Research Progress in Dielectric-Layer Material Systems of Memristors

Abstract

:1. Introduction

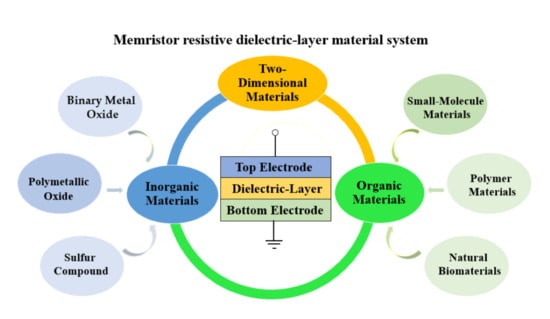

2. Memristor

2.1. Concept and Characteristics

2.2. Resistive Mechanism of Memristor

2.2.1. Interface Barrier Mechanism

2.2.2. Metal Conductive Wire Mechanism

2.2.3. Oxygen Vacancy Conductive Wire Mechanism

3. Selection of Dielectric Layer Material for Memristor

3.1. Memristors Based on Inorganic Materials

3.1.1. Binary Metal Oxide

3.1.2. Polymetallic Oxide

3.1.3. Sulfur Compound

3.2. Memristors Based on Organic Materials

3.2.1. Organic Small-Molecule Materials

3.2.2. Polymer Materials

3.2.3. Natural Biomaterials

3.3. Memristors Based on Two-Dimensional Materials

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zidan, M.A.; Strachan, J.P.; Lu, W.D. The future of electronics based on memristive systems. Nat. Electron. 2018, 1, 22–29. [Google Scholar] [CrossRef]

- Yao, P.; Wu, H.; Gao, B.; Tang, J.; Zhang, Q.; Zhang, W.; Yang, J.J.; Qian, H. Fully hardware-implemented memristor convolutional neural network. Nature 2020, 57, 641–646. [Google Scholar] [CrossRef]

- Waldrop, M. Neuroelectronics: Smart connections. Nature 2013, 50, 22–24. [Google Scholar] [CrossRef] [PubMed]

- Muthuswamy, B.; Chua, L.O. Simplest chaotic circuit. Int. J. Bifurc. Chaos 2010, 20, 1567–1580. [Google Scholar] [CrossRef]

- Migliato Marega, G.; Zhao, Y.; Avsar, A.; Wang, Z.; Tripathi, M.; Radenovic, A.; Kis, A. Logic-in-memory based on an atomically thin semiconductor. Nature 2020, 58, 72–77. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.Q.; Wang, R.; Ren, Y.; Mao, J.Y.; Wang, Z.P.; Zhou, Y.; Han, S.T. Neuromorphic engineering: From biological to spike-based hardware nervous systems. Adv. Mater. 2020, 32, 2003610. [Google Scholar] [CrossRef] [PubMed]

- Borkar, S.; Chien, A.A. The future of microprocessors. Commun. ACM 2011, 54, 67–77. [Google Scholar] [CrossRef]

- Kendall, J.D.; Kumar, S. The building blocks of a brain-inspired computer. Appl. Phys. Rev. 2020, 7, 011305. [Google Scholar] [CrossRef]

- Backus, J. Can programming be liberated from the von Neumann style? A functional style and its algebra of programs. Commun. ACM 1978, 21, 613–641. [Google Scholar] [CrossRef]

- Liu, C.; Yan, X.; Song, X.; Ding, S.; Zhang, D.W.; Zhou, P. A semi-floating gate memory based on van der Waals heterostructures for quasi-non-volatile applications. Nat. Nanotechnol. 2018, 13, 404–410. [Google Scholar] [CrossRef]

- Lan, S.; Wang, X.; Yu, R.; Zhou, C.; Wang, M.; Cai, X. Organic synaptic transistors based on a hybrid trapping layer for neuromorphic computing. IEEE Electron Device Lett. 2022, 43, 1255–1258. [Google Scholar] [CrossRef]

- Sun, K.; Chen, J.; Yan, X. The future of memristors: Materials engineering and neural networks. Adv. Funct. Mater. 2021, 31, 2006773. [Google Scholar] [CrossRef]

