Extraction, Identification, and In Vitro Anti-Inflammatory Activity of Feruloylated Oligosaccharides from Baijiu Distillers’ Grains

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

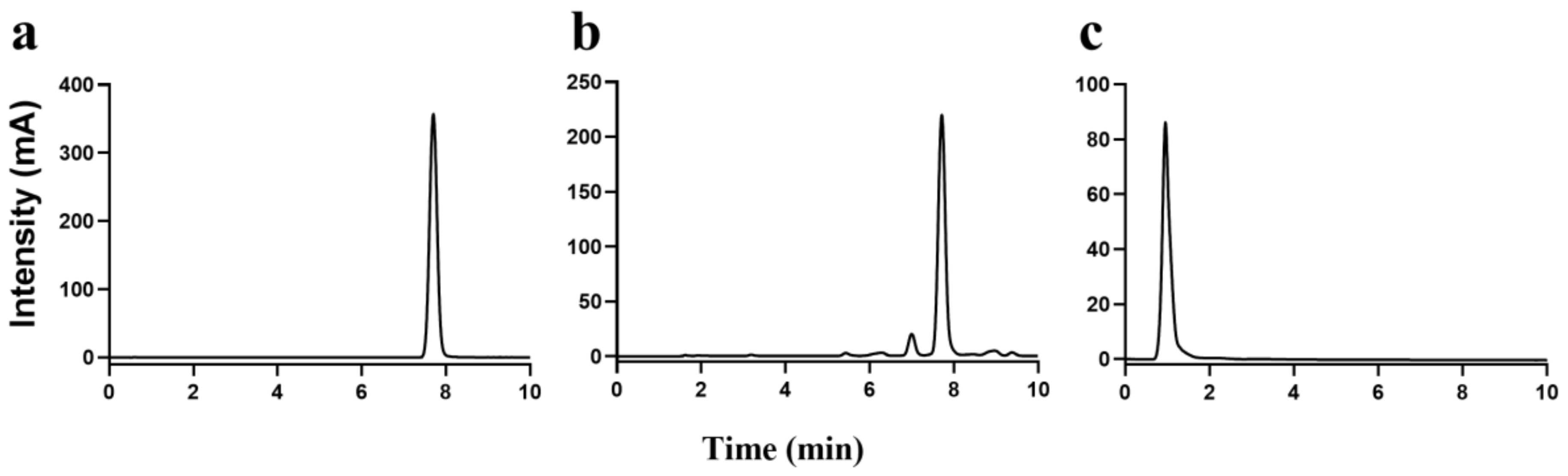

2.2. Identification of Phenolic Acids in BDGs

2.3. Extraction of FOs from BDGs

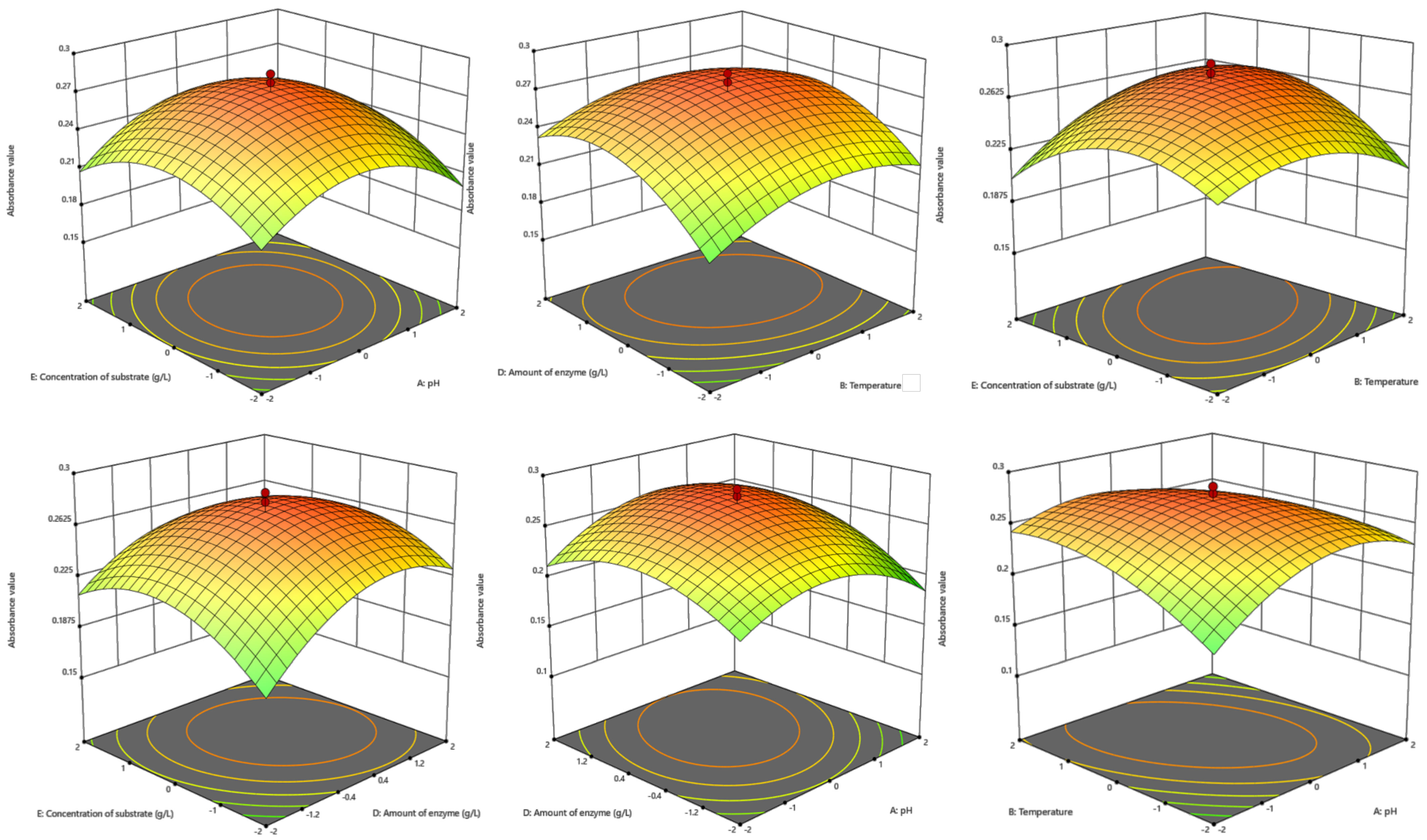

2.4. Response Surface Optimization of Extraction Process

2.5. Characterization of FOs

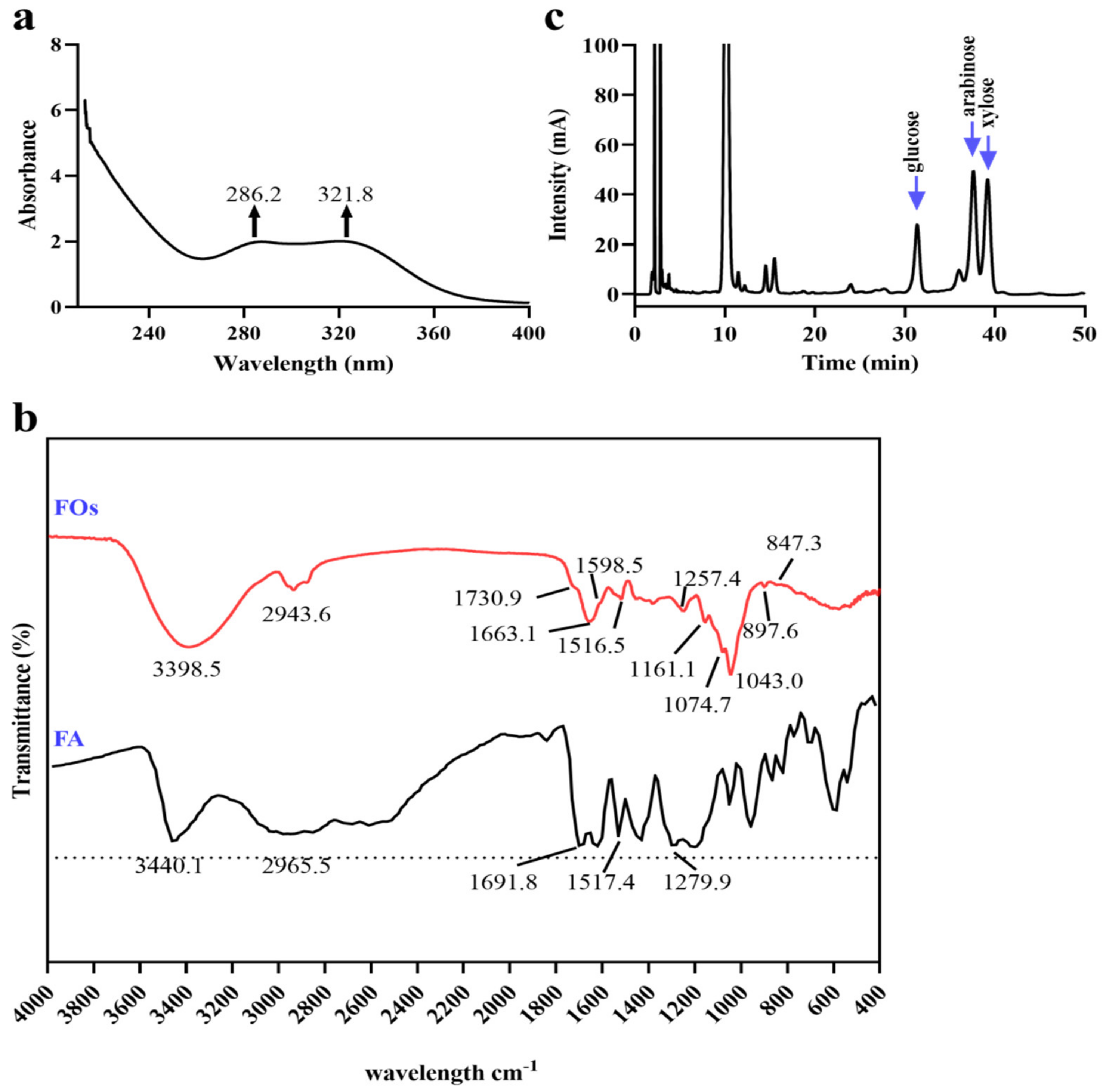

2.5.1. Determination of the Degree of Substitution

