Pattern Recognition Approach for the Screening of Potential Adulteration of Traditional and Bourbon Barrel-Aged Maple Syrups by Spectral Fingerprinting and Classical Methods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Reference Analyses

2.2.1. °Brix

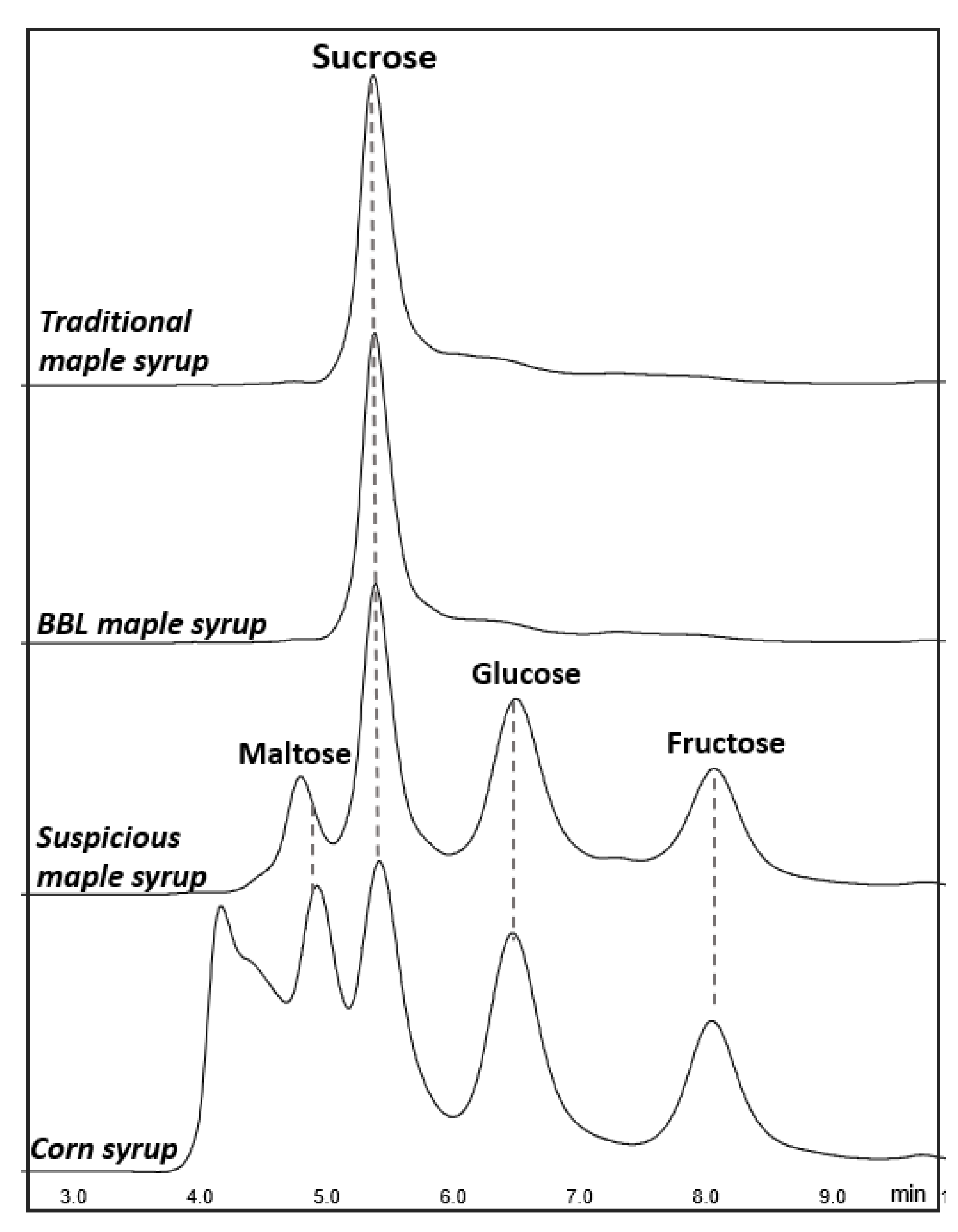

2.2.2. High-Performance Liquid Chromatography

2.2.3. Total Phenolics

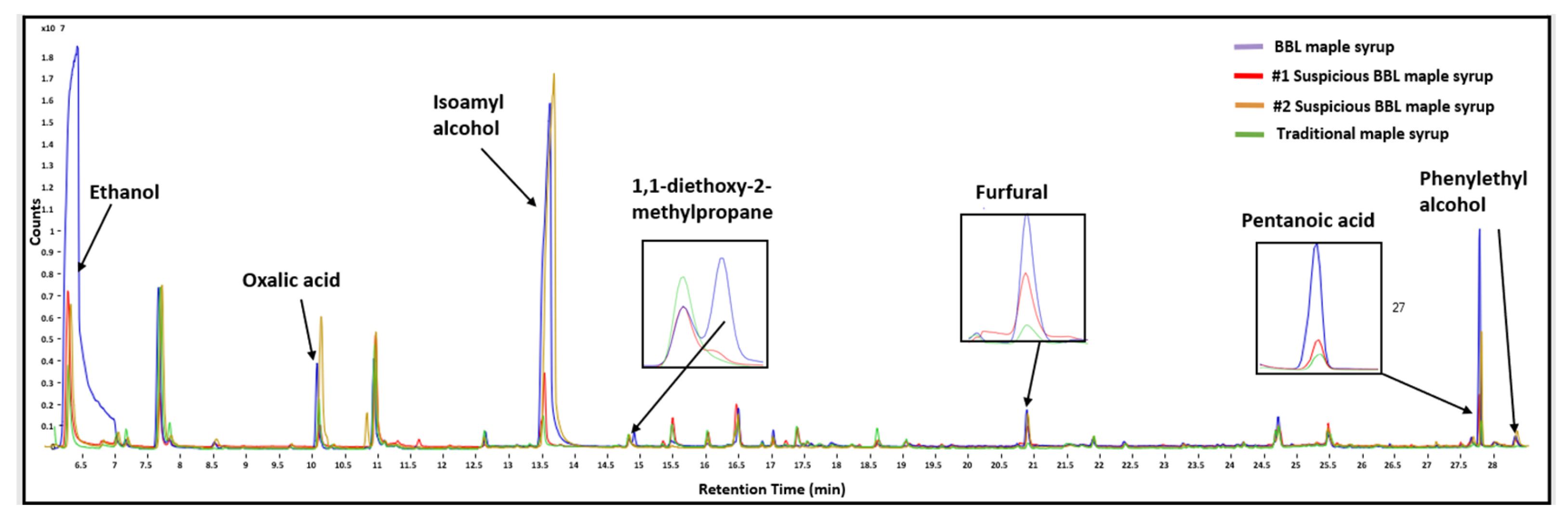

2.2.4. Gas Chromatography—Mass Spectrometry

2.2.5. Statistics of Reference Analysis

2.3. Vibrational Spectroscopy

2.3.1. Mid-Infrared Analysis

2.3.2. Raman Analysis

2.4. Multivariate Data Analysis

2.4.1. SIMCA

2.4.2. PLSR

3. Results and Discussion

