Increased Effectiveness of Microbiological Verification by Concentration-Dependent Neutralization of Sanitizers Used in Poultry Slaughter and Fabrication Allowing Salmonella enterica Survival

Abstract

:1. Introduction

2. Materials and Methods

2.1. Salmonella Revival and Inoculum Preparation

2.2. Neutralizer-Supplemented Buffered Peptone Water Preparation

2.3. Sanitizer Preparation

2.4. Experimental Procedures

2.5. Analysis of Data

3. Results

3.1. Survival of Salmonella Isolates as a Function of CPC and CPC-Matched Neutralizer Combinations

3.2. Survival of Salmonella as a Function of PAA and PAA Neutralizer Combination

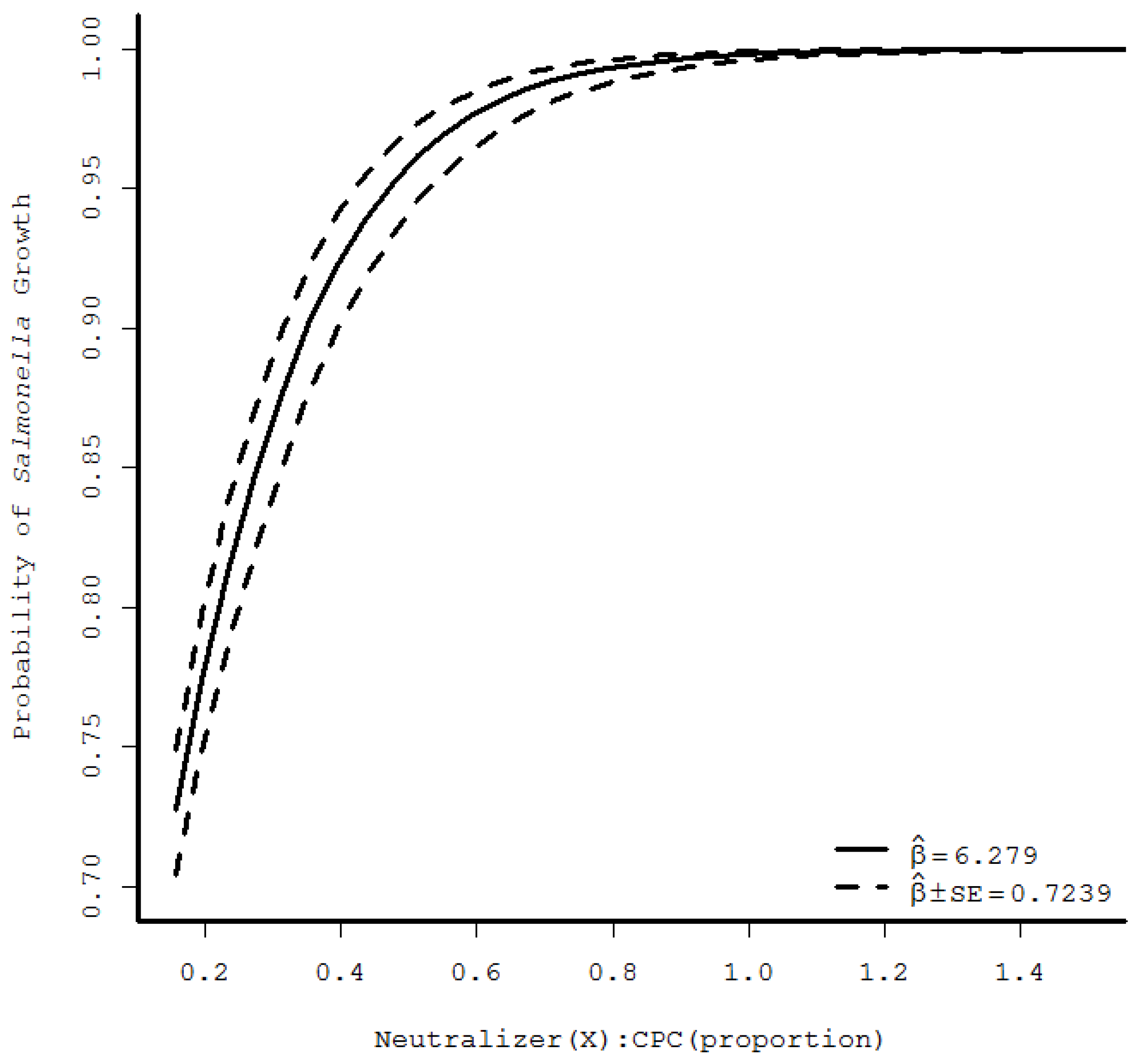

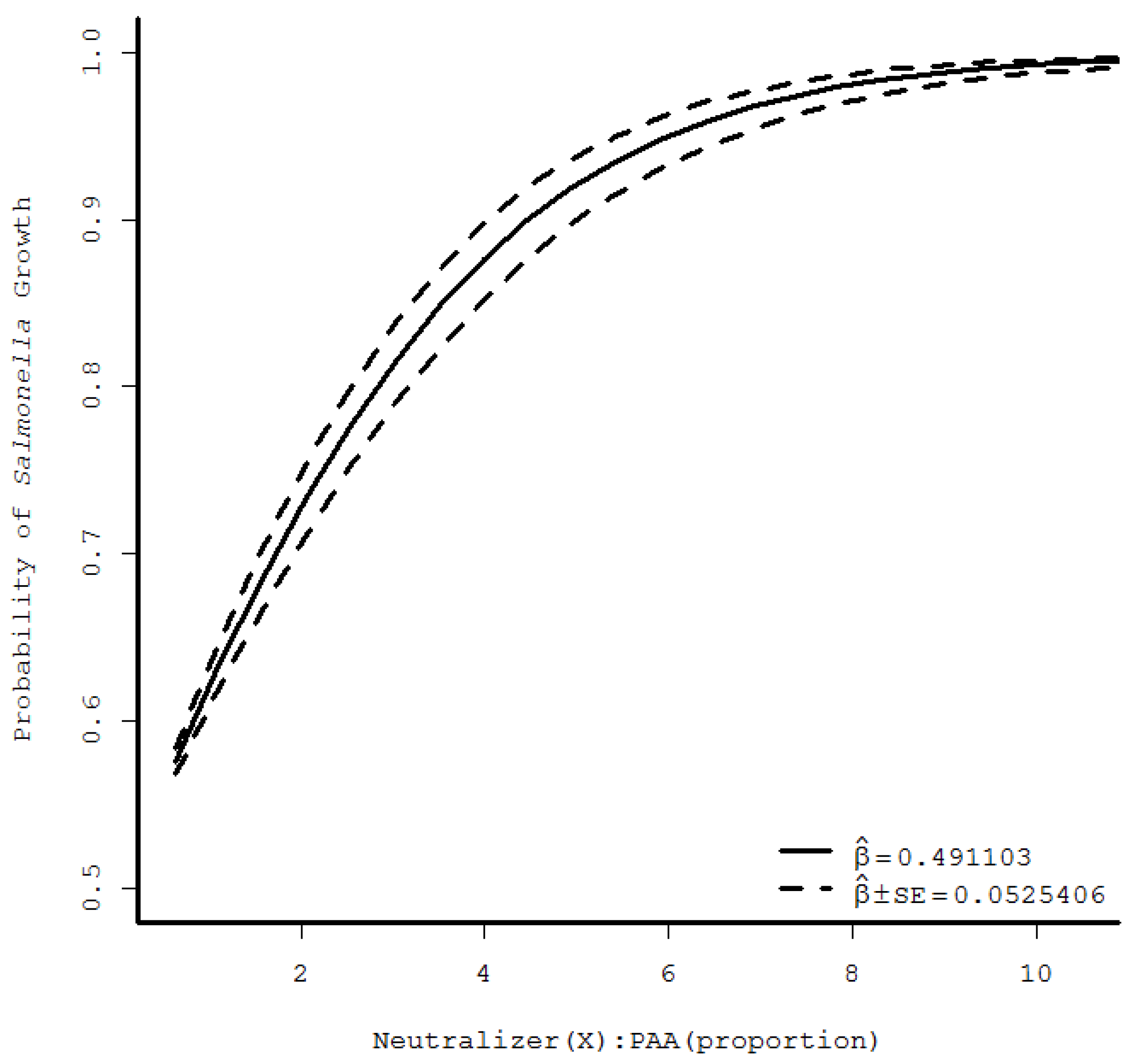

3.3. Modeling of Salmonella Survival As a Function of Sanitizer and Combined Neutralizers Exposure via Logistic Regression