2.5.2. Analysis of UV–Visible Transmission Spectra and Fourier-Transform Infrared Spectroscopy

2.5.3. Analysis of Monosaccharide Composition

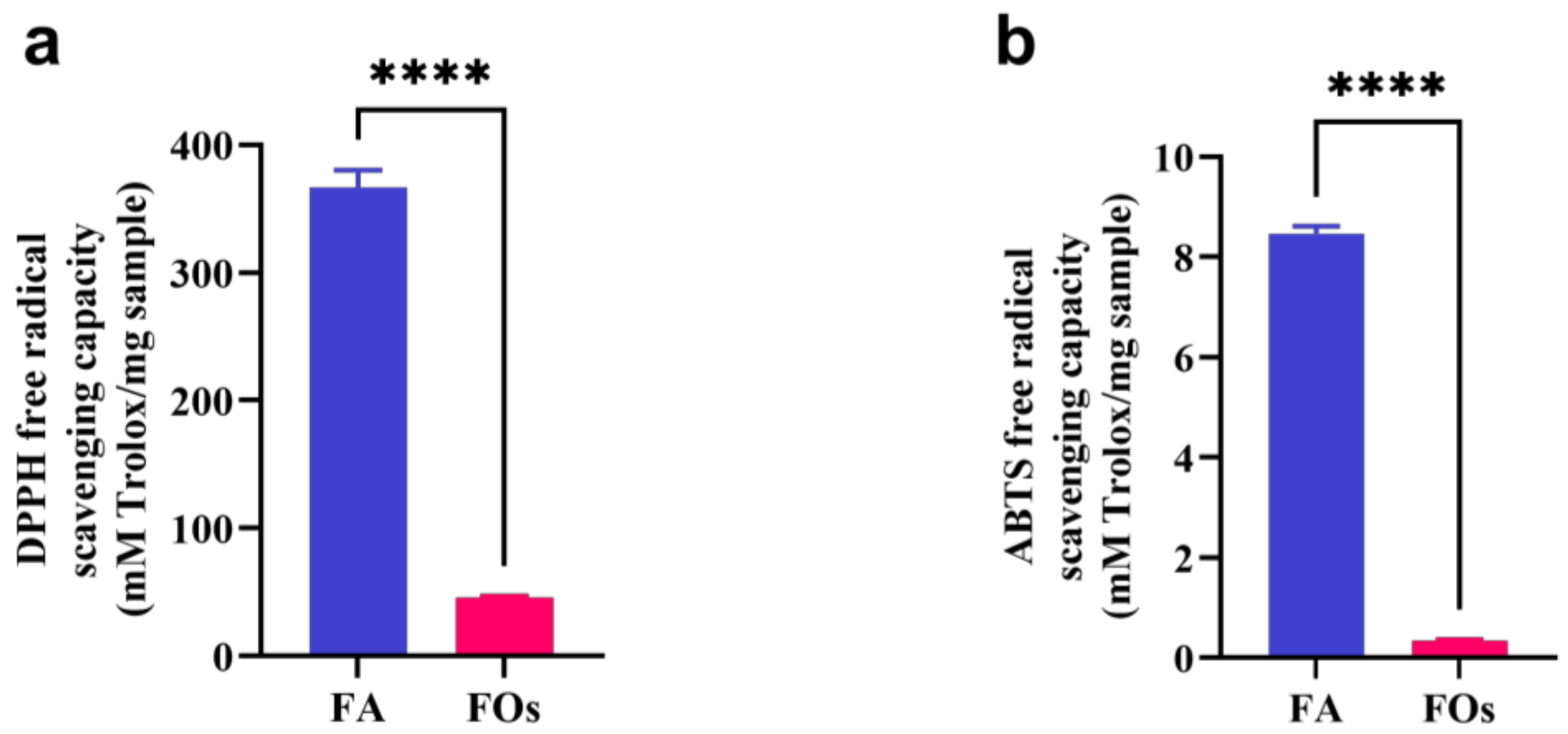

2.6. In Vitro Antioxidant Activity of FOs

2.7. FOs Alleviate LPS-Induced Inflammation in RAW 264.7 Cells

2.7.1. Incubation of RAW 264.7 Cells

2.7.2. LPS-Induced RAW 264.7 Cell Inflammation Model

2.7.3. Determination of Inflammatory Factors in RAW 264.7 Cells

2.8. Statistical Analysis

3. Results

3.1. Preparation of PO