3.1. Characterization of Maple Syrup Samples

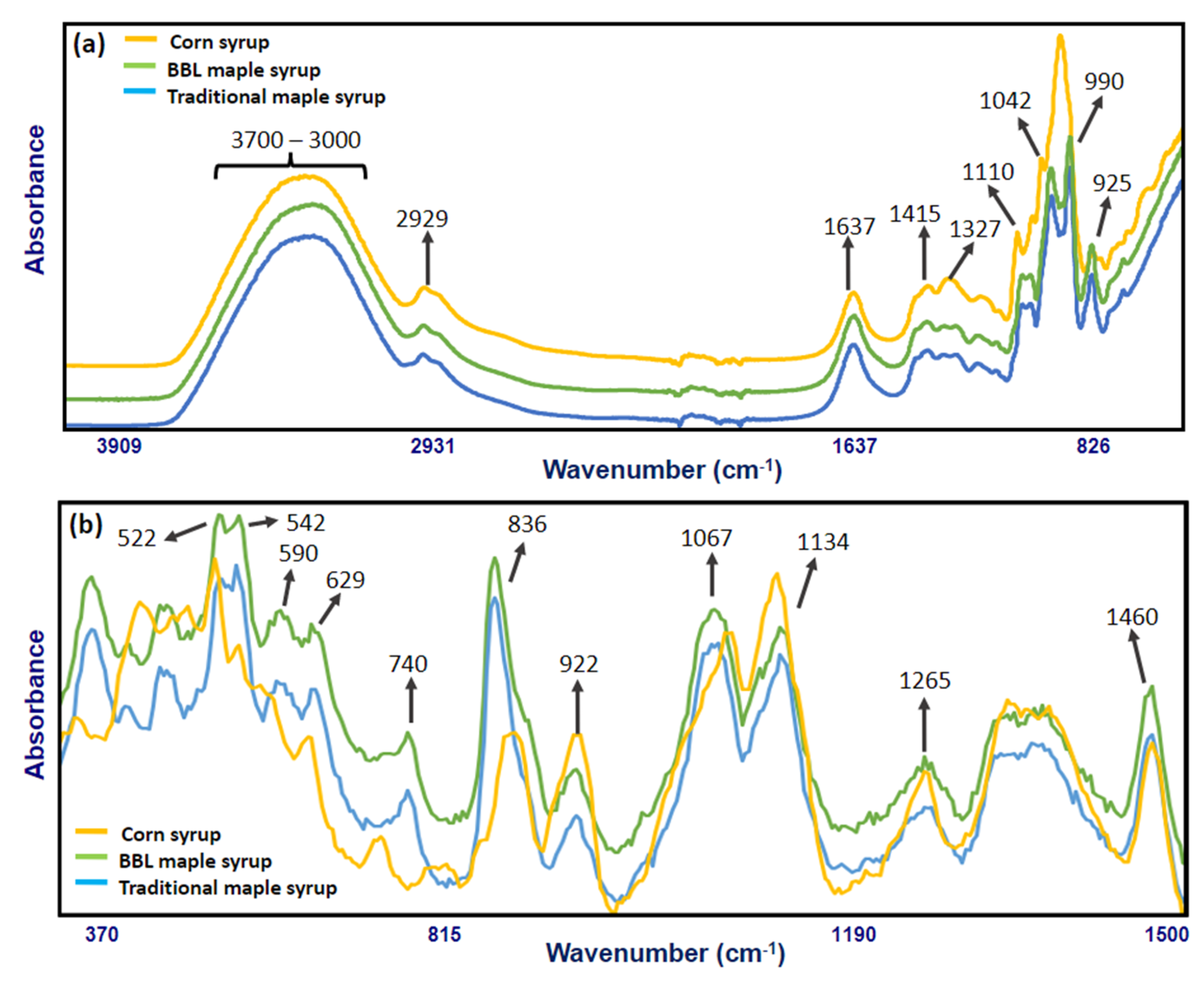

3.2. Spectral Information of Maple Syrup Samples

3.3. Multivariate Data Analysis

3.3.1. SIMCA Classification Model of GC-MS

3.3.2. SIMCA Classification Models of FT-IR and Raman Spectroscopy

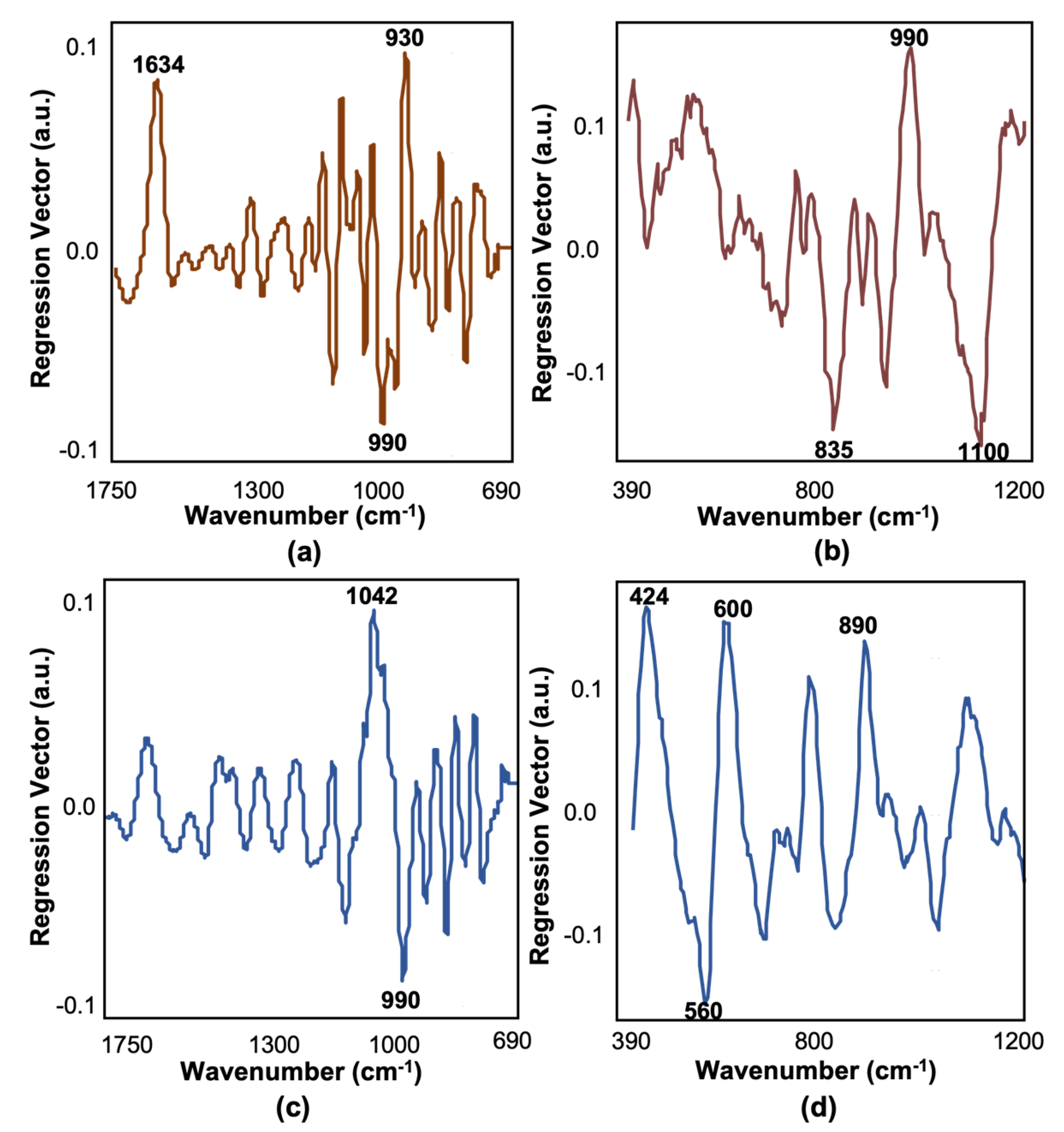

3.3.3. Regression Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| 2-Methylpropan-1-Ol | Ethanol | 3-Hydroxybutan-2-One | 1,1-Diethoxy-2-Methylpropane | Pentan-1-ol | 2-O-Butyl 1-O-Propyl Oxalate | 3-Methylbut-3-en-1-oll | Unknown Compound | 2-(2-Ethylhexoxy)Ethanol | 4-Butoxybutan-2-One | 2-Methylcyclopent-2-En-1-One | 1-O-(2-Methylpropyl) 4-O-Propan-2-Yl 2,2-Dimethyl-3-Propan-2-Ylbutanedioate | 2-Phenylethanol | 2-Methylpyrazine | Furan-2-Carbaldehyde | Benzaldehyde | 2,6-Dimethylpyrazine | 4-Methylbenzaldehyde | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ions (m/z) | 33-43-74 | 31-45 | 28-45-88 | 47-55-103 | 41-55-70 | 33-43-74 | 41-56-68 | 57-69-89 | 45-57-71 | 28-43-73 | 57-67-96 | 43-71-159 | 65-91-122 | 77-94-105 | 39-67-96 | 51-77-106 | 28-42-108 | 65-91-119 | |

| BBL | min | 7.60 × 105 | 3.10 × 107 | 2.70 × 104 | 1.40 × 105 | 8.10 × 106 | 5.20 × 104 | 1.30 × 104 | 8.70 × 102 | 2.10 × 105 | 1.10 × 103 | 9.20 × 103 | 1.40 × 105 | 1.00 × 105 | 2.40 × 104 | 5.70 × 105 | 5.00 × 104 | 1.40 × 104 | 4.80 × 103 |