- Hasina, D.; Mandal, A.; Basu, N.; Srivastava, S.; Mitra, A.; Som, T. Realization of Short-and Long-Term Memories at Nanoscale and their Temporal Evolution in Two-Terminal Memristive Synapses. Appl. Surf. Sci. 2023, 611, 155563. [Google Scholar] [CrossRef]

- Waldrop, M.M. The chips are down for Moore’s law. Nature 2016, 530, 144. [Google Scholar] [CrossRef]

- Sanchez Esqueda, I.; Yan, X.; Rutherglen, C.; Kane, A.; Cain, T.; Marsh, P.; Liu, Q.; Galatsis, K.; Wang, H.; Zhou, C. Aligned carbon nanotube synaptic transistors for large-scale neuromorphic computing. ACS Nano 2018, 12, 7352–7361. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, Y.; Jia, R.; Liang, Z.; Zhu, W.; Rehman, Z.U.; Bao, L.; Zhang, X.; Cai, Y.; Song, L. Ion gated synaptic transistors based on 2D van der Waals crystals with tunable diffusive dynamics. Adv. Mater. 2018, 30, 1800195. [Google Scholar] [CrossRef]

- Dongale, T.D.; Khot, A.C.; Takaloo, A.V.; Kim, T.G. Facile synthesis of nickel cobaltite quasi-hexagonal nanosheets for multilevel resistive switching and synaptic learning applications. NPG Asia Mater. 2021, 13, 16. [Google Scholar] [CrossRef]

- Lin, P.; Li, C.; Wang, Z.; Li, Y.; Jiang, H.; Song, W.; Rao, M.; Zhuo, Y.; Upadhyay, N.K.; Barnell, M. Three-dimensional memristor circuits as complex neural networks. Nat. Electron. 2020, 3, 225–232. [Google Scholar] [CrossRef]

- Hu, M.; Graves, C.E.; Li, C.; Li, Y.; Ge, N.; Montgomery, E.; Davila, N.; Jiang, H.; Williams, R.S.; Yang, J.J. Memristor-based analog computation and neural network classification with a dot product engine. Adv. Mater. 2018, 30, 1705914. [Google Scholar] [CrossRef]

- Andreou, A.G.; Meitzler, R.C.; Strohbehn, K.; Boahen, K.A. Analog VLSI neuromorphic image acquisition and pre-processing systems. Neural Netw. 1995, 8, 1323–1347. [Google Scholar] [CrossRef]

- Calimera, A.; Macii, E.; Poncino, M. The human brain project and neuromorphic computing. Funct. Neurol. 2013, 28, 191. [Google Scholar] [PubMed]

- Eberhardt; Duong. Thakoor Design of parallel hardware neural network systems from custom analog VLSI ’building block’chips. In Proceedings of the International 1989 Joint Conference on Neural Networks, Washington, DC, USA, 18–22 June 1989; Volume 2, pp. 183–190. [Google Scholar]

- Pershin, Y.V.; Di Ventra, M. Experimental demonstration of associative memory with memristive neural networks. Neural Netw. 2010, 23, 881–886. [Google Scholar] [CrossRef] [PubMed]

- Strukov, D.B.; Snider, G.S.; Stewart, D.R.; Williams, R.S. The missing memristor found. Nature 2008, 453, 80–83. [Google Scholar] [CrossRef]

- Di Ventra, M.; Pershin, Y.V. The parallel approach. Nat. Phys. 2013, 9, 200–202. [Google Scholar] [CrossRef]

- Wong, H.-S.P.; Salahuddin, S. Memory leads the way to better computing. Nat. Nanotechnol. 2015, 10, 191–194. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.J.; Strukov, D.B.; Stewart, D.R. Memristive devices for computing. Nat. Nanotechnol. 2013, 8, 13–24. [Google Scholar] [CrossRef] [PubMed]

- Borghetti, J.; Snider, G.S.; Kuekes, P.J.; Yang, J.J.; Stewart, D.R.; Williams, R.S. ‘Memristive’switches enable ‘stateful’ logic operations via material implication. Nature 2010, 464, 873–876. [Google Scholar] [CrossRef]

- Jo, S.H.; Chang, T.; Ebong, I.; Bhadviya, B.B.; Mazumder, P.; Lu, W. Nanoscale memristor device as synapse in neuromorphic systems. Nano Lett. 2010, 10, 1297–1301. [Google Scholar] [CrossRef]