3.2. Optimization of FO Extraction Process

3.3. Characterization of Structure of FOs

3.4. Evaluation of In Vitro Antioxidant Activity of FOs

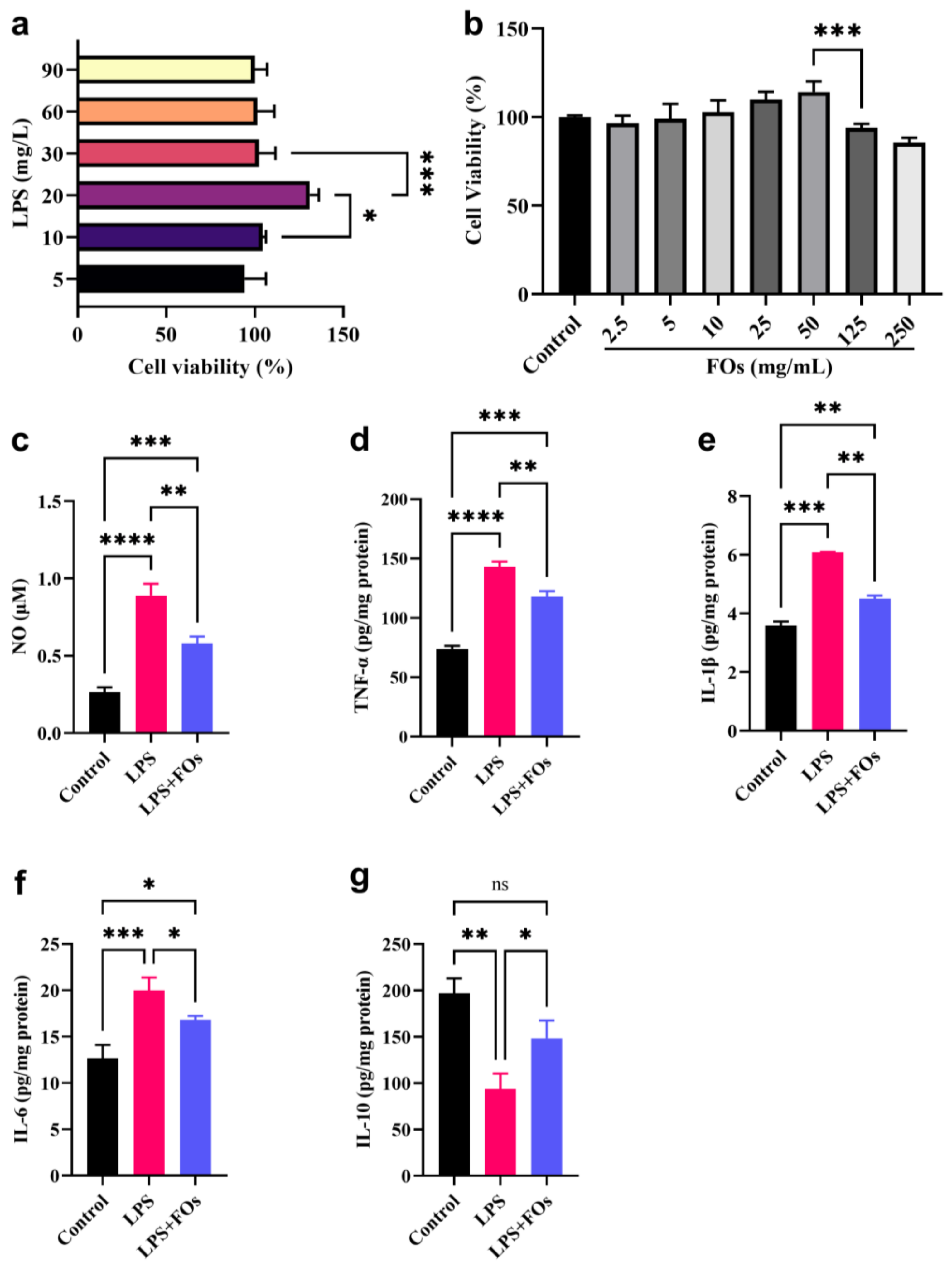

3.5. The Alleviating Effect of FOs on LPS-Induced RAW264.7 Cell Inflammation

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Guo, Q.; Xiao, X.; Lu, L.; Ai, L.; Xu, M.; Liu, Y.; Goff, H.D. Polyphenol-polysaccharide complex: Preparation, characterization, and potential utilization in food and health. Annu. Rev. Food Sci. Technol. 2022, 13, 59–87. [Google Scholar] [CrossRef]

- Wang, J.; Sun, B.; Cao, Y.; Song, H.; Tian, Y. Inhibitory effect of wheat bran feruloyl oligosaccharides on oxidative DNA damage in human lymphocytes. Food Chem. 2008, 109, 129–136. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Bai, J.; Wang, Y.; Zhang, K.; Li, Y.; Qian, H.; Zhang, H.; Wang, L. Feruloylated arabinoxylan from wheat bran inhibited M1-macrophage activation and enhanced M2-macrophage polarization. Int. J. Biol. Macromol. 2022, 194, 993–1001. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.; Zhu, L.; Lei, Z.; Song, Y.; Tang, F.; Yin, Z.; Wang, J.; Huang, J. Feruloylated oligosaccharides alleviate dextran sulfate sodium-induced colitis in vivo. J. Agric. Food Chem. 2019, 67, 9522–9531. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Li, S.; Ge, S.; Lin, S. Review of Distribution, Extraction Methods, and Health Benefits of Bound Phenolics in Food Plants. J. Agric. Food Chem. 2020, 68, 3330–3343. [Google Scholar] [CrossRef] [PubMed]