| (n = 11) | max | 6.10 × 106 | 8.80 × 107 | 3.80 × 105 | 2.70 × 106 | 3.10 × 107 | 6.10 × 106 | 1.60 × 105 | 3.70 × 105 | 4.90 × 105 | 3.20 × 105 | 1.90 × 105 | 7.70 × 106 | 7.20 × 105 | 2.40 × 105 | 2.70 × 106 | 2.10 × 105 | 1.90 × 105 | 6.80 × 105 |

| mean | 3.30 × 106 | 6.10 × 107 | 1.40 × 105 | 5.90 × 105 | 1.90 × 107 | 3.20 × 106 | 7.10 × 104 | 1.40 × 105 | 3.30 × 105 | 1.40 × 105 | 6.60 × 104 | 4.50 × 106 | 2.60 × 105 | 7.60 × 104 | 1.40 × 106 | 1.00 × 105 | 7.20 × 104 | 3.30 × 105 | |

| Abnormal BBL | min | 7.60 × 105 | 8.90 × 106 | 5.20 × 105 | 0.00 | 2.10 × 106 | 7.60 × 105 | 1.60 × 105 | 1.80 × 105 | 4.20 × 105 | 6.90 × 104 | 5.30 × 104 | 1.80 × 105 | 2.30 × 105 | 1.40 × 105 | 8.00 × 105 | 7.90 × 104 | 1.40 × 105 | 4.10 × 105 |

| (n = 2) | max | 6.00 × 106 | 9.40 × 106 | 8.90 × 105 | 0.00 | 3.20 × 107 | 6.00 × 106 | 2.70 × 105 | 2.90 × 105 | 5.20 × 105 | 2.20 × 105 | 2.20 × 105 | 2.50 × 105 | 6.00 × 105 | 2.10 × 106 | 1.70 × 106 | 8.80 × 104 | 1.20 × 106 | 5.30 × 105 |

| mean | 3.40 × 106 | 9.10 × 106 | 7.10 × 105 | 0.00 | 1.70 × 107 | 3.40 × 106 | 2.10 × 105 | 2.40 × 105 | 4.70 × 105 | 1.40 × 105 | 1.40 × 105 | 2.20 × 105 | 4.20 × 105 | 1.10 × 106 | 1.20 × 106 | 8.40 × 104 | 6.70 × 105 | 4.70 × 105 | |

| Golden and Amber | min | 2.70 × 104 | 2.90 × 105 | 6.90 × 102 | 0.00 | 9.10 × 103 | 9.70 × 103 | 2.60 × 103 | 5.20 × 103 | 6.10 × 104 | 1.30 × 103 | 4.00 × 103 | 2.90 × 102 | 3.20 × 103 | 8.10 × 102 | 1.90 × 103 | 8.10 × 102 | 1.20 × 103 | 2.30 × 102 |

| (n = 10) | max | 1.10 × 107 | 9.40 × 106 | 9.70 × 105 | 0.00 | 9.80 × 105 | 2.50 × 106 | 5.00 × 105 | 5.80 × 105 | 7.70 × 105 | 3.60 × 105 | 1.50 × 105 | 3.40 × 105 | 2.50 × 104 | 3.70 × 105 | 5.00 × 105 | 1.30 × 105 | 3.80 × 105 | 8.10 × 105 |

| mean | 2.40 × 106 | 2.30 × 106 | 4.90 × 105 | 0.00 | 3.30 × 105 | 8.90 × 105 | 2.10 × 105 | 1.90 × 105 | 3.70 × 105 | 1.60 × 105 | 6.30 × 104 | 1.60 × 105 | 1.60 × 104 | 8.80 × 104 | 1.50 × 105 | 6.40 × 104 | 1.10 × 105 | 3.50 × 105 | |

| Dark | min | 9.90 × 105 | 4.30 × 106 | 6.90 × 105 | 0.00 | 2.90 × 105 | 9.90 × 105 | 1.80 × 105 | 1.60 × 105 | 3.30 × 105 | 8.20 × 104 | 6.70 × 104 | 9.80 × 104 | 3.00 × 104 | 2.00 × 105 | 2.50 × 105 | 5.80 × 104 | 4.00 × 105 | 2.60 × 105 |

| (n = 5) | max | 2.70 × 106 | 1.70 × 107 | 1.00 × 106 | 0.00 | 3.00 × 106 | 2.70 × 106 | 3.00 × 105 | 2.20 × 105 | 5.30 × 105 | 2.90 × 105 | 5.30 × 105 | 2.30 × 105 | 6.50 × 104 | 1.60 × 106 | 5.20 × 105 | 1.40 × 105 | 1.30 × 106 | 4.40 × 105 |

| mean | 1.90 × 106 | 1.00 × 107 | 8.80 × 105 | 0.00 | 1.50 × 106 | 1.90 × 106 | 2.60 × 105 | 2.00 × 105 | 4.50 × 105 | 2.00 × 105 | 2.20 × 105 | 1.60 × 105 | 4.90 × 104 | 7.00 × 105 | 3.40 × 105 | 8.40 × 104 | 6.40 × 105 | 3.80 × 105 | |

| p-value | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.002 | 0.009 | 0.705 | 0.403 | 0.755 | 0.15 | <0.001 | <0.001 | <0.001 | <0.001 | 0.163 | <0.001 | 0.932 | |

| Ions (m/z) | 33-43-74 | 31-45 | 28-45-88 | 47-55-103 | 41-55-70 | 33-43-74 | 41-56-68 | 57-69-89 | 45-57-71 | 28-43-73 | 57-67-96 | 43-71-159 | 65-91-122 | 77-94-105 | 39-67-96 | 51-77-106 | 28-42-108 | 65-91-119 | |