- Ielmini, D.; Nardi, F.; Balatti, S. Evidence for voltage-driven set/reset processes in bipolar switching RRAM. IEEE Trans. Electron Devices 2012, 59, 2049–2056. [Google Scholar] [CrossRef]

- Scott, J.F.; Paz de Araujo, C.A. Ferroelectric memories. Science 1989, 246, 1400–1405. [Google Scholar] [CrossRef]

- Auciello, O.; Scott, J.F.; Ramesh, R. The physics of ferroelectric memories. Phys. Today 1998, 51, 22–27. [Google Scholar] [CrossRef]

- Ielmini, D. Modeling the universal set/reset characteristics of bipolar RRAM by field-and temperature-driven filament growth. IEEE Trans. Electron Devices 2011, 58, 4309–4317. [Google Scholar] [CrossRef]

- Cooper, L.N.; Bear, M.F. The BCM theory of synapse modification at 30: Interaction of theory with experiment. Nat. Rev. Neurosci. 2012, 13, 798–810. [Google Scholar] [CrossRef]

- Bi, G.-q.; Poo, M.-m. Synaptic modifications in cultured hippocampal neurons: Dependence on spike timing, synaptic strength, and postsynaptic cell type. J. Neurosci. 1998, 18, 10464–10472. [Google Scholar] [CrossRef] [PubMed]

- Deac, A.M.; Fukushima, A.; Kubota, H.; Maehara, H.; Suzuki, Y.; Yuasa, S.; Nagamine, Y.; Tsunekawa, K.; Djayaprawira, D.D.; Watanabe, N. Bias-driven high-power microwave emission from MgO-based tunnel magnetoresistance devices. Nat. Phys. 2008, 4, 803–809. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, T.; Yang, Y.; Huang, R. A comprehensive review on emerging artificial neuromorphic devices. Appl. Phys. Rev. 2020, 7, 011312. [Google Scholar] [CrossRef]

- Moodera, J.S.; Kinder, L.R.; Wong, T.M.; Meservey, R. Large magnetoresistance at room temperature in ferromagnetic thin film tunnel junctions. Phys. Rev. Lett. 1995, 74, 3273. [Google Scholar] [CrossRef]

- Pi, C.; Ren, Y.; Chim, W. Investigation of bipolar resistive switching and the time-dependent SET process in silver sulfide/silver thin films and nanowire array structures. Nanotechnology 2010, 21, 085709. [Google Scholar] [CrossRef]

- Shi, Y.; Nguyen, L.; Oh, S.; Liu, X.; Koushan, F.; Jameson, J.R.; Kuzum, D. Neuroinspired unsupervised learning and pruning with subquantum CBRAM arrays. Nat. Commun. 2018, 9, 5312. [Google Scholar] [CrossRef]

- Xu, X.; Lv, H.; Liu, H.; Gong, T.; Wang, G.; Zhang, M.; Li, Y.; Liu, Q.; Long, S.; Liu, M. Superior retention of low-resistance state in conductive bridge random access memory with single filament formation. IEEE Electron Device Lett. 2014, 36, 129–131. [Google Scholar] [CrossRef]

- Jarvis, K.; Evans, P.; Nelson, A.; Triani, G. Comparisons of alumina barrier films deposited by thermal and plasma atomic layer deposition. Mater. Today Chem. 2019, 11, 8–15. [Google Scholar] [CrossRef]

- Jeong, D.S.; Thomas, R.; Katiyar, R.; Scott, J.; Kohlstedt, H.; Petraru, A.; Hwang, C.S. Emerging memories: Resistive switching mechanisms and current status. Rep. Prog. Phys. 2012, 75, 076502. [Google Scholar] [CrossRef]

- Kvatinsky, S.; Nacson, Y.H.; Etsion, Y.; Friedman, E.G.; Kolodny, A.; Weiser, U.C. Memristor-based multithreading. IEEE Comput. Archit. Lett. 2013, 13, 41–44. [Google Scholar] [CrossRef]

- Meuffels, P.; Soni, R. Fundamental issues and problems in the realization of memristors. arXiv 2012, arXiv:1207.7319. [Google Scholar]

- Jeong, D.S.; Kim, K.M.; Kim, S.; Choi, B.J.; Hwang, C.S. Memristors for energy-efficient new computing paradigms. Adv. Electron. Mater. 2016, 2, 1600090. [Google Scholar] [CrossRef]