- Bei, Q.; Chen, G.; Lu, F.; Wu, S.; Wu, Z. Enzymatic action mechanism of phenolic mobilization in oats (Avena sativa L.) during solid-state fermentation with Monascus anka. Food Chem. 2018, 245, 297–304. [Google Scholar] [CrossRef]

- Huang, J.; Ren, J.; Tao, G.; Chen, Y.; Yao, S.; Han, D.; Qiu, R. Maize bran feruloylated oligosaccharides inhibited AGEs formation in glucose/amino acids and glucose/BSA models. Food Res. Int. 2019, 122, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Park, C.Y.; Lee, K.-Y.; Gul, K.; Rahman, M.S.; Kim, A.-N.; Chun, J.; Kim, H.-J.; Choi, S.-G. Phenolics and antioxidant activity of aqueous turmeric extracts as affected by heating temperature and time. LWT 2019, 105, 149–155. [Google Scholar] [CrossRef]

- Pazo-Cepeda, M.V.; Aspromonte, S.G.; Alonso, E. Extraction of ferulic acid and feruloylated arabinoxylo-oligosaccharides from wheat bran using pressurized hot water. Food Biosci. 2021, 44, 101374. [Google Scholar] [CrossRef]

- Moreirinha, C.; Vilela, C.; Silva, N.H.C.S.; Pinto, R.J.B.; Almeida, A.; Rocha, M.A.M.; Coelho, E.; Coimbra, M.A.; Silvestre, A.J.D.; Freire, C.S.R. Antioxidant and antimicrobial films based on brewers spent grain arabinoxylans, nanocellulose and feruloylated compounds for active packaging. Food Hydrocoll. 2020, 108, 105836. [Google Scholar] [CrossRef]

- Marquez-Escalante, J.A.; Carvajal-Millan, E.; Martinez-Lopez, A.L.; Martinez-Robinson, K.G.; Campa-Mada, A.C.; Rascon-Chu, A. Fine structural features and antioxidant capacity of ferulated arabinoxylans extracted from nixtamalized maize bran. J. Sci. Food Agric. 2023, 103, 4584–4591. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Liu, S.P.; Huang, C.H.; Ge, X.Y.; Xi, B.D.; Mao, J. Chinese Baijiu distiller’s grains resourcing: Current progress and future prospects. Resour. Conserv. Recycl. 2022, 176, 105900. [Google Scholar] [CrossRef]

- Chew, K.W.; Chia, S.R.; Chia, W.Y.; Cheah, W.Y.; Munawaroh, H.S.H.; Ong, W.-J. Abatement of hazardous materials and biomass waste via pyrolysis and co-pyrolysis for environmental sustainability and circular economy. Environ. Pollut. 2021, 278, 116836. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zheng, P. Spirit-based distillers’ grain as a promising raw material for succinic acid production. Biotechnol. Lett. 2013, 35, 679–684. [Google Scholar] [CrossRef] [PubMed]

- Luthria, D.L.; Memon, A.A.; Liu, K.S. Changes in phenolic acid content during dry-grind processing of corn into ethanol and DDGS. J. Sci. Food Agric. 2014, 94, 1723–1728. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.G.; Chang, R.; Zhou, Z.L.; Ren, Q.X.; Sheng, C.H.; Lan, Y.; Cao, X.N.; Mao, J. Conversion of Baijiu distillers’ grains to functional peptides: Process optimization and antioxidant activity evaluation. J. Funct. Foods 2023, 108, 105722. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Li, X.; Qin, H.; Huang, M.Y.; Liu, S.P.; Chang, R.; Xi, B.D.; Mao, J.; Zhang, S.Y. Obtaining non-digestible polysaccharides from distillers’ grains of Chinese Baijiu after extrusion with enhanced antioxidation capability. Int. J. Biol. Macromol. 2023, 243, 124799. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.H.; Smith, W.; Hao, D.J.; He, B.R.; Kong, L.B. M1 and M2 macrophage polarization and potentially therapeutic naturally occurring compounds. Int. Immunopharmacol. 2019, 70, 459–466. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.W.; Zhang, R.F.; Zhang, F.X.; Liu, R.H. Phenolic Profiles and Antioxidant Activity of Black Rice Bran of Different Commercially Available Varieties. J. Agric. Food Chem. 2010, 58, 7580–7587. [Google Scholar] [CrossRef]