| BBL | min | 7.60 × 105 | 3.10 × 107 | 2.70 × 104 | 1.40 × 105 | 8.10 × 106 | 5.20 × 104 | 1.30 × 104 | 8.70 × 102 | 2.10 × 105 | 1.10 × 103 | 9.20 × 103 | 1.40 × 105 | 1.00 × 105 | 2.40 × 104 | 5.70 × 105 | 5.00 × 104 | 1.40 × 104 | 4.80 × 103 |

| (n = 11) | max | 6.10 × 106 | 8.80 × 107 | 3.80 × 105 | 2.70 × 106 | 3.10 × 107 | 6.10 × 106 | 1.60 × 105 | 3.70 × 105 | 4.90 × 105 | 3.20 × 105 | 1.90 × 105 | 7.70 × 106 | 7.20 × 105 | 2.40 × 105 | 2.70 × 106 | 2.10 × 105 | 1.90 × 105 | 6.80 × 105 |

| mean | 3.30 × 106 | 6.10 × 107 | 1.40 × 105 | 5.90 × 105 | 1.90 × 107 | 3.20 × 106 | 7.10 × 104 | 1.40 × 105 | 3.30 × 105 | 1.40 × 105 | 6.60 × 104 | 4.50 × 106 | 2.60 × 105 | 7.60 × 104 | 1.40 × 106 | 1.00 × 105 | 7.20 × 104 | 3.30 × 105 | |

| Abnormal BBL | min | 7.60 × 105 | 8.90 × 106 | 5.20 × 105 | 0.00 | 2.10 × 106 | 7.60 × 105 | 1.60 × 105 | 1.80 × 105 | 4.20 × 105 | 6.90 × 104 | 5.30 × 104 | 1.80 × 105 | 2.30 × 105 | 1.40 × 105 | 8.00 × 105 | 7.90 × 104 | 1.40 × 105 | 4.10 × 105 |

| (n = 2) | max | 6.00 × 106 | 9.40 × 106 | 8.90 × 105 | 0.00 | 3.20 × 107 | 6.00 × 106 | 2.70 × 105 | 2.90 × 105 | 5.20 × 105 | 2.20 × 105 | 2.20 × 105 | 2.50 × 105 | 6.00 × 105 | 2.10 × 106 | 1.70 × 106 | 8.80 × 104 | 1.20 × 106 | 5.30 × 105 |

| mean | 3.40 × 106 | 9.10 × 106 | 7.10 × 105 | 0.00 | 1.70 × 107 | 3.40 × 106 | 2.10 × 105 | 2.40 × 105 | 4.70 × 105 | 1.40 × 105 | 1.40 × 105 | 2.20 × 105 | 4.20 × 105 | 1.10 × 106 | 1.20 × 106 | 8.40 × 104 | 6.70 × 105 | 4.70 × 105 | |

| Golden and Amber | min | 2.70 × 104 | 2.90 × 105 | 6.90 × 102 | 0.00 | 9.10 × 103 | 9.70 × 103 | 2.60 × 103 | 5.20 × 103 | 6.10 × 104 | 1.30 × 103 | 4.00 × 103 | 2.90 × 102 | 3.20 × 103 | 8.10 × 102 | 1.90 × 103 | 8.10 × 102 | 1.20 × 103 | 2.30 × 102 |

| (n = 10) | max | 1.10 × 107 | 9.40 × 106 | 9.70 × 105 | 0.00 | 9.80 × 105 | 2.50 × 106 | 5.00 × 105 | 5.80 × 105 | 7.70 × 105 | 3.60 × 105 | 1.50 × 105 | 3.40 × 105 | 2.50 × 104 | 3.70 × 105 | 5.00 × 105 | 1.30 × 105 | 3.80 × 105 | 8.10 × 105 |

| mean | 2.40 × 106 | 2.30 × 106 | 4.90 × 105 | 0.00 | 3.30 × 105 | 8.90 × 105 | 2.10 × 105 | 1.90 × 105 | 3.70 × 105 | 1.60 × 105 | 6.30 × 104 | 1.60 × 105 | 1.60 × 104 | 8.80 × 104 | 1.50 × 105 | 6.40 × 104 | 1.10 × 105 | 3.50 × 105 | |

| Dark | min | 9.90 × 105 | 4.30 × 106 | 6.90 × 105 | 0.00 | 2.90 × 105 | 9.90 × 105 | 1.80 × 105 | 1.60 × 105 | 3.30 × 105 | 8.20 × 104 | 6.70 × 104 | 9.80 × 104 | 3.00 × 104 | 2.00 × 105 | 2.50 × 105 | 5.80 × 104 | 4.00 × 105 | 2.60 × 105 |

| (n = 5) | max | 2.70 × 106 | 1.70 × 107 | 1.00 × 106 | 0.00 | 3.00 × 106 | 2.70 × 106 | 3.00 × 105 | 2.20 × 105 | 5.30 × 105 | 2.90 × 105 | 5.30 × 105 | 2.30 × 105 | 6.50 × 104 | 1.60 × 106 | 5.20 × 105 | 1.40 × 105 | 1.30 × 106 | 4.40 × 105 |

| mean | 1.90 × 106 | 1.00 × 107 | 8.80 × 105 | 0.00 | 1.50 × 106 | 1.90 × 106 | 2.60 × 105 | 2.00 × 105 | 4.50 × 105 | 2.00 × 105 | 2.20 × 105 | 1.60 × 105 | 4.90 × 104 | 7.00 × 105 | 3.40 × 105 | 8.40 × 104 | 6.40 × 105 | 3.80 × 105 | |

| p-value | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.002 | 0.009 | 0.705 | 0.403 | 0.755 | 0.15 | <0.001 | <0.001 | <0.001 | <0.001 | 0.163 | <0.001 | 0.932 |

References

- Heiligmann, R.B.; Koelling, M.R.; Perkins, T.D. North American Maple Syrup Producers Manual; Ohio State University Extension: Columbus, OH, USA, 2006; p. 29. [Google Scholar]

- Chamberlain, A.F. The Maple amongst the Algonkian Tribes. Am. Anthropol. 1891, 4, 39–44. [Google Scholar] [CrossRef]

- USDA Wisconsin Ag News—Maple Syrup. Available online: https://www.nass.usda.gov/Statistics_by_State/Wisconsin/Publications/Crops/2020/WI-Maple-Syrup-06-20.pdf (accessed on 10 September 2021).

