping on Microstructures and Thermoelectric Properties of BiCuSeO Thermoelectric Materials. Trans. Indian Inst. Met. 2021, 74, 2367–2377. [Google Scholar] [CrossRef]

- Yang, T.; Huang, L.; Guo, J.; Zhang, Y.; Feng, J.; Ge, Z. Enhanced Thermoelectric and Mechanical Properties of BaO-Doped BiCuSeO δ Ceramics. Appl. Energy Mater. 2021, 4, 13077–13084. [Google Scholar] [CrossRef]

- Liu, Y.; Lan, J.; Xu, W.; Liu, Y.; Pei, Y.L.; Cheng, B.; Liu, D.B.; Lin, Y.H.; Zhao, L.D. Enhanced thermoelectric performance of a BiCuSeO system via band gap tuning. Chem. Commun. 2013, 2, 8075–8077. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Guo, X.; Li, R.; Qin, J.; Li, H.; Chen, X.; Zhou, X. Band structure manipulated by high pressure-assisted Te doping realizing improvement in thermoelectric performance of BiCuSeO system. J. Mater. 2019, 5, 649–656. [Google Scholar] [CrossRef]

| Compound Parameter | Mean | Standard Deviation | Maximum | Minimum | Correlation Coefficient |

|---|---|---|---|---|---|

| TFM | 1.0397 | 0.4433 | 1.8000 | 0.3600 | 1.0000 |

| Temperature | 679.7333 | 115.1856 | 873.0000 | 423.0000 | −0.2122 |

| x | 2.2176 | 0.8213 | 3.5000 | 0.9700 | 0.2235 |

| A | 95.2833 | 24.3047 | 143.0000 | 54.0000 | 0.2522 |

| a | 0.4059 | 0.4531 | 1.5000 | 0.0050 | −0.0010 |

| B | 90.8333 | 16.7540 | 117.0000 | 54.0000 | 0.3530 |

| b | 0.8640 | 0.6599 | 2.0000 | 0.0050 | 0.2803 |

| C | 76.6000 | 41.0362 | 117.0000 | 0.0000 | 0.4448 |

| c | 0.5036 | 0.7025 | 2.0000 | 0.0000 | −0.0425 |

| D | 14.6000 | 40.6241 | 170.0000 | 0.0000 | −0.0624 |

| d | 0.0037 | 0.0133 | 0.0700 | 0.0000 | −0.1517 |

| Parameter | TFM-G-GSVR | TFM-P-GSVR |

|---|---|---|

| Regularization factor | 1 | 1 |

| Population size | 50 | 200 |

| Epsilon | 0.0001 | 0.0001 |

| Mapping function | Gaussian | Polynomial |

| Mapping kernel parameter | 30 | 0.0035 |

| Training | Testing | |||||

|---|---|---|---|---|---|---|

| CC | RMSE | MAE | CC | RMSE | MAE | |

| TFM-S-ELM | 1.0000 | 0.0000 | 0.0000 | 0.8198 | 0.6165 | 0.5889 |

| TFM-G-GSVR | 0.9825 | 0.0845 | 0.0341 | 0.9597 | 0.1726 | 0.1588 |

| TFM-P-GSVR | 0.7204 | 0.2987 | 0.1888 | 0.9598 | 0.2755 | 0.2187 |

| TFM-G-ELM | 0.3548 | 0.4336 | 0.3632 | 0.9610 | 0.1262 | 0.0953 |

| Compound | Temp (K) | Measured TFM | TFM-G-GSVR | Error | TFM-P-GSVR | Error | TFM-S-ELM | Error | TFM-G-ELM | Error |

|---|---|---|---|---|---|---|---|---|---|---|

| Mg1.86Sn0.837Si0.093Na0.14S0.07 | 673 | 0.52 [61] | 0.52 | 0.00 | 0.52 | 0.00 | 0.52 | 0.00 | 1.27 | 0.75 |

| Mg2Si0.53Sn0.4Ge0.05Bi0.02 | 800 | 1.40 [58] | 1.40 | 0.00 | 1.39 | 0.01 | 1.40 | 0.00 | 1.25 | 0.15 |

| MgAg0.97Sb0.99In0.01 | 525 | 1.10 [8] | 1.10 | 0.00 | 1.29 | 0.19 | 1.10 | 0.00 | 1.23 | 0.13 |

| Mg2Si0.6945Sn0.3Sb0.0055 | 620 | 0.55 [58] | 0.55 | 0.00 | 0.92 | 0.37 | 0.55 | 0.00 | 0.90 | 0.35 |

| Mg0.97Zn0.03Ag0.9Sb0.95 | 423 | 1.40 [58] | 1.40 | 0.00 | 1.12 | 0.28 | 1.40 | 0.00 | 1.25 | 0.15 |

| Mg2Sn0.8Sb0.2 | 750 | 0.90 [58] | 0.90 | 0.00 | 0.35 | 0.55 | 0.12 | 0.78 | 0.89 | 0.01 |

| MgAg0.97Sb0.99 | 450 | 1.20 [58] | 1.03 | 0.17 | 0.83 | 0.37 | 1.20 | 0.00 | 1.15 | 0.05 |

| Mg2.15Si0.28Sn0.71Sb0.006 | 700 | 1.30 [17] | 1.14 | 0.16 | 0.87 | 0.43 | 1.30 | 0.00 | 0.89 | 0.41 |

| Mg0.995Ca0.005Ag0.97Sb0.99 | 525 | 1.30 [58] | 1.06 | 0.24 | 1.35 | 0.05 | 1.72 | 0.42 | 1.23 | 0.07 |