- Yuan, X.P.; Wang, J.; Yao, H.Y. Antioxidant activity of feruloylated oligosaccharides from wheat bran. Food Chem. 2005, 90, 759–764. [Google Scholar] [CrossRef]

- Li, Y.C.; Luo, Y.; Meng, F.B.; Li, J.; Chen, W.J.; Liu, D.Y.; Zou, L.H.; Zhou, L. Preparation and characterization of feruloylated oat beta-glucan with antioxidant activity and colon-targeted delivery. Carbohydr. Polym. 2022, 279, 119002. [Google Scholar] [CrossRef] [PubMed]

- Fan, B.; Li, T.; Song, X.; Wu, C.; Qian, C. A rapid, Accurate and sensitive method for determination of monosaccharides in different varieties of Osmanthus fragrans Lour by pre-column derivatization with HPLC-MS/MS. Int. J. Biol. Macromol. 2019, 125, 221–231. [Google Scholar] [CrossRef] [PubMed]

- Jeong, B.-G.; Gwak, Y.-J.; Kim, J.; Hong, W.-H.; Park, S.-J.; Islam, M.A.; Jung, J.; Chun, J. Antioxidative Properties of Machine-Drip Tea Prepared with Citrus Fruit Peels Are Affected by the Type of Fruit and Drying Method. Foods 2022, 11, 2094. [Google Scholar] [CrossRef] [PubMed]

- Sollano-Mendieta, X.C.; Meza-Márquez, O.G.; Osorio-Revilla, G.; Téllez-Medina, D.I. Effect of in vitro digestion on the antioxidant compounds and antioxidant capacity of 12 plum (Spondias purpurea L.) ecotypes. Foods 2021, 10, 1995. [Google Scholar] [CrossRef] [PubMed]

- Schendel, R.R.; Puchbauer, A.K.; Britscho, N.; Bunzel, M. Feruloylated wheat bran arabinoxylans: Isolation and characterization of acetylated and O-2-monosubstituted structures. Cereal Chem. 2016, 93, 493–501. [Google Scholar] [CrossRef]

- Li, K.Y.; Lai, P.; Lu, S.; Fang, Y.T.; Chen, H.H. Optimization of acid hydrolysis conditions for feruloylated oligosaccharides from rice bran through response surface methodolgy. J. Agric. Food Chem. 2008, 56, 8975–8978. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Mao, W.; Gao, W.; Liu, J.; Wang, B.; Zhang, X.; Liu, X. Antioxidant properties of wheat bran FOs prepared by Bacillus amyloliquefaciens IT-45 fermentation. Int. J. Food Sci. Technol. 2024, 59, 816–828. [Google Scholar] [CrossRef]

- Cai, W.D.; Zhu, J.; Wu, L.X.; Qiao, Z.R.; Li, L.; Yan, J.K. Preparation, characterization, rheological and antioxidant properties of ferulic acid-grafted curdlan conjugates. Food Chem. 2019, 300, 125221. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yuan, X.; Sun, B.; Cao, Y.; Tian, Y.; Wang, C. On-line separation and structural characterisation of feruloylated oligosaccharides from wheat bran using HPLC-ESI-MSn. Food Chem. 2009, 115, 1529–1541. [Google Scholar] [CrossRef]

- Dobhal, M.P.; Hasan, A.M.; Sharma, M.C.; Joshi, B.C. Ferulic acid esters from Plumeria bicolor. Phytochemistry 1999, 51, 319–321. [Google Scholar] [CrossRef]

- Kacuráková, M.; Capek, P.; Sasinková, V.; Wellner, N.; Ebringerová, A. FT-IR study of plant cell wall model compounds: Pectic polysaccharides and hemicelluloses. Carbohydr. Polym. 2000, 43, 195–203. [Google Scholar] [CrossRef]