- Stuckel, J.G.; Low, N.H. The chemical composition of 80 pure maple syrup samples produced in North America. Food Res. Int. 1996, 29, 373–379. [Google Scholar] [CrossRef]

- St-Pierre, P.; Pilon, G.; Dumais, V.; Dion, C.; Dubois, M.J.; Dubé, P.; Desjardins, Y.; Marette, A. Comparative analysis of maple syrup to other natural sweeteners and evaluation of their metabolic responses in healthy rats. J. Funct. Foods 2014, 11, 460–471. [Google Scholar] [CrossRef]

- Li, S.; Duan, C. Astringency, bitterness and color changes in dry red wines before and during oak barrel aging: An updated phenolic perspective review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1840–1867. [Google Scholar] [CrossRef]

- Samuelson, E. What Is Bourbon Barrel Aged Maple Syrup? Available online: https://www.eatlikenoone.com/bourbon-barrel-aged-maple-syrup-2.htm (accessed on 10 September 2021).

- Paradkar, M.M.; Sivakesava, S.; Irudayaraj, J. Discrimination and classification of adulterants in maple syrup with the use of infrared spectroscopic techniques. J. Sci. Food Agric. 2002, 82, 497–504. [Google Scholar] [CrossRef]

- Carro, O.; Hillaire-Marcel, C.; Gagnon, M. Detection of Adulterated Maple Products by Stable Carbon Isotope Ratio. J. AOAC Int. 1980, 63, 840–844. [Google Scholar] [CrossRef]

- Stuckel, J.G.; Low, N.H. Maple Syrup Authenticity Analysis by Anion-Exchange Liquid Chromatography with Pulsed Amperometric Detection. J. Agric. Food Chem. 1995, 43, 3046–3051. [Google Scholar] [CrossRef]

- Tremblay, P.; Paquin, R. Improved Detection of Sugar Addition to Maple Syrup Using Malic Acid as Internal Standard and in 13 C Isotope Ratio Mass Spectrometry (IRMS). J. Agric. Food Chem. 2007, 55, 197–203. [Google Scholar] [CrossRef]

- Santos, P.M.; Pereira-Filho, E.R.; Rodriguez-Saona, L.E. Application of hand-held and portable infrared spectrometers in bovine milk analysis. J. Agric. Food Chem. 2013, 61, 1205–1211. [Google Scholar] [CrossRef]

- Paradkar, M.M.; Sakhamuri, S.; Irudayaraj, J. Comparison of FTIR, FT-Raman, and NIR Spectroscopy in a Maple Syrup Adulteration Study. J. Food Sci. 2002, 67, 2009–2015. [Google Scholar] [CrossRef]

- Lu, X.; Al-Qadiri, H.M.; Lin, M.; Rasco, B.A. Application of Mid-infrared and Raman Spectroscopy to the Study of Bacteria. Food Bioprocess Technol. 2011, 4, 919–935. [Google Scholar] [CrossRef]

- Nickless, E.M.; Holroyd, S.E.; Hamilton, G.; Gordon, K.C.; Wargent, J.J. Analytical method development using FTIR-ATR and FT-Raman spectroscopy to assay fructose, sucrose, glucose and dihydroxyacetone, in Leptospermum scoparium nectar. Vib. Spectrosc. 2016, 84, 38–43. [Google Scholar] [CrossRef]

- Mellado-Mojica, E.; Seeram, N.P.; López, M.G. Comparative analysis of maple syrups and natural sweeteners: Carbohydrates composition and classification (differentiation) by HPAEC-PAD and FTIR spectroscopy-chemometrics. J. Food Compos. Anal. 2016, 52, 1–8. [Google Scholar] [CrossRef]

- Lachenmeier, D.W. Rapid quality control of spirit drinks and beer using multivariate data analysis of Fourier transform infrared spectra. Food Chem. 2007, 101, 825–832. [Google Scholar] [CrossRef]

- Karoui, R.; Debaerdemaeker, J. A review of the analytical methods coupled with chemometric tools for the determination of the quality and identity of dairy products. Food Chem. 2007, 102, 621–640. [Google Scholar] [CrossRef]

- Waterhouse, A.L. Determination of Total Phenolics. In Current Protocols in Food Analytical Chemistry; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Kovalenko, I.V.; Rippke, G.R.; Hurburgh, C.R. Determination of amino acid composition of soybeans (Glycine max) by near-infrared spectroscopy. J. Agric. Food Chem. 2006, 54, 3485–3491. [Google Scholar] [CrossRef] [Green Version]

- Iacobucci, D.; Schneider, M.J.; Popovich, D.L.; Bakamitsos, G.A. Mean centering helps alleviate “micro” but not “macro” multicollinearity. Behav. Res. Methods 2016, 48, 1308–1317. [Google Scholar] [CrossRef]

