3.1. Energy and Carbon

The annual energy consumption (

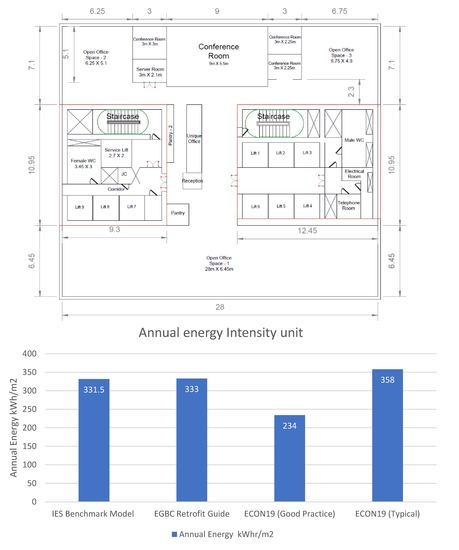

Table 14) for the baseline office model was 227.78 MWh with a breakdown of 59.7 MWh for district cooling and 168 MWh from office utility. Energy intensity unit (

Figure 1) of 331.5 kWh/m

2 was competitive with the industry benchmarks as it was 0.45% lower than the local Emirates Green Building Council (EGBC) guidelines. When compared with the Energy Consumption Guide 19 (ECON19) [

15], it was 7.40% lower than the typical prestige air-conditioned office and 29.4% higher than a good practice benchmark. While the annual carbon emission for baseline office model was 118,219 KgCO

2, which translated to a carbon intensity (

Table 14) of 172 KgCO

2/m

2.

The comparison of carbon intensities with ECON19 showed a variation of 7.63% against the typical office benchmark. However, at the same time, the baseline office model was 29.4% higher than the good practice carbon benchmark from ECON19, which could only be because the ECON19 is a British standard which takes into account the climatic conditions of UK region over a longer period of time. The energy and carbon results proved that the baseline office model was very competitive as it was able to retain its performance even after eight years of operation.

The implementation of Variable Speed Drive (VSD) fan in a baseline FCU system was a practical retrofit option with a reduction of 8% in annual energy consumption and carbon emission by targeting cooling and fan energy with a significant reduction of 20% and 9.90% (

Figure 2), which can be further seen from

Table 5. Ease of installation in office environment causing less downtime at moderate cost can be regarded as some of the advantages. On the other hand, the adoption of VAV cooling system was not a practical solution as it increased the energy consumption and carbon emission by 42% because of the greater number of air side and water side components. The air side consisted of the filter, cooling coil, supply fan, exhaust fan and VAV box. However, for the water side, virtual district cooling performance curve set, and pumps had been utilised for modelling the VAV system.

The VRF system was one of the most energy efficient cooling systems, as it was able to cut down the annual energy consumption and carbon emission by 30% with 79.2% reduction directly from cooling because of the use of direct expansion cooling coil on the air side and scroll compressor on the water side to regulate the flow of refrigerant as per the cooling demand. It can also be observed that the number of components on the air side and water side were significantly less because the system was completely based upon the split system.

Monodraught cool-phase was the second most energy efficient cooling system which was able to reduce the annual energy consumption and carbon emission by 22% with specific cooling energy and central fan energy saving up to 18.5% and 70.6%. This cooling system took advantage of the intelligent AHU system and thermal batteries to absorb heat [

16]. It also did not have any compressor or chiller on water side. While the air side only had sensors, actuators, VSD fan, controls and humidity monitoring systems.

As observed from

Figure 3, July had the highest electricity consumption because of the extremely high temperatures during peak summer months and February had the lowest energy consumption because of lower temperatures during winter months showing a strong correlation between the site microclimate and energy consumption. The energy trend had started to gradually increase from March onwards and came back to normal during mid-October. While the energy trend declined significantly between the months of November and February.

During the peak month of July, the VAV system had demonstrated 53% higher energy consumption in contrast to baseline office FCU system because of the greater number of components on the air side and water side. The energy trend showed a sharp variation throughout the different months of the year because of the external conditions. The VAV system is commonly known to occupy larger spatial footprint in any building because of the large sized components such as AHU, chillers, pumps and cooling towers, which are also very energy demanding.

Other cooling systems such as the VRF system had demonstrated an energy saving potential of 41% by eliminating AHU on the air side and chiller, pumps, cooling towers on water-side during peak month. The annual energy trend for VRF system was very steady throughout the months. The adoption of DX cooling coil in the split system was also very beneficial as it allowed the system to have indoor and outdoor units. The evaporator and fan were integrated in indoor units and the scroll compressor, condenser, expansion valve was located in an outdoor unit of the system.