- Silva, F.; Sanz, M.; Seixas, J.; Solano, E.; Omar, Y. Perceptrons from memristors. Neural Netw. 2020, 122, 273–278. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Midya, R.; Xia, Q.; Yang, J.J. Review of memristor devices in neuromorphic computing: Materials sciences and device challenges. J. Phys. D Appl. Phys. 2018, 51, 503002. [Google Scholar] [CrossRef]

- Chua, L. Memristor-the missing circuit element. IEEE. Trans. Circuit Theory 1971, 18, 507–519. [Google Scholar] [CrossRef]

- Chua, L.O.; Kang, S.M. Memristive devices and systems. Proc. IEEE 1976, 64, 209–223. [Google Scholar] [CrossRef]

- Chua, L. Resistance switching memories are memristors. In Handbook of Memristor Networks; Springer: Cham, Switzerland, 2019; pp. 197–230. [Google Scholar]

- Adhikari, S.P.; Sah, M.P.; Kim, H.; Chua, L.O. Three fingerprints of memristor. IEEE Trans. Circuits Syst. I Regul. Pap. 2013, 60, 3008–3021. [Google Scholar] [CrossRef]

- Wong, H.-S.P.; Lee, H.-Y.; Yu, S.; Chen, Y.-S.; Wu, Y.; Chen, P.-S.; Lee, B.; Chen, F.T.; Tsai, M.-J. Metal–oxide RRAM. Proc. IEEE 2012, 100, 1951–1970. [Google Scholar] [CrossRef]

- Yang, J.J.; Pickett, M.D.; Li, X.; Ohlberg, D.A.; Stewart, D.R.; Williams, R.S. Memristive switching mechanism for metal/oxide/metal nanodevices. Nat. Nanotechnol. 2008, 3, 429–433. [Google Scholar] [CrossRef] [PubMed]

- Waser, R.; Dittmann, R.; Staikov, G.; Szot, K. Redox-based resistive switching memories–nanoionic mechanisms, prospects, and challenges. Adv. Mater. 2009, 21, 2632–2663. [Google Scholar] [CrossRef] [PubMed]

- Chua, L.; Sirakoulis, G.C.; Adamatzky, A. Handbook of Memristor Networks; Springer Nature: Cham, Switzerland, 2019. [Google Scholar]

- Lee, H.; Chen, P.; Wu, T.; Chen, Y.; Wang, C.; Tzeng, P.; Lin, C.; Chen, F.; Lien, C.; Tsai, M.-J. Low power and high speed bipolar switching with a thin reactive Ti buffer layer in robust HfO2 based RRAM. In Proceedings of the 2008 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2008; pp. 1–4. [Google Scholar]

- Lee, J.; Shin, J.; Lee, D.; Lee, W.; Jung, S.; Jo, M.; Park, J.; Biju, K.P.; Kim, S.; Park, S. Diode-less nano-scale ZrOx/HfOx RRAM device with excellent switching uniformity and reliability for high-density cross-point memory applications. In Proceedings of the 2010 International Electron Devices Meeting, San Francisco, CA, USA, 6–8 December 2010; pp. 19.5.1–19.5.4. [Google Scholar]

- Dong, Y.-Y. Study on the Effect of Resistive Switching Characteristics of Rare Earth Doped the Oxide Memristors. Master’s Thesis, North China University of Technology, Beijing, China, 2023. (In Chinese). [Google Scholar]

- Gao, Q.; Huang, A.; Hu, Q.; Zhang, X.; Chi, Y.; Li, R.; Ji, Y.; Chen, X.; Zhao, R.; Wang, M. Stability and repeatability of a karst-like hierarchical porous silicon oxide-based memristor. ACS Appl. Mater. 2019, 11, 21734–21740. [Google Scholar] [CrossRef]

- Chen, J.-W. Research on Thermal Characteristic and Resistive Switching Mechanism of Chalcogenide Memristor Consisting of Ag. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2017. (In Chinese). [Google Scholar]

- Zhang, B.; Chen, W.; Zeng, J.; Fan, F.; Gu, J.; Chen, X.; Yan, L.; Xie, G.; Liu, S.; Yan, Q. 90% yield production of polymer nano-memristor for in-memory computing. Nat. Commun. 2021, 12, 1984. [Google Scholar] [CrossRef]