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- U.S. Department of Agriculture-Food Safety and Inspection Service. Salmonella Compliance Guidelines for Small and Very Small Meat and Poultry Establishments that Produce Ready-to-Eat (RTE) Products. Available online: http://www.fsis.usda.gov/wps/wcm/connect/2ed353b4-7a3a-4f31-80d8-20262c1950c8/Salmonella_Comp_Guide_091912.pdf?MOD = AJPERES (accessed on 5 June 2014).

- U.S. Department of Agriculture-Food Safety and Inspection Service. Safe and Suitable Ingredients Used in the Production of Meat, Poultry, and Egg Products. Directive 7120.1, Rev. 44. Available online: https://www.fsis.usda.gov/wps/wcm/connect/bab10e09-aefa-483b-8be8-809a1f051d4c/7120.1.pdf?MOD = AJPERES (accessed on 4 January 2018).

- Gamble, G.R.; Berrang, M.E.; Buhr, R.J.; Hinton, A., Jr.; Bourassa, D.V.; Johnston, J.J.; Ingram, K.D.; Adams, E.S.; Feldner, P.W. Effect of simulated sanitizer carryover on recovery of Salmonella from broiler carcass rinsates. J. Food Prot. 2016, 79, 710–714. [Google Scholar] [CrossRef] [PubMed]

- U.S. Department of Agriculture-Food Safety and Inspection Service. Notice 41–16: New Neutralizing Buffered Peptone Water to Replace Current Buffered Peptone Water for Poultry Verification Sampling. Available online: https://www.fsis.usda.gov/wps/wcm/connect/2cb982e0-625c-483f-9f50-6f24bc660f33/41-16.pdf?MOD = AJPERES (accessed on 18 March 2017).

- U.S. Department of Agriculture-Food Safety and Inspection Service. Neutralizing Buffered Peptone Water (nBPW) in Poultry Carcass and Parts Sampling. Available online: https://askfsis.custhelp.com/app/answers/detail/a_id/2007/~/neutralizing-buffered-peptone-water-%28nbpw%29-in-poultry-carcass-and-parts-sampling (accessed on 12 July 2017).

- Dey, B.P.; Engley, F.B., Jr. Methodology for recovery of chemically treated Staphylococcus aureus with neutralizing medium. Appl. Environ. Microbiol. 1983, 45, 1533–1537. [Google Scholar] [PubMed]

- Black and Veach Corp. White’s Handbook of Chlorination and Alternative Disinfectants, 5th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- U.S. Department of Agriculture-Food Safety and Inspection Service. Pathogen Reduction—Salmonella and Campylobacter Performance Standards Verification Testing. Available online: https://www.fsis.usda.gov/wps/wcm/connect/b0790997-2e74-48bf-9799-85814bac9ceb/28_IM_PR_Sal_Campy.pdf?MOD = AJPERES (accessed on 18 March 2017).

- U.S. Department of Agriculture-Food Safety and Inspection Service. Directive 10,250.1: Salmonella and Campylobacter Verification Program for Raw Meat and Poultry Products. Available online: https://www.fsis.usda.gov/wps/wcm/connect/ebf83112-4c3b-4650-8396-24cc8d38bf6c/10250.1.pdf?MOD = AJPERES (accessed on 18 March 2017).

- U.S. Department of Agriculture-Food Safety and Inspection Service. Microbiology Laboratory Guidebook Appendix 1.08: Media and Reagents. Available online: https://www.fsis.usda.gov/wps/wcm/connect/b089fb25-5d69-4b01-a470-da1d0182a5d7/MLG-Appendix-1-Media-Reagents.pdf?MOD = AJPERES (accessed on 15 March 2016).

- Gilmour, A.R.; Gogel, B.J.; Cullis, B.R.; Thompson, R. ASReml User Guide (Release 3.0). Available online: https://www.vsni.co.uk/downloads/asreml/release3/UserGuide.pdf (accessed on 10 August 2017).