The implementation of VSD in the FCU system had reduced the energy by 13.24% in comparison with the baseline office FCU as the variable speed drive fan matches the air supply to cooling requirement of space which helps to conserve energy and provided more tighter control. The annual energy trend was quite similar to the baseline FCU system with an average variation of 8%.

The energy trend for the Monodraught cool-phase was a bit different as the peak energy consumption was obtained during August with 27% energy reduction against the baseline office FCU as this system took advantage of intelligent AHU with CO2 sensors to match the cold-air supply with cooling demand, which represented August as the peak month and February as the base month. The annual energy trend for the cool-phase showed a slight increase throughout different months.

Further detailed analysis was performed by interpreting the space cooling energy and fan energy of different proposed cooling systems. The annual space cooling energy (

Figure 4) was determined by integrating all the proposed cooling systems to the IES baseline office model. The VAV system possessed the highest space cooling energy, which even surpassed the baseline FCU. The VRF system had outperformed all the other cooling systems by showing a reduction of 79% against the baseline FCU, which proves it to be of the most energy efficient cooling systems in the industry. However, the space cooling energy from FCU with VSD and the monodraught cool phase was very close by 1.43% because both of the systems utilised VSD fans. Energy saving of 19.62% was achieved by implementing VSD fans in FCU, which proves it to be a very feasible option considering the aspect of effort, time and cost, as it is a plug and play application.

The annual fan energy consumption (

Figure 5) was obtained from IES to determine the performance of different cooling systems. It can be observed that both of the fan coil unit (FCU) systems had central and local fans to provide a sufficient amount of airflow for cooling, while the VAV, VRF and Monodraught only relied on central fans. The baseline FCU had an annual fan energy consumption of 73.69 MWh as the highest. The source of energy for central and local fans is the office meter-1. Since different offices within the building have their own submeter. The central fan energy is higher because it is the primary fan inside the AHU. The fan for the monodraught cool-phase proved to be the most energy efficient as it had dropped the fan energy consumption by 74% since it had utilised a single VSD fan as a central fan. The VRF system and FCU with VSD had demonstrated a fan energy saving of 30% and 9.62%. The central fan in VAV system had the highest energy consumption because it heavily relied on traditional fan technology. This overall proved that the VRF and Monodraught cool phase are some of the most energy efficient cooling technologies. The central fan energy use was much higher than the joint FCU fan energy use because it was the assortment of the complete energy use of individual FCU units.

3.2. Indoor Air Quality (IAQ)

CO2 concentration was used as a parameter to examine the indoor air quality after the implementation of various cooling systems in office model because the health and well-being of office employees plays a crucial role towards utmost productivity of any organization. Numerous studies have indicated the significance of evaluating the indoor air quality because people spend more than 90% of their working hours in the office environment. Inadequate ventilation by HVAC systems could be identified as some of the major causes for poor indoor air quality.

The average CO

2 concentration (

Table 15) for the baseline office model was 624.2 PPM being fairly adequate as it was within the acceptable range of 600 PPM and 800 PPM [

17]. The adoption of the VSD fan in the baseline fan coil unit (FCU) did not impact the indoor air quality as the CO

2 concentration was fairly consistent because it was a part of medium retrofitting, which was being implemented by replacing the fan. The VAV system was able to enhance the indoor air quality by showing a reduction of 10.36% in CO

2 concentration only because the system heavily relied on treating outdoor fresh air in AHU and the proportion of fresh air is always maintained at 30%. The VRF system had shown an average CO

2 concentration of 3597 PPM, which meant that the indoor air quality was undesirable because of the lack of availability to supply fresh air as the cooling system was completely based upon unitary vapor compression with direct expansion technology [

18]. On the other hand, the Monodraught Cool Phase system was also able to maintain an appropriate level of CO

2 concentration being 6.1% lower than baseline FCU system because it utilised outdoor fresh air to supply the treated air into the space.

Figure 6 shows the CO

2 concentration level maintained throughout 17th July by various cooling systems. The CO

2 concentration trend started increasing once the occupants started entering the office from 8:30 a.m. onwards and persisted until 8:30 p.m. The peak CO

2 concentration for baseline office model was at 5:30 p.m. due to greater occupancy. The VRF system had drastically failed to maintain an optimum level of CO

2 concentration as it had surpassed the safety threshold causing sick building syndrome [

17]. While the VAV system and Monodraught cool-phase were able to maintain an optimum level of CO

2 concentration proving that the quality of indoor air was suitable for human occupancy in office environment. The cooling system’s ability to supply fresh air into the indoor spaces could be considered as the paramount to maintain a suitable level of CO

2 concentration for creating a pleasant work environment. The trend for the VRF in

Figure 6 somehow supports the average CO

2 concentration level from

Table 15 and justifies the incapability of VRF cooling systems to provide sufficient indoor air quality to meet the industry standards due to the lack of additional ventilation systems.