- Liu, S.-B. Study on Multilevel Storage and Performance of Silk Fibroin Based Memristors. Master’s Thesis, Donghua University, Shanghai, China, 2023. (In Chinese). [Google Scholar]

- Shen, Z.; Zhao, C.; Liu, Y.; Qi, Y.; Mitrovic, I.Z.; Yang, L.; Zhao, C. Performance variation of solution-processed memristor induced by different top electrode. Solid-State Electron. 2021, 186, 108132. [Google Scholar] [CrossRef]

- Dong, R.; Lee, D.; Xiang, W.; Oh, S.; Seong, D.; Heo, S.; Choi, H.; Kwon, M.; Seo, S.; Pyun, M. Reproducible hysteresis and resistive switching in metal-CuxO-metal heterostructures. Appl. Phys. Lett. 2007, 90, 042107. [Google Scholar] [CrossRef]

- Sim, H.; Choi, H.; Lee, D.; Chang, M.; Choi, D.; Son, Y.; Lee, E.-H.; Kim, W.; Park, Y.; Yoo, I.-K. Excellent resistance switching characteristics of Pt/SrTiO/sub 3/schottky junction for multi-bit nonvolatile memory application. In Proceedings of the 2005 IEEE International Electron Devices Meeting, Washington, DC, USA, 5 December 2005; pp. 758–761. [Google Scholar]

- Yeargan, J.; Taylor, H. The Poole-Frenkel effect with compensation present. J. Appl. Phys. 1968, 39, 5600–5604. [Google Scholar] [CrossRef]

- Sawa, A.; Fujii, T.; Kawasaki, M.; Tokura, Y. Interface transport properties and resistance switching in perovskite-oxide heterojunctions. In Proceedings of the Optics and Photonics 2005, San Diego, CA, USA, 31 July–4 August 2005; pp. 366–373. [Google Scholar]

- Valov, I.; Waser, R.; Jameson, J.R.; Kozicki, M.N. Electrochemical metallization memories—Fundamentals, applications, prospects. Nanotechnology 2011, 22, 254003. [Google Scholar] [CrossRef]

- Waser, R. Redox-based resistive switching memories. J. Nanosci. Nanotechnol. 2012, 12, 7628–7640. [Google Scholar] [CrossRef]

- Schindler, C.; Staikov, G.; Waser, R. Electrode kinetics of Cu–SiO2-based resistive switching cells: Overcoming the voltage-time dilemma of electrochemical metallization memories. Appl. Phys. Lett. 2009, 94, 072109. [Google Scholar] [CrossRef]

- Yang, Y.; Gao, P.; Gaba, S.; Chang, T.; Pan, X.; Lu, W. Observation of conducting filament growth in nanoscale resistive memories. Nat. Commun. 2012, 3, 732. [Google Scholar] [CrossRef]

- Strachan, J.P.; Pickett, M.D.; Yang, J.J.; Aloni, S.; David Kilcoyne, A.; Medeiros-Ribeiro, G.; Stanley Williams, R. Direct identification of the conducting channels in a functioning memristive device. Adv. Mater. 2010, 22, 3573–3577. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, C.; Kinoshita, K.; Yamasaki, T.; Sugiyama, Y. Direct observation of oxygen movement during resistance switching in NiO/Pt film. Appl. Phys. Lett. 2008, 93, 042106. [Google Scholar] [CrossRef]

- Wedig, A.; Luebben, M.; Cho, D.-Y.; Moors, M.; Skaja, K.; Rana, V.; Hasegawa, T.; Adepalli, K.K.; Yildiz, B.; Waser, R. Nanoscale cation motion in TaOx, HfOx and TiOx memristive systems. Nat. Nanotechnol. 2016, 11, 67–74. [Google Scholar] [CrossRef]

- Chen, C.; Song, C.; Yang, J.; Zeng, F.; Pan, F. Oxygen migration induced resistive switching effect and its thermal stability in W/TaOx/Pt structure. Appl. Phys. Lett. 2012, 100, 253509. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Hsin, C.-L.; Huang, C.-W.; Chiu, C.-H.; Huang, Y.-T.; Lin, S.-J.; Wu, W.-W.; Chen, L.-J. Dynamic evolution of conducting nanofilament in resistive switching memories. Nano Lett. 2013, 13, 3671–3677. [Google Scholar] [CrossRef]