- Zimmermann, B.; Kohler, A. Optimizing savitzky-golay parameters for improving spectral resolution and quantification in infrared spectroscopy. Appl. Spectrosc. 2013, 67, 892–902. [Google Scholar] [CrossRef] [Green Version]

- Cozzolino, D. The sample, the spectra and the maths-The critical pillars in the development of robust and sound applications of vibrational spectroscopy. Molecules 2020, 25, 3674. [Google Scholar] [CrossRef]

- Massart, D.; Vandeginste, B.; Deming, S.; Michotte, Y.; Kaufman, L. Data Handling in Science and Technology; Elsevier Ltd.: Amsterdam, The Netherlands, 2001; ISBN 9780444828538. [Google Scholar]

- Siegmann, B.; Jarmer, T. Comparison of different regression models and validation techniques for the assessment of wheat leaf area index from hyperspectral data. Int. J. Remote Sens. 2015, 36, 4519–4534. [Google Scholar] [CrossRef]

- Perkins, T.D.; van den Berg, A.K. Chapter 4 Maple Syrup-Production, Composition, Chemistry, and Sensory Characteristics, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2009; Volume 56, ISBN 9780123744395. [Google Scholar]

- Morselli, M.F. Nutrition Value of Pure Maple Syrup. Maple Syrup Dig. 1975, 14, 12. [Google Scholar]

- Aykas, D.P.; Shotts, M.; Rodriguez-Saona, L.E. Authentication of commercial honeys based on Raman fingerprinting and pattern recognition analysis. Food Control 2020, 117, 107346. [Google Scholar] [CrossRef]

- Singh, A.S.; Jones, A.M.P.; Saxena, P.K. Variation and Correlation of Properties in Different Grades of Maple Syrup. Plant Foods Hum. Nutr. 2014, 69, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Apostolidis, E.; Li, L.; Lee, C.; Seeram, N.P. In vitro evaluation of phenolic-enriched maple syrup extracts for inhibition of carbohydrate hydrolyzing enzymes relevant to type 2 diabetes management. J. Funct. Foods 2011, 3, 100–106. [Google Scholar] [CrossRef]

- Wallis, C.M.; Galarneau, E.R.-A. Phenolic Compound Induction in Plant-Microbe and Plant-Insect Interactions: A Meta-Analysis. Front. Plant Sci. 2020, 11, 580753. [Google Scholar] [CrossRef]

- Aoshima, H.; Hossain, S.; Koda, H.; Kiso, Y. Why Is an Aged Whiskey Highly Valued? Curr. Nutr. Food Sci. 2009, 5, 204–208. [Google Scholar] [CrossRef]

- Ball, D.W. The chemical composition of maple syrup. J. Chem. Educ. 2007, 84, 1647–1650. [Google Scholar] [CrossRef]

- Li, J.R.; Sun, S.Q.; Wang, X.X.; Xu, C.H.; Chen, J.B.; Zhou, Q.; Lu, G.H. Differentiation of five species of Danggui raw materials by FTIR combined with 2D-COS IR. J. Mol. Struct. 2014, 1069, 229–235. [Google Scholar] [CrossRef]

- Sekkal, M.; Dincq, V.; Legrand, P.; Huvenne, J.P. Investigation of the glycosidic linkages in several oligosaccharides using FT-IR and FT Raman spectroscopies. J. Mol. Struct. 1995, 349, 349–352. [Google Scholar] [CrossRef]

- Sinelli, N.; Spinardi, A.; Di Egidio, V.; Mignani, I.; Casiraghi, E. Evaluation of quality and nutraceutical content of blueberries (Vaccinium corymbosum L.) by near and mid-infrared spectroscopy. Postharvest Biol. Technol. 2008, 50, 31–36. [Google Scholar] [CrossRef]

- Gok, S.; Severcan, M.; Goormaghtigh, E.; Kandemir, I.; Severcan, F. Differentiation of Anatolian honey samples from different botanical origins by ATR-FTIR spectroscopy using multivariate analysis. Food Chem. 2015, 170, 234–240. [Google Scholar] [CrossRef]

- Fernández-Pierna, J.A.; Abbas, O.; Dardenne, P.; Baeten, V. Discrimination of Corsican honey by FT-Raman spectroscopy and chemometrics. Biotechnol. Agron. Soc. Environ. 2011, 15, 75–84. [Google Scholar]

- Salvador, L.; Guijarro, M.; Rubio, D.; Aucatoma, B.; Guillén, T.; Jentzsch, P.V.; Ciobotă, V.; Stolker, L.; Ulic, S.; Vásquez, L.; et al. Exploratory monitoring of the quality and authenticity of commercial honey in Ecuador. Foods 2019, 8, 105. [Google Scholar] [CrossRef] [Green Version]

- Lehtonen, P.J.; Keller, L.D.A.; Ali-Mattila, E.T. Multi-method analysis of matured distilled alcoholic beverages for brand identification. Eur. Food Res. Technol. 1999, 208, 413–417. [Google Scholar] [CrossRef]

- Suhandy, D.; Yulia, M. The use of UV spectroscopy and SIMCA for the authentication of Indonesian honeys according to botanical, entomological and geographical origins. Molecules 2021, 26, 915. [Google Scholar] [CrossRef]

- Picque, D.; Lieben, P.; Corrieu, G.; Cantagrel, R.; Lablanquie, O.; Snakkers, G. Discrimination of Cognacs and other distilled drinks by mid-infrared spectropscopy. J. Agric. Food Chem. 2006, 54, 5220–5226. [Google Scholar] [CrossRef]

- Sharma, K.; Sharma, S.P.; Lahiri, S. Novel Method for Identification and Quantification of Methanol and Ethanol in Alcoholic Beverages by Gas Chromatography-Fourier Transform Infrared Spectroscopy and Horizontal Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy. J. AOAC Int. 2009, 92, 518–526. [Google Scholar] [CrossRef] [Green Version]