3.3. Thermal Comfort

Predicted Mean Vote (PMV) was used to perform the thermal comfort analysis using different cooling systems in the office model and the values had been obtained from IES-VE Vista-Pro. The PMV is based upon the Fangers scale, which is also referred to as ASHRAE thermal sensation scale and mostly ranges between −3 (Cold) to +3 (Hot).

The average PMV for the baseline office model was obtained for different cooling systems to analyse the performance of cooling system to achieve the desirable thermal comfort satisfaction for occupants. According to ASHRAE standard 55, the PMV values varying between −0.5 to +0.5 are within the acceptable human comfort range. As per

Table 16 above, the baseline office with FCU had an average PMV of 0.53 being close to +0.5, which means that it was compliant with ASHRAE 55. While the adoption of VSD fans in FCU system had slightly increased the PMV by 16.5%, which was still within the acceptable range. However, the VAV system had outperformed other cooling systems as the PMV value was higher than the baseline FCU by 22.64%.

The degree of discomfort amongst occupants was greater with the use of VRF and Monodraught because the VRF system did not have any provision for fresh air supply, which somehow deteriorated the thermal comfort satisfaction for occupants, while in Monodraught the thermal battery (PCM) was not able to absorb the surrounding heat enough to meet the heavy cooling demand of the Middle East. The average PMV for the VRF system was 1.06, which was manageable as the values mostly ranged between 0.7 and 1.41.

3.3.1. Annual PMV Prediction

The annual PMV trend indicates long-term thermal comfort satisfaction for the occupants after adoption of different cooling techniques. From

Figure 7, it can be observed that the level of thermal discomfort was mostly high between July and August because of the extremely high summer temperatures. A cumulative trend was observed as PMV started increasing from May onwards because of the summer outset and remained high until December when PMV started to get back to normal at 0.5 because of the winter.

The PMV values for the baseline office were mostly within the acceptable thermal comfort range of −0.5 to +0.5 (ASHRAE 55) because the values were within the range and only became higher by 43% during mid-July because of excessive heat. The adoption of VSD in baseline Fan coil unit had increased the PMV range, which had also led to an increase in the thermal discomfort level by 80% during the peak interval.

The VAV cooling system had increased the PMV range with values mostly between +1.5 and −0.05, indicating that the level of thermal discomfort had drastically increased during peak summer months. The PMV range in VRF system was a bit constrained as the upper limit was reduced by 7% and the level of thermal dissatisfaction was also very similar to baseline office Fan Coil Unit (FCU) because the VRF system used sophisticated controls maintain an optimum temperature for the office occupant. The monodraught cool-phase had drastically deteriorated the thermal comfort as the PMV range was significantly increased because the system used a hybrid cooling technology with a thermal battery, which was not able to absorb the surrounding heat because of the extreme hot climatic conditions of the Middle East.

3.3.2. Daily PMV Prediction

Figure 8 displays the PMV trend of the office model on 17th July with the adoption of different cooling techniques. The PMV trend was at peak between 3:30 p.m. and 5:30 p.m. because of the intense solar radiation during the peak summer month of July. The PMV trend for the baseline office model showed an acceptable level of thermal comfort as most of the values ranged between 0.44 and 0.79, which were somehow between 0 (Neutral) and 1 (Slightly Warm). The adoption of the Variable Speed Drive (VSD) Fan had slightly increased the thermal discomfort level by an average 17% because it gave the fan coil unit the ability to adjust the fan speed according to set point temperature. The PMV values mostly varied between 0.45 and 1.14 showing a rise in degree of discomfort in upper range by 44.30%.

The VAV system was able to maintain an optimum level of thermal comfort as the PMV values mostly fluctuated between 0.28 and 1.5 indicating that the level of discomfort had increased by 24.5% when compared against baseline FCU. The PMV trend for VAV system had started gradually increasing from 8:30 a.m. onwards and continued increasing until 5:30 a.m. The VRF system showed a steady rise in PMV from 8:30 a.m. and continued increasing until 6:30 p.m. However, in the Monodraught Cool Phase System, the PMV trend had significant variation as the PMV gradually increased from 9:30 a.m. and only declined from 7:30 p.m.

The overall thermal comfort analysis proves that the VRF and monodraught cool-phase systems were not able to comply with the ASHRAE 55 because of the design failure and climatic variation. The VRF cooling systems suffered with the problem of poor indoor air quality, which somehow also affected its thermal comfort performance, while the Monodraught cool-phase was a hybrid cooling system that heavily relied on the thermal batteries for space cooling. However, the thermal battery could not meet the sufficient cooling demands because of the heavy cooling demands as the thermal batteries require some time to get recharged.