- Terai, M.; Sakotsubo, Y.; Kotsuji, S.; Hada, H. Resistance Controllability of Ta2O5/TiO2 Stack ReRAM for Low-Voltage and Multilevel Operation. IEEE Electron Device Lett. 2010, 31, 204–206. [Google Scholar] [CrossRef]

- Yoshida, C.; Tsunoda, K.; Noshiro, H.; Sugiyama, Y. High speed resistive switching in Pt∕TiO2∕TiN film for nonvolatile memory application. Appl. Phys. Lett. 2007, 91, 223510. [Google Scholar] [CrossRef]

- Shin, H.W.; Son, J.Y. Resistive switching characteristics of graphene/NiO/highly ordered pyrolytic graphite resistive random access memory capacitors. J. Alloys Compd. 2019, 772, 900–904. [Google Scholar] [CrossRef]

- Lien, Y.-C.; Wu, T.-T.; Wong, S.S. 3-D Vertical via Nitrogen-Doped Aluminum Oxide Resistive Random-Access Memory. IEEE Trans. Electron Devices 2021, 68, 2712–2716. [Google Scholar] [CrossRef]

- Robertson, J. High dielectric constant oxides. EPJ Appl. Phys. 2004, 28, 265–291. [Google Scholar] [CrossRef]

- Sheu, S.-S.; Chang, M.-F.; Lin, K.-F.; Wu, C.-W.; Chen, Y.-S.; Chiu, P.-F.; Kuo, C.-C.; Yang, Y.-S.; Chiang, P.-C.; Lin, W.-P. A 4Mb embedded SLC resistive-RAM macro with 7.2 ns read-write random-access time and 160ns MLC-access capability. In Proceedings of the 2011 IEEE International Solid-State Circuits Conference, San Francisco, CA, USA, 20–24 February 2011; pp. 200–202. [Google Scholar]

- Azzaz, M.; Benoist, A.; Vianello, E.; Garbin, D.; Jalaguier, E.; Cagli, C.; Charpin, C.; Bernasconi, S.; Jeannot, S.; Dewolf, T. Improvement of performances HfO2-based RRAM from elementary cell to 16 kb demonstrator by introduction of thin layer of Al2O3. Solid-State Electron. 2016, 125, 182–188. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, W.-J.; Lai, L.-Y.; Li, S.; Hsu, C.-H.; Lin, H.-T.; Lee, H.-Y.; Su, J.-W.; Xie, Y.; Sheu, S.-S. A 16Mb dual-mode ReRAM macro with sub-14ns computing-in-memory and memory functions enabled by self-write termination scheme. In Proceedings of the 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017; pp. 28.2.1–28.2.4. [Google Scholar]

- Sekar, D.; Bateman, B.; Raghuram, U.; Bowyer, S.; Bai, Y.; Calarrudo, M.; Swab, P.; Wu, J.; Nguyen, S.; Mishra, N. Technology and circuit optimization of resistive RAM for low-power, reproducible operation. In Proceedings of the 2014 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2014; pp. 28.3.1–28.3.4. [Google Scholar]

- Yu, S.; Li, Z.; Chen, P.-Y.; Wu, H.; Gao, B.; Wang, D.; Wu, W.; Qian, H. Binary neural network with 16 Mb RRAM macro chip for classification and online training. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016; pp. 16.2.1–16.2.4. [Google Scholar]

- Lee, H.-Y.; Chen, P.-S.; Wang, C.-C.; Maikap, S.; Tzeng, P.-J.; Lin, C.-H.; Lee, L.-S.; Tsai, M.-J. Low-power switching of nonvolatile resistive memory using hafnium oxide. Jpn. J. Appl. Phys. 2007, 46, 2175. [Google Scholar] [CrossRef]

- Napari, M.; Stathopoulos, S.; Prodromakis, T.; Simanjuntak, F. Forming-Free and Non-linear Resistive Switching in Bilayer HfOx/TaOx Memory Devices by Interface-Induced Internal Resistance. Electron. Mater. Lett. 2024. [Google Scholar] [CrossRef]