- Kim, J.-W.; Slavik, M.F. Cetylpyridinium chloride (CPC) treatment on poultry skin to reduce attached Salmonella. J. Food Prot. 1996, 59, 322–326. [Google Scholar] [CrossRef] [PubMed]

- Bauermeister, L.J.; Bowers, J.W.J.; Townsend, J.C.; McKee, S.R. The microbial and quality properties of poultry carcasses treated with peracetic acid as an antimicrobial treatment. Poult. Sci. 2008, 87, 2390–2398. [Google Scholar] [CrossRef] [PubMed]

- Nagel, G.M.; Bauermeister, L.J.; Bratcher, C.L.; Singh, M.; McKee, S.R. Salmonella and Campylobacter reduction and quality characteristics of poultry carcasses treated with various antimicrobials in a post-chill immersion tank. Int. J. Food Microbiol. 2013, 165, 281–286. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Chen, Y.; Schaffner, D.W. Comparison of logistic regression and linear regression in modeling percentage data. Appl. Environ. Microbiol. 2001, 67, 2129–2135. [Google Scholar] [CrossRef] [PubMed]

| Neutralizer Addition 1 | 0.8% 2 | 0.6% | 0.4% | 0.2% | 0.1% |

|---|---|---|---|---|---|

| 2X | 1.0 A 3 | 1.0 A | 1.0 A | 1.0 A | 1.0 A |

| 1X | 1.0 A | 1.0 A | 1.0 A | 1.0 A | 1.0 A |

| 0.5X | 0.0 D | 0.06 D | 0.94 A | 1.0 A | 1.0 A |

| 0.25X | 0.0 D | 0.0 D | 0.0 D | 0.5 B | 1.0 A |

| 0.125X | 0.0 D | 0.0 D | 0.0 D | 0.0 D | 0.28 C |

| Pooled Standard Error = 0.04 | |||||

| Neutralizer Addition 1 | 0.2% 2 | 0.1% | 0.05% | 0.025% | 0.0125% |

|---|---|---|---|---|---|

| 3X | 1.0 A 3 | 1.0 A | 1.0 A | 1.0 A | 1.0 A |

| 2X | 1.0 A | 1.0 A | 1.0 A | 1.0 A | 1.0 A |

| 1X | 0.0 D | 0.06 D | 0.94 A | 1.0 A | 1.0 A |

| 0.5X | 0.0 D | 0.0 D | 0.0 D | 0.5 B | 1.0 A |

| 0.25X | 0.0 D | 0.0 D | 0.0 D | 0.0 D | 0.28 C |

| Pooled Standard Error = 0.05 | |||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammad, Z.H.; Hasan, A.A.; Kerth, C.R.; Riley, D.G.; Taylor, T.M. Increased Effectiveness of Microbiological Verification by Concentration-Dependent Neutralization of Sanitizers Used in Poultry Slaughter and Fabrication Allowing Salmonella enterica Survival. Foods 2018, 7, 32. https://doi.org/10.3390/foods7030032

Mohammad ZH, Hasan AA, Kerth CR, Riley DG, Taylor TM. Increased Effectiveness of Microbiological Verification by Concentration-Dependent Neutralization of Sanitizers Used in Poultry Slaughter and Fabrication Allowing Salmonella enterica Survival. Foods. 2018; 7(3):32. https://doi.org/10.3390/foods7030032

Chicago/Turabian StyleMohammad, Zahra H., Amer A. Hasan, Chris R. Kerth, David G. Riley, and T. Matthew Taylor. 2018. "Increased Effectiveness of Microbiological Verification by Concentration-Dependent Neutralization of Sanitizers Used in Poultry Slaughter and Fabrication Allowing Salmonella enterica Survival" Foods 7, no. 3: 32. https://doi.org/10.3390/foods7030032

APA StyleMohammad, Z. H., Hasan, A. A., Kerth, C. R., Riley, D. G., & Taylor, T. M. (2018). Increased Effectiveness of Microbiological Verification by Concentration-Dependent Neutralization of Sanitizers Used in Poultry Slaughter and Fabrication Allowing Salmonella enterica Survival. Foods, 7(3), 32. https://doi.org/10.3390/foods7030032