- Sivakesava, S.; Irudayaraj, J.; Demirci, A. Monitoring a bioprocess for ethanol production using FT-MIR and FT-Raman spectroscopy. J. Ind. Microbiol. Biotechnol. 2001, 26, 185–190. [Google Scholar] [CrossRef]

- Grassi, S.; Jolayemi, O.S.; Giovenzana, V.; Tugnolo, A.; Squeo, G.; Conte, P.; De Bruno, A.; Flamminii, F.; Casiraghi, E.; Alamprese, C. Near Infrared Spectroscopy as a Green Technology for the Quality Prediction of Intact Olives. Foods 2021, 10, 1042. [Google Scholar] [CrossRef]

- Shenk, J.S.; Westerhaus, M.O. Calibration the ISI Way. In Near Infrared Spectroscopy: The Future Waves; Davis, A.M.C., Williams, P., Eds.; NIR Publications: Chichester, UK, 1996. [Google Scholar]

- Anguebes, F.; Pat, L.; Ali, B.; Guerrero, A.; Córdova, A.V.; Abatal, M.; Garduza, J.P. Application of Multivariable Analysis and FTIR-ATR Spectroscopy to the Prediction of Properties in Campeche Honey. J. Anal. Methods Chem. 2016, 2016, 5427526. [Google Scholar] [CrossRef] [Green Version]

- Anguebes-Franseschi, F.; Abatal, M.; Pat, L.; Flores, A.; Quiroz, A.V.C.; Ramírez-Elias, M.A.; Pedro, L.S.; Tzuc, O.M.; Bassam, A. Raman Spectroscopy and Chemometric Modeling to Predict Physical-Chemical Honey Properties from Campeche, Mexico. Molecules 2019, 24, 4091. [Google Scholar] [CrossRef] [Green Version]

| Traditional Maple Syrup (n = 19) | BBL Maple Syrup (n = 13) | Table Syrups (n = 5) | |||

|---|---|---|---|---|---|

| °Brix | Minimum | 65.51 | 65.39 | 39.63 | |

| Maximum | 67.65 | 68.69 | 78.27 | ||

| Mean | 66.57 | 66.56 | 67.64 | ||

| SD | 0.55 | 0.87 | 14.32 | ||

| Sucrose (%, g/100 g) | Minimum | 22.02 | 60.13 | 3.51 | |

| Maximum | 67.60 | 69.42 | 51.49 | ||

| Mean | 57.56 | 63.72 | 21.75 | ||

| SD | 14.78 | 2.73 | 17.77 | ||

| Fructose (%, g/100 g) | Minimum | 0.00 | 0.00 | 12.62 | |

| Maximum | 17.14 | 0.00 | 14.36 | ||

| Mean | 2.01 | 0.00 | 13.31 | ||

| SD | 4.86 | 0.00 | 0.76 | ||

| Glucose (%, g/100 g) | Minimum | 0.00 | 0.00 | 9.75 | |

| Maximum | 17.06 | 0.00 | 14.11 | ||

| Mean | 2.31 | 0.00 | 12.34 | ||

| SD | 5.48 | 0.00 | 1.86 | ||

| Golden and Amber (n = 10) | Dark (n= 5) | BBL Maple Syrup (n= 13) | Table Syrups (n= 5) | ||

| Total phenolics (µg GAE/mL) a | Minimum | 115.64 | 387.01 | 317.37 | NA c |

| Maximum | 338.94 | 582.39 | 713.40 | NA | |

| Mean | 271.15 | 479.53 | 458.25 | NA | |

| SD | 64.93 | 72.85 | 124.78 | NA | |

| p-Value | <0.001 b | NA | |||

| Approach | Sugar | Training Model | External Validation Model | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Range | N a | Factor | SECV b | Rcal | Range | N c | SEP d | Rval | ||

| FT-IR | °Brix | 39.3–78.7 | 30 | 5 | 0.56 | 0.99 | 65.2–78.4 | 7 | 0.88 | 0.98 |

| Sucrose | 3.3–66.2 | 30 | 4 | 1.68 | 0.99 | 18.4–65.3 | 7 | 1.66 | 0.99 | |

| Raman | °Brix | 39.9–78.5 | 29 | 5 | 1.00 | 0.98 | 65.0–78.7 | 7 | 1.23 | 0.96 |

| Sucrose | 3.5–66.6 | 30 | 3 | 1.69 | 0.99 | 17.5–65.1 | 7 | 1.67 | 0.99 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, K.; Aykas, D.P.; Rodriguez-Saona, L.E. Pattern Recognition Approach for the Screening of Potential Adulteration of Traditional and Bourbon Barrel-Aged Maple Syrups by Spectral Fingerprinting and Classical Methods. Foods 2022, 11, 2211. https://doi.org/10.3390/foods11152211

Zhu K, Aykas DP, Rodriguez-Saona LE. Pattern Recognition Approach for the Screening of Potential Adulteration of Traditional and Bourbon Barrel-Aged Maple Syrups by Spectral Fingerprinting and Classical Methods. Foods. 2022; 11(15):2211. https://doi.org/10.3390/foods11152211

Chicago/Turabian StyleZhu, Kuanrong, Didem P. Aykas, and Luis E. Rodriguez-Saona. 2022. "Pattern Recognition Approach for the Screening of Potential Adulteration of Traditional and Bourbon Barrel-Aged Maple Syrups by Spectral Fingerprinting and Classical Methods" Foods 11, no. 15: 2211. https://doi.org/10.3390/foods11152211