- Mai, V.; Moradpour, A.; Senzier, P.A.; Pasquier, C.; Wang, K.; Rozenberg, M.; Giapintzakis, J.; Mihailescu, C.; Orfanidou, C.; Svoukis, E. Memristive and neuromorphic behavior in a LixCoO2 nanobattery. Sci. Rep. 2015, 5, 7761. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Li, R.; Zhang, X.; Gao, Q.; Wang, M.; Shi, H.; Xiao, Z.; Chu, P.K.; Huang, A. Lithium ion trapping mechanism of SiO2 in LiCoO2 based memristors. Sci. Rep. 2019, 9, 5081. [Google Scholar] [CrossRef]

- Nayak, A.; Ohno, T.; Tsuruoka, T.; Terabe, K.; Hasegawa, T.; Gimzewski, J.K.; Aono, M. Controlling the synaptic plasticity of a Cu2S gap-type atomic switch. Adv. Funct. Mater. 2012, 22, 3606–3613. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, H.; Zhang, J.; Xu, X.; Miao, X. Electrode materials for Ge2Sb2Te5-based memristors. J. Electron. Mater. 2012, 41, 3417–3422. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, H.; Li, Y.; Wang, Q.; Xu, X.; Miao, X. AgInSbTe memristor with gradual resistance tuning. Appl. Phys. Lett. 2013, 102, 183513. [Google Scholar] [CrossRef]

- Zhang, J.-J. Memristive Behaviors in Te-Based Chalcogenide Materials. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2014. (In Chinese). [Google Scholar]

- Xu, L.; Li, Y.; Yu, N.; Zhong, Y.; Miao, X. Local order origin of thermal stability enhancement in amorphous Ag doping GeTe. Appl. Phys. Lett. 2015, 106, 031904. [Google Scholar] [CrossRef]

- Henisch, H.; Smith, W. Switching in organic polymer films. Appl. Phys. Lett. 1974, 24, 589–591. [Google Scholar] [CrossRef]

- Ma, L.; Liu, J.; Yang, Y. Organic electrical bistable devices and rewritable memory cells. Appl. Phys. Lett. 2002, 80, 2997–2999. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Pal, A.J. Key to design functional organic molecules for binary operation with large conductance switching. Chem. Phys. Lett. 2003, 371, 86–90. [Google Scholar] [CrossRef]

- Chang, T.-Y.; Cheng, Y.-W.; Lee, P.-T. Electrical characteristics of an organic bistable device using an Al/Alq3/nanostructured MoO3/Alq3/p+-Si structure. Appl. Phys. Lett. 2010, 96, 043309. [Google Scholar] [CrossRef]

- Gergel-Hackett, N.; Tedesco, J.L.; Richter, C.A. Memristors with flexible electronic applications. Proc. IEEE 2011, 100, 1971–1978. [Google Scholar] [CrossRef]

- Lin, W.P.; Liu, S.J.; Gong, T.; Zhao, Q.; Huang, W. Polymer-based resistive memory materials and devices. Adv. Mater. 2014, 26, 570–606. [Google Scholar] [CrossRef]

- Ouyang, J.; Chu, C.-W.; Szmanda, C.R.; Ma, L.; Yang, Y. Programmable polymer thin film and non-volatile memory device. Nat. Mater. 2004, 3, 918–922. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Z.; Lin, J.; Yang, J.; Xie, L.; Yi, M.; Li, W.; Ling, H.; Ou, C.; Huang, W. Long-term homeostatic properties complementary to Hebbian rules in CuPc-based multifunctional memristor. Sci. Rep. 2016, 6, 35273. [Google Scholar] [CrossRef] [PubMed]

- Li, T.-F. ZnTPP-Based Memristors for Neuromorphic Application. Master’s Thesis, Nanjing University of Posts and Telecommunications, Nanjing, China, 2018. (In Chinese). [Google Scholar]

- Liu, L.-T. Porphyrin Organic Semiconductor Memristors for Immune Function and Neurosynaptic Application. Master’s Thesis, Nanjing University of Posts and Telecommunications, Nanjing, China, 2019. (In Chinese). [Google Scholar]

- Zhou, J.; Li, W.; Chen, Y.; Lin, Y.H.; Yi, M.; Li, J.; Qian, Y.; Guo, Y.; Cao, K.; Xie, L. A monochloro copper phthalocyanine memristor with high-temperature resilience for electronic synapse applications. Adv. Mater. 2021, 33, 2006201. [Google Scholar] [CrossRef]