- Nandini, C.D.; Salimath, P.V. Structural features of arabinoxylans from sorghum having good roti-making quality. Food Chem. 2001, 74, 417–422. [Google Scholar] [CrossRef]

- Chaikumpollert, O.; Methacanon, P.; Suchiva, K. Structural elucidation of hemicelluloses from Vetiver grass. Carbohydr. Polym. 2004, 57, 191–196. [Google Scholar] [CrossRef]

- Wu, X.-H.; Zheng, X.-W.; Han, B.-Z.; Vervoort, J.; Nout, M.J.R. Characterization of Chinese liquor starter, “Daqu”, by flavor type with 1H NMR-based nontargeted analysis. J. Agric. Food Chem. 2009, 57, 11354–11359. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.-W.; Tabrizi, M.R.; Nout, M.J.R.; Han, B.-Z. Daqu—A traditional chinese liquor fermentation starter. J. Inst. Brew. 2011, 117, 82–90. [Google Scholar] [CrossRef]

- Wu, Q.; Chen, L.; Xu, Y. Yeast community associated with the solid state fermentation of traditional Chinese Maotai-flavor liquor. Int. J. Food Microbiol. 2013, 166, 323–330. [Google Scholar] [CrossRef]

- Ou, J.; Sun, Z. Feruloylated oligosaccharides: Structure, metabolism and function. J. Funct. Foods 2014, 7, 90–100. [Google Scholar] [CrossRef]

- Shehata, I.A.; El-harshany, E.; Abdallah, H.M.; Esmat, A.; Abdel-Sattar, E.A. Anti-inflammatory activity of Kleinia odora. Eur. J. Integr. Med. 2018, 23, 64–69. [Google Scholar] [CrossRef]

- Fang, H.-Y. Chen, Y.-K.; Chen, H.-H.; Lin, S.-Y.; Fang, Y.-T. Immunomodulatory effects of feruloylated oligosaccharides from rice bran. Food Chem. 2012, 134, 836–840. [Google Scholar] [CrossRef]

| Categories of Statistics | Numerical Value |

|---|---|

| R2 | 0.9824 |

| Adjusted R2 | 0.9595 |

| Predicted R2 | 0.8719 |

| Adeq Precision | 21.2933 |

| Monosaccharide Residue | Mass (µg) | Mol % |

|---|---|---|

| Mannose (Man) | 27.63 | 2.76 |

| Rhamnose (Rha) | 3.15 | 0.32 |

| Glucuronic acid (GlcA) | 22.14 | 2.21 |

| Galacturonic acid (GalA) | 12.33 | 1.23 |

| Glucose (Glc) | 159.12 | 15.91 |

| Galactose (Gal) | 41.67 | 4.17 |

| Xylose (Xyl) | 272.16 | 27.22 |

| Arabinose (Ara) | 248.04 | 24.80 |

| Fucose (Fuc) | 5.4 | 0.54 |

| Total | 791.73 | 79.17 |

| Phenolic Acid Species | Mass (µg) | Degree of Substitution |

| Ferulic acid | 39.69 | 5.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Z.; Liu, M.; Wang, B.; Zhao, D.; Li, H.; Sun, J. Extraction, Identification, and In Vitro Anti-Inflammatory Activity of Feruloylated Oligosaccharides from Baijiu Distillers’ Grains. Foods 2024, 13, 1283. https://doi.org/10.3390/foods13081283

Yin Z, Liu M, Wang B, Zhao D, Li H, Sun J. Extraction, Identification, and In Vitro Anti-Inflammatory Activity of Feruloylated Oligosaccharides from Baijiu Distillers’ Grains. Foods. 2024; 13(8):1283. https://doi.org/10.3390/foods13081283

Chicago/Turabian StyleYin, Zhongtian, Mengyao Liu, Bowen Wang, Dongrui Zhao, Hehe Li, and Jinyuan Sun. 2024. "Extraction, Identification, and In Vitro Anti-Inflammatory Activity of Feruloylated Oligosaccharides from Baijiu Distillers’ Grains" Foods 13, no. 8: 1283. https://doi.org/10.3390/foods13081283