| Mg1.86Li0.14Si0.3Sn0.7 | 750 | 0.50 [59] | 0.50 | 0.00 | 0.50 | 0.00 | 0.50 | 0.00 | 0.89 | 0.39 |

| Mg2.4875Zn0.5Na0.0125Sb2 | 773 | 0.80 [54] | 0.80 | 0.00 | 0.97 | 0.17 | 0.10 | 0.70 | 0.89 | 0.09 |

| Mg2Si0.6Ge0.4Ga0.008 | 625 | 0.36 [58] | 0.60 | 0.24 | 0.88 | 0.52 | 0.36 | 0.00 | 0.89 | 0.53 |

| Mg2.9875Na0.0125Sb2 | 773 | 0.60 [58] | 0.69 | 0.09 | 0.80 | 0.20 | 0.60 | 0.00 | 0.89 | 0.29 |

| Mg1.95Li0.05Ge | 700 | 0.50 [9] | 0.50 | 0.00 | 0.50 | 0.00 | 0.50 | 0.00 | 0.89 | 0.39 |

| Mg0.99Li0.01Ag0.97Sb0.99 | 525 | 1.25 [58] | 1.25 | 0.00 | 1.25 | 0.00 | 1.25 | 0.00 | 1.23 | 0.02 |

| Mg1.95Ag0.05Si0.4Sn0.6 | 690 | 0.45 [55] | 0.45 | 0.00 | 0.70 | 0.25 | 0.45 | 0.00 | 0.89 | 0.44 |

| Mg2.39Zn0.6Ag0.01Sb2 | 773 | 0.84 [60] | 0.78 | 0.06 | 0.89 | 0.05 | 0.09 | 0.75 | 0.89 | 0.05 |

| Mg3.2Sb1.5Bi0.49Te0.01 | 700 | 1.50 [58] | 1.42 | 0.08 | 1.58 | 0.08 | 1.50 | 0.00 | 0.92 | 0.58 |

| MgAg0.965Ni0.005Sb0.99 | 450 | 1.40 [58] | 1.17 | 0.23 | 0.44 | 0.96 | 1.12 | 0.28 | 1.32 | 0.08 |

| Mg3.07Sb1.5Bi0.48Se0.02 | 725 | 1.23 [15] | 1.23 | 0.00 | 1.23 | 0.00 | 1.23 | 0.00 | 0.89 | 0.34 |

| Mg2.85Cd0.5Sb2 | 773 | 0.75 [13] | 0.75 | 0.00 | 0.75 | 0.00 | 0.75 | 0.00 | 0.89 | 0.14 |

| Mg2.1Si0.38Sn0.6Sb0.02 | 700 | 0.85 [58] | 1.06 | 0.21 | 0.85 | 0.00 | 0.85 | 0.00 | 0.89 | 0.04 |

| Mg3.5Nd0.04Sb1.97Te0.03 | 775 | 1.65 [4] | 1.65 | 0.00 | 1.65 | 0.00 | 1.65 | 0.00 | 0.89 | 0.76 |

| Mg3.15Mn0.05Sb1.5Bi0.49Se0.01 | 623 | 1.70 [56] | 1.70 | 0.00 | 1.47 | 0.23 | 1.70 | 0.00 | 1.25 | 0.45 |

| Mg3.5Sc0.04Sb1.97Te0.03 | 725 | 1.50 [58] | 1.50 | 0.00 | 1.50 | 0.00 | 0.90 | 0.60 | 1.23 | 0.27 |

| Mg3.032Y0.018SbBi | 700 | 1.80 [58] | 1.80 | 0.00 | 1.49 | 0.31 | 1.80 | 0.00 | 1.23 | 0.57 |

| Mg2.985Ag0.015Sb2 | 725 | 0.51 [6] | 0.51 | 0.00 | 0.84 | 0.33 | 0.51 | 0.00 | 0.89 | 0.38 |

| Mg2.15Sm0.5Ca0.5Bi1.99Ge0.01 | 873 | 0.71 [57] | 0.71 | 0.00 | 1.01 | 0.30 | 0.71 | 0.00 | 1.23 | 0.52 |

| Mg1.95Na0.01ZnSb2 | 773 | 0.87 [14] | 0.90 | 0.03 | 0.87 | 0.00 | 0.87 | 0.00 | 0.89 | 0.02 |

| Mg3.5Tm0.03Sb1.97Te0.03 | 775 | 1.75 [4] | 1.50 | 0.25 | 1.54 | 0.21 | 1.75 | 0.00 | 0.89 | 0.86 |

| Mean absolute percentage error (MAPE) | 0.06 | 0.19 | 0.12 | 0.31 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibn Shamsah, S.M. Modeling Temperature-Dependent Thermoelectric Performance of Magnesium-Based Compounds for Energy Conversion Efficiency Enhancement Using Intelligent Computational Methods. Inorganics 2024, 12, 85. https://doi.org/10.3390/inorganics12030085

Ibn Shamsah SM. Modeling Temperature-Dependent Thermoelectric Performance of Magnesium-Based Compounds for Energy Conversion Efficiency Enhancement Using Intelligent Computational Methods. Inorganics. 2024; 12(3):85. https://doi.org/10.3390/inorganics12030085

Chicago/Turabian StyleIbn Shamsah, Sami M. 2024. "Modeling Temperature-Dependent Thermoelectric Performance of Magnesium-Based Compounds for Energy Conversion Efficiency Enhancement Using Intelligent Computational Methods" Inorganics 12, no. 3: 85. https://doi.org/10.3390/inorganics12030085