- Li, S.; Zeng, F.; Chen, C.; Liu, H.; Tang, G.; Gao, S.; Song, C.; Lin, Y.; Pan, F.; Guo, D. Synaptic plasticity and learning behaviours mimicked through Ag interface movement in an Ag/conducting polymer/Ta memristive system. J. Mater. Chem. C 2013, 1, 5292–5298. [Google Scholar] [CrossRef]

- Liu, G.; Wang, C.; Zhang, W.; Pan, L.; Zhang, C.; Yang, X.; Fan, F.; Chen, Y.; Li, R.W. Organic biomimicking memristor for information storage and processing applications. Adv. Electron. Mater. 2016, 2, 1500298. [Google Scholar] [CrossRef]

- Zhi, W. Research on Neuromorphic Devices Based on Organic Polymer Memristor. Master’s Thesis, Lanzhou University, Lanzhou, China, 2022. (In Chinese). [Google Scholar]

- Xing, Y.; Shi, C.; Zhao, J.; Qiu, W.; Lin, N.; Wang, J.; Yan, X.B.; Yu, W.D.; Liu, X.Y. Mesoscopic-Functionalization of Silk Fibroin with Gold Nanoclusters Mediated by Keratin and Bioinspired Silk Synapse. Small 2017, 13, 1702390. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Wang, S.; Li, D.; Wang, R.; Li, F.; Wu, M.; Liang, K.; Ren, H.; Zheng, X.; Guo, C. Silk protein based volatile threshold switching memristors for neuromorphic computing. Adv. Electron. Mater. 2022, 8, 2101139. [Google Scholar] [CrossRef]

- He, N.; Yan, J.; Zhang, Z.; Qin, H.; Hu, E.; Wang, X.; Zhang, H.; Chen, P.; Xu, F.; Sheng, Y.; et al. Artificial Neurons Using Ag–In–Zn–S/Sericin Peptide-Based Threshold Switching Memristors for Spiking Neural Networks. Adv. Electron. Mater. 2023, 9, 2300467. [Google Scholar] [CrossRef]

- Zhang, W.; Gao, H.; Deng, C.; Lv, T.; Hu, S.; Wu, H.; Xue, S.; Tao, Y.; Deng, L.; Xiong, W. Ultrathin memristor based on two-dimensional WS2/MoS2 heterojunction. Nanoscale 2021, 13, 11497–11504. [Google Scholar] [CrossRef]

- Xie, W.; Zhong, Y.; Wang, D.; Zhong, L.; Han, L.; Yang, Q.; Jie, W. Co-existence of digital and analog resistive switching in 2D layered BiOI nanosheets for synaptic applications. Mater. Des. 2023, 234, 112367. [Google Scholar] [CrossRef]

| Dielectric Layer Material | Memristor Structure | Resistance Window | Storage Time/s | Scan Voltage/V | Literature |

|---|---|---|---|---|---|

| Binary metal oxide materials | Ta/La: HfOx/Au/Cr/SiO2/Si | 1.16 × 103 | 5 × 103 | −0.8~1.5 | [59] |

| Polymetallic oxide materials | Au/LixCoO2/PSiOx/Si | 105 | 105 | −3.8~5 | [60] |

| Sulfur-based compound materials | Ag/AgGeTe/Ta | 2.54 × 102 | 103 | −2~2.2 | [61] |

| Organic materials | Au/PBDTT-BQTPA/TTO | 103 | >104 | −0.3~0.3 | [62] |

| Two-dimensional materials | ITO/GO/SF/GO/Al | 102 | 104 | −2~2 | [63] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Li, X.; Sun, Z.; Liu, Y.; Yang, Y.; Chen, L. Research Progress in Dielectric-Layer Material Systems of Memristors. Inorganics 2024, 12, 87. https://doi.org/10.3390/inorganics12030087

Wang C, Li X, Sun Z, Liu Y, Yang Y, Chen L. Research Progress in Dielectric-Layer Material Systems of Memristors. Inorganics. 2024; 12(3):87. https://doi.org/10.3390/inorganics12030087

Chicago/Turabian StyleWang, Chunxia, Xuemei Li, Zhendong Sun, Yang Liu, Ying Yang, and Lijia Chen. 2024. "Research Progress in Dielectric-Layer Material Systems of Memristors" Inorganics 12, no. 3: 87. https://doi.org/10.3390/inorganics12030087